Measurements OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 3541 of 6000

RESTRAINT CONTROL SYSTEM 9J1–54

Diagnostic Aids:

An intermittent condition is likely to be caused by a poor

connection at terminals “3” and “4” of the driver

pretensioner assembly 2–pin connector at the base of the

driver seat. SDM terminals “21” and “22” or a poor wire to

terminal connection in IB13–BLU/RED orIB14–BLU/YEL. The test for this diagnostic trouble code

is only run while the “AIR BAG” warning lamp is

performing the bulb check. When a scan tool “Clear

Codes” command is issued and the malfunction is still

present, the DTC will not reappear until the next ignition

cycle.

DTC 41 Driver Pretensioner Loop Resistance High

StepActionYe sNo

1Perform the “SRS Diagnostic System Check”.

Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Repeat the “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

2. Use scan tool data list function, read and record the driver

pretensioner loop resistance.

Is driver resistance more than 3.7 ohms?

Go to Step 3Go to Chart A

31. Ignition switch “OFF.”

2. Disconnect driver pretensioner assembly yellow 2–pin

connector located at base of the driver seat.

Is the 2–pin connector connected properly?

Go to Step 4

Driver

pretensioner

assembly 2–pin

connector

properly

Go to Step 7

41. Disconnect and inspect the driver pretensioner assembly

yellow 2–Pin connector located base of the driver seat.

2. If ok, reconnect the driver pretensioner assembly yellow 2–pin

connector.

3. Ignition switch “ON.”

Is DTC 41 current?

Go to Step 5Go to Step 7

51. Ignition switch “OFF.”

2. Disconnect driver pretensioner assembly, yellow 2–pin

connector located at the base of the driver seat.

3. Connect SRS driver / passenger load tool 5–8840–2421–0

and appropriate adapter to driver pretensioner assembly

harness connectors.

4. Ignition switch “ON.”

Is DTC 41 current?

Go to Step 6Go to Step 7

61. Ignition switch “Off.”

2. There has been a increase in the total circuit resistance of the

driver pretensioner loop.

3. Use the high resolution ohmmeter mode of the DVM while

checking IB13–BLU/RED and IB14–BLU/YEL, and SDM

connector terminal “21” and “22” to locate the root cause.

Was a fault found?

Replace SRS

harness or repair

chassis harness

Go to Step 7

Go to Chart A

71. Reconnect all components ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Repeat the “SRS

Diagnostic

System Check”

Go to Step 7

Page 3543 of 6000

RESTRAINT CONTROL SYSTEM 9J1–56

only run while the “AIR BAG” warning lamp is performing

the bulb check. When a scan tool “Clear Codes”command is issued and the malfunction is still present,

the DTC will not reappear until the next ignition cycle.

DTC 42 Driver Pretensioner Loop Resistance Low

StepActionYe sNo

1Perform the “SRS Diagnostic System Check.”

WAS THE “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

2. Use scan tool data list function, read and record the driver

pretensioner loop resistance.

Is driver pretensioner loop resistance less than 1.4 OHMS?

Go to Step 3Go to Chart A

31. Ignition switch “OFF.”

2. Make sure the driver pretensioner assembly yellow 2–pin

connector located at the base of the driver seat is connected

properly.

Is the 2–pin connector connected properly?

Go to Step 4

Seat driver

pretensioner

assembly 2–pin

connector

properly

Go to Step 7

41. Disconnect and inspect the driver pretensioner assembly

yellow 2–pin connector located base of the driver seat.

2. If ok, reconnect the driver pretensioner assembly yellow 2–pin

connector.

3. Ignition switch “ON.”

Is DTC 42 current?

Go to Step 5Go to Step 7

51. Ignition switch “OFF.”

2. Disconnect driver pretensioner assembly, yellow 2–pin

connector located at the base of driver seat.

3. Connect SRS driver / passenger load tool 5–8840–2421–0

and appropriate adapter to driver pretensioner assembly

harness connectors.

4. Ignition switch “ON.”

Is DTC 42 current?

Go to Step 6Go to Step 7

61. Ignition switch “OFF.”

2. There has been a decrease in the total circuit resistance of the

driver pretensioner loop.

3. Use the high resolution ohmmeter mode of the DVM while

checking IB13–BLU/RED and IB14–BLU/YEL, and SDM

connector terminal “21” and “22” to locate the root cause.

Was a fault found?

Replace SRS

harness or repair

chassis harness

Go to Step 7

Go to Chart A

71. Reconnect all components, ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Go to the “SRS

Diagnostic

System Check”

Go to Step 7

Page 3545 of 6000

RESTRAINT CONTROL SYSTEM 9J1–58

DTC 44 Driver Pretensioner Loop Open

StepActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

2. Use scan tool data list function, read and record the driver

pretensioner circuit differential voltage.

Is driver pretensioner VDIF more than 4.25 volts?

Go to Step 3Go to Chart A

31. Ignition switch “OFF.”

2. Make sure the driver pretensioner assembly yellow 2–pin

connector located at the base of the driver seat is seated

properly.

Is the yellow 2–pin connector connected properly?

Go to Step 4

Seat driver

pretensioner

assembly 2–pin

connector

Go to Step 7

41. Disconnect and inspect the driver pretensioner assembly

yellow 2–pin connector located base of the driver seat.

2. If ok, reconnect the driver pretensioner assembly yellow 2–pin

connector.

3. Ignition switch “ON.”

Is DTC 44 current?

Go to Step 5Go to Step 7

51. Ignition switch “OFF”.

2. Disconnect driver pretensioner assembly, yellow 2–pin

connectors located at the base of the driver seat.

3. Connect SRS driver/passenger load tool 5–8840–2421–0 and

appropriate adapter to driver pretensioner assembly harness

connectors.

4. Ignition switch “ON.”

Is DTC 44 current?

Go to Step 6Go to Step 7

61. Ignition switch “OFF.”

2. There has been an open circuit in the driver pretensioner loop.

3. Use the high resolution ohmmeter mode of the DVM while

checking IB13–BLU/RED and IB14–BLU/YEL, and SDM

connector terminal “21” and “22” to locate the root cause.

Was a fault found?

Replace SRS

harness or repair

chassis harness

Go to Step 7

Go to Chart A

71. Reconnect all components ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Repeat the “SRS

Diagnostic

System Check”

Go to Step 7

Page 3547 of 6000

RESTRAINT CONTROL SYSTEM 9J1–60

DTC 45 Driver Pretensioner Loop Short To Ground

StepActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

2. Ignition switch “OFF.”

3. Connect scan tool data link connector. follow directions as

given in the scan tool operator’s manual.

4. Ignition switch “ON.”

5. Read driver belt sense LO.

Is driver belt sense LO less than 1.5 volts?

Go to Step 3Go to Chart A

31. Ignition switch “OFF.”

2. Disconnect driver pretensioner assembly yellow 2–pin

connector located at base of the driver seat, leave passenger

pretensioner assembly connected.

3. Connect SRS driver / passenger load tool 5–8840–2421–0

and appropriate adapter to driver pretensioner assembly

harness connector.

4. Ignition switch “ON.”

Is DTC 45 current?

Go to Step 4Go to Step 6

41. Ignition switch “OFF.”

2. Disconnect SDM.

3. Disconnect SRS driver / passenger load tool.

4. Measure resistance on SDM harness connector “21” to

terminal “6” (ground).

Does 5–8840–0285–0 display “OL” (infinite)?

Go to Step 5

Replace SRS

harness or repair

chassis harness

Go to Step 6

5Measure resistance on SDM harness connector from terminal

“22” to terminal “6” (ground).

Does 5–8840–0285–0 display “OL” (infinite)?

Go to Chart A

Replace SRS

harness or repair

chassis harness

Go to Step 6

61. Reconnect all components ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Go to the “SRS

Diagnostic

System Check”

Go to Step 6

Page 3549 of 6000

RESTRAINT CONTROL SYSTEM 9J1–62

DTC 46 Driver Pretensioner Loop Short To Ignition

StepActionYe sNo

1Was the “SRS Diagnostic System Check” performed?

Go to Step 2

Go to the “SRS

Diagnostic

System Check”

21. When measurements are requested in this chart use

5–8840–0285–0 DVM with correct terminal adapter from

5–8840–0385–0.

Ignition switch “OFF.”

Connect scan tool data link connector. follow directions as

given in the scan tool operator’s manual.

2. Ignition switch “ON.”

3. Read driver belt sense LO .

Is driver belt sense LO more than 3.5 volts?

Go to Step 3Go to Chart A

31. Ignition switch “OFF.”

2. Disconnect driver pretensioner assembly yellow 2–pin

connector at the base of the driver seat, leave passenger

pretensioner assembly connected.

3. Connect SRS driver /passenger load tool 5–8840–2421–0 and

appropriate adapter to driver pretensioner assembly harness

connector.

4. Ignition switch “ON.”

Is DTC 46 current?

Go to Step 4

Ignition switch

“OFF”

Replace driver

pretensioner

assembly

Go to Step 6

41. Ignition switch “OFF.”

2. Disconnect SDM.

3. Disconnect SRS driver /passenger load tool.

4. Measure resistance on SDM harness connector “21” to

terminal “12” (ignition).

Does 5–8840–0285–0 display “OL” (infinite)?

Go to Step 5

Replace SRS

harness or repair

chassis harness

Go to Step 6

5Measure resistance on SDM harness connector from terminal

“22” to terminal “12” (ignition).

Does 5–8840–0285–0 display “OL” (infinite)?

Go to Chart A

Replace SRS

harness or repair

chassis harness

Go to Step 6

61. Reconnect all components ensure all component are properly

mounted.

2. Clear diagnostic trouble codes.

Was this step finished?

Go to the “SRS

Diagnostic

System Check”

Go to Step 6

Page 4355 of 6000

5A–5 BRAKE CONTROL SYSTEM

FR

Front Right

GEN

Generator

MV

Millivolts

RL

Rear Left

RR

Rear RightRPS

Revolution per Second

VDC

Vo l t s D C

VA C

Vo l t s A C

W/L

Warning Light

WSS

Wheel Speed Sensor

General Diagnosis

General Information

ABS malfunction can be classified into two types, those

which can be detected by the ABS warning light and those

which can be detected as a vehicle abnormality by the

driver.

In either case, locate the fault in accordance with the

“BASIC DIAGNOSTIC FLOWCHART” and repair.

Please refer to Section 5C for the diagnosis of

mechanical troubles such as brake noise, brake judder

(brake pedal or vehicle vibration felt when braking),

uneven braking, and parking brake trouble.

ABS Service Precautions

Required Tools and Items:

Box Wrench

Brake Fluid

Special Tool

Some diagnosis procedures in this section require the

installation of a special tool.

J-39200 High Impedance Multimeter

When circuit measurements are requested, use a circuit

tester with high impedance.

Computer System Service Precautions

The Anti-lock Brake System interfaces directly with the

Electronic Hydraulic Control Unit (EHCU) which is a

control computer that is similar in some regards to the

Powertrain Control Module. These modules are designed

to withstand normal current draws associated with

vehicle operation. However, care must be taken to avoid

overloading any of the EHCU circuits. In testing for opens

or shorts, do not ground or apply voltage to any of the

circuits unless instructed to do so by the appropriate

diagnostic procedure. These circuits should only be

tested with a high impedance multimeter (J-39200) or

special tools as described in this section. Power should

never be removed or applied to any control module with

the ignition in the “ON” position.

Before removing or connecting battery cables, fuses or

connectors, always turn the ignition switch to the “OFF”

position.

General Service Precautions

The following are general precautions which should be

observed when servicing and diagnosing the Anti-lock

Brake System and/or other vehicle systems. Failure toobserve these precautions may result in Anti-lock Brake

System damage.

If welding work is to be performed on the vehicle using

an electric arc welder, the EHCU and valve block

connectors should be disconnected before the

welding operation begins.

The EHCU and valve block connectors should never

be connected or disconnected with the ignition “ON” .

EHCU of the Anti-lock Brake System are not

separately serviceable and must be replaced as

assemblies. Do not disassemble any component

which is designated as non-serviceable in this

Section.

If only rear wheels are rotated using jacks or drum

tester, the system will diagnose a speed sensor

malfunction and the “ABS” warning light will

illuminate. But actually no trouble exists. After

inspection stop the engine once and re-start it, then

make sure that the “ABS” warning light does not

illuminate.

If the battery has been discharged

The engine may stall if the battery has been completely

discharged and the engine is started via jumper cables.

This is because the Anti-lock Brake System (ABS)

requires a large quantity of electricity. In this case, wait

until the battery is recharged, or set the ABS to a

non-operative state by removing the fuse for the ABS

(40A). After the battery has been recharged, stop the

engine and install the ABS fuse. Start the engine again,

and confirm that the ABS warning light does not light.

Note on Intermittents

As with virtually any electronic system, it is difficult to

identify an intermittent failure. In such a case duplicating

the system malfunction during a test drive or a good

description of vehicle behavior from the customer may be

helpful in locating a “most likely” failed component or

circuit. The symptom diagnosis chart may also be useful

in isolating the failure. Most intermittent problems are

caused by faulty electrical connections or wiring. When

an intermittent failure is encountered, check suspect

circuits for:

Suspected harness damage.

Poor mating of connector halves or terminals not fully

seated in the connector body (backed out).

Improperly formed or damaged terminals.

Page 4756 of 6000

6E–99 ENGINE DRIVEABILITY AND EMISSIONS

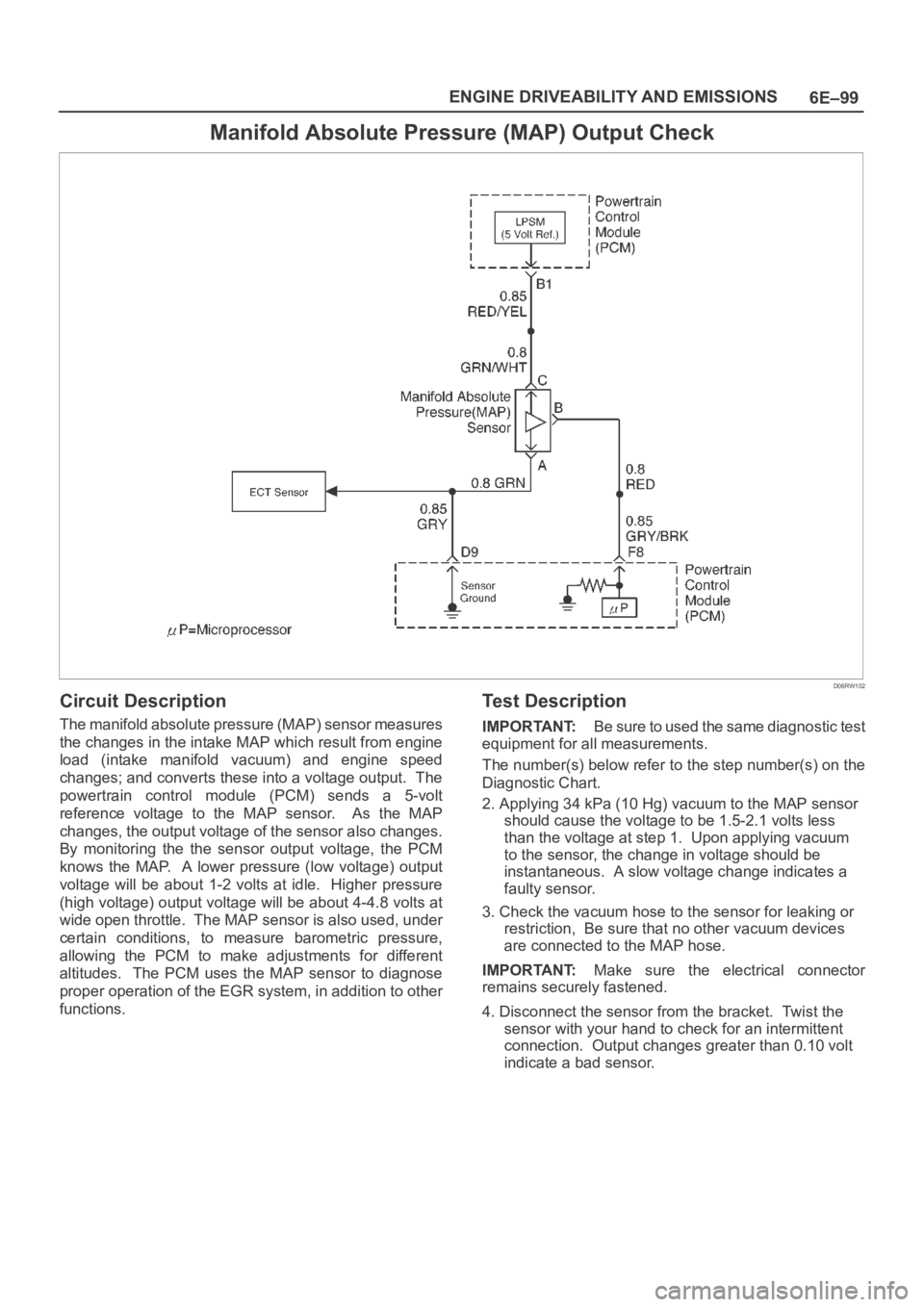

Manifold Absolute Pressure (MAP) Output Check

D06RW102

Circuit Description

The manifold absolute pressure (MAP) sensor measures

the changes in the intake MAP which result from engine

load (intake manifold vacuum) and engine speed

changes; and converts these into a voltage output. The

powertrain control module (PCM) sends a 5-volt

reference voltage to the MAP sensor. As the MAP

changes, the output voltage of the sensor also changes.

By monitoring the the sensor output voltage, the PCM

knows the MAP. A lower pressure (low voltage) output

voltage will be about 1-2 volts at idle. Higher pressure

(high voltage) output voltage will be about 4-4.8 volts at

wide open throttle. The MAP sensor is also used, under

certain conditions, to measure barometric pressure,

allowing the PCM to make adjustments for different

altitudes. The PCM uses the MAP sensor to diagnose

proper operation of the EGR system, in addition to other

functions.

Test Description

IMPORTANT:Be sure to used the same diagnostic test

equipment for all measurements.

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Applying 34 kPa (10 Hg) vacuum to the MAP sensor

should cause the voltage to be 1.5-2.1 volts less

than the voltage at step 1. Upon applying vacuum

to the sensor, the change in voltage should be

instantaneous. A slow voltage change indicates a

faulty sensor.

3. Check the vacuum hose to the sensor for leaking or

restriction, Be sure that no other vacuum devices

are connected to the MAP hose.

IMPORTANT:Make sure the electrical connector

remains securely fastened.

4. Disconnect the sensor from the bracket. Twist the

sensor with your hand to check for an intermittent

connection. Output changes greater than 0.10 volt

indicate a bad sensor.

Page 5845 of 6000

7A–64 AUTOMATIC TRANSMISSION (AW30-40LE)

F07RY00003

TIME LAG TEST

If the shift lever is shifted while the engine is idling, there will be

a cer tain time elapse or lag before the shock can be felt. This is

used for checking the condition of the forward clutch, direct

clutch, No. 3 brake, and No. 2 one-way clutch.

NOTE:

(1) Perform the test at normal operation fluid temperature

(50 – 80

C or 122 – 176F).

(2) Be sure to allow one minute interval between tests.

(3) Make three measurements and take the average value.

MEASURE TIME LAG

1) Fully apply the parking brake.

2) Start the engine.

Check idling speed (A/C OFF)

3) Shift the shift lever from "N" to "D" range. Using a stop

watch, measure the time it takes from shifting the lever until

the shock is felt.

4) In same manner, measure the time lag for "N"

"R".

EVALUATION

1) If "N" "D" time lag is longer than specified:

• Line pressure too low

• Forward clutch malfunction

• No. 2 one-way clutch not operating properly

2) If "N"

"R" time lag is longer than specified:

• Line pressure too low

• Direct clutch malfunction

• No. 3 brake malfunction

3) If both time lag is longer than specified:

• Line pressure too low"N" range 695 – 745 rpm

Time lag Less than 0.7 seconds

Time lag Less than 1.2 seconds