service OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 811 of 6000

5A–1 BRAKE CONTROL SYSTEM

BRAKES

CONTENTS

Brake Control System 5A. . . . . . . . . . . . . . . . . . . .

Anti–lock Brake System 5B. . . . . . . . . . . . . . . . . . Power–Assisted Brake System 5C. . . . . . . . . . . .

Parking Brakes 5D. . . . . . . . . . . . . . . . . . . . . . . . .

BRAKE CONTROL SYSTEM

CONTENTS

Service Precaution 5A–2. . . . . . . . . . . . . . . . . . . . . .

General Description 5A–3. . . . . . . . . . . . . . . . . . . . .

System Components 5A–3. . . . . . . . . . . . . . . . . . .

Electronic Hydraulic Control Unit (EHCU) 5A–3.

ABS Warning Light 5A–4. . . . . . . . . . . . . . . . . . . .

Wheel Speed Sensor 5A–4. . . . . . . . . . . . . . . . . .

G-Sensor 5A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normal and Anti-lock Braking 5A–4. . . . . . . . . . .

Brake Pedal Travel 5A–4. . . . . . . . . . . . . . . . . . . .

Acronyms and Abbreviations 5A–4. . . . . . . . . . . .

General Diagnosis 5A–5. . . . . . . . . . . . . . . . . . . . . . .

General Information 5A–5. . . . . . . . . . . . . . . . . . . .

ABS Service Precautions 5A–5. . . . . . . . . . . . . . .

Computer System Service Precautions 5A–5. . .

General Service Precautions 5A–5. . . . . . . . . . . .

Note on Intermittents 5A–5. . . . . . . . . . . . . . . . . . .

Test Driving ABS Complaint Vehicles 5A–6. . . . .

“ABS” Warning Light 5A–6. . . . . . . . . . . . . . . . . . .

Normal Operation 5A–6. . . . . . . . . . . . . . . . . . . . .

Basic Diagnostic Flow Chart 5A–6. . . . . . . . . . . .

Basic Inspection Procedure 5A–7. . . . . . . . . . . . .

Tech 2 Scan Tool 5A–8. . . . . . . . . . . . . . . . . . . . . .

Getting Started 5A–9. . . . . . . . . . . . . . . . . . . . . . . .

Operating Procedure 5A–10. . . . . . . . . . . . . . . . . . .

Data List 5A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EHCU Connector Pin-out Checks 5A–12. . . . . . . .

Circuit Diagram (LHD model / 6VD1 and

4JG2) 5A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram (LHD model / 4JG2) 5A–14. . . . .

Circuit Diagram (LHD model / 4JG2) 5A–15. . . . .

Circuit Diagram (LHD model / 6VD1) 5A–16. . . . .

Circuit Diagram (LHD model / 6VD1) 5A–17. . . . .

Connector List (LHD model) 5A–18. . . . . . . . . . . .

Part Location (LHD model) 5A–20. . . . . . . . . . . . . .

Circuit Diagram (RHD model / 6VD1 and

4JG2) 5A–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram (RHD model / 4JG2) 5A–22. . . . .

Circuit Diagram (RHD model / 4JG2) 5A–23. . . . .

Circuit Diagram (RHD model / 6VD1) 5A–24. . . . .

Circuit Diagram (RHD model / 6VD1) 5A–25. . . . .

Circuit Diagram (RHD model / 6VE1 and

4JX1) 5A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Circuit Diagram (RHD model / 4JX1) 5A–27. . . . .

Circuit Diagram (RHD model / 4JX1) 5A–28. . . . .

Circuit Diagram (RHD model / 6VE1) 5A–29. . . . .

Circuit Diagram (RHD model / 6VE1) 5A–30. . . . .

Connector List (RHD model) 5A–31. . . . . . . . . . . .

Part Location (RHD model) 5A–34. . . . . . . . . . . . .

Symptom Diagnosis 5A–35. . . . . . . . . . . . . . . . . . . . .

Chart A–1 ABS Works Frequently But

Vehicle Does Not Decelerate 5A–35. . . . . . . . . . .

Chart TA-1 ABS Works Frequently But

Vehicle Does Not Decelerate (Use

TECH 2) 5A–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart A-2 Uneven Braking Occurs While

ABS Works 5A–36. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart A-3, TA-3 The Wheels Are Locked 5A–36.

Chart A-4 Brake Pedal Feed Is Abnormal 5A–37.

Chart A-5, TA-5 Braking Sound (From

EHCU) Is Heard While Not Braking 5A–38. . . . . .

Diagnostic Trouble Codes 5A–39. . . . . . . . . . . . . . . .

Diagnosis By “ABS” Warning Light

Illumination Pattern 5A–40. . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Codes (DTCs) 5A–40. . . . . . .

Chart B-1 With the key in the ON position

(Before starting the engine). Warning light

(W/L) is not activated. 5A–43. . . . . . . . . . . . . . . . .

Chart B-2 EHCU Abnormality (DTC 14) 5A–43. . .

Chart B-3 Power Voltage Drop (DTC 15) 5A–44. .

Chart B-4 CLASS-2 Communication Line

Abnormality (DTC 16) 5A–44. . . . . . . . . . . . . . . . .

Chart B-5 G-Sensor Circuit (DTC 21) 5A–45. . . . .

Chart B-6 Abnormal Transmission Input

(DTC 23) 5A–46. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart B-7 Transfer Monitor (DTC 24) 5A–47. . . . .

Chart B-8 EHCU Pump Motor And Motor

Relay Circuit (DTC 32) 5A–47. . . . . . . . . . . . . . . . .

Chart B-9 EHCU Pump Valve And Valve

Relay Circuit (DTC 35) 5A–47. . . . . . . . . . . . . . . . .

Chart B-10 FL Isolation Solenoid Valve

Abnormality (DTC 41) 5A–48. . . . . . . . . . . . . . . . .

Chart B-11 FL Dump Solenoid Valve

Abnormality (DTC 42) 5A–48. . . . . . . . . . . . . . . . .

Chart B-12 FR Isolation Solenoid Valve

Abnormality (DTC 43) 5A–48. . . . . . . . . . . . . . . . .

Chart B-13 FR Dump Solenoid Valve

Abnormality (DTC 44) 5A–49. . . . . . . . . . . . . . . . .

Chart B-14 Rear Isolation Solenoid Valve

Abnormality (DTC 45) 5A–49. . . . . . . . . . . . . . . . .

Chart B-15 Rear Dump Solenoid Valve

Abnormality (DTC 46) 5A–49. . . . . . . . . . . . . . . . .

Page 812 of 6000

5A–2

BRAKE CONTROL SYSTEM

Chart B-16 FL Speed Sensor Disconnection

(DTC 51) 5A–50. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart B-17 FR Speed Sensor Disconnection

(DTC 52) 5A–50. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart B-18 RL Speed Sensor Disconnection

(DTC 53) 5A–51. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart B-19 RR Speed Sensor Disconnection

(DTC 54) 5A–51. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart B-20 FL Speed Sensor Short Circuit

(DTC 61) 5A–52. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart B-21 FR Speed Sensor Short Circuit

(DTC 62) 5A–53. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart B-22 RL Speed Sensor Short Circuit

(DTC 63) 5A–54. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart B-23 RR Speed Sensor Short Circuit

(DTC 64) 5A–55. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart B-24 Sensor Signal Input Abnormality

(DTC 65) 5A–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . Sensor Signal Abnormality Criteria using

TECH 2 5A–56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Inspection Procedure 5A–57. . . . . . . . . . . . . . . .

Chart C-1-1 FL Sensor Output Inspection

Procedure 5A–57. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart C-1-2 FR Sensor Output Inspection

Procedure 5A–58. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart C-1-3 RL Sensor Output Inspection

Procedure 5A–58. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart C-1-4 RR Sensor Output Inspection

Procedure 5A–59. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart TC-1 Sensor Output Inspection

Procedure (Use TECH 2) 5A–59. . . . . . . . . . . . . .

Chart C-2 Transmission Input Inspection

Procedure 5A–60. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chart TC-2 Transmission Input Inspection

Procedure (Use TECH 2) 5A–61. . . . . . . . . . . . . .

Special Tools 5A–62. . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 815 of 6000

5A–5 BRAKE CONTROL SYSTEM

FR

Front Right

GEN

Generator

MV

Millivolts

RL

Rear Left

RR

Rear RightRPS

Revolution per Second

VDC

Vo l t s D C

VA C

Vo l t s A C

W/L

Warning Light

WSS

Wheel Speed Sensor

General Diagnosis

General Information

ABS malfunction can be classified into two types, those

which can be detected by the ABS warning light and those

which can be detected as a vehicle abnormality by the

driver.

In either case, locate the fault in accordance with the

“BASIC DIAGNOSTIC FLOWCHART” and repair.

Please refer to Section 5C for the diagnosis of

mechanical troubles such as brake noise, brake judder

(brake pedal or vehicle vibration felt when braking),

uneven braking, and parking brake trouble.

ABS Service Precautions

Required Tools and Items:

Box Wrench

Brake Fluid

Special Tool

Some diagnosis procedures in this section require the

installation of a special tool.

J-39200 High Impedance Multimeter

When circuit measurements are requested, use a circuit

tester with high impedance.

Computer System Service Precautions

The Anti-lock Brake System interfaces directly with the

Electronic Hydraulic Control Unit (EHCU) which is a

control computer that is similar in some regards to the

Powertrain Control Module. These modules are designed

to withstand normal current draws associated with

vehicle operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for opens

or shorts, do not ground or apply voltage to any of the

circuits unless instructed to do so by the appropriate

diagnostic procedure. These circuits should only be

tested with a high impedance multimeter (J-39200) or

special tools as described in this section. Power should

never be removed or applied to any control module with

the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure toobserve these precautions may result in Anti-lock Brake

System damage.

If welding work is to be performed on the vehicle using

an electric arc welder, the EHCU and valve block

connectors should be disconnected before the

welding operation begins.

The EHCU and valve block connectors should never

be connected or disconnected with the ignition “ON” .

EHCU of the Anti-lock Brake System are not

separately serviceable and must be replaced as

assemblies. Do not disassemble any component

which is designated as non-serviceable in this

Section.

If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS” warning light will

illuminate. But actually no trouble exists. After

inspection stop the engine once and re-start it, then

make sure that the “ABS” warning light does not

illuminate.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS)

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS to a

non-operative state by removing the fuse for the ABS

(40A). After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning light does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may be

helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be useful

in isolating the failure. Most intermittent problems are

caused by faulty electrical connections or wiring. When

an intermittent failure is encountered, check suspect

circuits for:

Suspected harness damage.

Poor mating of connector halves or terminals not fully

seated in the connector body (backed out).

Improperly formed or damaged terminals.

Page 818 of 6000

5A–8

BRAKE CONTROL SYSTEM

Tech 2 Scan Tool

From 98 MY, Isuzu dealer service departments are

recommended to use Tech 2. Please refer to Tech 2 scan

tool user guide.

901RW257

Legend

(1) PCMCIA Card

(2) SAE 16/19 Adaptor(3) DLC Cable

(4) Tech–2

Page 873 of 6000

5B–1 ANTI–LOCK BRAKE SYSTEM

BRAKES

ANTI-LOCK BRAKE SYSTEM

CONTENTS

Service Precaution 5B–1. . . . . . . . . . . . . . . . . . . . . .

Electronic Hydraulic Control Unit 5B–2. . . . . . . . . .

Electronic Hydraulic Control Unit and

Associated Parts 5B–2. . . . . . . . . . . . . . . . . . . . . .

Removal 5B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

G-Sensor 5B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 5B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 5B–3. . . . . . . . . . . . . . . . . .

Installation 5B–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Wheel Speed Sensor 5B–4. . . . . . . . . . . . . . . Front Wheel Speed Sensor and

Associated Parts 5B–4. . . . . . . . . . . . . . . . . . . . . .

Removal 5B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 5B–5. . . . . . . . . . . . . . . . . .

Installation 5B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Wheel Speed Sensor 5B–6. . . . . . . . . . . . . . .

Rear Wheel Speed Sensor and

Associated Parts 5B–6. . . . . . . . . . . . . . . . . . . . . .

Removal 5B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 5B–6. . . . . . . . . . . . . . . . . .

Installation 5B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM(SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.CAUTION: Replace all components included in

repair kits used to service this system. Lubricate

rubber parts with clean, fresh brake fluid to ease

assembly. Do not use shop air with in–line

lubricators on brake parts, as damage to rubber

components may result. If any hydraulic component

is removed or brake line disconnected, it may be

necessary to bleed part or all of the brake system.

NOTE: The use of rubber hoses or parts other than those

furnished specifically for the Anti–lock Brake System may

lead to functional problems requiring major overhaul.

Page 957 of 6000

6A–1

ENGINE MECHANICAL

ENGINE

CONTENTS

Engine Mechanical 6A. . . . . . . . . . . . . . . . . . . . . .

Engine Cooling 6B. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Fuel 6C. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Electrical 6D1. . . . . . . . . . . . . . . . . . . . . . . .

Ignition System 6D2. . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Charging System 6D3. . . . . . . . . . . . Driveability and Emissions 6E. . . . . . . . . . . . . . . .

Engine Exhaust 6F. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Lubrication 6G. . . . . . . . . . . . . . . . . . . . . .

Engine Speed Control System 6H. . . . . . . . . . . .

Inducton 6J. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE MECHANICAL

CONTENTS

Service Precaution 6A–2. . . . . . . . . . . . . . . . . . . . . .

General Description 6A–3. . . . . . . . . . . . . . . . . . . . .

Engine Diagnosis 6A–4. . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover LH 6A–18. . . . . . . . . . . . . . . . .

Removal 6A–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover RH 6A–21. . . . . . . . . . . . . . . . .

Removal 6A–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–22. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Chamber 6A–24. . . . . . . . . . . . . . . . . . . . . .

Removal 6A–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold LH 6A–26. . . . . . . . . . . . . . . . . . . . .

Removal 6A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold RH 6A–27. . . . . . . . . . . . . . . . . . . .

Removal 6A–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Pulley 6A–28. . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt 6A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 6A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A–37. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Stem Oil Controller , Valve Spring and

Valve Guide 6A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston, Piston Ring and Connecting Rod 6A–40. . . Removal 6A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Main Bearings 6A–42. . . . . . . . . . . .

Removal 6A–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal 6A–47. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–47. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Assembly 6A–48. . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–48. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A–52. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Associated Parts 6A–52. . . . .

Disassembly 6A–52. . . . . . . . . . . . . . . . . . . . . . . . . .

Clean 6A–53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–53

. . . . . . . . . . . . . . . . . .

Reassembly 6A–53. . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve,

Valve Guide 6A–56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve,

Valve Guide and Associated Parts 6A–56. . . . . . .

Disassembly 6A–56. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–57. . . . . . . . . . . . . . . . . .

Reassembly 6A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Clearance Adjustments 6A–61. . . . . . . . . . . . .

Camshaft 6A–63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft and Associated Parts 6A–63. . . . . . . . .

Disassembly 6A–63. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–64. . . . . . . . . . . . . . . . . .

Reassembly 6A–66. . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft 6A–69. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Associated Parts 6A–69. . . . . . . .

Disassembly 6A–69. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–70. . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–71. . . . . . . . . . . . . . . . . .

Reassembly 6A–73. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 958 of 6000

6A–2

ENGINE MECHANICAL

Piston and Connecting Rod 6A–77. . . . . . . . . . . . . . .

Piston, Connecting Rod and Associate

Parts 6A–77. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 6A–77. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–78. . . . . . . . . . . . . . . . . .

Reassembly 6A–82. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Block 6A–85. . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Block and Associated Parts 6A–85. . . . .

Disassembly 6A–85. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–86. . . . . . . . . . . . . . . . . .

Reassembly 6A–87. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specification 6A–90. . . . . . . . . . . . . .

Special Tool 6A–96. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 959 of 6000

6A–3

ENGINE MECHANICAL

General Description

Engine Cleanliness And Care

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousandths of a

millimeter (ten thousandths of an inch). Accordingly,

when any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and protection

of machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice even if not specifically stated.

A liberal coating of engine oil should be applied to all

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

The six cylinders of this engine are identified by

numbers; Right side cylinders 1, 3 and 5, Left side

cylinders 2, 4 and 6, as counted from crankshaft

pulley side to flywheel side.

General Information on Engine Service

The following information on engine service should be

noted carefully, as it is important in preventing damage

and contributing to reliable engine performance:

When raising or supporting the engine for any reason,

do not use a jack under the oil pan. Due to the small

clearance between the oil pan and the oil pump

strainer, jacking against the oil pan may cause

damage to the oil pick–up unit.

The 12–volt electrical system is capable of damaging

circuits. When performing any work where electrical

terminals could possibly be grounded, the ground

cable of the battery should be disconnected at the

battery.

Any time the intake air duct or air cleaner is removed,

the intake opening should be covered. This will

protect against accidental entrance of foreign

material into the cylinder which could cause extensive

damage when the engine is started.

Cylinder Block

The cylinder block is made of aluminum die–cast casting

for 75

V–type six cylinders. It has a rear plate integrated

structure and employs a deep skint. The cylinder liner is

cast and the liner inner diameter and crankshaft journal

diameter are classified into grades. The crankshaft is

supported by four bearings of which width of No.3 bearing

on the body side is different in order to support the thrust

bearing. The bearing cap is made of nodular cast iron and

each bearing cap uses four bolts and two side bolts.

Cylinder Head

The cylinder head, made of aluminum alloy casting

employs a pent–roof type combustion chamber with a

spark plug in the center. The intake and exhaust valves

are placed in V–type design. The ports are cross–flow

type.

Va l v e Tr a i n

Intake and exhaust camshaft on the both side of banks

are driven through an camshaft drive gear by timing belt.

The valves are operated by the camshaft and the valve

clearance is adjusted to select suitable thickness shim.

Intake Manifold

The intake manifold system is composed of the aluminum

cast common chamber and intake manifold attached with

six fuel injectors.

Exhaust Manifold

The exhaust manifold is made of nodular cast iron.

Pistons and Connecting Rods

Aluminum pistons are used after selecting the grade that

meets the cylinder bore diameter. Each piston has two

compression rings and one oil ring. The piston pin is made

of chromium steel is offset 1mm toward the thrust side,

and the thrust pressure of piston to the cylinder wall varies

gradually as the piston travels. The connecting rods are

made of forged steel. The connecting rod bearings are

graded for correct seze selection.

Crankshaft and Bearings

The crankshaft is made of Ductile cast–iron. Pins and

journals are graded for correct size selection for their

bearing.

Engine Lubrication

The oil discharged by a trochoid–type oil pump driven by

the crankshaft is fed through full–flow oil filter and to the oil

gallery provided under the crankshaft bearing cap. The oil

is then led to the crankshaft journals and cylinder head.

The crank pins are lubricated with oil from crankshaft

journals through oil holes. Also, an oil jet is fed to each

cylinder from crankshaft juornals on the connecting rod

for piston cleaning. The oil pan flange is dealed with liquid

packing only; do not deform or damage the flange surface

during removal or installation.

Page 1034 of 6000

6A–78

ENGINE MECHANICAL

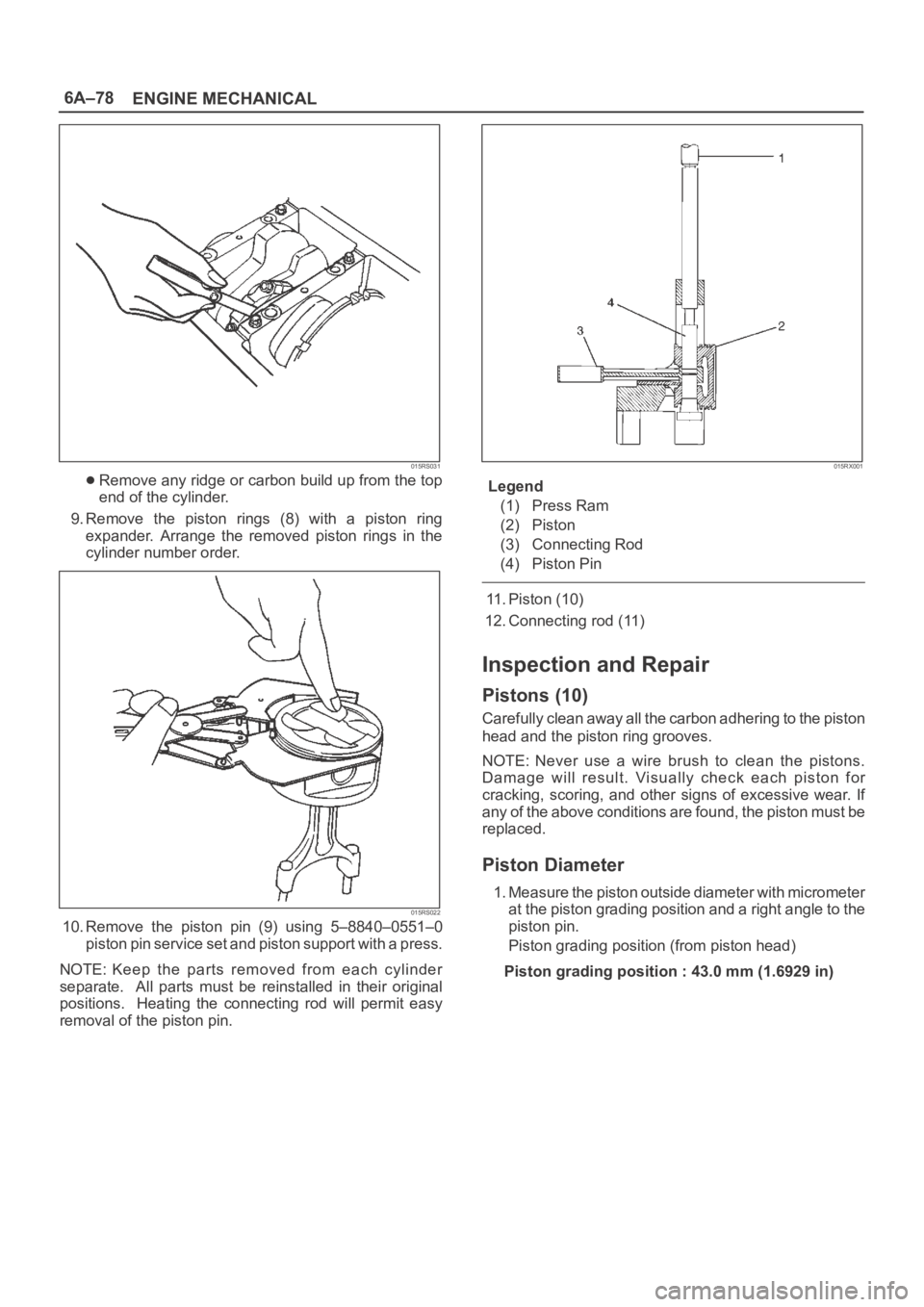

015RS031

Remove any ridge or carbon build up from the top

end of the cylinder.

9. Remove the piston rings (8) with a piston ring

expander. Arrange the removed piston rings in the

cylinder number order.

015RS022

10. Remove the piston pin (9) using 5–8840–0551–0

piston pin service set and piston support with a press.

NOTE: Keep the parts removed from each cylinder

separate. All parts must be reinstalled in their original

positions. Heating the connecting rod will permit easy

removal of the piston pin.

015RX001

Legend

(1) Press Ram

(2) Piston

(3) Connecting Rod

(4) Piston Pin

11. Piston (10)

12. Connecting rod (11)

Inspection and Repair

Pistons (10)

Carefully clean away all the carbon adhering to the piston

head and the piston ring grooves.

NOTE: Never use a wire brush to clean the pistons.

Damage will result. Visually check each piston for

cracking, scoring, and other signs of excessive wear. If

any of the above conditions are found, the piston must be

replaced.

Piston Diameter

1. Measure the piston outside diameter with micrometer

at the piston grading position and a right angle to the

piston pin.

Piston grading position (from piston head)

Piston grading position : 43.0 mm (1.6929 in)

Page 1039 of 6000

6A–83

ENGINE MECHANICAL

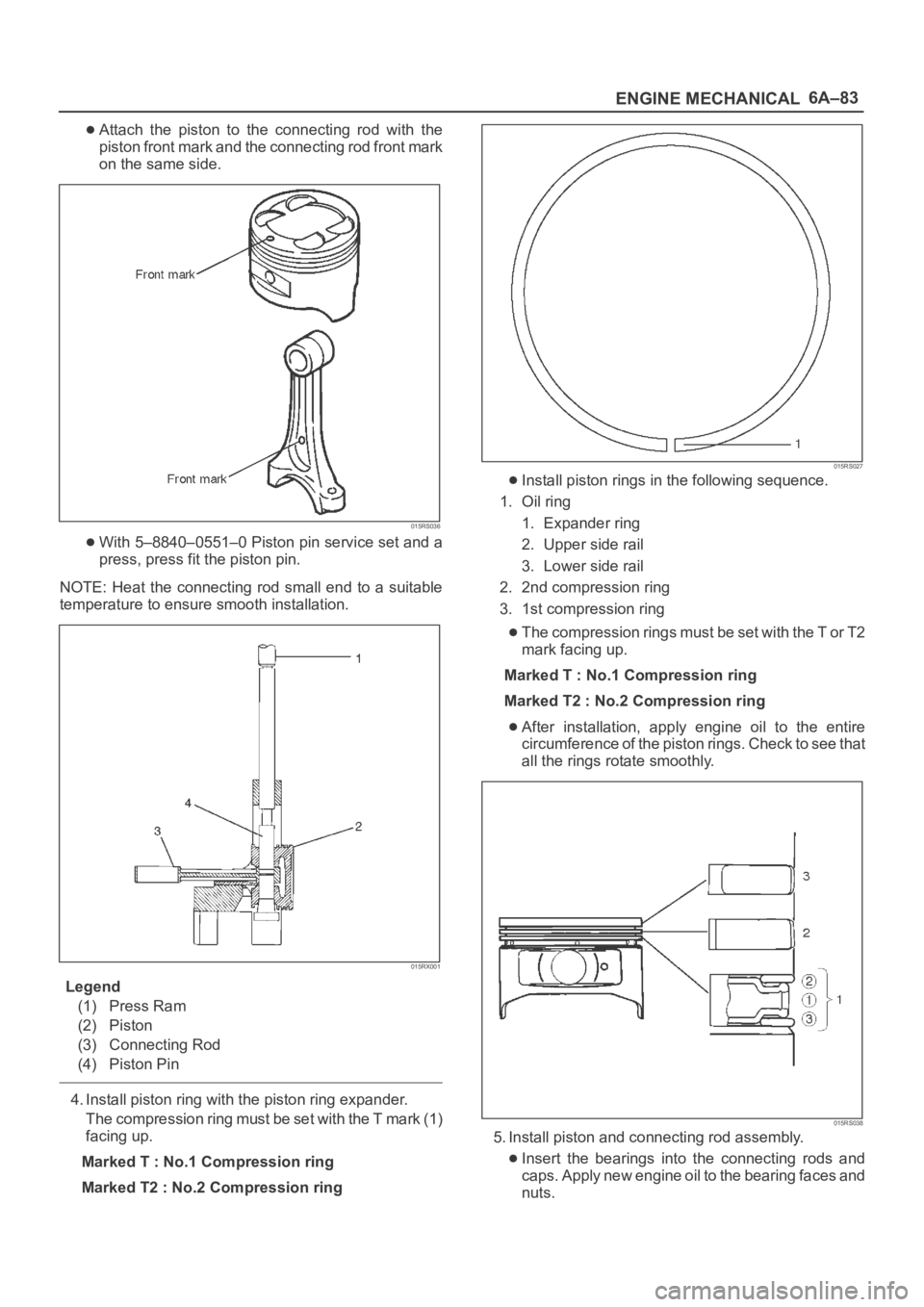

Attach the piston to the connecting rod with the

piston front mark and the connecting rod front mark

on the same side.

015RS036

With 5–8840–0551–0 Piston pin service set and a

press, press fit the piston pin.

NOTE: Heat the connecting rod small end to a suitable

temperature to ensure smooth installation.

015RX001

Legend

(1) Press Ram

(2) Piston

(3) Connecting Rod

(4) Piston Pin

4. Install piston ring with the piston ring expander.

The compression ring must be set with the T mark (1)

facing up.

Marked T : No.1 Compression ring

Marked T2 : No.2 Compression ring

015RS027

Install piston rings in the following sequence.

1. Oil ring

1. Expander ring

2. Upper side rail

3. Lower side rail

2. 2nd compression ring

3. 1st compression ring

The compression rings must be set with the T or T2

mark facing up.

Marked T : No.1 Compression ring

Marked T2 : No.2 Compression ring

After installation, apply engine oil to the entire

circumference of the piston rings. Check to see that

all the rings rotate smoothly.

015RS038

5. Install piston and connecting rod assembly.

Insert the bearings into the connecting rods and

caps. Apply new engine oil to the bearing faces and

nuts.