check engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1407 of 6000

6E–290

ENGINE DRIVEABILITY AND EMISSIONS

Symptoms Default Section(s)Initial Diagnosis

Backfire1. OBD system check.

2. Ignition system.

3. Fuel system diagnosis.

4. Fuel injector and fuel injector

balance test.

5. EGR operation, EGR system

check.Exhaust System Diagnosis,

Intake Casting Flash, Ignition

System Check

Catalyst Monitor1. OBD system check.

2. Careful visual/physical inspection.

3. Heated oxygen sensors.Exhaust System

Fuel Trim1. OBD system check.

2. Careful visual/physical inspection.

3. Fuel system diagnosis.

4. Heated oxygen sensors, MAF

sensors.Exhaust System Intake Air

System

Evaporative Emissions1. OBD system check.

2. Careful visual/physical inspection.

3. Fuel system diagnosis.—

Heated Oxygen Sensors1. OBD system check.

2. Careful visual/physical inspection.Exhaust System

Page 1416 of 6000

6E–299 ENGINE DRIVEABILITY AND EMISSIONS

damage, therefore, it is important to use care when

handling and testing electronic components.

NOTE: To prevent possible Electrostatic Discharge

damage, follow these guidelines:

Do not touch the control module connector pins or

soldered components on the control module circuit

board.

Do not open the replacement part package until the

part is ready to be installed.

Before removing the part from the package, ground

the package to a known good ground on the vehicle.

If the part has been handled while sliding across the

seat, or while sitting down from a standing position, or

while walking a distance, touch a known good ground

before installing the part.

NOTE: To prevent internal PCM damage, the ignition

must be in the “OFF” position in order to disconnect or

reconnect power to the PCM (for example: battery cable,

PCM pigtail, PCM fuse, jumper cables, etc.).

IMPORTANT:When replacing the production PCM

with a service PCM, it is important to transfer the

broadcast code and production PCM number to the

service PCM label. This will allow positive identification of

PCM parts throughout the service life of the vehicle. Do

not record this information on the metal PCM cover.

IMPORTANT:The ignition should always be in the

“OFF” position in order to install or remove the PCM

connectors.

Service of the PCM should normally consist of either re-

placement of the PCM or EEPROM programming. If the

diagnostic procedures call for the PCM to be replaced,

the PCM should be checked first to ensure it is the correct

part. If it is, remove the faulty PCM and install the new

service PCM.

The service PCM EEPROM will not be programmed.

DTC P0601 indicates the check sum error.

Removal Procedure

1. Disconnect the negative battery cable.

2. Block the wheels.

3. Remove the front console assembly.

1. Remove the four screws.

TS23755

2. Remove the transfer shift lever knob by

unscrewing the knob.

3. Move the transmission gear selector out of the

park position.

4. Lift up sharply on the back edge of the assembly.

5. Disconnect the seat heater switch connectors (if

equipped).

6. Disconnect the POWER and WINTER switch

connectors.

7. Lift out the front console assembly.

TS23756

Page 1417 of 6000

6E–300

ENGINE DRIVEABILITY AND EMISSIONS

4. Disconnect the red, white, and blue electrical

connectors at the PCM.

5. Remove the two screws in the front of the PCM.

6. Remove the one screw at the left rear of the PCM.

7. Pull the PCM straight out from the dashboard.

TS23757

Installation Procedure

1. Insert the PCM into the dashboard.

Line up the holes in front for the mounting screws.

2. Install the PCM with two screws in the front and one

screw at the left rear.

3. Plug the red, white, and blue connectors into the

appropriate sockets.

TS23757

EEPROM

General Description

The Electronically Erasable Programmable Read Only

Memory (EEPROM) is a permanent memory that is

physically soldered within the PCM. The EEPROM

contains program and calibration information that the

PCM needs to control powertrain operation.

EEPROM Programming

1. Step-up – Ensure that the following conditions have

been met:

The battery is fully charged.

The ignition is “ON.”

The Vehicle Interface Module cable connection at

the DLC is secure.

2. Program the PCM using the latest software matching

the vehicle. Refer to up-to-date Techline equipment

user’s instructions.

3. If the PCM fails to program, Refer to

UBS 98 model

year Immobilizer Workshop Manual.

Functional Check

1. Perform the On-Board Diagnostic System Check.

2. Start the engine and run for one minute.

3. Scan for DTCs using the Tech 2.

Power Steering Pressure (PSP)

Switch

General Description

The Power Steering Pressure (PSP) switch closes when

the hydraulic pressure reaches 3920

690 kPa (570

100 psi). This causes the PCM to actuate the idle air

control valve in order to prevent the additional load from

slowing down the engine. The switch opens when the

hydraulic pressure drops to 2970

560 kPa (430 80

psi).

Removal Procedure

1. Disconnect the PSP switch pigtail from the wiring

harness.

The pigtail is permanently attached to the switch.

Do not attempt to remove the wires from the

sensor.

Have a container ready to catch the power steering

fluid that leaks out of the line when the switch is

removed.

Page 1418 of 6000

6E–301 ENGINE DRIVEABILITY AND EMISSIONS

2. Remove the PSP switch from the power steering line.

Plug the line to prevent excessive loss of fluid and

possible contamination of the power steering

system.

TS23760

Installation Procedure

1. Install the PSP switch in the power steering line.

TS23760

2. Connect the PSP switch pigtail to the wiring harness.

3. Check the power steering fluid level. Refer to

Power

Steering

.

4. Start the engine. Watch the PSP switch for signs of

fluid leakage.

Throttle Position (TP) Sensor

Removal Procedure

1. Disconnect the negative battery cable.

2. Disconnect the TPS electrical connector.3. Remove the bolts and the TP sensor from the throttle

body.

TS23747

NOTE: Do not clean the TP sensor by soaking it in

solvent. The sensor will be damaged as a result.

Function Check

Use a Tech 2 to check the TP sensor output voltage at

closed throttle.

The voltage should be under 0.85 volt.

If the reading is greater than 0.85 volt, check the

throttle shaft to see if it is binding. Check that the

throttle cable is properly adjusted, also. Refer to

Throttle Cable Adjustment.

If the throttle shaft is not binding and the throttle cable

is properly adjusted, install a new TP sensor.

Installation Procedure

1. Install the TP sensor on the throttle body with the

bolts.

TS23747

Page 1420 of 6000

6E–303 ENGINE DRIVEABILITY AND EMISSIONS

4. Check the transfer case oil level. Add fluid if

necessary.

5. Connect the negative battery cable.

Air Cleaner/Air Filter

Removal Procedure

1. Loosen the clamp between the air cleaner lid and the

mass air flow sensor.

2. Release the four latches securing the lid to the air

cleaner housing.

3. Remove the air cleaner lid.

TS23973

4. Remove the air filter element.

TS23794

5. Remove the retaining bolts and the air cleaner

housing from the vehicle.

130RT002

Installation Procedure

1. Install the air cleaner housing in the vehicle with the

retaining bolts.

130RT002

Page 1423 of 6000

6E–306

ENGINE DRIVEABILITY AND EMISSIONS

4. Remove the accelerator control cable (on the

accelerator pedal end).

TS23982

5. Remove the grommet.

6. Remove the accelerator control cable.

TS23983

Inspection Procedure

Check the following items, and replace the control cable if

any abnormality is found:

The control cable should move smoothly.

The control cable should not be bent or kinked.

The control cable should be free of damage and

corrosion.

Installation Procedure

1. Install the accelerator control cable.

TS23983

2. Install the grommet.

3. Install the accelerator control cable (on the

accelerator pedal end).

TS23982

Page 1427 of 6000

6E–310

ENGINE DRIVEABILITY AND EMISSIONS

Pedal Stroke Adjustment Procedure

1. Loosen the jam nut and rotate the kick-down switch

counterclockwise.

TS24039

2. Fully depress the pedal and hold it by hand. Rotate

the switch clockwise until the switch clicks.

3. Rotate the switch 1/2 turn further and lock it in this

position by tightening the jam nut.

TS24040

4. Step on the accelerator pedal and make sure there is

a clicking sound at the full-stroke position.

Fuel Filter Cap

General Description

The fuel filler cap includes a vacuum valve and a pressure

valve.If high vacuum or high pressure occurs in the fuel tank,

each valve works to adjust the pressure in order to

prevent damage to the tank at the EGR valve.

TS23767

Inspection Procedure

NOTE: Replace the fuel filler cap with the same type of

filler cap that was originally installed on the vehicle.

Check the seal ring in the filler cap for any abnormality

and for seal condition.

Replace the filler cap if any abnormality is found.

Fuel Filter

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the fuel filler cap.

041RW005

Page 1431 of 6000

6E–314

ENGINE DRIVEABILITY AND EMISSIONS

3. Connect the wiring connector to the fuel gauge unit.

TS23771

4. Fill the fuel tank with fuel.

Tighten the fuel filler cap.

Check for leaks at the fuel gauge unit gasket.

5. Connect the negative battery cable.

Fuel Injectors

Removal Procedure

NOTE: If the fuel injectors are leaking, the engine oil may

be contaminated with fuel. Check the oil for signs of

contamination and change the oil and the filter if

necessary.

NOTE: Use care in removing the fuel injectors in order to

prevent damage to the fuel injector electrical connector

pins or the fuel injector nozzles. The fuel injector is an

electrical component and should not be immersed in any

type of cleaner as this may damage the fuel injector.

IMPORTANT:Fuel injectors are serviced as a complete

assembly only.

1. Disconnect the negative battery cable.

2. Remove the upper intake manifold. Refer to

Common Chamber in Engine Mechanical..

3. Remove the fuel rail. Refer to

Fuel Rail.

014RW164

4. Remove the injector retainer clip.

055RW009

5. Remove the fuel injector assembly.

6. Remove the O-ring from the fuel injector.

7. Remove the O-ring backup from the fuel injector .

Inspection Procedure

1. Inspect the O-rings for cracks or leaks.

2. Replace worn or damaged O-rings.

3. Lubricate the new O-rings with engine oil before

installation.

Page 1442 of 6000

6E–325 ENGINE DRIVEABILITY AND EMISSIONS

Spark Plug Gap Check

Check the gap of all spark plugs before installation.

Use a round wire feeler gauge to ensure an accurate

check.

Plugs installed with the wrong gap can cause poor

engine performance and excessive emissions.

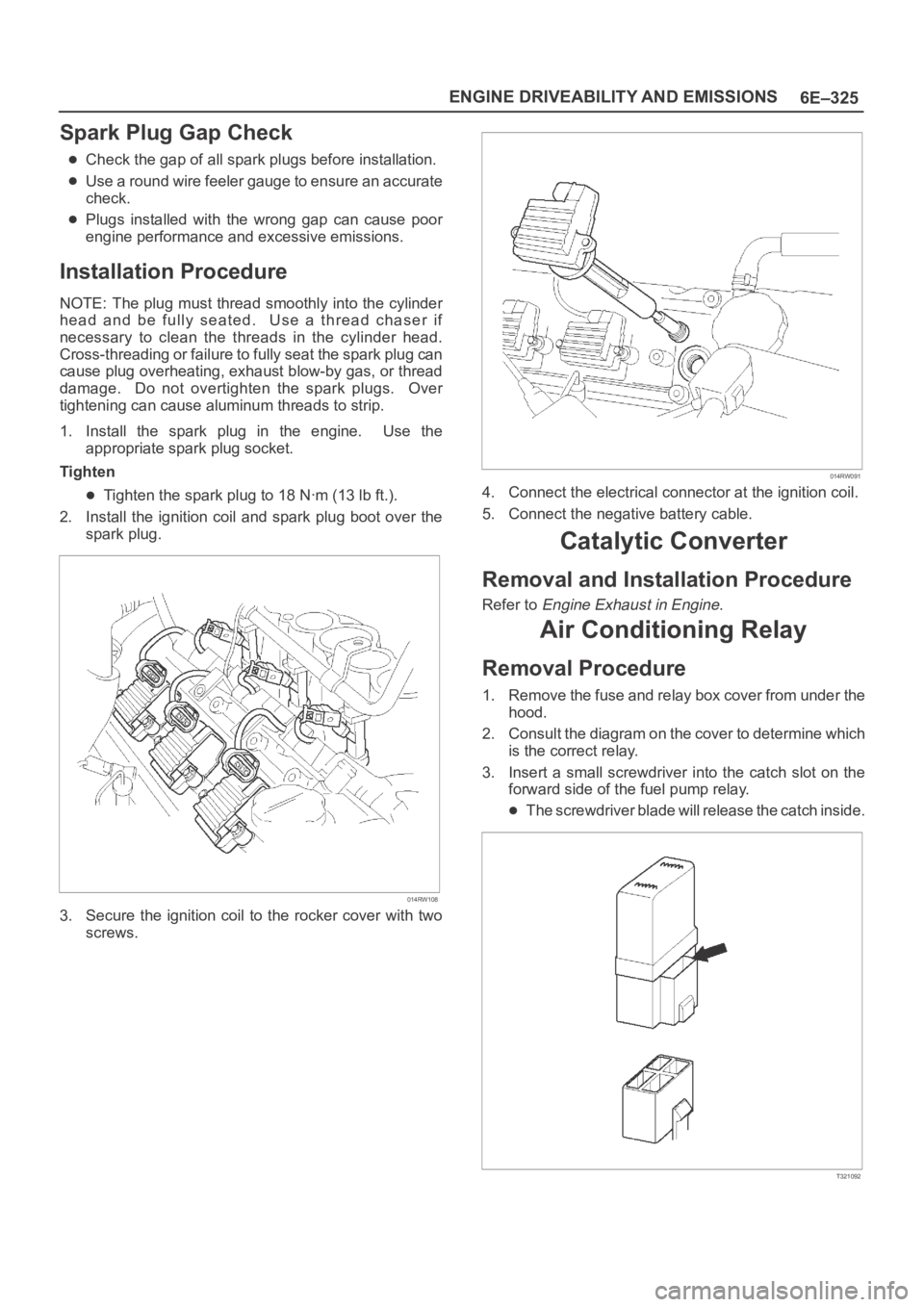

Installation Procedure

NOTE: The plug must thread smoothly into the cylinder

head and be fully seated. Use a thread chaser if

necessary to clean the threads in the cylinder head.

Cross-threading or failure to fully seat the spark plug can

cause plug overheating, exhaust blow-by gas, or thread

damage. Do not overtighten the spark plugs. Over

tightening can cause aluminum threads to strip.

1. Install the spark plug in the engine. Use the

appropriate spark plug socket.

Tighten

Tighten the spark plug to 18 Nꞏm (13 lb ft.).

2. Install the ignition coil and spark plug boot over the

spark plug.

014RW108

3. Secure the ignition coil to the rocker cover with two

screws.

014RW091

4. Connect the electrical connector at the ignition coil.

5. Connect the negative battery cable.

Catalytic Converter

Removal and Installation Procedure

Refer to Engine Exhaust in Engine.

Air Conditioning Relay

Removal Procedure

1. Remove the fuse and relay box cover from under the

hood.

2. Consult the diagram on the cover to determine which

is the correct relay.

3. Insert a small screwdriver into the catch slot on the

forward side of the fuel pump relay.

The screwdriver blade will release the catch inside.

T321092

Page 1447 of 6000

6E–330

ENGINE DRIVEABILITY AND EMISSIONS

Wiring and Connectors

Wiring Harness Service

The control module harness electrically connects the

control module to the various solenoids, switches and

sensors in the vehicle engine compartment and

passenger compartment.

Replace wire harnesses with the proper part number

replacement.

Because of the low amperage and voltage levels utilized

in powertrain control systems, it is essential that all wiring

in environmentally exposed areas be repaired with crimp

and seal splice sleeves.

The following wire harness repair information is intended

as a general guideline only. Refer to

Chassis Electrical f o r

all wire harness repair procedures.

Connectors and Terminals

Use care when probing a connector and when replacing

terminals. It is possible to short between opposite

terminals. Damage to components could result. Always

use jumper wires between connectors for circuit

checking. NEVER probe through Weather-Pack seals.

Use an appropriate connector test adapter kit which

contains an assortment of flexible connectors used to

probe terminals during diagnosis. Use an appropriate

fuse remover and test tool for removing a fuse and to

adapt the fuse holder to a meter for diagnosis.

Open circuits are often difficult to locate by sight because

oxidation or terminal misalignment are hidden by the

connectors. Merely wiggling a connector on a sensor, or

in the wiring harness, may temporarily correct the open

circuit. Intermittent problems may also be caused by

oxidized or loose connections.

Be certain of the type of connector/terminal before

making any connector or terminal repair. Weather-Pack

and Com-Pack III terminals look similar, but are serviced

differently.

PCM Connectors and Terminals

Removal Procedure

1. Remove the connector terminal retainer.

2. Push the wire connected to the affected terminal

through the connector face so that the terminal is

exposed.

3. Service the terminal as necessary.

Installation Procedure

1. Bend the tab on the connector to allow the terminal to

be pulled into position within the connector.

2. Pull carefully on the wire to install the connector

terminal retainer.

Wire Harness Repair: Twisted

Shielded Cable

Removal Procedure

1. Remove the outer jacket.

2. Unwrap the aluminum/mylar tape. Do not remove the

mylar.

047

3. Untwist the conductors.

4. Strip the insulation as necessary.

048