check engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1366 of 6000

6E–249 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1404 EGR Closed Stuck

D06RW106

Circuit Description

The powertrain control module (PCM) monitors the EGR

valve pintle position input to ensure that the valve

responds properly to commands from the PCM, and to

detect a fault if current pintle zero position is different from

the learned zero position. If the PCM detects a pintle

position signal indicates more than 30 % different

between current zero position and the learned zero

position and more than 5 seconds, and this condition

meet 3 times during trip, then the PCM will set DTC

P1404.

Conditions for Setting the DTC

Ignition voltage is between 11 and 16 volts.

Intake Air temp is more than 3C.

Desire EGR position is 0.

Difference EGR pintle position between current and

the learned zero is more than 30 % last more than 5

seconds, and meet three time to the above condition

during a trip. Then it trigger the PCM lights on.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after consecutive 2nd trip in which the fault is

detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in Failure

Records data.

Conditions for Clearing the MIL/DTC

DTC P1404 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Excessive carbon deposit on EGR valve shaft or/and

foreign material may cause no return to EGR valve

fully seated. Those carbon deposit may occur by

unusual port operation. Remove foreign material

or/and excessive carbon deposit on EGR valve shaft

may make return to EGR valve fully seated.

Poor connection or damaged harness – Inspect the

wiring harness for damage. Same as P1406

description

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 1367 of 6000

6E–250

ENGINE DRIVEABILITY AND EMISSIONS

DTC P1404 – EGR Closed Stuck

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “DTC inf. for DTC P1404

until the DTC P1404 test runs. Note the result.

Does the Tech 2 indicates DTC P1404 failed this

ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

31. Disconnect the EGR valve harness connector.

2. Inspect the EGR valve and connectors for damaged

pin or terminals.

Were there any damaged pins or terminals?

—Go to Step 4Go to Step 5

4Repair the damaged pin or terminal.

Is the action complete?

—Verify repair—

51. Remove EGR valve from Engine.

2. Inspect EGR valve whether there is any excessive

carbon deposit on EGR shaft.

3. Inspect any foreign material inside of EGR valve.

Was excessive carbon deposit on EGR valve shaft

or/and foreign material in EGR valve ?

—Go to Step 6Go to Step 7

61. Clean up EGR valve shaft and inside of EGR valve.

2. Remove foreign material from EGR valve.

3. Visually inspect damage of pintle and seat whether

there is bent, leakage may occur.

Was there any severe damage which affects function?

3–6 ohmsGo to Step 8

Verify repair

Go to

Step 7

71. Reconnect.

2. Ignition “OFF”.

3. Install the Tech 2.

4. Run the engine at idle.

5. On the Tech 2, select F3:Misc. Test F5:EGR.

6. Use the “UP” arrow to increase the EGR from 0% to

40%.

Did EGR work properly?

——Go to Step 8

81. Reset the learned zero EGR valve position.

2. Repeat step 7.

Did EGR work properly?

—Verify repairGo to Step 9

9Replace the EGR valve.

Replace the EGR valve. Does DTC P1404 still fail

“specific DTC” test on the Tech 2?

—Go to Step 10Verify repair

10Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1368 of 6000

6E–251 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1508 IAC System Low RPM

T321115

Circuit Description

The powertrain control module (PCM) controls engine

idle speed by adjusting the position of the idle air control

(IAC) motor pintle. The IAC is a bi-directional stepper

motor driven by two coils. The PCM applies current to the

IAC coils in steps (counts) to extend the IAC pintle into a

passage in the throttle body to decrease air flow. The

PCM reverses the current to retract the pintle, increasing

air flow. This method allows highly accurate control of idle

speed and quick response to changes in engine load. If

the PCM detects a condition where too low of an idle

speed is present and the PCM is unable to adjust idle

speed by increasing the IAC counts, DTC P1508 will set,

indicating a problem with the idle control system.

Conditions for Setting the DTC

No Tech 2 test is being run.

None of these DTCs are set: TP sensor, VSS, ECT,

EGR, fuel system, MAF, MAP, IAT, canister purge,

injector control or ignition control.

Barometric pressure is above 75 kPa.

Engine coolant temperature (ECT) is above 50C

(120

F).

Engine speed is more than 100-200 RPM lower than

desired idle, based upon coolant temperature.

The engine has been running for at least 125 seconds.

Vehicle speed is less than 1 mph.

Canister purge duty cycle is above 10%.

Ignition voltage is between 9.5 volts and 16.7 volts.

The throttle is closed.

Engine speed is lower than desired idle.

All of the above conditions are met for 10 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1508 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM or IAC motor – Inspect

harness connectors for backed-out terminals,

improper mating, broken locks, improperly formed or

damaged terminals, and poor terminal-to-wire

connection.

Damaged harness – Inspect the wiring for damage.

Restricted air intake system – Check for a possible

collapsed air intake duct, restricted air filter element,

or foreign objects blocking the air intake system.

Throttle body – Check for objects blocking the IAC

passage or throttle bore, excessive deposits in the IAC

Page 1369 of 6000

6E–252

ENGINE DRIVEABILITY AND EMISSIONS

passage and on the IAC pintle, and excessive deposits

in the throttle bore and on the throttle plate.

Large vacuum leak – Check for a condition that causes

a large vacuum leak, such as an incorrectly installed or

faulty PCV valve or a disconnected brake booster

hose.Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P1508 – IAC System Low RPM

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Start the engine.

2. Turn all accessories “OFF”(A/C, rear defroster,

etc).

3. Using a Tech 2, command RPM up to 1500, down to

500, and the up to 1500 while monitoring the

“Engine Speed” on the Tech 2.

NOTE: This Tech 2 command may cause the engine to

“cut out” when RPM goes above 1500. If this occurs,

the “cutting out” will stop when the Tech 2 command for

the test is discontinued, or if the Tech 2 command is

changed to less than 1500 RPM.

Does the “Engine Speed” remain within the specified

value of the “Desired Idle” for each RPM command?

50 RPM

No trouble

found. Go to

Diagnostic

Aids

Go to Step 3

31. Disconnect the IAC.

2. Install IAC Node Light 5-8840-2312-0 or equivalent.

3. With the engine running, command RPM up to

1500, down to 500, and then up to 1500 while

observing the node light.

NOTE: This Tech 2 command may cause the engine to

“cut out” when RPM goes above 1500. If this occurs,

the “cutting out” will stop when the Tech 2 command for

the test is discontinued, or if the Tech 2 command is

changed to less than 1500 RPM.

Does each node light cycle red and green (never

“OFF”)?

—Go to Step 5Go to Step 4

41. Check the following circuits for an open, short to

voltage, short ground, or poor connections at the

PCM:

IAC “A” Low.

IAC “A” High.

IAC “B” Low.

IAC “B” High.

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

Page 1370 of 6000

6E–253 ENGINE DRIVEABILITY AND EMISSIONS

DTC P1508 – IAC System Low RPM

StepNo Ye s Va l u e ( s ) Action

5Visually/physically inspect for following conditions:

Restricted air intake system. Check for a possible

collapsed air intake duct, restricted air filter

element, or foreign objects blocking the air intake

system.

T h r o t t l e b o d y. C h e c k f o r o b j e c t s b l o c k i n g t h e I A C

passage or throttle bore, excessive deposits in

the IAC passage and on the IAC pintle, and

excessive deposits in the throttle bore and on the

throttle plate.

Do any of the above require a repair?

—

Refer to

appropriate

section for

on-vehicle

service

Go to Step 6

61. Check for a poor connection at the IAC harness

connector.

2. If a problem is found, replace faulty terminals as

necessary.

Was a problem found?

—Verify repairGo to Step 7

7Replace the IAC valve.

Is the action complete?

—Verify repair—

8Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1371 of 6000

6E–254

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1509 IAC System High RPM

T321115

Circuit Description

The powertrain control module (PCM) controls engine

idle speed by adjusting the position of the idle air control

(IAC) motor pintle. The IAC is a bi-directional stepper

motor driven by two coils. The PCM applies current to the

IAC coils in steps (counts) to extend the IAC pintle into a

passage in the throttle body to decrease air flow. The

PCM reverses the current to retract the pintle, increasing

air flow. This method allows highly accurate control of idle

speed and quick response to changes in engine load. If

the PCM detect a condition where too high of an idle

speed is present and the PCM is unable to adjust idle

speed by increasing the IAC counts, DTC P1509 will set,

indicating a problem with the idle control system.

Conditions for Setting the DTC

No Tech 2 test is being run.

None of these DTCs are set: TP sensor, VSS, ECT,

EGR, fuel system, MAF, MAP, IAT, canister purge,

injector control or ignition control.

Barometric pressure is above 75 kPa.

Engine coolant temperature is above 50C (120F).

Engine speed is more than 100-200 RPM lower than

desired idle, based upon coolant temperature.

The engine has been running for at least 125 seconds.

Vehicle speed is less than 1 mph.

Canister purge duty cycle is above 10%.

Ignition voltage is between 9.5 volts and 16.7 volts.

Engine speed is lower than desired idle.

All of the above conditions are met for 5 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1509 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at PCM or IAC motor – Inspect

harness connectors for backed-out terminals,

improper mating, broken locks, improperly formed or

damaged terminals, and poor terminal-to-wire

connection.

Damaged harness – Inspect the wiring for damage.

Vacuum leak – Check for a condition that causes a

vacuum leak, such as disconnected or damaged

h o s e s , l e a k s a t t h e E G R v a l v e a n d t h e E G R p i p e t o t h e

intake manifold, leaks at the throttle body, faulty or

incorrectly installed PCV valve, leaks at the intake

manifold, etc.

Page 1372 of 6000

6E–255 ENGINE DRIVEABILITY AND EMISSIONS

Throttle body – Check for sticking throttle plate. Also

inspect the IAC passage for deposits or objects which

keep the IAC pintle from fully extending.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how oftenthe condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

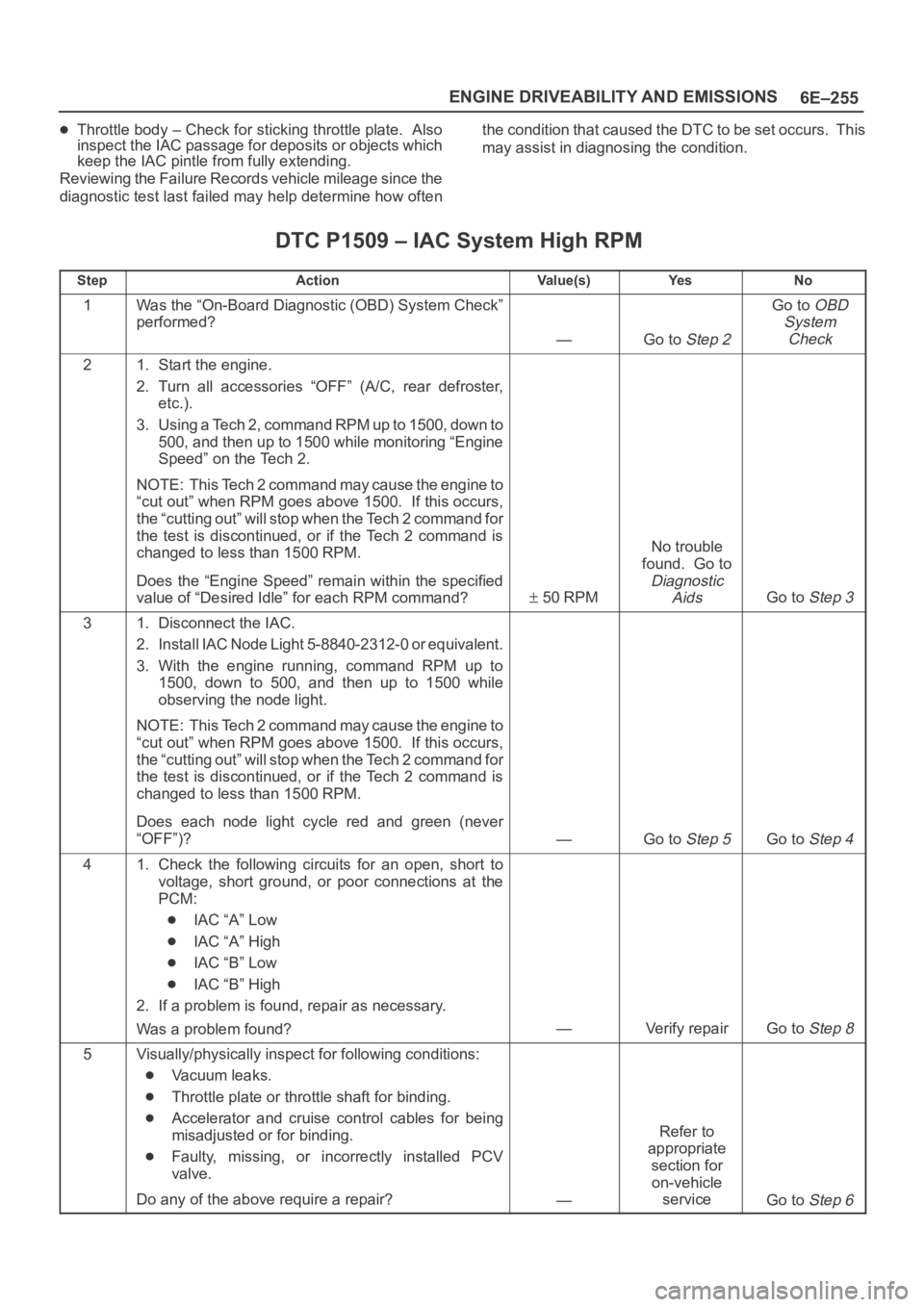

DTC P1509 – IAC System High RPM

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Start the engine.

2. Turn all accessories “OFF” (A/C, rear defroster,

etc.).

3. Using a Tech 2, command RPM up to 1500, down to

500, and then up to 1500 while monitoring “Engine

Speed” on the Tech 2.

NOTE: This Tech 2 command may cause the engine to

“cut out” when RPM goes above 1500. If this occurs,

the “cutting out” will stop when the Tech 2 command for

the test is discontinued, or if the Tech 2 command is

changed to less than 1500 RPM.

Does the “Engine Speed” remain within the specified

value of “Desired Idle” for each RPM command?

50 RPM

No trouble

found. Go to

Diagnostic

Aids

Go to Step 3

31. Disconnect the IAC.

2. Install IAC Node Light 5-8840-2312-0 or equivalent.

3. With the engine running, command RPM up to

1500, down to 500, and then up to 1500 while

observing the node light.

NOTE: This Tech 2 command may cause the engine to

“cut out” when RPM goes above 1500. If this occurs,

the “cutting out” will stop when the Tech 2 command for

the test is discontinued, or if the Tech 2 command is

changed to less than 1500 RPM.

Does each node light cycle red and green (never

“OFF”)?

—Go to Step 5Go to Step 4

41. Check the following circuits for an open, short to

voltage, short ground, or poor connections at the

PCM:

IAC “A” Low

IAC “A” High

IAC “B” Low

IAC “B” High

2. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

5Visually/physically inspect for following conditions:

Vacuum leaks.

Throttle plate or throttle shaft for binding.

Accelerator and cruise control cables for being

misadjusted or for binding.

Faulty, missing, or incorrectly installed PCV

valve.

Do any of the above require a repair?

—

Refer to

appropriate

section for

on-vehicle

service

Go to Step 6

Page 1373 of 6000

6E–256

ENGINE DRIVEABILITY AND EMISSIONS

DTC P1509 – IAC System High RPM

StepNo Ye s Va l u e ( s ) Action

61. Check for a poor connection at the IAC harness

connector.

2. If a problem is found, replace faulty terminals as

necessary.

Was a problem found?

—Verify repairGo to Step 7

7Replace the IAC valve.

Is the action complete?

—Verify repair—

8Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed, Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1374 of 6000

6E–257 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1618 Serial Peripheral Interface (SPI) PCM

Interprocessor Communication Error

Circuit Description

The serial peripheral interface (SPI) communication is

used internally by the PCM to send messages between

the engine processor and the automatic transmission

processor. Included in each message sent between the

two-processors is a checksum of the message. Both the

engine processor and automatic transmission processor

will compare this check sum value with the calculated

value. If the checksums don’t match, the processor will

view the new data as being corrupted and ignore the

values. The processor will then use the previous

message. The receiving processor will then send a

message to the sending processor informing it that it’s

last message was corrupted.

Conditions for Setting the DTC

Battery voltage is above 9.0 V for 2 seconds.

The PCM detects an internal program fault (check sum

of data communications error).

Check sum fault present for 3 out 6 seconds.

No TCM resets for 2 seconds.

Action Taken When the DTC Sets

The PCM will flash the “Check Trans” lamp the first

time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

The automatic transmission will operate in the “safety

mode” to protect the mechanical parts of the

transmission. Shift quality and/or gear changes may

not be normal.

Conditions for Clearing the MIL/DTC

DTC P1618 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

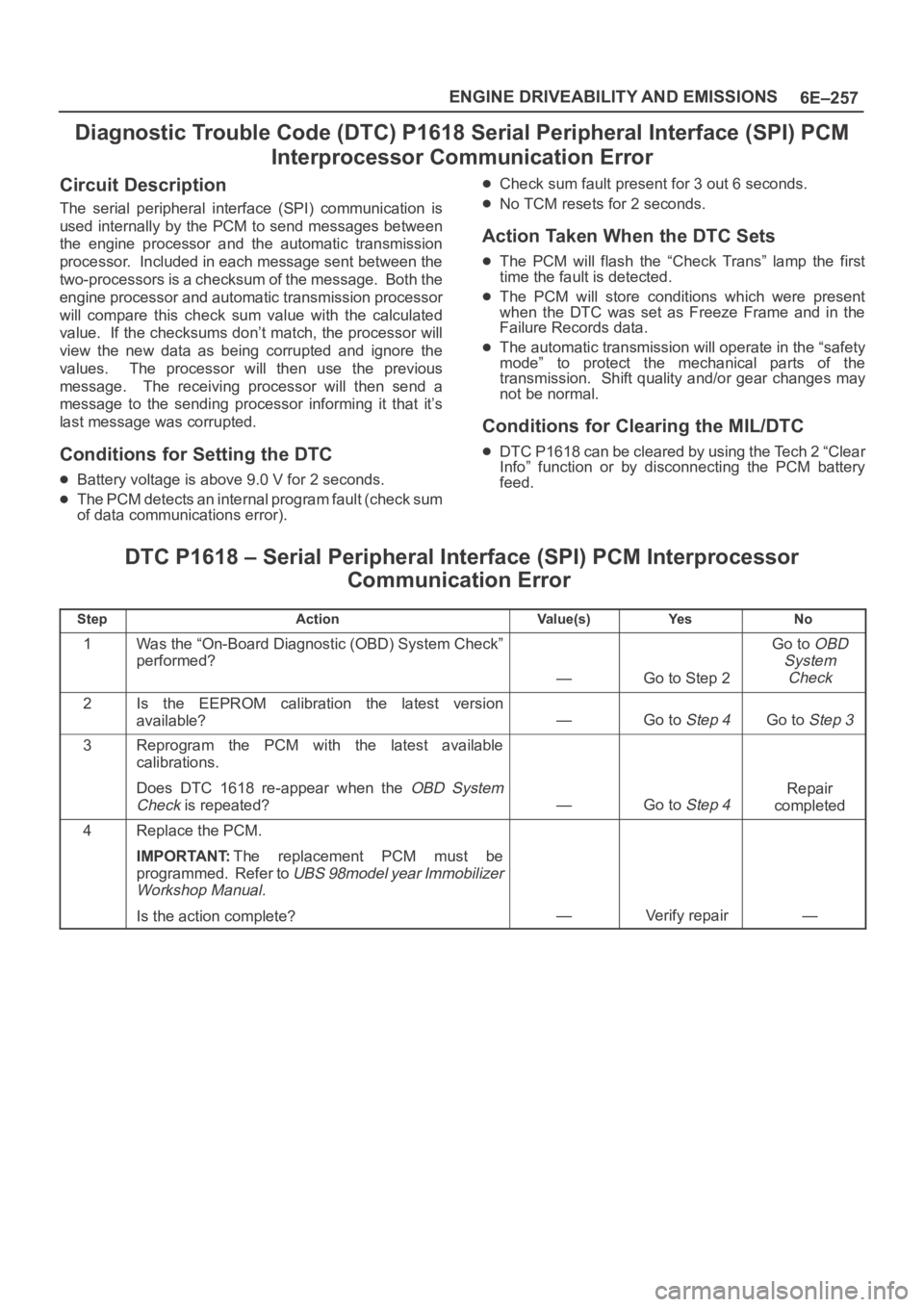

DTC P1618 – Serial Peripheral Interface (SPI) PCM Interprocessor

Communication Error

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Is the EEPROM calibration the latest version

available?

—Go to Step 4Go to Step 3

3Reprogram the PCM with the latest available

calibrations.

Does DTC 1618 re-appear when the

OBD System

Check

is repeated?—Go to Step 4

Repair

completed

4Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1375 of 6000

6E–258

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1625 PCM Unexpected Reset

Circuit Description

The powertrain control module (PCM) monitors

unexpected PCM reset. This will not turn on MIL light on,

only records code DTC P1625.

Conditions for Setting the DTC

Clock or COP reset.

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store conditions which were present

when the DTC was set as Failure Records only. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

DTC P1625 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

P1625 alone stored does not need diagnosis. Clear

DTC code.