check engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1333 of 6000

6E–216

ENGINE DRIVEABILITY AND EMISSIONS

Poor connection at PCM – Inspect the harness

connectors for backed-out terminals, improper mating,

broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connections.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Tech 2 display related to DTC P0354 while moving theconnector and wiring related to the ignition system. A

change in the display will indicate the location of the

fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

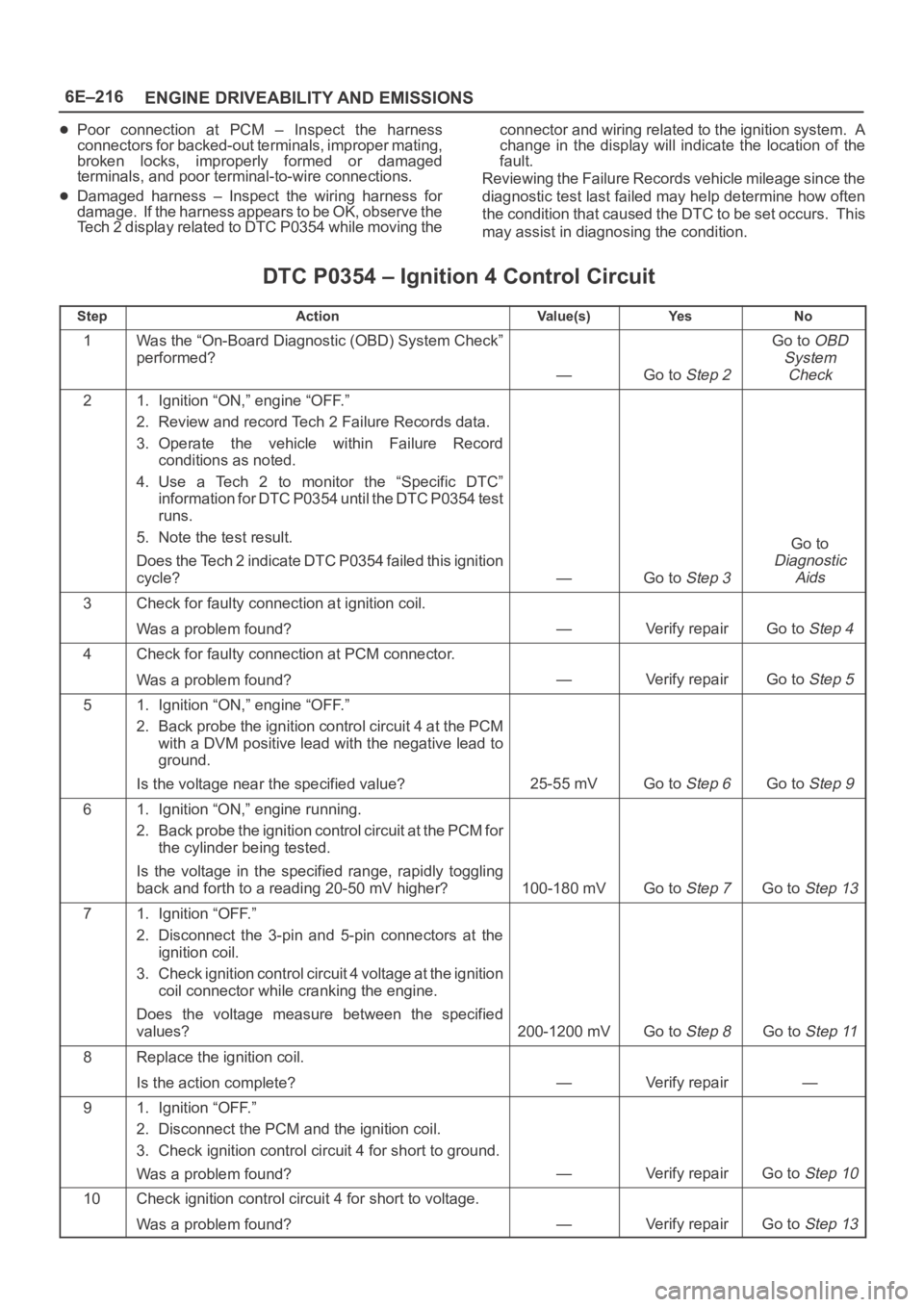

DTC P0354 – Ignition 4 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Record

conditions as noted.

4. Use a Tech 2 to monitor the “Specific DTC”

information for DTC P0354 until the DTC P0354 test

runs.

5. Note the test result.

Does the Tech 2 indicate DTC P0354 failed this ignition

cycle?

—Go to Step 3

Go to

Diagnostic

Aids

3Check for faulty connection at ignition coil.

Was a problem found?

—Verify repairGo to Step 4

4Check for faulty connection at PCM connector.

Was a problem found?

—Verify repairGo to Step 5

51. Ignition “ON,” engine “OFF.”

2. Back probe the ignition control circuit 4 at the PCM

with a DVM positive lead with the negative lead to

ground.

Is the voltage near the specified value?

25-55 mVGo to Step 6Go to Step 9

61. Ignition “ON,” engine running.

2. Back probe the ignition control circuit at the PCM for

the cylinder being tested.

Is the voltage in the specified range, rapidly toggling

back and forth to a reading 20-50 mV higher?

100-180 mVGo to Step 7Go to Step 13

71. Ignition “OFF.”

2. Disconnect the 3-pin and 5-pin connectors at the

ignition coil.

3. Check ignition control circuit 4 voltage at the ignition

coil connector while cranking the engine.

Does the voltage measure between the specified

values?

200-1200 mVGo to Step 8Go to Step 11

8Replace the ignition coil.

Is the action complete?

—Verify repair—

91. Ignition “OFF.”

2. Disconnect the PCM and the ignition coil.

3. Check ignition control circuit 4 for short to ground.

Was a problem found?

—Verify repairGo to Step 10

10Check ignition control circuit 4 for short to voltage.

Was a problem found?

—Verify repairGo to Step 13

Page 1334 of 6000

6E–217 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0354 – Ignition 4 Control Circuit

StepNo Ye s Va l u e ( s ) Action

11Check for an open ignition control circuit 1.

Was the ignition control circuit open?

—Go to Step 12Go to Step 13

12Repair the open in ignition control circuit.

Is the action complete?

—Verify repair—

13Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1335 of 6000

6E–218

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0355 Ignition 5 Control Circuit

D06RW072

Circuit Description

The powertrain control module’s (PCM) control circuit 5

provides a zero-volt or a 5-volt output signal to the ignition

coil. The normal voltage on the circuit is zero volts. When

the ignition coil receives the 5-volt signal from the PCM, it

provides a ground path for the B+ supply to the primary

side of the number 5 ignition coil. When the PCM shuts off

the 5 volts to the ignition coil, the ignition coil turns “OFF.”

This causes the ignition coil primary magnetic field to

collapse, producing a voltage in the secondary coil which

fires the spark plug.

The circuit between the PCM and ignition coil is monitored

for an open circuit, short to voltage, and short to ground.

When the PCM detects a problem on ignition control

circuit 5, it will set a DTC P0355.

Conditions for Setting the DTC

The ignition is “ON.”

The engine is turning, determined by the 58X

crankshaft position input signal.

The output voltage is not equal to 5 volts when output

is “ON.”

The output voltage is not equal to 0 volts when output

is “OFF.”

Twenty test failures occur within 40 samples of

continuous spark events.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0355 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Page 1336 of 6000

6E–219 ENGINE DRIVEABILITY AND EMISSIONS

Poor connection at PCM – Inspect the harness

connectors for backed-out terminals, improper mating,

broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connections.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Tech 2 display related to DTC P0355 while moving theconnector and wiring related to the ignition system. A

change in the display will indicate the location of the

fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0355 – Ignition 5 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Record

conditions as noted.

4. Use a Tech 2 to monitor the “Specific DTC”

information for DTC P0355 until the DTC P0355 test

runs.

5. Note the test result.

Does the Tech 2 indicate DTC P0355 failed this ignition

cycle?

—Go to Step 3

Go to

Diagnostic

Aids

3Check for faulty connection at ignition coil.

Was a problem found?

—Verify repairGo to Step 4

4Check for faulty connection at PCM connector.

Was a problem found?

—Verify repairGo to Step 5

51. Ignition “ON,” engine “OFF.”

2. Back probe the ignition control circuit 5 at the PCM

with a DVM positive lead with the negative lead to

ground.

Is the voltage near the specified value?

25-55 mVGo to Step 6Go to Step 9

61. Ignition “ON,” engine running.

2. Back probe the ignition control circuit at the PCM for

the cylinder being tested.

Is the voltage in the specified range, rapidly toggling

back and forth to a reading 20-50 mV higher?

100-180 mVGo to Step 7Go to Step 13

71. Ignition “OFF.”

2. Disconnect the 3-pin and 5-pin connectors at the

ignition coil.

3. Check ignition control circuit 5 voltage at the ignition

coil connector while cranking the engine.

Does the voltage measure between the specified

values?

200-1200 mVGo to Step 8Go to Step 11

8Replace the ignition coil.

Is the action complete?

—Verify repair—

91. Ignition “OFF.”

2. Disconnect the PCM and the ignition coil.

3. Check ignition control circuit 5 for short to ground.

Was a problem found?

—Verify repairGo to Step 10

10Check ignition control circuit 5 for short to voltage.

Was a problem found?

—Verify repairGo to Step 13

Page 1337 of 6000

6E–220

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0355 – Ignition 5 Control Circuit

StepNo Ye s Va l u e ( s ) Action

11Check for an open ignition control circuit 1.

Was the ignition control circuit open?

—Go to Step 12Go to Step 13

12Repair the open ignition control circuit.

Is the action complete?

—Verify repair—

13Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1338 of 6000

6E–221 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0356 Ignition 6 Control Circuit

D06RW072

Circuit Description

The powertrain control module’s (PCM) control circuit 6

provides a zero-volt or a 5-volt output signal to the ignition

coil. The normal voltage on the circuit is zero volts. When

the ignition coil receives the 5-volt signal from the PCM, it

provides a ground path for the B+ supply to the primary

side of the number 6 ignition coil. When the PCM shuts off

the 5 volts to the ignition coil, the ignition coil turns “OFF.”

This causes the ignition coil primary magnetic field to

collapse, producing a voltage in the secondary coil which

fires the spark plug.

The circuit between the PCM and ignition coil is monitored

for an open circuit, short to voltage, and short to ground.

When the PCM detects a problem on ignition control

circuit 6, it will set a DTC P0356.

Conditions for Setting the DTC

The ignition is “ON.”

The engine is turning, determined by the 58X

crankshaft position input signal.

The output voltage is not equal to 5 volts when output

is “ON.”

The output voltage is not equal to 0 volts when output

is “OFF.”

Twenty test failures occur within 40 samples of

continuous circuit monitoring.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0356 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Page 1339 of 6000

6E–222

ENGINE DRIVEABILITY AND EMISSIONS

Poor connection at PCM – Inspect the harness

connectors for backed-out terminals, improper mating,

broken locks, improperly formed or damaged

terminals, and poor terminal-to-wire connections.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Tech 2 display related to DTC P0356 while moving theconnector and wiring related to the ignition system. A

change in the display will indicate the location of the

fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0356 – Ignition 6 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Record

conditions as noted.

4. Use a Tech 2 to monitor the “Specific DTC”

information for DTC P0356 until the DTC P0356 test

runs.

5. Note the test result.

Does the Tech 2 indicate DTC P0356 failed this ignition

cycle?

—Go to Step 3

Go to

Diagnostic

Aids

3Check for faulty connection at ignition coil.

Was a problem found?

—Verify repairGo to Step 4

4Check for faulty connection at PCM connector.

Was a problem found?

—Verify repairGo to Step 5

51. Ignition “ON,” engine “OFF.”

2. Back probe the ignition control circuit 6 at the PCM

with a DVM positive lead with the negative lead to

ground.

Is the voltage near the specified value?

25-55 mVGo to Step 6Go to Step 9

61. Ignition “ON,” engine running.

2. Back probe the ignition control circuit at the PCM for

the cylinder being tested.

Is the voltage in the specified range, rapidly toggling

back and forth to a reading 20-50 mV higher?

100-180 mVGo to Step 7Go to Step 13

71. Ignition “OFF.”

2. Disconnect the 3-pin and 5-pin connectors at the

ignition coil.

3. Check ignition control circuit 6 voltage at the ignition

coil connector while cranking the engine.

Does the voltage measure between the specified

values?

200-1200 mVGo to Step 8Go to Step 11

8Replace the ignition coil.

Is the action complete?

—Verify repair—

91. Ignition “OFF.”

2. Disconnect the PCM and the ignition coil.

3. Check ignition control circuit 6 for short to ground.

Was a problem found?

—Verify repairGo to Step 10

10Check ignition control circuit 6 for short to voltage.

Was a problem found?

—Verify repairGo to Step 13

Page 1340 of 6000

6E–223 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0356 – Ignition 6 Control Circuit

StepNo Ye s Va l u e ( s ) Action

11Check for an open ignition control circuit 1.

Was the ignition control circuit open?

—Go to Step 12Go to Step 13

12Repair the open ignition control circuit.

Is the action complete?

—Verify repair—

13Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1341 of 6000

6E–224

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0402 EGR Pintle Crank Error

D06RW106

Circuit Description

The powertrain control module (PCM) monitors the EGR

valve pintle position input to ensure that the valve

responds properly to commands from the PCM, and to

detect a fault if pintle position is stuck open. If the PCM

detects a pintle position signal indicates more than 21.5%

and more than for 625 msec during cranking, the PCM will

set DTC P0402.

Conditions for Setting the DTC

Ignition voltage is between 11 and 16 volts.

Intake Air temp is more than 3C

At Engine revolution less than 600 RPM, EGR pintle

position indicates more than 21.5% and more than for

625 msecs.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

The PCM will store conditions which were present

w h e n t h e D T C w a s s e t a s F r e e z e F r a m e a n d i n F a i l u r e

Records data.

Conditions for Clearing the MIL/DTC

DTC P0402 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

Foreign material on EGR valve between pintle and

seat may cause EGR stuck open. Inspect foreign

material in EGR valve.

Excessive carbon deposit may cause unsmooth

operation of EGR valve shaft. Inspect carbon deposit

and clean up inside of carbon deposit.

Poor connection or damaged harness–inspect the

wiring harness for damage If the harness appears to be

OK, observe the EGR actual position display on Tech

2 while moving connectors and wiring harnesses

related to EGR valve. A change in the display will

indicate the location of the fault.

NOTE: If the EGR valve shows signs of excessive heat,

check the exhaust system for blockage (possibly a

plugged catalytic converter) using the “Restricted

Exhaust System Check”.

Page 1342 of 6000

6E–225 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0402 – EGR Pintle Crank Open Error

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON”, engine “OFF”, review and record

Tech 2 Failure Records data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using Tech 2, monitor “Specific DTC” info for DTC

P0402 until the DTC P0402 test runs. Note the

result.

Does Tech 2 indicates DTC P0402 failed this ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

31. Disconnect the EGR valve harness connector.

2. Inspect the EGR valve and connectors for damaged

pin or terminals.

Were there any damaged pins or terminals?

—Go to Step 4Go to Step 5

4Repair the damaged pin or terminal.

Is the action complete?

—Verify repair—

51. Remove EGR valve from Engine.

2. Inspect EGR valve whether there is any foreign

material between seat and pintle.

Was any foreign material in EGR valve?

—Go to Step 6Go to Step 7

61. Remove EGR valve foreign material from EGR

valve and clean up inside.

2. Visually inspect damage of pintle and seat, which

leakage may occur.

Was there any severe damage which affects function?

—Go to Step 7

Verify repair

Go to

Step 8

71. Reconnect.

2. Ignition “OFF”.

3. Install Tech 2.

4. Run the engine at idle.

5. On Tech-II, select special function for EGR.

6. Use the “UP” arrow to increase the EGR from 0% to

40%.

Did EGR work properly?

——Go to Step 8

8Replace the EGR valve.

Does DTC P0402 still fail “DTC” test on Tech 2?

—Go to Step 9Verify repair

9Replace the EGR valve.

Is the action complete?

—Verify repair—