engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1172 of 6000

6E–55 ENGINE DRIVEABILITY AND EMISSIONS

Damaged harness–Inspect the wiring harness for

damage. If the harness appears to OK, observe the

A/C clutch while moving connectors and wiring

harnesses related to the A/C. A sudden clutch

malfunction will indicate the source of the intermittent

fault.

A/C Clutch Diagnosis

This chart should be used for diagnosing the electrical

p o r t i o n o f t h e A / C c o m p r e s s o r c l u t c h c i r c u i t . A Te c h 2 w i l l

be used in diagnosing the system. The Tech 2 has the

ability to read the A/C request input to the PCM. The Tech

2 can display when the PCM has commanded the A/C

clutch “ON.” The Tech 2 should have the ability to

override the A/C request signal and energize the A/C

compressor relay.

Test Description

IMPORTANT:Do not engage the A/C compressor

clutch with the engine running if an A/C mode is not

selected at the A/C control switch.

The numbers below refer to the step numbers on the

Diagnostic Chart:3. This a test determine is the problem is with the

refrigerant system. If the switch is open, A/C

pressure gauges will be used to determine if the

pressure switch is faulty or if the system is partially

discharged or empty.

4. Although the normal complaint will be the A/C clutch

failing to engage, it is possible for a short circuit to

cause the clutch to run when A/C has not been

selected. This step is a test for that condition.

7. There is an extremely low probability that both relays

will fail at the same time, so the substitution process

is one way to check the A/C Thermostat relay. Use

a known good relay to do a substitution check.

9. The blower system furnishes a ground for the A/C

control circuit, and it also shares a power source

through the Heater and A/C Relay. The blower

must be “ON” in order to test the A/C system.

A/C Clutch Control Circuit Diagnosis

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Are any other DTCs stored?

—

Go to the

other DTC

chart(s) first

Go to Step 3

31. Disconnect the electrical connector at the pressure

switch located on the receiver/drier.

2. Use an ohmmeter to check continuity across the

pressure switch.

Is the pressure switch open?

—

Go to Air

Conditioning

to diagnose

the cause of

the open

pressure

switch

Go to Step 4

4IMPORTANT:Before continuing with the diagnosis, the

following conditions must be met:

The intake air temperature must be greater than

15

C. (60F).

The engine coolant temperature must be less

than 119

C (246F).

1. A/C “OFF.”

2. Start the engine and idle for 1 minute.

3. Observe the A/C compressor.

Is the A/C compressor clutch engaged even though

A/C has not been requested?

—Go to Step 45Go to Step 5

51. Idle the engine.

2. A/C “ON”.

3. Blower “ON”.

4. Observe the A/C compressor.

Is the A/C compressor magnetic clutch engaged?

—

Refer to

Diagnostic

Aids

Go to Step 6

Page 1173 of 6000

6E–56

ENGINE DRIVEABILITY AND EMISSIONS

A/C Clutch Control Circuit Diagnosis

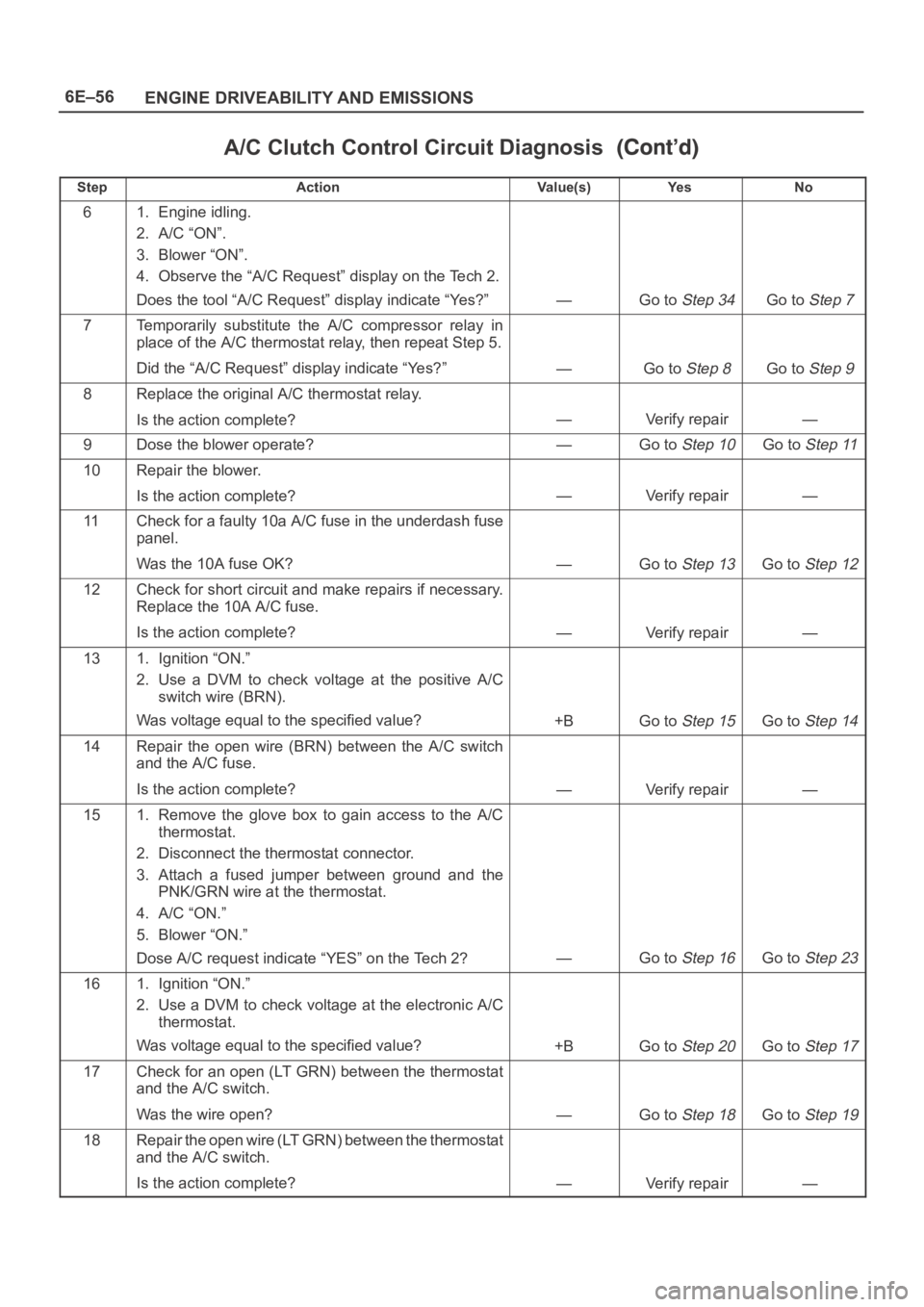

StepNo Ye s Va l u e ( s ) Action

61. Engine idling.

2. A/C “ON”.

3. Blower “ON”.

4. Observe the “A/C Request” display on the Tech 2.

Does the tool “A/C Request” display indicate “Yes?”

—Go to Step 34Go to Step 7

7Temporarily substitute the A/C compressor relay in

place of the A/C thermostat relay, then repeat Step 5.

Did the “A/C Request” display indicate “Yes?”

—Go to Step 8Go to Step 9

8Replace the original A/C thermostat relay.

Is the action complete?

—Verify repair—

9Dose the blower operate?—Go to Step 10Go to Step 11

10Repair the blower.

Is the action complete?

—Verify repair—

11Check for a faulty 10a A/C fuse in the underdash fuse

panel.

Was the 10A fuse OK?

—Go to Step 13Go to Step 12

12Check for short circuit and make repairs if necessary.

Replace the 10A A/C fuse.

Is the action complete?

—Verify repair—

131. Ignition “ON.”

2. Use a DVM to check voltage at the positive A/C

switch wire (BRN).

Was voltage equal to the specified value?

+BGo to Step 15Go to Step 14

14Repair the open wire (BRN) between the A/C switch

and the A/C fuse.

Is the action complete?

—Verify repair—

151. Remove the glove box to gain access to the A/C

thermostat.

2. Disconnect the thermostat connector.

3. Attach a fused jumper between ground and the

PNK/GRN wire at the thermostat.

4. A/C “ON.”

5. Blower “ON.”

Dose A/C request indicate “YES” on the Tech 2?

—Go to Step 16Go to Step 23

161. Ignition “ON.”

2. Use a DVM to check voltage at the electronic A/C

thermostat.

Was voltage equal to the specified value?

+BGo to Step 20Go to Step 17

17Check for an open (LT GRN) between the thermostat

and the A/C switch.

Was the wire open?

—Go to Step 18Go to Step 19

18Repair the open wire (LT GRN) between the thermostat

and the A/C switch.

Is the action complete?

—Verify repair—

Page 1174 of 6000

6E–57 ENGINE DRIVEABILITY AND EMISSIONS

A/C Clutch Control Circuit Diagnosis

StepNo Ye s Va l u e ( s ) Action

19Replace the A/C switch.

Is the action complete?

—Verify repair—

20Use an ohmmeter to check continuity between the

electronic A/C thermostat and the blower switch.

Was there an open circuit?

—Go to Step 21Go to Step 22

21Repair the open wire (GRN/YEL) between the

thermostat and the blower switch.

Is the action complete?

—Verify repair—

22Replace the electronic A/C thermostat.

Is the an action complete?

—Verify repair—

23Check for an open circuit between A/C thermostat relay

and PCM A/C request terminal (E-15).

Was there an open circuit?

—Go to Step 24Go to Step 25

24Repair the open circuit between the PCM and A/C

thermostat relay.

Is the action complete?

—Verify repair—

25Check for an open circuit between the A/C switch (LT

GRN) and the A/C thermostat relay (LT GRN).

Was there an open circuit?

—Go to Step 26Go to Step 27

26Repair the open circuit between the A/C switch and the

A/C thermostat relay.

Is the action complete?

—Verify repair—

271. Ignition “ON.”

2. Use a DVM to check voltage at the A/C pressure

switch (BRN).

Was voltage equal to the specified value?

+BGo to Step 29Go to Step 28

28Repair the open circuit between the 10A A/C fuse and

the pressure switch.

Is the action complete?

—Verify repair—

29Use an ohmmeter to check continuity between the

pressure switch (GRN/WHT) and the A/C thermostat

relay (GRN/WHT).

Was the circuit open?

—Go to Step 30Go to Step 31

30Repair the open circuit between the pressure switch

and the A/C thermostat relay.

Is the action complete?

—Verify repair—

31Check for damaged pin or terminal at E-15 of the PCM.

Was a damaged pin or terminal found?

—Go to Step 32Go to Step 33

32Repair the damaged pin or terminal.

Is the action complete?

—Verify repair—

33Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1175 of 6000

6E–58

ENGINE DRIVEABILITY AND EMISSIONS

A/C Clutch Control Circuit Diagnosis

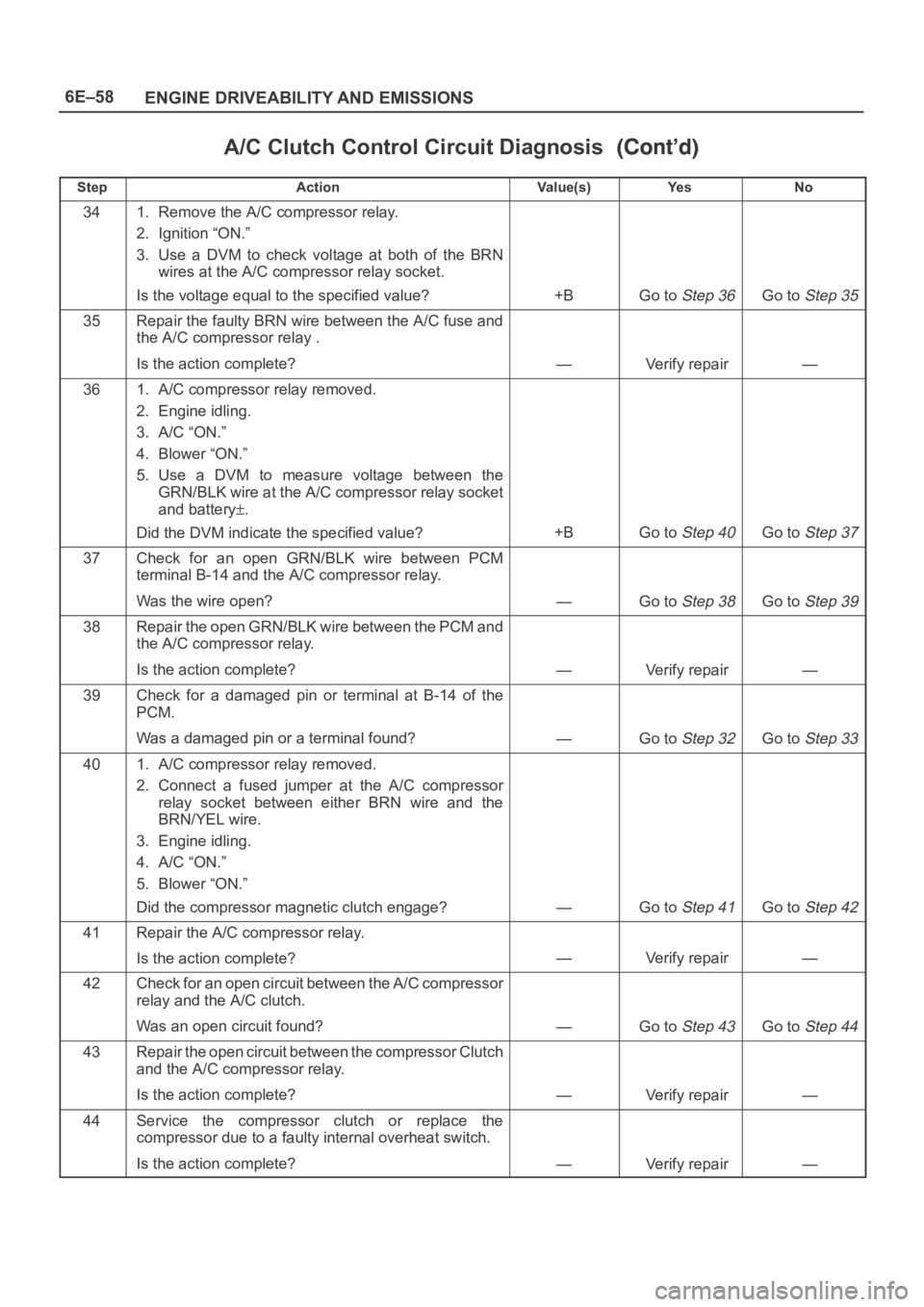

StepNo Ye s Va l u e ( s ) Action

341. Remove the A/C compressor relay.

2. Ignition “ON.”

3. Use a DVM to check voltage at both of the BRN

wires at the A/C compressor relay socket.

Is the voltage equal to the specified value?

+BGo to Step 36Go to Step 35

35Repair the faulty BRN wire between the A/C fuse and

the A/C compressor relay .

Is the action complete?

—Verify repair—

361. A/C compressor relay removed.

2. Engine idling.

3. A/C “ON.”

4. Blower “ON.”

5. Use a DVM to measure voltage between the

GRN/BLK wire at the A/C compressor relay socket

and battery

.

Did the DVM indicate the specified value?

+BGo to Step 40Go to Step 37

37Check for an open GRN/BLK wire between PCM

terminal B-14 and the A/C compressor relay.

Was the wire open?

—Go to Step 38Go to Step 39

38Repair the open GRN/BLK wire between the PCM and

the A/C compressor relay.

Is the action complete?

—Verify repair—

39Check for a damaged pin or terminal at B-14 of the

PCM.

Was a damaged pin or a terminal found?

—Go to Step 32Go to Step 33

401. A/C compressor relay removed.

2. Connect a fused jumper at the A/C compressor

relay socket between either BRN wire and the

BRN/YEL wire.

3. Engine idling.

4. A/C “ON.”

5. Blower “ON.”

Did the compressor magnetic clutch engage?

—Go to Step 41Go to Step 42

41Repair the A/C compressor relay.

Is the action complete?

—Verify repair—

42Check for an open circuit between the A/C compressor

relay and the A/C clutch.

Was an open circuit found?

—Go to Step 43Go to Step 44

43Repair the open circuit between the compressor Clutch

and the A/C compressor relay.

Is the action complete?

—Verify repair—

44Service the compressor clutch or replace the

compressor due to a faulty internal overheat switch.

Is the action complete?

—Verify repair—

Page 1176 of 6000

6E–59 ENGINE DRIVEABILITY AND EMISSIONS

A/C Clutch Control Circuit Diagnosis

StepNo Ye s Va l u e ( s ) Action

451. Remove the A/C compressor relay.

2. Idle the engine.

Is the compressor clutch still engaged when A/C is not

selected?

—Go to Step 46Go to Step 47

46Repair the short to voltage between the A/C clutch and

A/C compressor relay.

Is the action complete?

—Verify repair—

471. Reinstall the A/C compressor relay.

2. Remove the A/C thermostat relay.

3. Engine idling.

Is the compressor clutch still engaged when A/C is not

selected?

—Go to Step 48Go to Step 50

48Use a DVM to check for a short to ground between the

A/C compressor relay and B-14 of the PCM.

Was a short detected?

—Go to Step 49Go to Step 33

49Repair the short to ground between the PCM and A/C

compressor relay.

Is the action complete?

—Verify repair—

50Repair the short to ground between the A/C thermostat

relay and the electronic thermostat.

Is the action complete?

—Verify repair—

Page 1177 of 6000

6E–60

ENGINE DRIVEABILITY AND EMISSIONS

Electronic Ignition System Diagnosis

If the engine cranks but will not run or immediately stalls,

the Engine Cranks But Will Not Start chart must be used

to determine if the failure is the ignition system or the fuel

system. If DTC P0341, or P0336 is set, the appropriate

diagnostic trouble code chart must be used for diagnosis.

If a misfire is being experienced with no DTC set, refer to

the

Symptoms section for diagnosis.

Fuel Metering System Check

Some failures of the fuel metering system will result in an

“Engine Cranks But Will Not Run” symptom. If this

condition exists, refer to the

Cranks But Will Not Run

chart. This chart will determine if the problem is caused

by the ignition system, the PCM, or the fuel pump

electrical circuit.

Refer to

Fuel System Electrical Test for the fuel system

wiring schematic.

If there is a fuel delivery problem, refer to

Fuel System

Diagnosis

, which diagnoses the fuel injectors, the fuel

pressure regulator, and the fuel pump. If a malfunction

occurs in the fuel metering system, it usually results in

either a rich HO2S signal or a lean HO2S signal. This

condition is indicated by the HO2S voltage, which causes

the PCM to change the fuel calculation (fuel injector pulse

width) based on the HO2S reading. Changes made to the

fuel calculation will be indicated by a change in the long

term fuel trim values which can be monitored with a Tech

2. Ideal long term fuel trim values are around 0%; for a

lean HO2S signal, the PCM will add fuel, resulting in a fuel

trim value above 0%. Some variations in fuel trim values

are normal because all engines are not exactly the same.

If the fuel trim values are greater than +23%, refer to

DTC

P0131, DTC P0151, DTC P0171, and DTC 1171

f o r i t e m s

which can cause a lean HO2S signal.

Idle Air Control (IAC) Valve

The Tech 2 displays the IAC pintle position in counts. A

count of “0” indicates the PCM is commanding the IAC

pintle to be driven all the way into a fully-seated position.

This is usually caused by a large vacuum leak.

The higher the number of counts, the more air is being

commanded to bypass the throttle blade. Refer to IAC

System Check in order to diagnose the IAC system.

Refer to

Rough, Unstable, or Incorrect Idle, Stalling in

Symptoms for other possible causes of idle problems.

Fuel System Pressure Test

A fuel system pressure test is part of several of the

diagnostic charts and symptom checks. To perform this

test, refer to

Fuel Systems Diagnosis.

Fuel Injector Coil Test Procedure and

Fuel Injector Balance Test Procedure

T32003

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart:

2. Relieve the fuel pressure by connecting the

5-8840-0378-0 Fuel Pressure Gauge to the fuel

pressure connection on the fuel rail.

CAUTION: In order to reduce the risk of fire and

personal injury, wrap a shop towel around the fuel

pressure connection. The towel will absorb any fuel

leakage that occurs during the connection of the fuel

pressure gauge. Place the towel in an approved

container when the connection of the fuel pressure

gauge is complete.

Place the fuel pressure gauge bleed hose in an

approved gasoline container.

With the ignition switch “OFF,” open the valve on the

fuel pressure gauge.

3. Record the lowest voltage displayed by the DVM

after the first second of the test. (During the first

second, voltage displayed by the DVM may be

inaccurate due to the initial current surge.)

Injector Specifications:

Resistance Ohms

Voltage Specification at

10

C-35C (50F-95F)

11.8 – 12.65.7 – 6.6

The voltage displayed by the DVM should be within

the specified range.

The voltage displayed by the DVM may increase

throughout the test as the fuel injector windings

warm and the resistance of the fuel injector windings

changes.

Page 1178 of 6000

6E–61 ENGINE DRIVEABILITY AND EMISSIONS

An erratic voltage reading (large fluctuations in

voltage that do not stabilize) indicates an

intermittent connection within the fuel injector.

5. Injector Specifications:

Highest Acceptable

Voltage Reading

Above/Below 35

C/10C

(95

F/50F)

Acceptable Subtracted

Va l u e

9.5 Volts0.6 Volts

7. The Fuel Injector Balance Test portion of this chart

(Step 7 through Step 11) checks the mechanical

(fuel delivery) portion of the fuel injector. An engine

cool-down period of 10 minutes is necessary in

order to avoid irregular fuel pressure readings due

to “Hot Soak” fuel boiling.

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure (Steps 7-11)

R262001

CYLINDER123456

1st Reading (1)296 kPa

(43 psi)296 kPa

(43 psi)296 kPa

(43 psi)296 kPa

(43 psi)296 kPa

(43 psi)296 kPa

(43 psi)

2nd Reading (2)131 kPa

(19 psi)11 7 k P a

(17 psi)124 kPa

(18 psi)145 kPa

(21 psi)131 kPa

(19 psi)130 kPa

(19 psi)

Amount of Drop (1st

Reading–2nd Reading)165 kPa

(24 psi)179 kPa

(26 psi)172 kPa

(25 psi)151 kPa

(22 psi)165 kPa

(24 psi)166 kPa

(24 psi)

Av.drop = 166 kPa/24 psi

10 kPa/1.5 psi

= 156 – 176 kPa or

22.5 – 25.5 psi

OKFaulty, Rich

(Too Much

Fuel Drop)OKFaulty, Lean

(Too Little

Fuel Drop)OKOK

NOTE: These figures are examples only.

Page 1179 of 6000

6E–62

ENGINE DRIVEABILITY AND EMISSIONS

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure

(Steps 7-11)

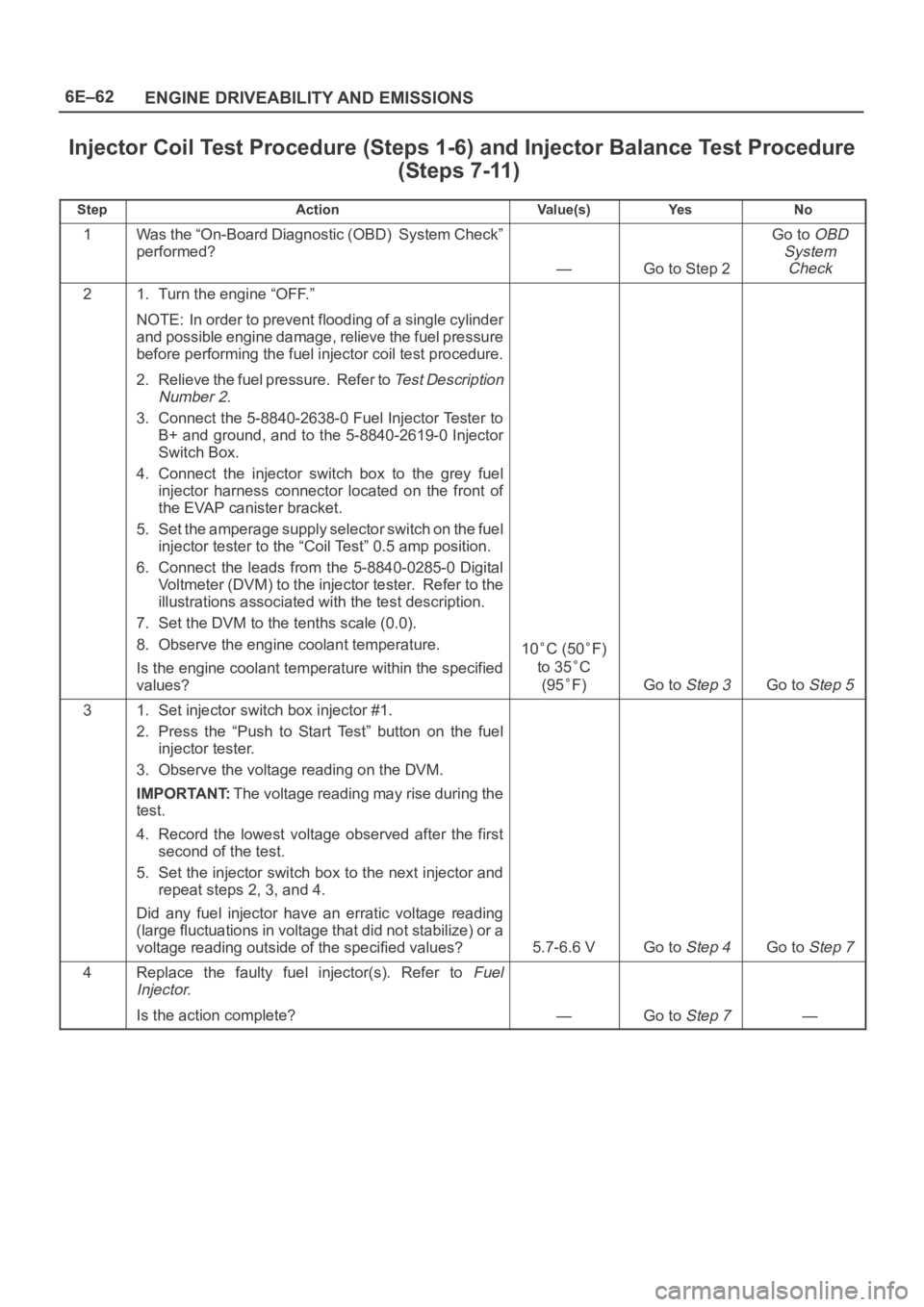

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Turn the engine “OFF.”

NOTE: In order to prevent flooding of a single cylinder

and possible engine damage, relieve the fuel pressure

before performing the fuel injector coil test procedure.

2. Relieve the fuel pressure. Refer to

Test Description

Number 2.

3. Connect the 5-8840-2638-0 Fuel Injector Tester to

B+ and ground, and to the 5-8840-2619-0 Injector

Switch Box.

4. Connect the injector switch box to the grey fuel

injector harness connector located on the front of

the EVAP canister bracket.

5. Set the amperage supply selector switch on the fuel

injector tester to the “Coil Test” 0.5 amp position.

6. Connect the leads from the 5-8840-0285-0 Digital

Voltmeter (DVM) to the injector tester. Refer to the

illustrations associated with the test description.

7. Set the DVM to the tenths scale (0.0).

8. Observe the engine coolant temperature.

Is the engine coolant temperature within the specified

values?

10C (50F)

to 35

C

(95

F)Go to Step 3Go to Step 5

31. Set injector switch box injector #1.

2. Press the “Push to Start Test” button on the fuel

injector tester.

3. Observe the voltage reading on the DVM.

IMPORTANT:The voltage reading may rise during the

test.

4. Record the lowest voltage observed after the first

second of the test.

5. Set the injector switch box to the next injector and

repeat steps 2, 3, and 4.

Did any fuel injector have an erratic voltage reading

(large fluctuations in voltage that did not stabilize) or a

voltage reading outside of the specified values?

5.7-6.6 VGo to Step 4Go to Step 7

4Replace the faulty fuel injector(s). Refer to Fuel

Injector.

Is the action complete?—Go to Step 7—

Page 1180 of 6000

6E–63 ENGINE DRIVEABILITY AND EMISSIONS

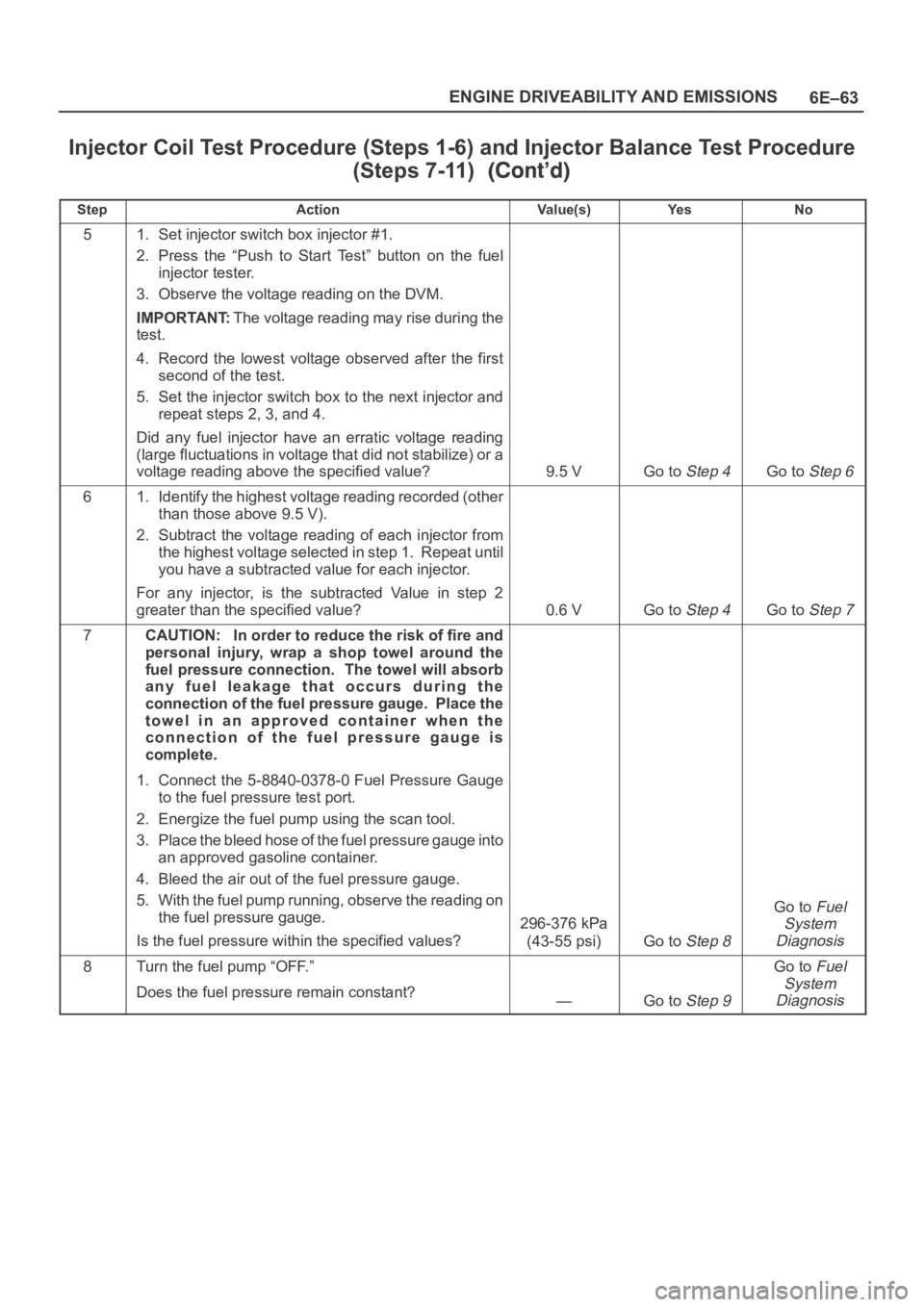

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure

(Steps 7-11)

StepNo Ye s Va l u e ( s ) Action

51. Set injector switch box injector #1.

2. Press the “Push to Start Test” button on the fuel

injector tester.

3. Observe the voltage reading on the DVM.

IMPORTANT:The voltage reading may rise during the

test.

4. Record the lowest voltage observed after the first

second of the test.

5. Set the injector switch box to the next injector and

repeat steps 2, 3, and 4.

Did any fuel injector have an erratic voltage reading

(large fluctuations in voltage that did not stabilize) or a

voltage reading above the specified value?

9.5 VGo to Step 4Go to Step 6

61. Identify the highest voltage reading recorded (other

than those above 9.5 V).

2. Subtract the voltage reading of each injector from

the highest voltage selected in step 1. Repeat until

you have a subtracted value for each injector.

For any injector, is the subtracted Value in step 2

greater than the specified value?

0.6 VGo to Step 4Go to Step 7

7CAUTION: In order to reduce the risk of fire and

personal injury, wrap a shop towel around the

fuel pressure connection. The towel will absorb

any fuel leakage that occurs during the

connection of the fuel pressure gauge. Place the

towel in an approved container when the

connection of the fuel pressure gauge is

complete.

1. Connect the 5-8840-0378-0 Fuel Pressure Gauge

to the fuel pressure test port.

2. Energize the fuel pump using the scan tool.

3. Place the bleed hose of the fuel pressure gauge into

an approved gasoline container.

4. Bleed the air out of the fuel pressure gauge.

5. With the fuel pump running, observe the reading on

the fuel pressure gauge.

Is the fuel pressure within the specified values?

296-376 kPa

(43-55 psi)

Go to Step 8

Go to Fuel

System

Diagnosis

8Turn the fuel pump “OFF.”

Does the fuel pressure remain constant?

—Go to Step 9

Go to Fuel

System

Diagnosis

Page 1181 of 6000

6E–64

ENGINE DRIVEABILITY AND EMISSIONS

Injector Coil Test Procedure (Steps 1-6) and Injector Balance Test Procedure

(Steps 7-11)

StepNo Ye s Va l u e ( s ) Action

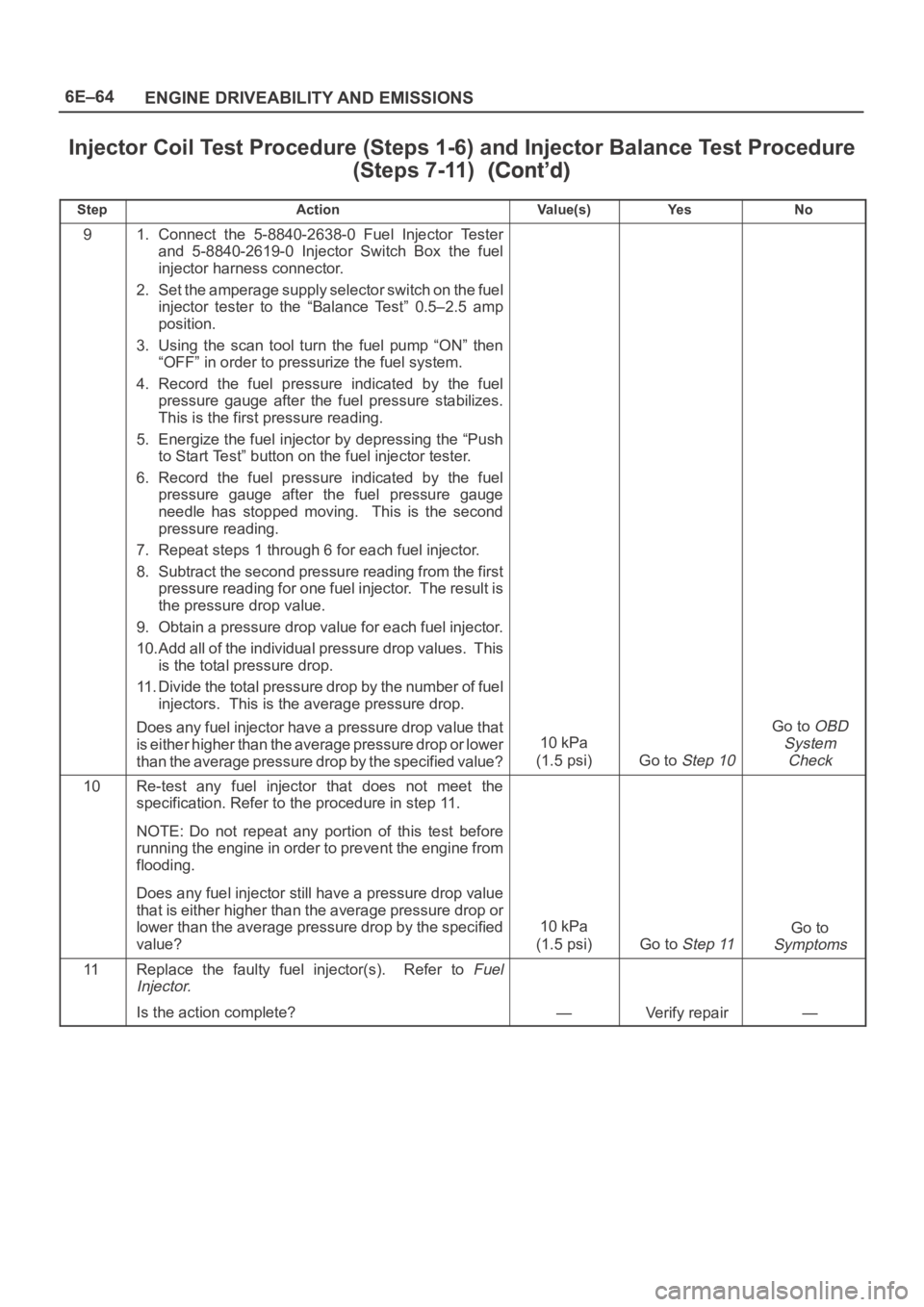

91. Connect the 5-8840-2638-0 Fuel Injector Tester

and 5-8840-2619-0 Injector Switch Box the fuel

injector harness connector.

2. Set the amperage supply selector switch on the fuel

injector tester to the “Balance Test” 0.5–2.5 amp

position.

3. Using the scan tool turn the fuel pump “ON” then

“OFF” in order to pressurize the fuel system.

4. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure stabilizes.

This is the first pressure reading.

5. Energize the fuel injector by depressing the “Push

to Start Test” button on the fuel injector tester.

6. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure gauge

needle has stopped moving. This is the second

pressure reading.

7. Repeat steps 1 through 6 for each fuel injector.

8. Subtract the second pressure reading from the first

pressure reading for one fuel injector. The result is

the pressure drop value.

9. Obtain a pressure drop value for each fuel injector.

10.Add all of the individual pressure drop values. This

is the total pressure drop.

11. Divide the total pressure drop by the number of fuel

injectors. This is the average pressure drop.

Does any fuel injector have a pressure drop value that

is either higher than the average pressure drop or lower

than the average pressure drop by the specified value?

10 kPa

(1.5 psi)

Go to Step 10

Go to OBD

System

Check

10Re-test any fuel injector that does not meet the

specification. Refer to the procedure in step 11.

NOTE: Do not repeat any portion of this test before

running the engine in order to prevent the engine from

flooding.

Does any fuel injector still have a pressure drop value

that is either higher than the average pressure drop or

lower than the average pressure drop by the specified

value?

10 kPa

(1.5 psi)

Go to Step 11

Go to

Symptoms

11Replace the faulty fuel injector(s). Refer to Fuel

Injector.

Is the action complete?—Verify repair—