Pressure fuel regulator OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1434 of 6000

6E–317 ENGINE DRIVEABILITY AND EMISSIONS

Installation Procedure

1. Install the fuel pressure regulator attaching screw.

Tighten

Tighten the fuel pressure regulator attaching screw

to 3 Nꞏm (26 lb in.).

F06RW043

2. Install the fuel pressure regulator on the fuel rail.

3. Install the two bolts to the protector that secures the

common chamber.

014RW109

4. Install the pressure regulator hose to the fuel

pressure regulator.

014RW110

5. Install the fuel pump relay. Refer to Fuel Pump Relay.

6. Connect the negative battery cable.

7. Crank the engine until it starts. Cranking the engine

may take longer than usual due to trapped air in the

fuel lines.

Fuel Metering System

Fuel Pressure Relief Procedure

CAUTION: To reduce the risk of fire and personal

injury, it is necessary to relieve the fuel system

pressure before servicing the fuel system

components.

CAUTION: After relieving the system pressure, a

small amount of fuel may be released when servicing

fuel lines or connections. Reduce the chance of

personal injury by covering the fuel line fittings with

a shop towel before you disconnect the fittings. The

towels will absorb any fuel that may leak out. When

the disconnect is completed, place the towel in an

approved container.

1. Remove the fuel cap.

Page 1437 of 6000

6E–320

ENGINE DRIVEABILITY AND EMISSIONS

IMPORTANT:An eight-digit identification number is

stamped on the side of the fuel rail. Refer to this number

when you service the fuel rail or when a replacement part

is required.

TS24022

Before removal, the fuel rail assembly may be cleaned

with a spray type engine cleaner. Follow the spray

package instructions. Do not immerse the fuel rails in

liquid cleaning solvent.

1. Depressurize the fuel system. Refer to Fuel Pressure

Relief Procedure in this Section.

2. Disconnect the negative battery cable.

3. Remove the engine cover.

4. Disconnect the accelerator pedal cable from throttle

body and cable bracket.

5. Disconnect the connectors from manifold absolute

pressure sensor, solenoid valve, electric vacuum

sensing valve.

6. Disconnect the vacuum hose on canister VSV and

positive crankcase ventilation hose.

7. Remove the common chamber. Refer to the common

chamber in Engine Mechanical.

1. Lift up carefully on the fuel injectors. Do not

separate the fuel injectors from the fuel rail.

2. If an injector becomes separated from the fuel

rail, the infector O-ring seals and the retainer clip

must be replaced.

3. Drain residual fuel into an approved container.

014RW164

8. If removal of the fuel pressure regulator is necessary,

refer to

Fuel Pressure Regulator.

9. If removal of the fuel injectors is necessary, refer to

Fuel Injectors.

Installation Procedure

1. If the fuel injectors were removed, install them. Refer

to

Fuel Injectors.

2. If the fuel pressure regulator was removed, install it.

Refer to

Fuel Pressure Regulator.

3. Install the common chamber. Refer to common

chamber in engine Mechanical.

014RW164

Page 1459 of 6000

6E–342

ENGINE DRIVEABILITY AND EMISSIONS

PCM to calculate true sequential multiport fuel injection

(SFI). Loss of this signal will set a DTC P0341. If the CMP

signal is lost while the engine is running, the fuel injection

system will shift to a calculated sequential fuel injection

based on the last fuel injection pulse, and the engine will

continue to run. The engine can be restarted and will run

in the calculated sequential mode as long as the fault is

present, with a 1-in-6 chance of being correct.

Clear Flood Mode

Clear a flooded engine by pushing the accelerator pedal

down all the way. The PCM then de-energizes the fuel

injectors. The PCM holds the fuel injectors de-energized

as long as the throttle remains above 80% and the engine

speed is below 800 RPM. If the throttle position becomes

less than 80%, the PCM again begins to pulse the

injectors “ON” and “OFF,” allowing fuel into the cylinders.

Deceleration Mode

The PCM reduces the amount of fuel injected when it

detects a decrease in the throttle position and the air flow.

When deceleration is very fast, the PCM may cut off fuel

completely for short periods.

Engine Speed/Vehicle Speed/Fuel Disable

Mode

The PCM monitors engine speed. It turns off the fuel

injectors when the engine speed increase above 6400

RPM. The fuel injectors are turned back on when engine

speed decreases below 6150 RPM.

Fuel Cutoff Mode

No fuel is delivered by the fuel injectors when the ignition

is “OFF.” This prevents engine run-on. In addition, the

PCM suspends fuel delivery if no reference pulses are

detected (engine not running) to prevent engine flooding.

Fuel Injector

The sequential multiport fuel injection (SFI) fuel injector is

a solenoid-operated device controlled by the PCM. The

PCM energizes the solenoid, which opens a valve to allow

fuel delivery.

The fuel is injected under pressure in a conical spray

pattern at the opening of the intake valve. Excess fuel not

used by the injectors passes through the fuel pressure

regulator before being returned to the fuel tank.

A fuel injector which is stuck partly open will cause a loss

of fuel pressure after engine shut down, causing long

crank times.

0003

Fuel Metering System Components

The fuel metering system is made up of the following

parts:

The fuel injectors.

The throttle body.

The fuel rail.

The fuel pressure regulator.

The PCM.

The crankshaft position (CKP) sensor.

The camshaft position (CMP) sensor.

The idle air control (IAC) valve.

The fuel pump.

The fuel pump relay.

Basic System Operation

The fuel metering system starts with the fuel in the fuel

tank. An electric fuel pump, located in the fuel tank,

pumps fuel to the fuel rail through an in-line fuel filter. The

pump is designed to provide fuel at a pressure above the

pressure needed by the injectors. A fuel pressure

regulator in the fuel rail keeps fuel available to the fuel

injectors at a constant pressure. A return line delivers

unused fuel back to the fuel tank. Refer to

Section 6C f o r

further information on the fuel tank, line filter, and fuel

pipes.

Fuel Metering System Purpose

The basic function of the air/fuel metering system is to

control the air/fuel delivery to the engine. Fuel is delivered

to the engine by individual fuel injectors mounted in the

intake manifold near each intake valve.

The main control sensor is the heated oxygen sensor

(HO2S) located in the exhaust system. The HO2S tells

the PCM how much oxygen is in the exhaust gas. The

PCM changes the air/fuel ratio to the engine by controlling

the amount of time that fuel injector is “ON.” The best

mixture to minimize exhaust emissions is 14.7 parts of air

to 1 part of gasoline by weight, which allows the catalytic

converter to operate most efficiently. Because of the

Page 1460 of 6000

6E–343 ENGINE DRIVEABILITY AND EMISSIONS

constant measuring and adjusting of the air/fuel ratio, the

fuel injection system is called a “closed loop” system.

The PCM monitors signals from several sensors in order

to determine the fuel needs of the engine. Fuel is

delivered under one of several conditions called “modes.”

All modes are controlled by the PCM.

Fuel Pressure Regulator

The fuel pressure regulator is a diaphragm-operated

relief valve mounted on the fuel rail with fuel pump

pressure on one side and manifold pressure on the other

side. The fuel pressure regulator maintains the fuel

pressure available to the injector at three times

barometric pressure adjusted for engine load. It may be

serviced separate.

If the pressure is too low, poor performance and a DTC

P0131, DTC P0151,DTC P0171 or DTC P1171 will be the

result. If the pressure is too high, excessive odor and/or a

DTC P0132, DTC P0152,DTC P0172 or DTC P0175 will

be the result. Refer to

Fuel System Diagnosis for

information on diagnosing fuel pressure conditions.

0011

Fuel Pump Electrical Circuit

When the key is first turned “ON,” the PCM energizes the

fuel pump relay for two seconds to build up the fuel

pressure quickly. If the engine is not started within two

seconds, the PCM shuts the fuel pump off and waits until

the engine is cranked. When the engine is cranked and

the 58 X crankshaft position signal has been detected by

the PCM, the PCM supplies 12 volts to the fuel pump relay

to energize the electric in-tank fuel pump.

An inoperative fuel pump will cause a “no-start” condition.

A fuel pump which does not provide enough pressure will

result in poor performance.

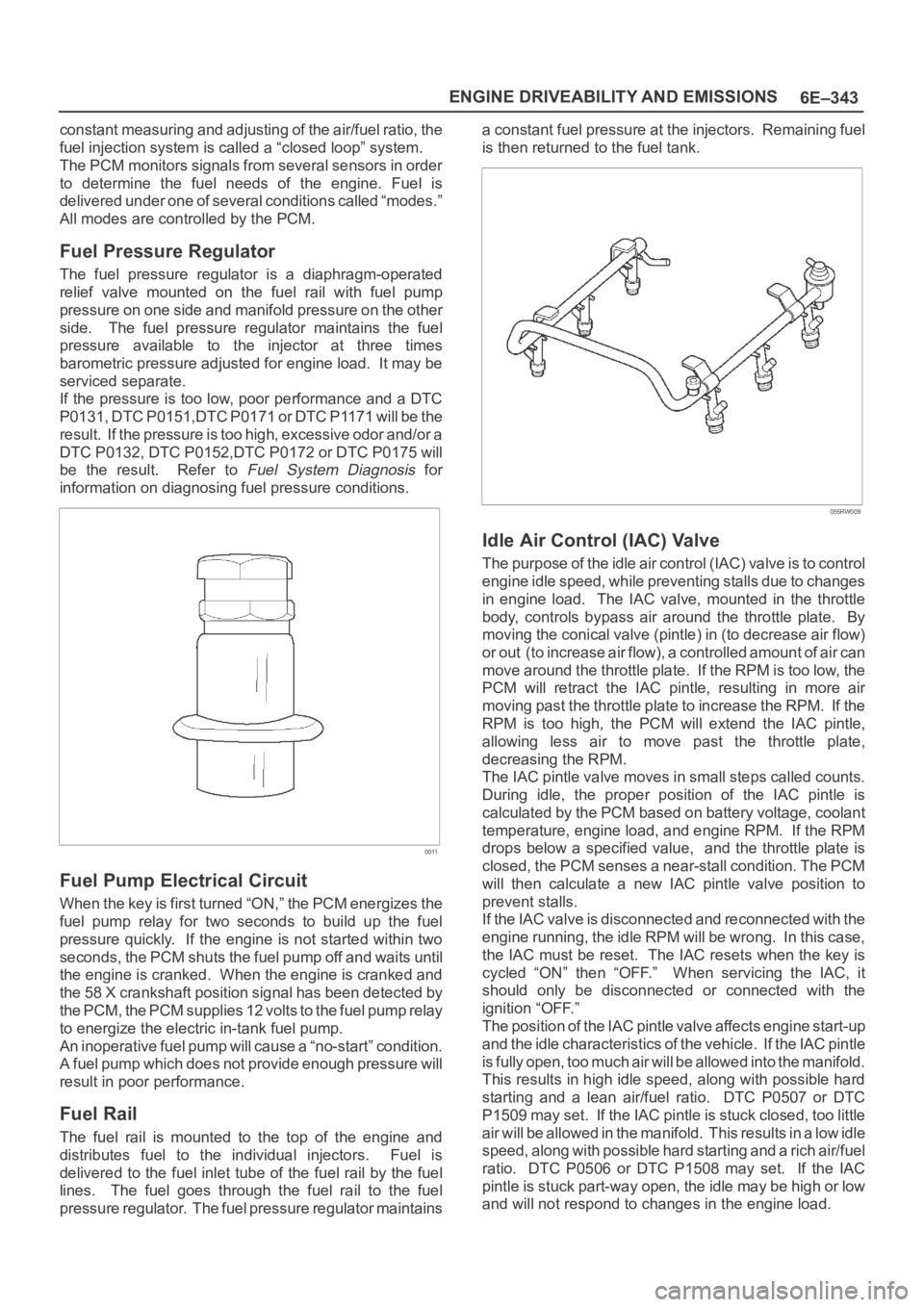

Fuel Rail

The fuel rail is mounted to the top of the engine and

distributes fuel to the individual injectors. Fuel is

delivered to the fuel inlet tube of the fuel rail by the fuel

lines. The fuel goes through the fuel rail to the fuel

pressure regulator. The fuel pressure regulator maintainsa constant fuel pressure at the injectors. Remaining fuel

is then returned to the fuel tank.

055RW009

Idle Air Control (IAC) Valve

The purpose of the idle air control (IAC) valve is to control

engine idle speed, while preventing stalls due to changes

in engine load. The IAC valve, mounted in the throttle

body, controls bypass air around the throttle plate. By

moving the conical valve (pintle) in (to decrease air flow)

or out (to increase air flow), a controlled amount of air can

move around the throttle plate. If the RPM is too low, the

PCM will retract the IAC pintle, resulting in more air

moving past the throttle plate to increase the RPM. If the

RPM is too high, the PCM will extend the IAC pintle,

allowing less air to move past the throttle plate,

decreasing the RPM.

The IAC pintle valve moves in small steps called counts.

During idle, the proper position of the IAC pintle is

calculated by the PCM based on battery voltage, coolant

temperature, engine load, and engine RPM. If the RPM

drops below a specified value, and the throttle plate is

closed, the PCM senses a near-stall condition. The PCM

will then calculate a new IAC pintle valve position to

prevent stalls.

If the IAC valve is disconnected and reconnected with the

engine running, the idle RPM will be wrong. In this case,

the IAC must be reset. The IAC resets when the key is

cycled “ON” then “OFF.” When servicing the IAC, it

should only be disconnected or connected with the

ignition “OFF.”

The position of the IAC pintle valve affects engine start-up

and the idle characteristics of the vehicle. If the IAC pintle

is fully open, too much air will be allowed into the manifold.

This results in high idle speed, along with possible hard

starting and a lean air/fuel ratio. DTC P0507 or DTC

P1509 may set. If the IAC pintle is stuck closed, too little

air will be allowed in the manifold. This results in a low idle

speed, along with possible hard starting and a rich air/fuel

ratio. DTC P0506 or DTC P1508 may set. If the IAC

pintle is stuck part-way open, the idle may be high or low

and will not respond to changes in the engine load.

Page 2134 of 6000

ENGINE LUBRICATION 6G – 3

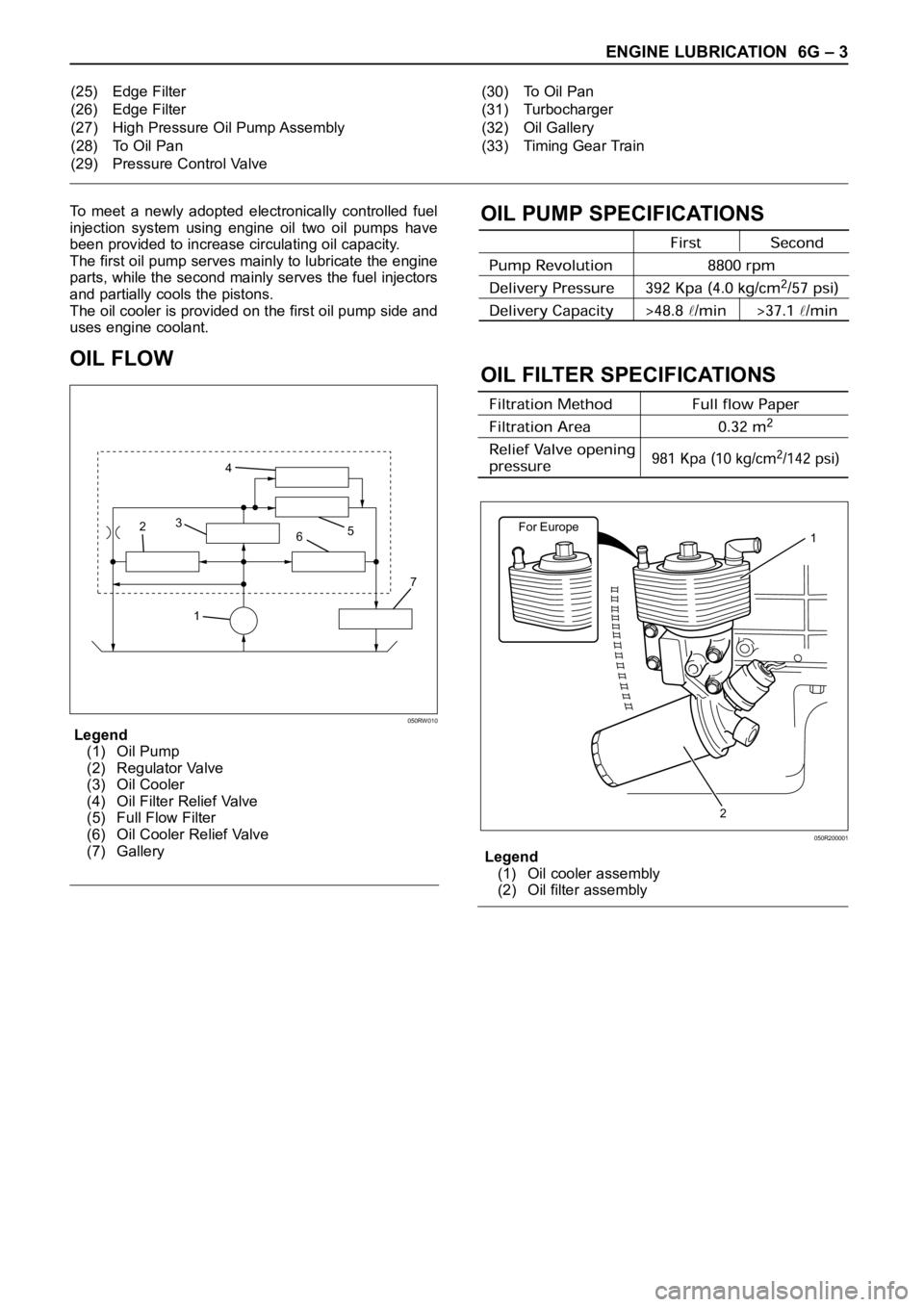

To meet a newly adopted electronically controlled fuel

injection system using engine oil two oil pumps have

been provided to increase circulating oil capacity.

The first oil pump serves mainly to lubricate the engine

parts, while the second mainly serves the fuel injectors

and partially cools the pistons.

The oil cooler is provided on the first oil pump side and

uses engine coolant.

OIL FLOW

Legend

(1) Oil Pump

(2) Regulator Valve

(3) Oil Cooler

(4) Oil Filter Relief Valve

(5) Full Flow Filter

(6) Oil Cooler Relief Valve

(7) Gallery

OIL PUMP SPECIFICATIONS

OIL FILTER SPECIFICATIONS

Legend

(1) Oil cooler assembly

(2) Oil filter assembly (25) Edge Filter

(26) Edge Filter

(27) High Pressure Oil Pump Assembly

(28) To Oil Pan

(29) Pressure Control Valve(30) To Oil Pan

(31) Turbocharger

(32) Oil Gallery

(33) Timing Gear Train

17 65 4

3

2

050RW010

For Europe1

2

050R200001

Page 4660 of 6000

6E–3 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0351

Ignition 1 Control Circuit 6E–206. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0352

Ignition 2 Control Circuit 6E–209. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0353

Ignition 3 Control Circuit 6E–212. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0354

Ignition 4 Control Circuit 6E–215. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0355

Ignition 5 Control Circuit 6E–218. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0356

Ignition 6 Control Circuit 6E–221. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0402

EGR Pintle Crank Error 6E–224. . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0404

EGR Open Stuck 6E–226. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0405

EGR Low Voltage 6E–228. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0406

EGR High Voltage 6E–231. . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0502

VSS Circuit Low Input 6E–234. . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0562

System Voltage Low 6E–237. . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0563

System Voltage High 6E–239. . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0601

PCM Memory 6E–240. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1154

HO2S Circuit Transition Time Ratio Bank 2

Sensor 1 6E–241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1171

Fuel System Lean During Acceleration 6E–245. . . .

Diagnostic Trouble Code (DTC) P1380

ABS Rough Road ABS System Fault 6E–248. . . . . .

Diagnostic Trouble Code (DTC) P1404

EGR Closed Stuck 6E–249. . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1508

IAC System Low RPM 6E–251. . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1509

IAC System High RPM 6E–254. . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1618

Serial Peripheral Interface (SPI) PCM

Interprocessor Communication Error 6E–257. . . . . .

Diagnostic Trouble Code (DTC) P1625

PCM Unexpected Reset 6E–258. . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1640

Driver-1-Input High Voltage 6E–259. . . . . . . . . . . . . .

Symptom Diagnosis 6E–262. . . . . . . . . . . . . . . . . . . . .

Default Matrix Table 6E–288. . . . . . . . . . . . . . . . . . . . .

Camshaft Position (CMP) Sensor 6E–291. . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–292. . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–292.

Heated Oxygen Sensor (HO2S) 6E–293. . . . . . . . . . .

Intake Air Temperature (IAT) Sensor 6E–295. . . . . . .

Knock Sensor (KS) 6E–296. . . . . . . . . . . . . . . . . . . . . . Mass Air Flow (MAF) Sensor 6E–297. . . . . . . . . . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–297.

Malfunction Indicator Lamp (MIL) 6E–298. . . . . . . . . .

Powertrain Control Module (PCM) 6E–298. . . . . . . . .

EEPROM 6E–300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Steering Pressure (PSP) Switch 6E–300

. . . .

Throttle Position (TP) Sensor 6E–301. . . . . . . . . . . . .

Vehicle Speed Sensor (VSS) 6E–302. . . . . . . . . . . . .

Air Cleaner/Air Filter 6E–303. . . . . . . . . . . . . . . . . . . . .

Idle Air Control (IAC) Valve 6E–304. . . . . . . . . . . . . . .

Common Chamber 6E–305. . . . . . . . . . . . . . . . . . . . . .

Accelerator Cable Assembly 6E–305. . . . . . . . . . . . . .

Accelerator Pedal Replacement 6E–308. . . . . . . . . . .

Fuel Filter Cap 6E–310. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 6E–310. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge Unit 6E–313. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Injectors 6E–314. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pressure Regulator 6E–315. . . . . . . . . . . . . . . . .

Fuel Metering System 6E–317. . . . . . . . . . . . . . . . . . . .

Fuel Pump Assembly 6E–318. . . . . . . . . . . . . . . . . . . .

Fuel Pump Relay 6E–319. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Rail Assembly 6E–319. . . . . . . . . . . . . . . . . . . . . .

Fuel Tank 6E–321. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Throttle Body (TB) 6E–323. . . . . . . . . . . . . . . . . . . . . . .

Electronic Ignition System 6E–324. . . . . . . . . . . . . . . .

Catalytic Converter 6E–325. . . . . . . . . . . . . . . . . . . . . .

Air Conditioning Relay 6E–325. . . . . . . . . . . . . . . . . . .

EVAP Canister Hoses 6E–326. . . . . . . . . . . . . . . . . . . .

EVAP Canister 6E–326. . . . . . . . . . . . . . . . . . . . . . . . . .

EVAP Canister Purge Solenoid 6E–327. . . . . . . . . . . .

Fuel Tank Vent Valve 6E–328. . . . . . . . . . . . . . . . . . . .

Linear Exhaust Gas Recirculation

(EGR) Valve 6E–328. . . . . . . . . . . . . . . . . . . . . . . . . . .

Positive Crankcase Ventilation (PCV) Valve 6E–329.

Wiring and Connectors 6E–330. . . . . . . . . . . . . . . . . . .

PCM Connectors and Terminals 6E–330. . . . . . . . . . .

Wire Harness Repair: Twisted Shielded

Cable 6E–330. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Twisted Leads 6E–331. . . . . . . . . . . . . . . . . . . . . . . . . .

Weather-Pack Connector 6E–332. . . . . . . . . . . . . . . . .

Com-Pack III 6E–333. . . . . . . . . . . . . . . . . . . . . . . . . . .

Metri-Pack 6E–333. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6E–335. . . . . . . . . . . . . . . . . . . . .

General Description (PCM and Sensors) 6E–335. . .

58X Reference PCM Input 6E–335. . . . . . . . . . . . . .

A/C Request Signal 6E–335. . . . . . . . . . . . . . . . . . . .

Crankshaft Position (CKP) Sensor 6E–335. . . . . . .

Camshaft Position (CMP) Sensor and

Signal 6E–335. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Coolant Temperature (ECT) Sensor 6E–335

Electrically Erasable Programmable Read

Only Memory (EEPROM) 6E–336. . . . . . . . . . . . . .

Fuel Control Heated Oxygen Sensors 6E–336. . . .

Intake Air Temperature (IAT) Sensor 6E–336. . . . .

Page 4661 of 6000

6E–4

ENGINE DRIVEABILITY AND EMISSIONS

Knock Sensor 6E–337. . . . . . . . . . . . . . . . . . . . . . . . .

Linear Exhaust Gas Recirculation (EGR)

Control 6E–337. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mass Air Flow (MAF) Sensor 6E–337. . . . . . . . . . . .

Manifold Absolute Pressure (MAP) Sensor 6E–338

Powertrain Control Module (PCM) 6E–338. . . . . . .

PCM Function 6E–338. . . . . . . . . . . . . . . . . . . . . . . . .

PCM Components 6E–339. . . . . . . . . . . . . . . . . . . . .

PCM Voltage Description 6E–339. . . . . . . . . . . . . . .

PCM Input/Outputs 6E–339. . . . . . . . . . . . . . . . . . . .

PCM Service Precautions 6E–339. . . . . . . . . . . . . .

Reprogramming The PCM 6E–339. . . . . . . . . . . . . .

Throttle Position (TP) Sensor 6E–339. . . . . . . . . . .

Transmission Fluid Temperature (TFT)

Sensor 6E–340. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Range Switch 6E–340. . . . . . . . . . . . .

Vehicle Speed Sensor (VSS) 6E–340. . . . . . . . . . . .

Use of Circuit Testing Tools 6E–340. . . . . . . . . . . . .

Aftermarket Electrical and Vacuum

Equipment 6E–340. . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic Discharge Damage 6E–341. . . . . . . . .

Upshift Lamp 6E–341. . . . . . . . . . . . . . . . . . . . . . . . .

General Description (Air Induction) 6E–341. . . . . . . .

Air Induction System 6E–341. . . . . . . . . . . . . . . . . . .

General Description (Fuel Metering) 6E–341. . . . . . .

Acceleration Mode 6E–341. . . . . . . . . . . . . . . . . . . . .

Accelerator Controls 6E–341. . . . . . . . . . . . . . . . . . .

Battery Voltage Correction Mode 6E–341. . . . . . . .

CMP Signal 6E–341. . . . . . . . . . . . . . . . . . . . . . . . . . .

Clear Flood Mode 6E–342. . . . . . . . . . . . . . . . . . . . .

Deceleration Mode 6E–342. . . . . . . . . . . . . . . . . . . .

Engine Speed/Vehicle Speed/Fuel

Disable Mode 6E–342. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Cutoff Mode 6E–342. . . . . . . . . . . . . . . . . . . . . .

Fuel Injector 6E–342. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Metering System Components 6E–342. . . . . . Fuel Metering System Purpose 6E–342. . . . . . . . . .

Fuel Pressure Regulator 6E–343. . . . . . . . . . . . . . . .

Fuel Pump Electrical Circuit 6E–343. . . . . . . . . . . . .

Fuel Rail 6E–343. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Idle Air Control (IAC) Valve 6E–343. . . . . . . . . . . . .

Run Mode 6E–344. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting Mode 6E–344. . . . . . . . . . . . . . . . . . . . . . . . .

Throttle Body Unit 6E–344. . . . . . . . . . . . . . . . . . . . .

General Description (Electronic Ignition

System) 6E–344. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft Position (CMP) Sensor 6E–344. . . . . . . .

Crankshaft Position (CKP) Sensor 6E–345. . . . . . .

Electronic Ignition 6E–345. . . . . . . . . . . . . . . . . . . . .

Ignition Coils 6E–345. . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition Control 6E–345. . . . . . . . . . . . . . . . . . . . . . . .

Ignition Control PCM Output 6E–347. . . . . . . . . . . .

Knock Sensor (KS) PCM Input 6E–347

. . . . . . . . . .

Powertrain Control Module (PCM) 6E–347. . . . . . .

Spark Plug 6E–347. . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/C Clutch Diagnosis 6E–349. . . . . . . . . . . . . . . . . . . .

A/C Clutch Circuit Operation 6E–349. . . . . . . . . . . .

A/C Clutch Circuit Purpose 6E–349. . . . . . . . . . . . .

A/C Request Signal 6E–349. . . . . . . . . . . . . . . . . . . .

General Description (Exhaust Gas

Recirculation (EGR) System) 6E–349. . . . . . . . . . . . .

EGR Purpose 6E–349. . . . . . . . . . . . . . . . . . . . . . . . .

Linear EGR Valve 6E–349. . . . . . . . . . . . . . . . . . . . .

Linear EGR Control 6E–349. . . . . . . . . . . . . . . . . . . .

Linear EGR Valve Operation and Results

of Incorrect Operation 6E–349. . . . . . . . . . . . . . . . .

EGR Pintle Position Sensor 6E–350. . . . . . . . . . . . .

General Description (Positive Crankcase

Ventilation (PCV) System) 6E–350. . . . . . . . . . . . . . .

Crankcase Ventilation System Purpose 6E–350. . .

Crankcase Ventilation System Operation 6E–350.

Page 4662 of 6000

6E–5 ENGINE DRIVEABILITY AND EMISSIONS

Specifications

Tightening Specifications

ApplicationNꞏmLb Ft.Lb In.

Camshaft Position Sensor Retaining Screw9—78

Crankshaft Position Sensor Mounting Bolt10—87

EGR Bolt2821—

EGR Nut2821—

Engine Coolant Temperature Sensor207.7—

Fuel Drain Plug2922—

Fuel Pressure Regulator Attaching Screw6.5—60

Fuel Rail Bolts2518—

Fuel Tank Undercover Retaining Bolts3627—

Heated Oxygen Sensor4231—

Lower Intake Manifold to Engine Block Bolts2518—

Lower Intake Manifold to Engine Block Nuts2518—

Spark Plugs1813—

Throttle Body Mounting Bolts2518—

Upper Intake Manifold to Lower Intake Manifold Bolts2518—

VSS Retaining Bolt13—120

Vehicle Type Specifications

ECAUSTRALIA

THAILAND

SOUTH-EA

ST-ASIA

LATIN

AMERICAGULF

CONTRIES

SAUDI

CHINASOU

TH

AFRI

CA

EXPORTSpecifications

UBSUBSUBSUBSUBSUBS

OBD

O2

SENCATEGRMTATMTATMTATMTATMTMTATOBDSEN

SORAEGR

I21

I21

11

11

11

11

1

1

I

Page 4686 of 6000

6E–29 ENGINE DRIVEABILITY AND EMISSIONS

Engine Component Locator Table

Number

NameLocation

1Linear Exhaust Gas Recirculation (EGR) ValveRear right side of the engine

2Throttle Position (TP) SensorOn the rear of the throttle body

3Intake Air Temperature (IAT) SensorOn the intake air duct near the throttle body

4Check Engine (MIL) LightOn the instrument panel beneath the

tachometer

5Positive Crankcase Ventilation (PCV) ValveOn the left of the cylinder head cover

6Air CleanerLeft front of the engine bay

7Mass Air Flow (MAF) SensorAttached to the air filter box

8Camshaft Position (CMP) SensorOn the rear right side at the left of the cylinder

head cover

9Fuel Pressure RegulatorRear right side of the engine

10Idle Air Control (IAC) ValveOn the left of the throttle body

11Upper Intake ManifoldTop of the engine

12Fuse/Relay BoxAlong the inside of the right fender

13Manifold Absolute Pressure (MAP) SensorBolted to the top of the upper intake manifold

14Throttle BodyBetween the intake air duct and the upper

intake manifold

15Engine Coolant Temperature SensorOn the coolant crossover pipe at the front of

the engine, near the throttle body

Page 4688 of 6000

6E–31 ENGINE DRIVEABILITY AND EMISSIONS

Engine Component Locator Table

Number

NameLocation

1Linear Exhaust Gas Recirculation (EGR) ValveRear right side of the engine

2Throttle Position (TP) SensorOn the rear of the throttle body

3Intake Air Temperature (IAT) SensorOn the intake air duct near the throttle body

4Check Engine (MIL) LightOn the instrument panel beneath the

tachometer

5Positive Crankcase Ventilation (PCV) ValveOn the left of the cylinder head cover

6Air CleanerLeft front of the engine bay

7Mass Air Flow (MAF) SensorAttached to the air filter box

8Camshaft Position (CMP) SensorOn the rear right side at the left of the cylinder

head cover

9Fuel Pressure RegulatorRear right side of the engine

10Idle Air Control (IAC) ValveOn the left of the throttle body

11Upper Intake ManifoldTop of the engine

12Fuse/Relay BoxAlong the inside of the right fender

13Manifold Absolute Pressure (MAP) SensorBolted to the top of the upper intake manifold

14Throttle BodyBetween the intake air duct and the upper

intake manifold

15Engine Coolant Temperature SensorOn the coolant crossover pipe at the front of

the engine, near the throttle body