engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5723 of 6000

7A–34

AUTOMATIC TRANSMISSION (4L30–E)

4. Disconnect shift lock cable from the selector lever

assembly side.

256RW012

5. Disconnect wiring harness connectors.

6. Disconnect shift control rod from the selector lever

assembly side.

256RW013

7. Remove selector lever assembly (3).

8. Remove transfer control lever (4).

9. Remove transfer and exhaust protector (5).

10. Remove rear propeller shaft (6).

11. Remove front propeller shaft (7).

12. Remove harness protector (8).

13. Support transfer case with a jack and remove two rear

mount nuts (9) from the 3rd crossmember side.

14. Remove eight third crossmember bolts and third

crossmember (10).15. Disconnect one oxygen sensor connector from the

transmission harness.

150RW002

16. Remove exhaust pipe (11).

17. Disconnect transmission oil cooler pipe (12) from A/T

side.

18. Remove oil pipe clamp from torque converter

housing bracket.

253RY001

19. Loosen oil pipe clamp bolt at the engine mount side.

20. Remove starter (13).

21. Disconnect fuel pipe clamp bracket from

transmission side.

22. Disconnect transmission harness connectors (14)

from transmission, and transfer.

23. Remove under covers (3 pieces) (15) from

transmission case.

24. Lower the front of the transmission a little, then

remove flex plate torque converter fixing bolts (6

pieces) (16) by turning crankshaft.

25. Support the transmission with a transmission jack,

and hoist engine with a chain block.

26. Remove engine transmission fixing bolts (17).

Page 5724 of 6000

7A–35 AUTOMATIC TRANSMISSION (4L30–E)

27. Remove transmission assembly (18).

Installation

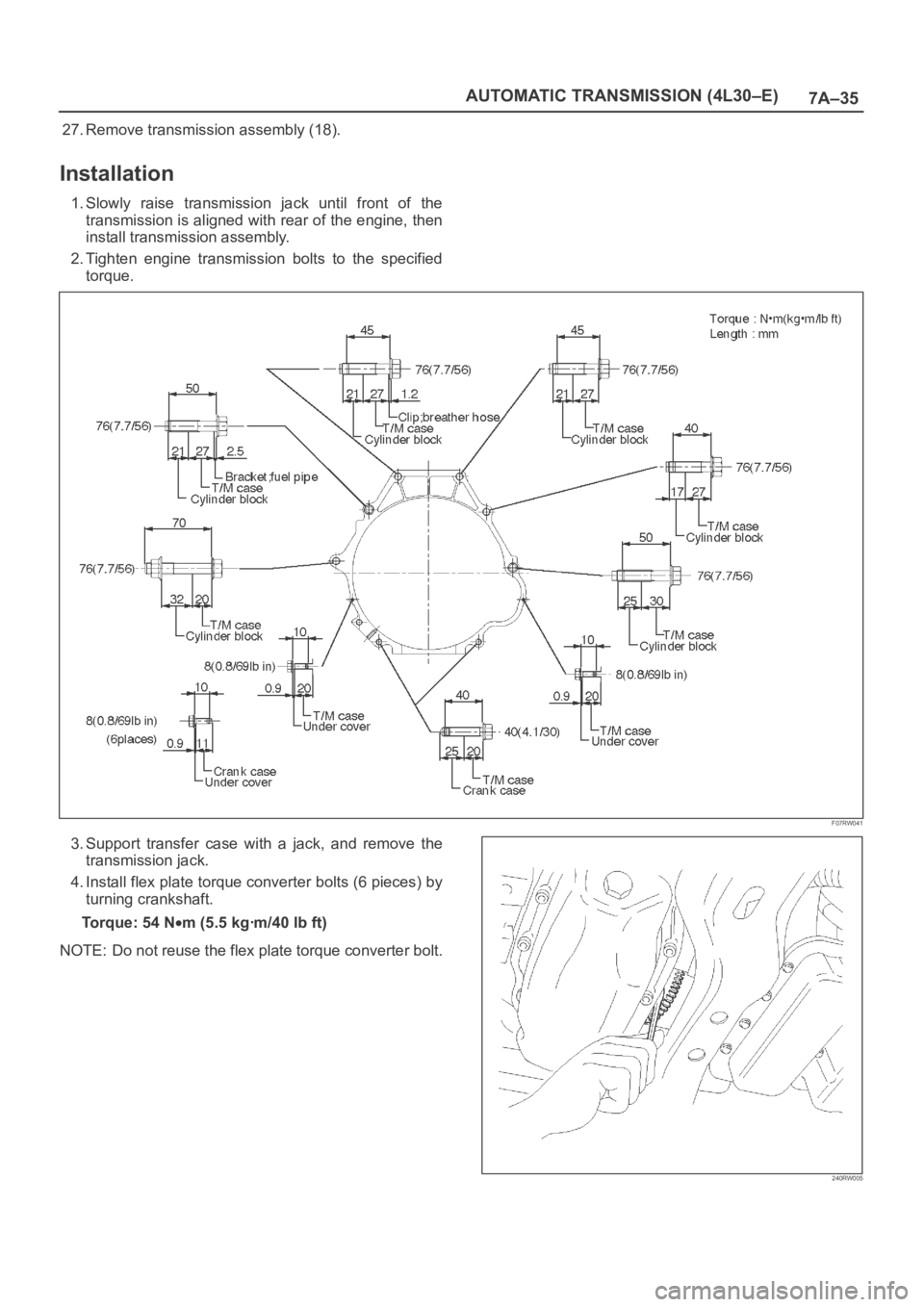

1. Slowly raise transmission jack until front of the

transmission is aligned with rear of the engine, then

install transmission assembly.

2. Tighten engine transmission bolts to the specified

torque.

F07RW041

3. Support transfer case with a jack, and remove the

transmission jack.

4. Install flex plate torque converter bolts (6 pieces) by

turning crankshaft.

Torque: 54 N

m (5.5 kgꞏm/40 lb ft)

NOTE: Do not reuse the flex plate torque converter bolt.

240RW005

Page 5726 of 6000

7A–37 AUTOMATIC TRANSMISSION (4L30–E)

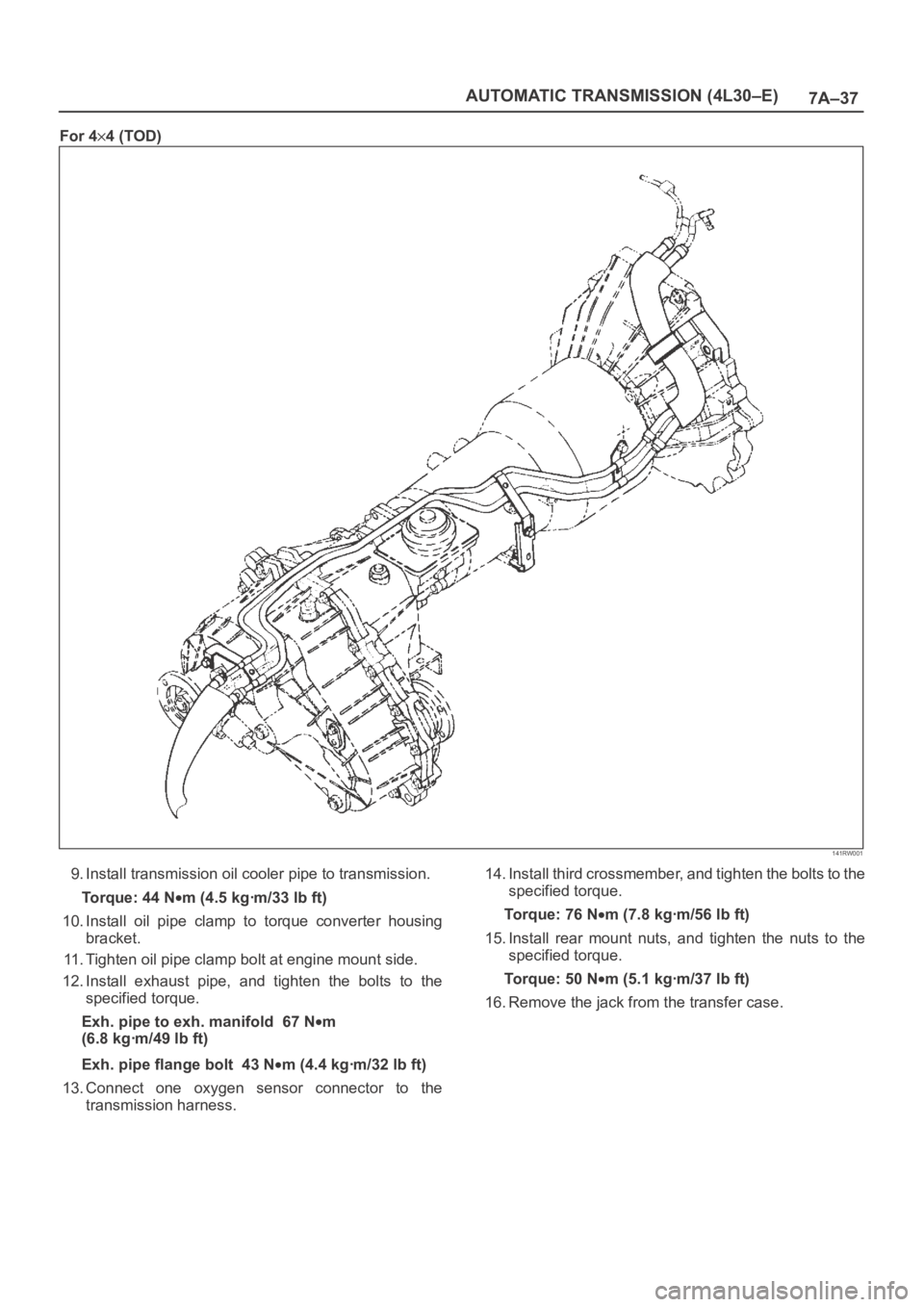

For 44 (TOD)

141RW001

9. Install transmission oil cooler pipe to transmission.

Torque: 44 N

m (4.5 kgꞏm/33 lb ft)

10. Install oil pipe clamp to torque converter housing

bracket.

11. Tighten oil pipe clamp bolt at engine mount side.

12. Install exhaust pipe, and tighten the bolts to the

specified torque.

Exh. pipe to exh. manifold 67 N

m

(6.8 kgꞏm/49 lb ft)

Exh. pipe flange bolt 43 N

m (4.4 kgꞏm/32 lb ft)

13. Connect one oxygen sensor connector to the

transmission harness.14. Install third crossmember, and tighten the bolts to the

specified torque.

To r q u e : 7 6 N

m (7.8 kgꞏm/56 lb ft)

15. Install rear mount nuts, and tighten the nuts to the

specified torque.

To r q u e : 5 0 N

m (5.1 kgꞏm/37 lb ft)

16. Remove the jack from the transfer case.

Page 5727 of 6000

7A–38

AUTOMATIC TRANSMISSION (4L30–E)

17. Install harness protector.

815RW002

18. Install the front propeller shaft, and tighten the bolts to

the specified torque.

Torque: 63 N

m (6.4 kgꞏm/46 lb ft)

19. Install the rear propeller shaft, and tighten the bolts to

the specified torque.

Torque: 63 N

m (6.4 kgꞏm/46 lb ft)

20. Install the transfer and exhaust protectors, and

tighten the bolts to the specified torque.

Torque: 37 N

m (3.8 kgꞏm/27 lb ft)

21. Install the transfer control lever.

22. Install the selector lever assembly.

23. Connect the shift control rod to selector lever

assembly.

24. Connect the wiring harness connectors.

25. Connect the shift lock cable to selector lever

assembly. Refer to Selector Lever in this section.

26. Connect the wiring harness connectors to front

console.

27. Install the front console.

28. Install the transfer control lever knob.

29. Connect the battery ground cable.

30. Install the engine hood.

Page 5748 of 6000

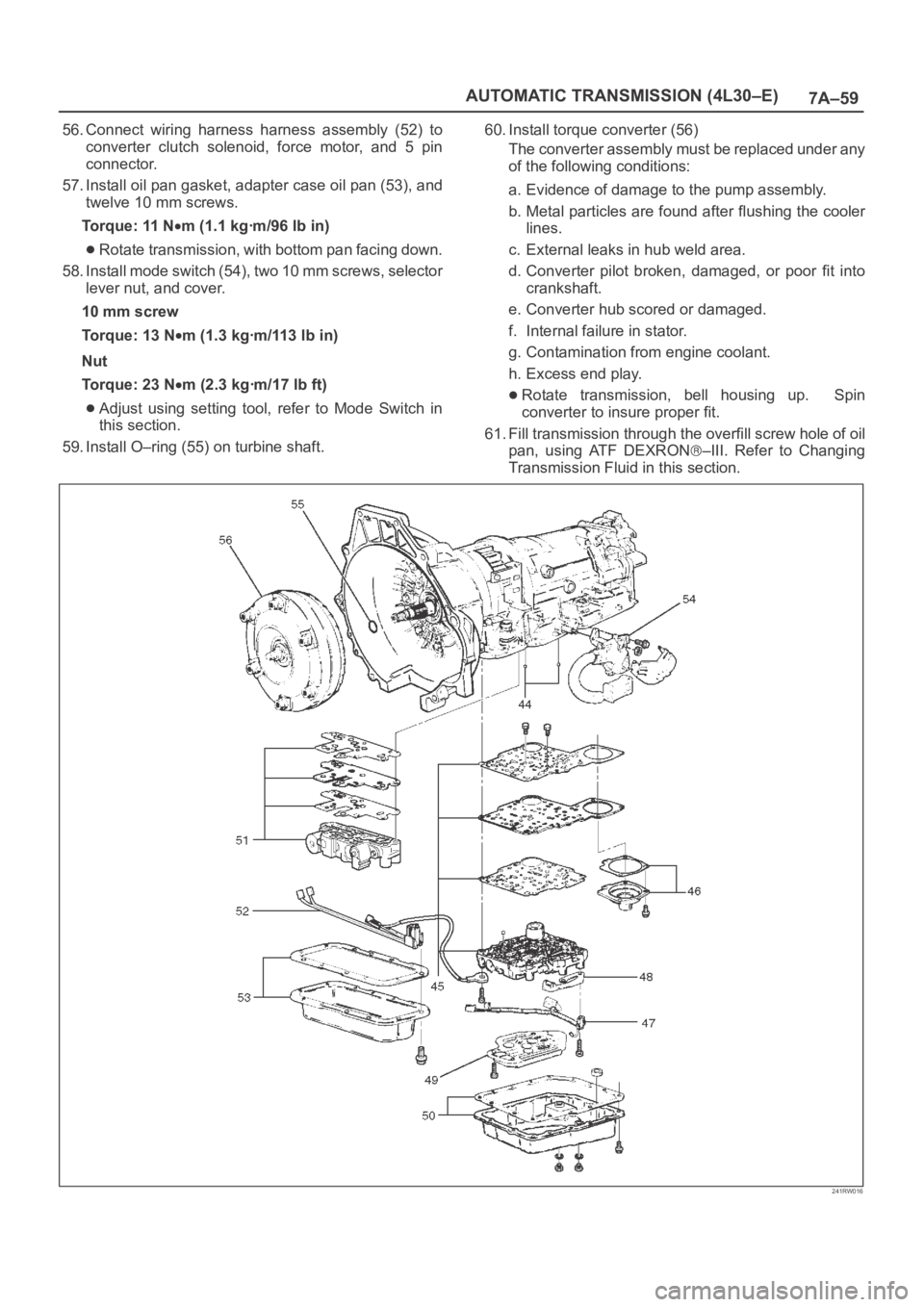

7A–59 AUTOMATIC TRANSMISSION (4L30–E)

56. Connect wiring harness harness assembly (52) to

converter clutch solenoid, force motor, and 5 pin

connector.

57. Install oil pan gasket, adapter case oil pan (53), and

twelve 10 mm screws.

Torque: 11 N

m (1.1 kgꞏm/96 lb in)

Rotate transmission, with bottom pan facing down.

58. Install mode switch (54), two 10 mm screws, selector

lever nut, and cover.

10 mm screw

Torque: 13 N

m (1.3 kgꞏm/113 lb in)

Nut

Torque: 23 N

m (2.3 kgꞏm/17 lb ft)

Adjust using setting tool, refer to Mode Switch in

this section.

59. Install O–ring (55) on turbine shaft.60. Install torque converter (56)

The converter assembly must be replaced under any

of the following conditions:

a. Evidence of damage to the pump assembly.

b. Metal particles are found after flushing the cooler

lines.

c. External leaks in hub weld area.

d. Converter pilot broken, damaged, or poor fit into

crankshaft.

e. Converter hub scored or damaged.

f. Internal failure in stator.

g. Contamination from engine coolant.

h. Excess end play.Rotate transmission, bell housing up. Spin

converter to insure proper fit.

61. Fill transmission through the overfill screw hole of oil

pan, using ATF DEXRON

–III. Refer to Changing

Transmission Fluid in this section.

241RW016

Page 5768 of 6000

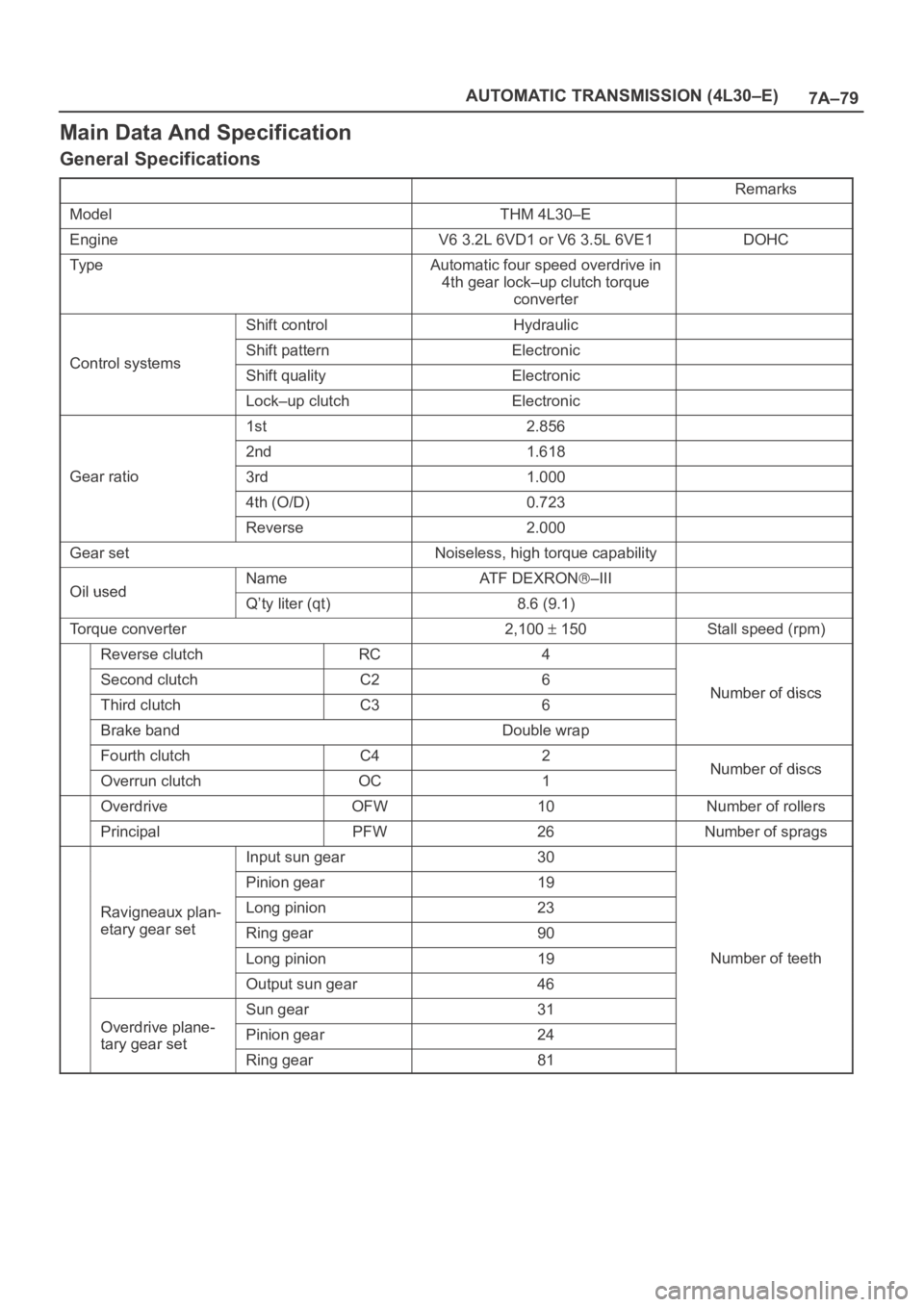

7A–79 AUTOMATIC TRANSMISSION (4L30–E)

Main Data And Specification

General Specifications

Remarks

ModelTHM 4L30–E

EngineV6 3.2L 6VD1 or V6 3.5L 6VE1DOHC

Ty p eAutomatic four speed overdrive in

4th gear lock–up clutch torque

converter

Shift controlHydraulic

Control systemsShift patternElectronicControl systemsShift qualityElectronic

Lock–up clutchElectronic

1st2.856

2nd1.618

Gear ratio3rd1.000

4th (O/D)0.723

Reverse2.000

Gear setNoiseless, high torque capability

Oil usedNameAT F D E X R O N–IIIOil usedQ’ty liter (qt)8.6 (9.1)

Torque converter2,100 150Stall speed (rpm)

Reverse clutchRC4

Second clutchC26Number of discsThird clutchC36Number of discs

Brake bandDouble wrap

Fourth clutchC42Number of discsOverrun clutchOC1Number of discs

OverdriveOFW10Number of rollers

PrincipalPFW26Number of sprags

Input sun gear30

Pinion gear19

Ravigneaux plan-Long pinion23g

etary gear setRing gear90

Long pinion19Number of teeth

Output sun gear46

Odi l

Sun gear31

Overdrive plane-

tary gear setPinion gear24tary gear set

Ring gear81

Page 5788 of 6000

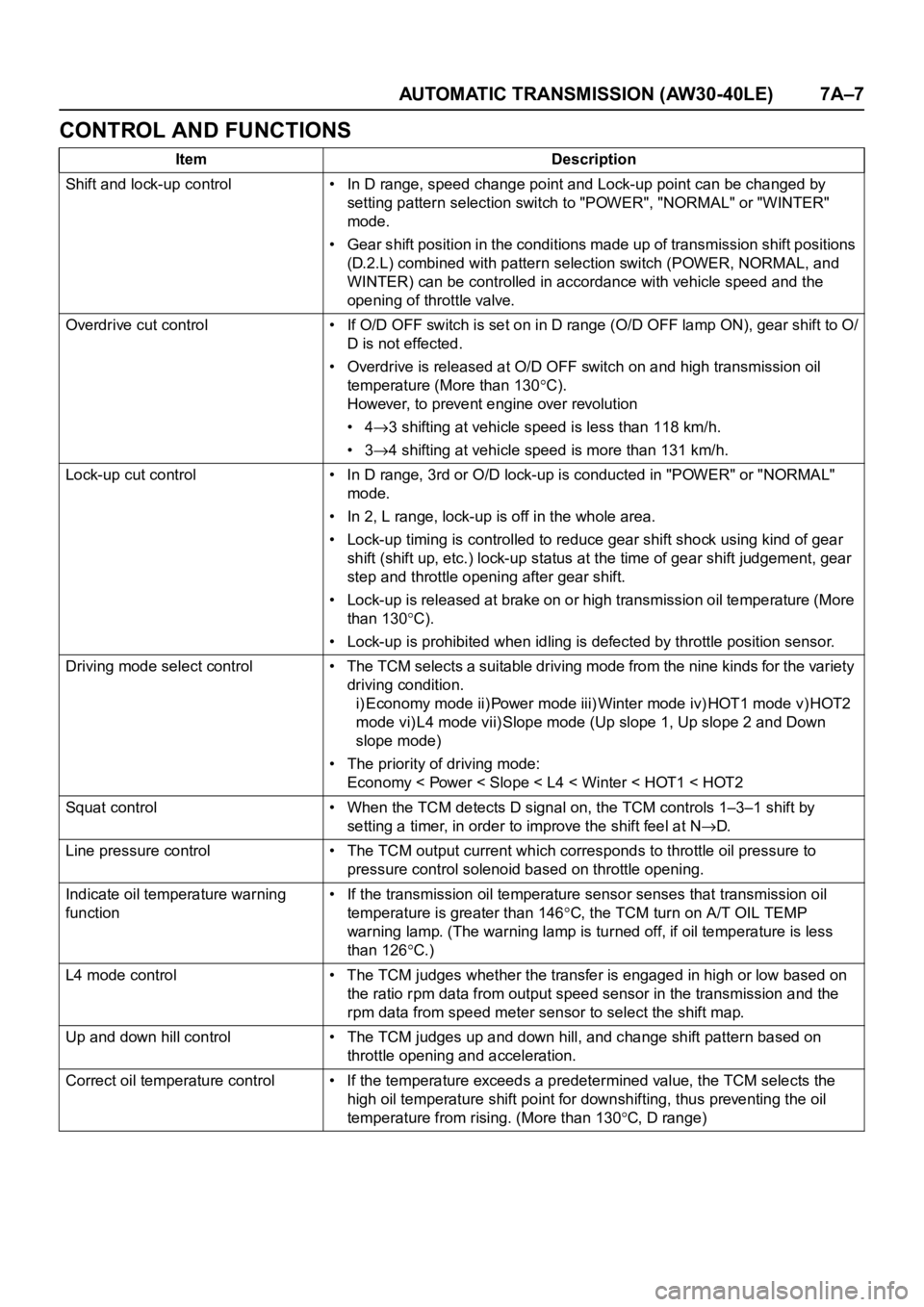

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–7

CONTROL AND FUNCTIONS

Item Description

Shift and lock-up control • In D range, speed change point and Lock-up point can be changed by

setting pattern selection switch to "POWER", "NORMAL" or "WINTER"

mode.

• Gear shift position in the conditions made up of transmission shift positions

(D.2.L) combined with pattern selection switch (POWER, NORMAL, and

WINTER) can be controlled in accordance with vehicle speed and the

opening of throttle valve.

Overdrive cut control • If O/D OFF switch is set on in D range (O/D OFF lamp ON), gear shift to O/

D is not effected.

• Overdrive is released at O/D OFF switch on and high transmission oil

temperature (More than 130

C).

However, to prevent engine over revolution

•4

3 shifting at vehicle speed is less than 118 km/h.

•3

4 shifting at vehicle speed is more than 131 km/h.

Lock-up cut control • In D range, 3rd or O/D lock-up is conducted in "POWER" or "NORMAL"

mode.

• In 2, L range, lock-up is off in the whole area.

• Lock-up timing is controlled to reduce gear shift shock using kind of gear

shift (shift up, etc.) lock-up status at the time of gear shift judgement, gear

step and throttle opening after gear shift.

• Lock-up is released at brake on or high transmission oil temperature (More

than 130

C).

• Lock-up is prohibited when idling is defected by throttle position sensor.

Driving mode select control • The TCM selects a suitable driving mode from the nine kinds for the variety

driving condition.

i) Economy mode ii) Power mode iii) Winter mode iv) HOT1 mode v) HOT2

mode vi) L4 mode vii) Slope mode (Up slope 1, Up slope 2 and Down

slope mode)

• The priority of driving mode:

Economy < Power < Slope < L4 < Winter < HOT1 < HOT2

Squat control • When the TCM detects D signal on, the TCM controls 1–3–1 shift by

setting a timer, in order to improve the shift feel at N

D.

Line pressure control • The TCM output current which corresponds to throttle oil pressure to

pressure control solenoid based on throttle opening.

Indicate oil temperature warning

function• If the transmission oil temperature sensor senses that transmission oil

temperature is greater than 146

C, the TCM turn on A/T OIL TEMP

warning lamp. (The warning lamp is turned off, if oil temperature is less

than 126

C.)

L4 mode control • The TCM judges whether the transfer is engaged in high or low based on

the ratio rpm data from output speed sensor in the transmission and the

rpm data from speed meter sensor to select the shift map.

Up and down hill control • The TCM judges up and down hill, and change shift pattern based on

throttle opening and acceleration.

Correct oil temperature control • If the temperature exceeds a predetermined value, the TCM selects the

high oil temperature shift point for downshifting, thus preventing the oil

temperature from rising. (More than 130

C, D range)

Page 5790 of 6000

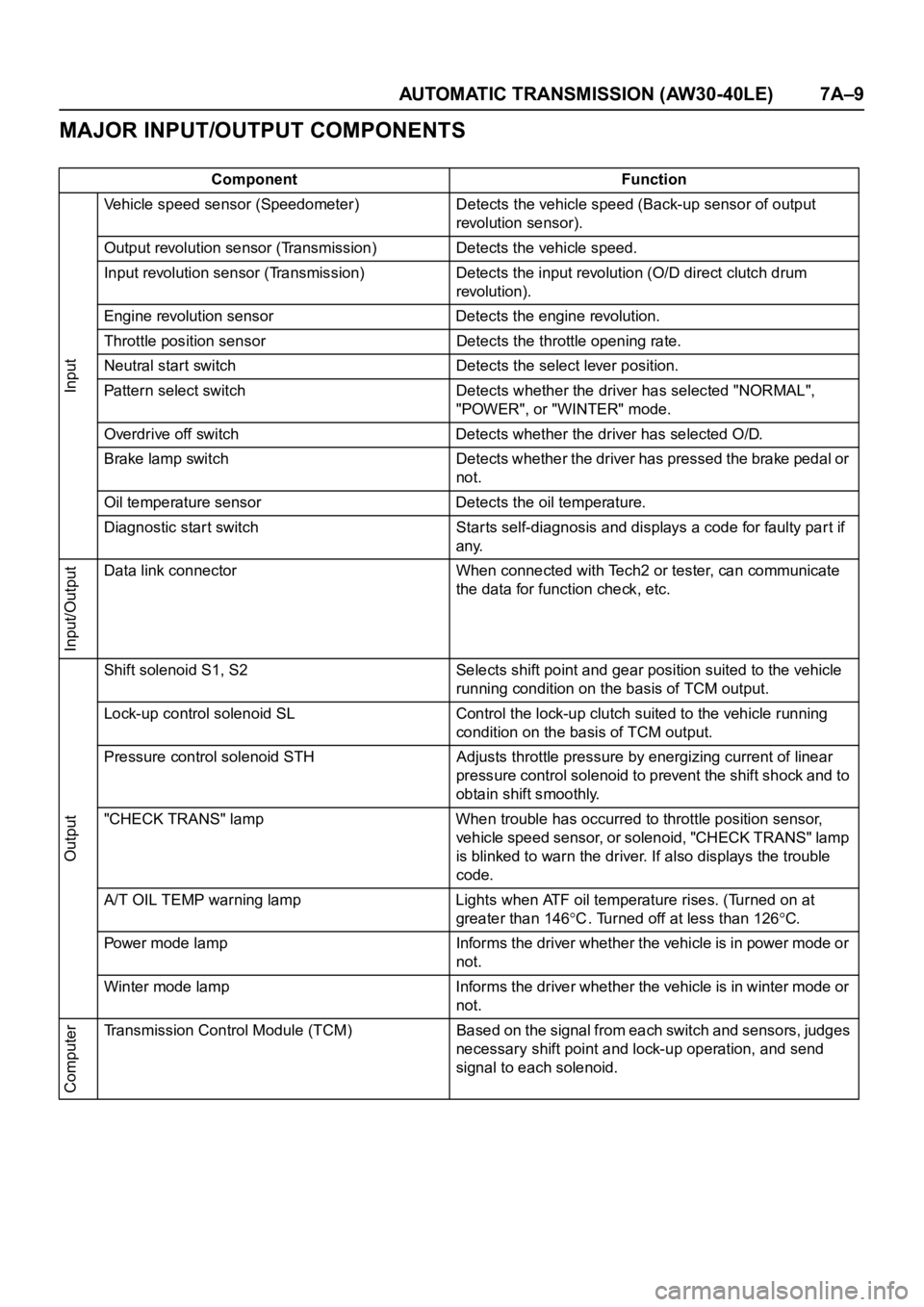

AUTOMATIC TRANSMISSION (AW30-40LE) 7A–9

MAJOR INPUT/OUTPUT COMPONENTS

Component Function

Input

Vehicle speed sensor (Speedometer) Detects the vehicle speed (Back-up sensor of output

revolution sensor).

Output revolution sensor (Transmission) Detects the vehicle speed.

Input revolution sensor (Transmission) Detects the input revolution (O/D direct clutch drum

revolution).

Engine revolution sensor Detects the engine revolution.

Throttle position sensor Detects the throttle opening rate.

Neutral start switch Detects the select lever position.

Pattern select switch Detects whether the driver has selected "NORMAL",

"POWER", or "WINTER" mode.

Overdrive off switch Detects whether the driver has selected O/D.

Brake lamp switch Detects whether the driver has pressed the brake pedal or

not.

Oil temperature sensor Detects the oil temperature.

Diagnostic star t switch Star ts self-diagnosis and displays a code for faulty part if

any.

Input/Output

Data link connector When connected with Tech2 or tester, can communicate

the data for function check, etc.

Output

Shift solenoid S1, S2 Selects shift point and gear position suited to the vehicle

running condition on the basis of TCM output.

Lock-up control solenoid SL Control the lock-up clutch suited to the vehicle running

condition on the basis of TCM output.

Pressure control solenoid STH Adjusts throttle pressure by energizing current of linear

pressure control solenoid to prevent the shift shock and to

obtain shift smoothly.

"CHECK TRANS" lamp When trouble has occurred to throttle position sensor,

vehicle speed sensor, or solenoid, "CHECK TRANS" lamp

is blinked to warn the driver. If also displays the trouble

code.

A/T OIL TEMP warning lamp Lights when ATF oil temperature rises. (Turned on at

greater than 146

C . Turned off at less than 126C.

Power mode lamp Informs the driver whether the vehicle is in power mode or

not.

Winter mode lamp Informs the driver whether the vehicle is in winter mode or

not.

Computer

Transmission Control Module (TCM) Based on the signal from each switch and sensors, judges

necessary shift point and lock-up operation, and send

signal to each solenoid.

Page 5795 of 6000

7A–14 AUTOMATIC TRANSMISSION (AW30-40LE)

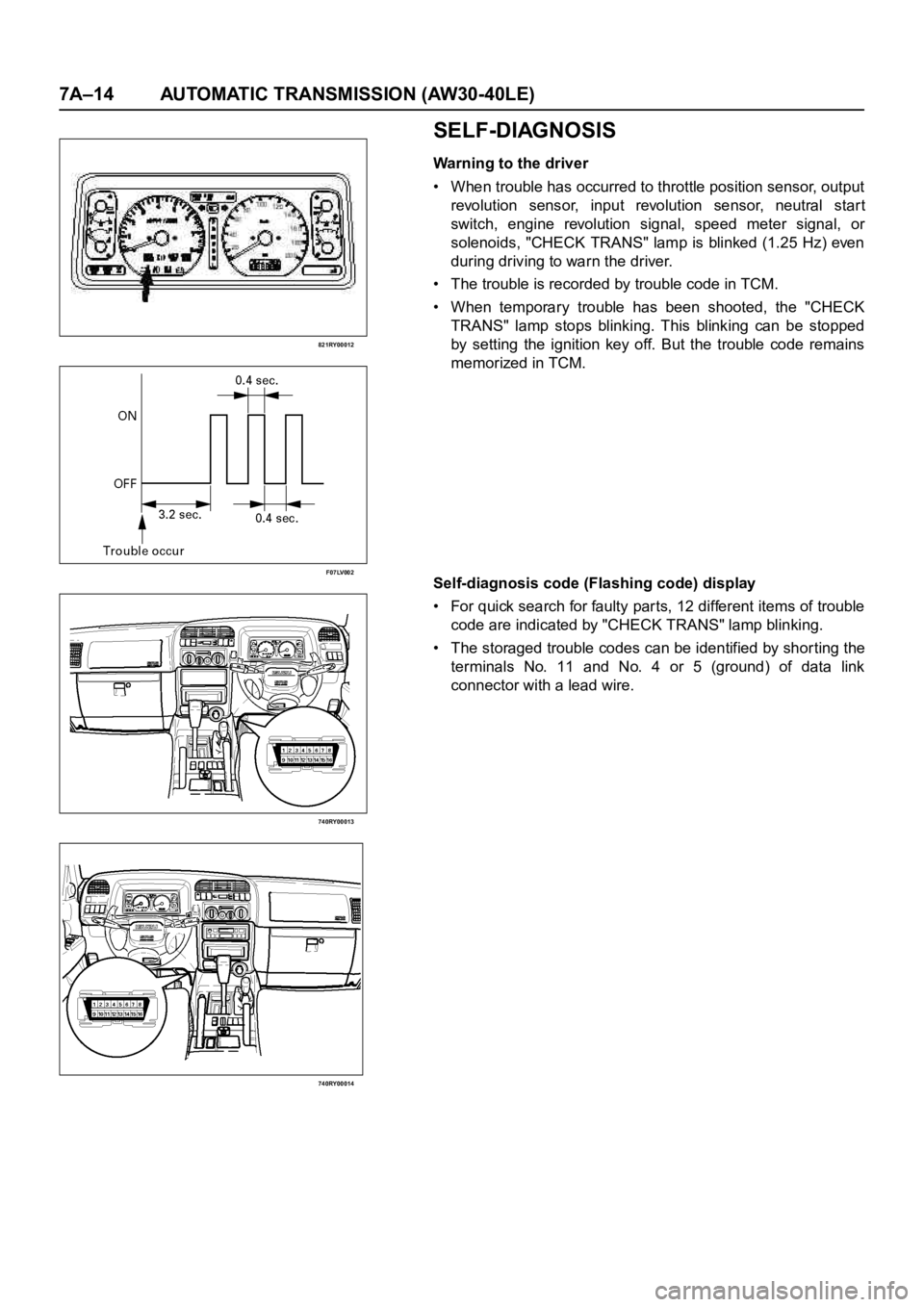

821RY00012

F07LV002

740RY00013

740RY00014

SELF-DIAGNOSIS

Warning to the driver

• When trouble has occurred to throttle position sensor, output

revolution sensor, input revolution sensor, neutral star t

switch, engine revolution signal, speed meter signal, or

solenoids, "CHECK TRANS" lamp is blinked (1.25 Hz) even

during driving to warn the driver.

• The trouble is recorded by trouble code in TCM.

• When temporary trouble has been shooted, the "CHECK

TRANS" lamp stops blinking. This blinking can be stopped

by setting the ignition key off. But the trouble code remains

memorized in TCM.

Self-diagnosis code (Flashing code) display

• For quick search for faulty parts, 12 different items of trouble

code are indicated by "CHECK TRANS" lamp blinking.

• The storaged trouble codes can be identified by shor ting the

terminals No. 11 and No. 4 or 5 (ground) of data link

connector with a lead wire.

Page 5801 of 6000

7A–20 AUTOMATIC TRANSMISSION (AW30-40LE)

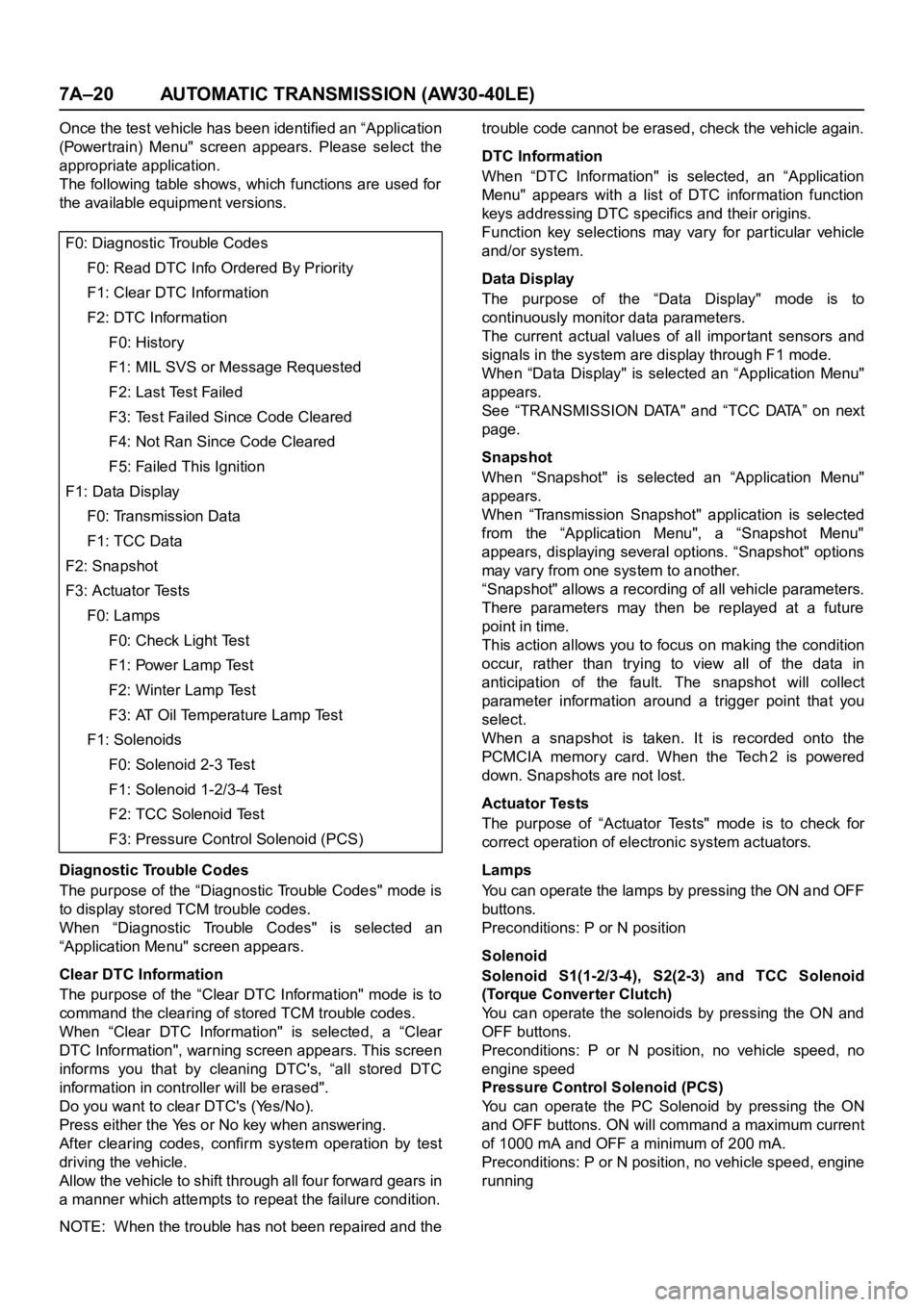

Once the test vehicle has been identified an “Application

(Power train) Menu" screen appears. Please select the

appropriate application.

The following table shows, which functions are used for

the available equipment versions.

Diagnostic Trouble Codes

The purpose of the “Diagnostic Trouble Codes" mode is

to display stored TCM trouble codes.

When “Diagnostic Trouble Codes" is selected an

“Application Menu" screen appears.

Clear DTC Information

The purpose of the “Clear DTC Information" mode is to

command the clearing of stored TCM trouble codes.

When “Clear DTC Information" is selected, a “Clear

DTC Information", warning screen appears. This screen

informs you that by cleaning DTC's, “all stored DTC

information in controller will be erased".

Do you want to clear DTC's (Yes/No).

Press either the Yes or No key when answering.

After clearing codes, confirm system operation by test

driving the vehicle.

Allow the vehicle to shift through all four forward gears in

a manner which attempts to repeat the failure condition.

NOTE: When the trouble has not been repaired and thetrouble code cannot be erased, check the vehicle again.

DTC Information

When “DTC Information" is selected, an “Application

Menu" appears with a list of DTC information function

keys addressing DTC specifics and their origins.

Function key selections may vary for particular vehicle

and/or system.

Data Display

The purpose of the “Data Display" mode is to

continuously monitor data parameters.

The current actual values of all impor tant sensors and

signals in the system are display through F1 mode.

When “Data Display" is selected an “Application Menu"

appears.

See “TRANSMISSION DATA" and “TCC DATA” on next

page.

Snapshot

When “Snapshot" is selected an “Application Menu"

appears.

When “Transmission Snapshot" application is selected

from the “Application Menu", a “Snapshot Menu"

appears, displaying several options. “Snapshot" options

may vary from one system to another.

“Snapshot" allows a recording of all vehicle parameters.

There parameters may then be replayed at a future

point in time.

This action allows you to focus on making the condition

occur, rather than trying to view all of the data in

anticipation of the fault. The snapshot will collect

parameter information around a trigger point that you

select.

When a snapshot is taken. It is recorded onto the

PCMCIA memory card. When the Tech2 is powered

down. Snapshots are not lost.

Actuator Tests

The purpose of “Actuator Tests" mode is to check for

correct operation of electronic system actuators.

Lamps

You can operate the lamps by pressing the ON and OFF

buttons.

Preconditions: P or N position

Solenoid

Solenoid S1(1-2/3-4), S2(2-3) and TCC Solenoid

(Torque Converter Clutch)

You can operate the solenoids by pressing the ON and

OFF buttons.

Preconditions: P or N position, no vehicle speed, no

engine speed

Pressure Control Solenoid (PCS)

You can operate the PC Solenoid by pressing the ON

and OFF buttons. ON will command a maximum current

of 1000 mA and OFF a minimum of 200 mA.

Preconditions: P or N position, no vehicle speed, engine

running F0: Diagnostic Trouble Codes

F0: Read DTC Info Ordered By Priority

F1: Clear DTC Information

F2: DTC Information

F0: History

F1: MIL SVS or Message Requested

F2: Last Test Failed

F3: Test Failed Since Code Cleared

F4: Not Ran Since Code Cleared

F5: Failed This Ignition

F1: Data Display

F0: Transmission Data

F1: TCC Data

F2: Snapshot

F3: Actuator Tests

F0: Lamps

F0: Check Light Test

F1: Power Lamp Test

F2: Winter Lamp Test

F3: AT Oil Temperature Lamp Test

F1: Solenoids

F0: Solenoid 2-3 Test

F1: Solenoid 1-2/3-4 Test

F2: TCC Solenoid Test

F3: Pressure Control Solenoid (PCS)