check engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1354 of 6000

6E–237 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0562 System Voltage Low

D06RW020

Circuit Description

The powertrain control module (PCM) monitors the

system voltage on the ignition feed terminal to the PCM.

A system voltage DTC will set whenever the voltage is

below a calibrated value.

Conditions for Setting the DTC

Ignition “ON.”

System voltage is below 11.5 volts for 15 minutes.

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store as Failure Records conditions

which were present when the DTC was set. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

A history DTC P0562 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

DTC P0562 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

If the DTC sets when an accessory is operated, check for

a poor connection or excessive current draw.

Page 1355 of 6000

6E–238

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0562 – System Voltage Low

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a Tech 2, measure the battery voltage at the

battery.

Is the battery voltage greater than the specified value?

11.5 VGo to Step 3

Charge

battery, then

go to

Step 3

31. Using a Tech 2.

2. Select “Ignition Volts” on the Tech 2.

3. Start the engine and raise the engine speed to the

specified value.

4. Load the electrical system by turning on the

headlights, high blower, etc.

Is the ignition voltage approximately equal to the

specified value?

2000 RPM

12.8-14.1 V

Go to Step 4

Go to

Starting/Char

ging

41. Ignition “OFF.”

2. Disconnect the PCM connector at the PCM.

3. Using a DVM, measure the battery voltage at the

PCM connector A-4.

Is it approximately equal to battery voltage?

—

Check for

excessive

current draw

with ignition

“OFF,” engine

“OFF.”

Go to Step 5

51. Check for faulty connections at the PCM harness

terminals.

2. Repair as necessary.

Was a repair necessary?

—Verify repairGo to Step 6

6Check for an open battery feed circuit to the PCM.

Is the action complete?

—Verify repairGo to Step 7

7Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1356 of 6000

6E–239 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0563 System Voltage High

Circuit Description

The powertrain control module (PCM) monitors the

system voltage on the ignition feed terminals to the PCM.

A system voltage DTC will set whenever the voltage is

above a calibrated value.

Conditions for Setting the DTC

Ignition “ON.”

System voltage is above 16 volts for 15 minutes.

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store as Failure Records only conditions

which were present when the DTC was set. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

A history DTC P0563 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

DTC P0563 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

If the DTC sets when an accessory is operated, check for

a poor connection or excessive current draw.

DTC P0563 – System Voltage High

StepActionVa l u e ( s )Ye sNo

1Was the “ON-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Using a Tech 2, measure the battery voltage at the

battery.

Is the battery voltage less than the specified value?

11 . 5 VGo to Step 3Go to Step 4

31. Charge the battery and clean the battery terminals.

2. Clean the battery ground cable connection if

corrosion is indicated.

Is the battery voltage less than the specified value?

11 . 5 V

Replace

battery

Go to Step 4

41. Turn “OFF” all the accessories.

2. Install a Tech 2.

3. Select the ignition voltage parameter on the Tech 2.

4. Start the engine and raise the engine RPM to the

specified value.

Is the voltage more than 2.5 volts greater than the

measurement taken in step 2 or 3?

2000 RPM

Go to

Starting/Char

ging

Go to Step 5

5Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98 model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1357 of 6000

6E–240

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0601 PCM Memory

Circuit Description

The powertrain control module (PCM) used in this vehicle

utilizes an electrically erasable programmable read-only

memory (EEPROM). The EEPROM contains program

information and the calibrations required for engine,

transmission, and powertrain diagnostics operation.

Unlike the PROM used in past applications, the EEPROM

is not replaceable.

Conditions for Setting the DTC

The PCM detects an internal program fault (check sum

error).

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store conditions which were present

when the DTC was set in the Failure Records data only.

Conditions for Clearing the MIL/DTC

DTC P0601 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

DTC P0601 indicates that the contents of the

EEPROM have changed since the PCM was

programmed. The only possible repair is PCM

replacement.

DTC P0601 – PCM Memory

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1358 of 6000

6E–241 ENGINE DRIVEABILITY AND EMISSIONS

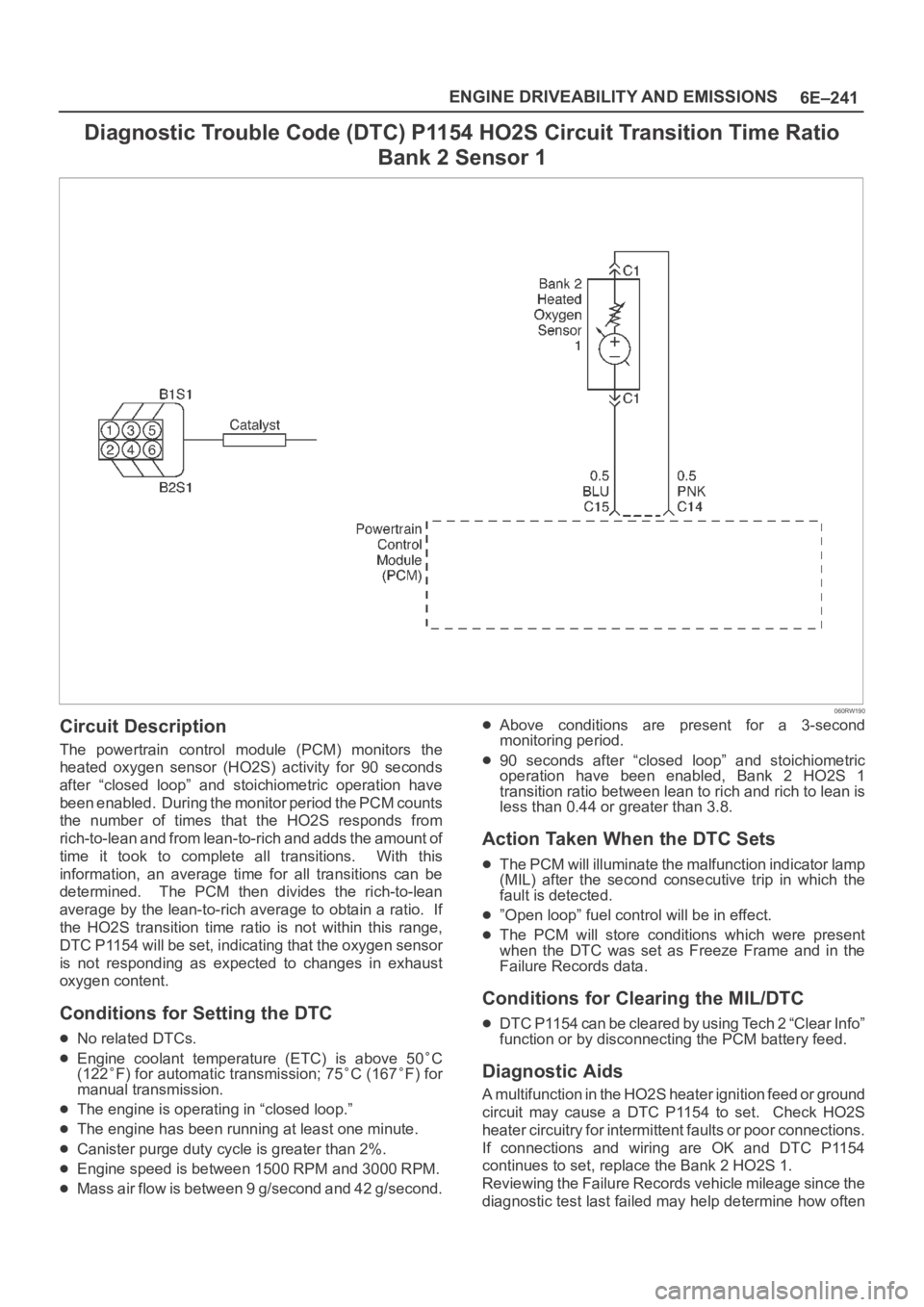

Diagnostic Trouble Code (DTC) P1154 HO2S Circuit Transition Time Ratio

Bank 2 Sensor 1

060RW190

Circuit Description

The powertrain control module (PCM) monitors the

heated oxygen sensor (HO2S) activity for 90 seconds

after “closed loop” and stoichiometric operation have

been enabled. During the monitor period the PCM counts

the number of times that the HO2S responds from

rich-to-lean and from lean-to-rich and adds the amount of

time it took to complete all transitions. With this

information, an average time for all transitions can be

determined. The PCM then divides the rich-to-lean

average by the lean-to-rich average to obtain a ratio. If

the HO2S transition time ratio is not within this range,

DTC P1154 will be set, indicating that the oxygen sensor

is not responding as expected to changes in exhaust

oxygen content.

Conditions for Setting the DTC

No related DTCs.

Engine coolant temperature (ETC) is above 50C

(122F) for automatic transmission; 75C (167F) for

manual transmission.

The engine is operating in “closed loop.”

The engine has been running at least one minute.

Canister purge duty cycle is greater than 2%.

Engine speed is between 1500 RPM and 3000 RPM.

Mass air flow is between 9 g/second and 42 g/second.

Above conditions are present for a 3-second

monitoring period.

90 seconds after “closed loop” and stoichiometric

operation have been enabled, Bank 2 HO2S 1

transition ratio between lean to rich and rich to lean is

less than 0.44 or greater than 3.8.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) after the second consecutive trip in which the

fault is detected.

”Open loop” fuel control will be in effect.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1154 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

A multifunction in the HO2S heater ignition feed or ground

circuit may cause a DTC P1154 to set. Check HO2S

heater circuitry for intermittent faults or poor connections.

If connections and wiring are OK and DTC P1154

continues to set, replace the Bank 2 HO2S 1.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

Page 1359 of 6000

6E–242

ENGINE DRIVEABILITY AND EMISSIONS

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. A condition that affects other heated oxygen sensors

indicates probable contamination. To avoid

damaging replacement sensors, correct the

condition which caused the contamination before

replacing the affected sensors.5. This step checks for conditions which may cause the

heated oxygen sensor to appear faulty. Correct any

of the described conditions if present.

8. To avoid damaging replacement sensors, correct the

condition which caused the contamination before

replacing the affected sensors.

DTC P1154 – HO2S Transition Time Ratio Bank 2 Sensor 1

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2IMPORTANT:If any other DTCs are set (except P1133

and/or P1134), refer to those DTCs before proceeding

with this diagnostic chart.

1. Idle the engine at operating temperature.

2. Operate the vehicle within parameters specified

under “Conditions for Setting the DTC” criteria

included in Diagnostic Support.

3. Using a Tech 2, monitor “Specific DTC” info for DTC

P1154 until the DTC P1154 test runs.

Note the test result.

Does Tech 2 indicate DTC failed this ignition?

—Go to Step 3

Refer to

Diagnostic

Aids

3Did Tech 2 also indicate P1133, and/or P1134 test

failed?

—Go to Step 17Go to Step 4

4Check for leaks at the pipe joints.

Are the joints leaking?

—Go to Step 5Go to Step 6

5Tighten the U-bolt nuts at the leaking joints.

Is your action complete?

—Go to Step 2—

6Check for gaskets that are damaged or improperly

installed.

Are there damaged or misaligned gaskets?

—Go to Step 7Go to Step 8

71. Replace the damaged gaskets.

2. Align the connections.

3. Tighten the connections.

Is your action complete?

—Go to Step 2—

8Check for loose exhaust flange connections.

Are the flange connections loose?

—Go to Step 9Go to Step 10

9Tighten the stud nuts or bolts to specifications.

Is your action complete?

—Go to Step 2—

10Check for burned or corroded exhaust pipes.

Are the exhaust pipes burned or corroded?

—Go to Step 11Go to Step 12

11Replace the exhaust pipes, as required.

Is your action complete?

—Go to Step 2—

Page 1360 of 6000

6E–243 ENGINE DRIVEABILITY AND EMISSIONS

DTC P1154 – HO2S Transition Time Ratio Bank 2 Sensor 1

StepNo Ye s Va l u e ( s ) Action

12Check for leaks at the exhaust manifold.

Are there leaks at the exhaust manifold?

—Go to Step 13Go to Step 14

13Tighten the bolts to specifications or replace the

manifold if necessary.

Is your action complete?

—Go to Step 2—

14Visually/physically inspect the following items:

Ensure that the Bank 2 HO2S 1 is securely

installed.

Check for corrosion on terminals.

Check terminal tension (at Bank 2 HO2S 1 and at

the PCM).

Check for damaged wiring.

Was a problem found in any of the above areas?

—Go to Step 18Go to Step 15

151. Disconnect Bank 1 HO2S 1.

2. Ignition “ON.”

3. Using a DVM at the PCM side of the HO2S 1

connector, measure the voltage between the high

signal circuit and ground.

Also measure the voltage between the low signal

circuit and ground.

Are both voltages in the specified range?

3-4 V

Go to Step

16

Go to Step 19

161. With Bank 1 HO2S 1 disconnected, jumper the high

and low (PCM side) signal circuits to ground.

2. Ignition “ON.”

3. Using Tech 2, monitor the Bank 2 HO2S 1 voltage.

Does the scan too indicate less than 10 mV and

immediately return to about 450 mV when the jumper is

removed?

—Go to Step 21Go to Step 22

17Replace affected heated oxygen sensors.

NOTE: Before replacing sensors, the cause of the

contamination must be determined and corrected.

Fuel contamination.

Use of improper RTV sealant.

Engine oil/coolant consumption.

Is the action complete?

—Verify repair—

18Repair condition as necessary.

Is the action complete?

—Verify repair—

19Check for faulty PCM connections or terminal damage.

Is the action complete?

—Verify repairGo to Step 20

20Repair open, short or grounded signal circuit.

Is the action complete?

—Verify repair—

Page 1363 of 6000

6E–246

ENGINE DRIVEABILITY AND EMISSIONS

amounts of fuel at idle, but may not be able to supply

enough fuel during heavy acceleration.

Water or alcohol in the fuel may cause low HO2S

voltage during acceleration.

Check for faulty or plugged fuel injector(s).

Check for low fuel.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.4. When the engine is idling or at steady cruise, the

HO2S voltage should vary from between

approximately 100 mV to 900 mV. It is possible to

measure a satisfactory fuel pressure at idle even

though the pressure may drop at high flow

requirements. It may be necessary to watch fuel

pressure at high engine load.

5. Wrap a shop towel around the fuel pressure

connector to absorb any small amount of fuel

leakage that may occur when installing gauge.

Ignition “ON,” pump pressure should be 280-320

kPa.

DTC P1171 – Fuel System Lean During Acceleration

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Are any component-related DTCs set?

—

Go to

component

DTC charts

Go to Step 3

31. Check the vehicle’s fuel tank for an adequate

amount of fuel.

2. Add fuel to the vehicle’s fuel tank if the tank is almost

empty.

Was fuel added to the vehicle’s fuel tank?

—Go to Step 4Go to Step 5

41. Place the transmission in park.

2. Using Tech 2, observe HO2S 1 voltage while

running warm engine 75

C-95C (167F-203F) at

1200 RPM.

3. HO2S 1 voltage should vary within the specified

range.

4. Quickly open the throttle halfway for a few seconds.

Did the voltage suddenly rise toward the high end of the

specified range?

100-900 mV

Go to Chart

A-7

Go to Step 5

51. Disconnect the fuel pump relay and crank the

engine to relieve the fuel pressure.

2. Install the fuel pressure gauge.

3. Start the engine and idle at normal operating

temperature.

4. Disconnect the vacuum line going to the fuel

pressure regulator.

With the engine running, is the fuel pressure within the

specified range?

280-325 kPa

(41-46 psi)

Go to OBD

System

Check

Go to Step 6

6Check for restricted fuel lines or restricted in-line filter.

Was a problem found?

—Verify repairGo to Step 7

Page 1364 of 6000

6E–247 ENGINE DRIVEABILITY AND EMISSIONS

DTC P1171 – Fuel System Lean During Acceleration

StepNo Ye s Va l u e ( s ) Action

71. Ignition “OFF.”

2. Remove the fuel pump relay and replace it with a

fused jumper which will connect the relay’s battery

terminal to the terminal leading to the fuel pump

fuse.

3. While the fuel pump is operating, use pliers to slowly

close the return line (do not exceed the first

specified value).

Using the pliers to restrict the return line, can the fuel

pressure be manipulated to exceed the second

specified value?

414 kPa

(60 psi)

325 kPa

(46 psi)

Go to

Diagnostic

Aids

Go to Step 8

8Check for:

Faulty fuel pump

Restricted fuel pump strainer (sock)

Incorrect fuel pump

Incorrect fuel being used

Hot fuel

Is the action complete?

—Verify repair—

Page 1365 of 6000

6E–248

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1380 ABS Rough Road ABS System Fault

Circuit Description

The powertrain control module (PCM) monitors ABS fault

signal. When PCM receives fault signal, PCM will set

DTC P1380.

Conditions for Setting the DTC

Vehicle speed is more than 5 mph.

Load is less than 99%.

Engine revolution is less than 6250 rpm.

PCM receives ABS fault signals from ABS unit.

Ignition on.

Misfire DTCs exist.

100 test failures within 120 test samples.

Action Taken When the DTC Sets

The PCM will store DTC 1380 only, no MIL turn on.

Conditions for Clearing the MIL/DTC

A history DTC P1380 will clear after 40 consecutive

warm-up cycles have occurred without a fault.

DTC 1380 can be cleared by using Tech-2 or

disconnecting the PCM battery feed.

Diagnostic Aids

Check for the following conditions:

PCM and ABS communication line short circuit to other

line may cause faulty signal. Inspect communication

line.

Follow ABS ECU diagnosis procedure, refer to ABS

procedure page.

DTC P1380 – ABS Rough Road ABS System Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF”, review and record

Tech 2 Failure Records Data.

2. Operate the vehicle within Failure Records

conditions as noted.

3. Using a Tech 2, monitor “Specific DTC” info for DTC

P1380 and Misfire DTCs until the DTC P1380 and

Misfire DTCs test runs. Note the result.

Does the Tech 2 indicates DTC P1380 and Misfire

DTCs failed this ignition?

—

Refer to ABS

diagnosis

After inspect

ABS, unit re-

peat

Step 2

Still problem

exists, go to

Step 3

Clear DTC by

Te c h 2

3Check short circuit among communication line of

PCM/ABS and others.

Was short circuit?

—

Repair wiring

Verify repair

Go to Step 4

4Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—