key battery OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2992 of 6000

WIRING SYSTEM 8D–399

1. Check to see if the battery voltage is normal.

2. Check to see if the fuse is normal.

3. Replace the anti–theft & keyless entry control unit with one reserved for test. If a trouble recurs even after replacing

the control unit, find out the cause of the trouble by referring to “System check procedure” and the following list.

ITEM MALFUNCTION POSSIBLE CAUSE DETECTING METHOD REMARKS

ANTI–THEFT

indicator light

does not flash

ANTI–THEFT

indicator light

does not turn off.

(Steadily on)

When door is

opened by pulling

up locking knob,

alarm does not

operate

Alarm does not

stop. Indicator light

does not change

to fully ON

condition, or does

not come on at

all.Burnt out indicator

light bulb possible.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system.

Refer to “Connector

check table” in this

system. Defective contact of door switch,

or open circuit in door switch

wiring.

Short circuit in the detect switch.

Engine hood, doors and tailgate

are not fully closed and locked.

Defective door switch, or short

circuit in switch wiring.

Defective tamper switch, or short

circuit in wiring.

Defective lock switch, or short

circuit in wiring.

Defective engine hood switch, or

short circuit in wiring.

Defective tailgate switch, or short

circuit in wiring.

Defective control unit.

Poor contact of lock switch, or

open circuit in wiring.

Broken wire in wiring to headlight

and horn, or a blown fuse.

Defective contact of detect

switch, or damaged switch wiring.With door open, dome light and

courtesy light do not come on.

Check the control unit connector.

Check to see if doors are closed

and locked.

Dome light and courtesy light

remain lit on after closing doors.

Check the control unit connector.

Check the control unit connector.

Check the control unit connector.

Luggage room light remains lit

after closing tailgate.

Check alarm operation (See No.

46 of “System check procedure”),

possible cause is a poor contact

of lock switch of an open circuit in

wiring.

Check to see if headlights go out.

Check the control unit connector.

Check the control unit connector. A

C

D

E B

Page 2998 of 6000

WIRING SYSTEM 8D–405

TERMINAL

CONNECTIONCHECK

OPERATIONCIRCUIT

NO. ITEM CONDITION

1 FRT door switch–LH, RH ContinuityOpen door Continuity

Close door No continuity

2 RR door switch–LH, RH ContinuityOpen door Continuity

Close door No continuity

3— — – –

4 Door lock key switch–LH, RH Continuity Lock with key Continuity

5 FRT door lock switch–LH, RH Continuity Lock Continuity

6 Tailgate switch ContinuityOpen tailgate Continuity

Close tailgate No continuity

8 Anti–theft horn Voltage – Approx. 12V

10 Battery Voltage – Approx. 12V

11 Door switch ContinuityUnlock with locking knob Continuity

Lock with locking knob No continuity

12 Engine hood switch ContinuityOpen engine hood Continuity

Close engine hood No continuity

13 Detect switch ContinuityUnlock with key Continuity

Lock with key No continuity

14 Door lock key switch Continuity Unlock Continuity

15 FRT door lock switch–LH, RH Continuity Unlock Continuity

16 Tamper switch Continuity – No continuity

17 Ground Continuity – Continuity

18 Starter switch Voltage Starter switch “ACC” Approx. 12V

19 Indicator light Voltage – Approx. 12V

20 Dome light Voltage Dome light “DOOR” position Approx. 12V

21 Anti-theft relay Voltage – Approx. 12V

22 Starter relay VoltageMode switch “P” or “N” Approx. 12V

Clutch pedal depressed Approx. 12V

Check the anti–theft & keyless entry control unit harness side connector B–20 by using a circuit tester.

Page 3343 of 6000

8H–4SECURITY AND LOCKS

Front Outside Handle and Door Lock Cylinder

Front Outside Handle, Door Lock Cylinder and Associated Parts

632RS006

Legend

(1) Door Trim Panel

(2) Waterproof Sheet

(3) Outside Handle(4) Door Lock Cylinder

(5) Clip

(6) Key Switch (W/Anti-Theft)

Removal

1. Disconnect the battery ground cable.

2. Remove the door trim panel.

3. Remove the waterproof sheet.

Refer to the Window Regulator removal procedure in

Body Structure section.

Page 3356 of 6000

SECURITY AND LOCKS8H–17

Tailgate Outside Handle and/or Tailgate Lock Cylinder

Tailgate Outside Handle and/or Tailgate Lock Cylinder and Associated Parts

684RW007

Legend

(1) Tailgate Trim Panel (LH)

(2) Waterproof Sheet

(3) Grommet(4) Tailgate Lock Cylinder

(5) Tailgate Outside Handle

(6) Key Switch (W/Anti–Theft)

Removal

1. Disconnect the battery ground cable.

2. Remove the tailgate trim panel.

3. Remove the waterproof sheet.

Refer to the Tailgate Lock Assembly (LH) in this

section.

4. Remove the grommet.

Page 3359 of 6000

8H–20SECURITY AND LOCKS

Power Door Lock System

General Description

The circuit consists of the door lock (& power window)

switch, door lock actuator for the front and rear door,

tailgate lock actuator and the door lock key switch. The

front door lock switch –LH is always provided with battery

voltage.

The key or the inside lock button on the both driver’s and

the front passenger’s door can activate the lock

mechanism of all the doors (including the tailgate).

When the driver’s door lock switch or the front

passenger’s door lock switch is turned on, current flows

for about one second to the door lock actuator of each

door connected in parallel with the front door lock (&

power window) switch –LH to activate the actuator to lock

and unlock the doors.

Front Door Lock Actuator Removal

1. Refer to the Front Door Lock Assembly removal

procedure in this section.

2. Remove the door lock actuator(1).

632RS021

632RS020

Front Door Lock Actuator Installation

To install, follow the removal steps in the reverse order.

Rear Door Lock Actuator Removal

1. Refer to the Rear Door Lock Assembly removal

procedure in this section.

2. Removal the door lock actuator(1).

632RS019

Page 3361 of 6000

8H–22SECURITY AND LOCKS

Anti-theft System

General Description

The circuit consists of the starter switch, anti-theft &

keyless entry control unit, anti-theft horn, front door and

tailgate key switch (detect and tamper switch), door lock

(& power window) switch, door lock actuator for each

door, engine hood switch, clutch start switch (M/T),

ANTI-THEFT indicator light and mode switch (A/T).

The system operates as follows: After locking the starter

switch and removing the starter key (this sets the alarm),

if the door is unlocked in any way other than with the

proper key, the headlights start flashing, the horn sounds,

and the starter circuit is disabled. (However, the engine

hood and all the doors must be locked and closed.)

Once the system has been placed in the warning or alarm

condition, it can be released only when the starter switch

is shifted from “OFF” to “ACC” by the starter key, or when

the lock of the front door or the tailgate is released (to

activate the detect switch) by the starter key.

Anti-theft & Keyless Entry Control

Unit Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly.

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the lower cluster assembly.

Refer to the Instrument Panel Assembly in Body

Structure section.

4. Disconnect the connector(2).

5. Remove four screws to remove the anti-theft &

keyless entry control unit with bracket(1).

825RW029

6. Remove two nuts from the anti-theft & keyless entry

control unit with bracket(3) to remove the anti-theft &

keyless entry controller(4).

825RW028

Anti-theft & Keyless Entry Control

Unit Installation

To install, follow the removal steps in the reverse order.

Anti-theft Indicator Removal

1. Disconnect the battery ground cable.

2. Remove the front console assembly(1).

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove the lower cluster assembly(2).

Refer to the Instrument Panel Assembly in Body

Structure section.

4. Remove the instrument panel driver lower cover

assembly(3).

Refer to the Instrument Panel Assembly in Body

Structure section.

821RW024

Page 3366 of 6000

SECURITY AND LOCKS8H–27

StepNo Ye s Action

41. Lock the door and unlock it three times.

2. Close the door and then open it.

NOTE: This step must be performed within ten seconds after step

3.

Is the action complete?

Go to Step 5Finished

5Answer back mode changes.

Is this step complete?

Go to Step 6Go to Step 7

6The control unit makes lock/unlock response once with interval of

one second.

Is the response complete?

Finished—

7The control unit makes lock/unlock response three times with

interval of one second.

Is the response complete?

Finished—

Anti–theft & Keyless Entry Control

Unit/Transmitter Replacement

Anti–theft & Keyless Entry Control Unit

Replacement

1. Remove and install the control unit.

Refer to Anti–theft & Keyless Entry Control Unit

Removal and Installation in this section.

2. Register ID code.

Refer to ID Code Registration in this section.

3. Check that the keyless entry system works normally.

Transmitter Replacement

1. Prepare a new transmitter.

2. Regiter ID code.

Refer to ID Code Registration in this section.

3. Check that the keyless entry system works normally.

Transmitter Battery Replacement

1. Remove a screw to remove the cover.

2. Remove the batteries.

3. Set the new batteries into the transmitter.

4. Install the cover to the transmitter.

5. Check that the keyless entry system works normally.

Page 3444 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–7

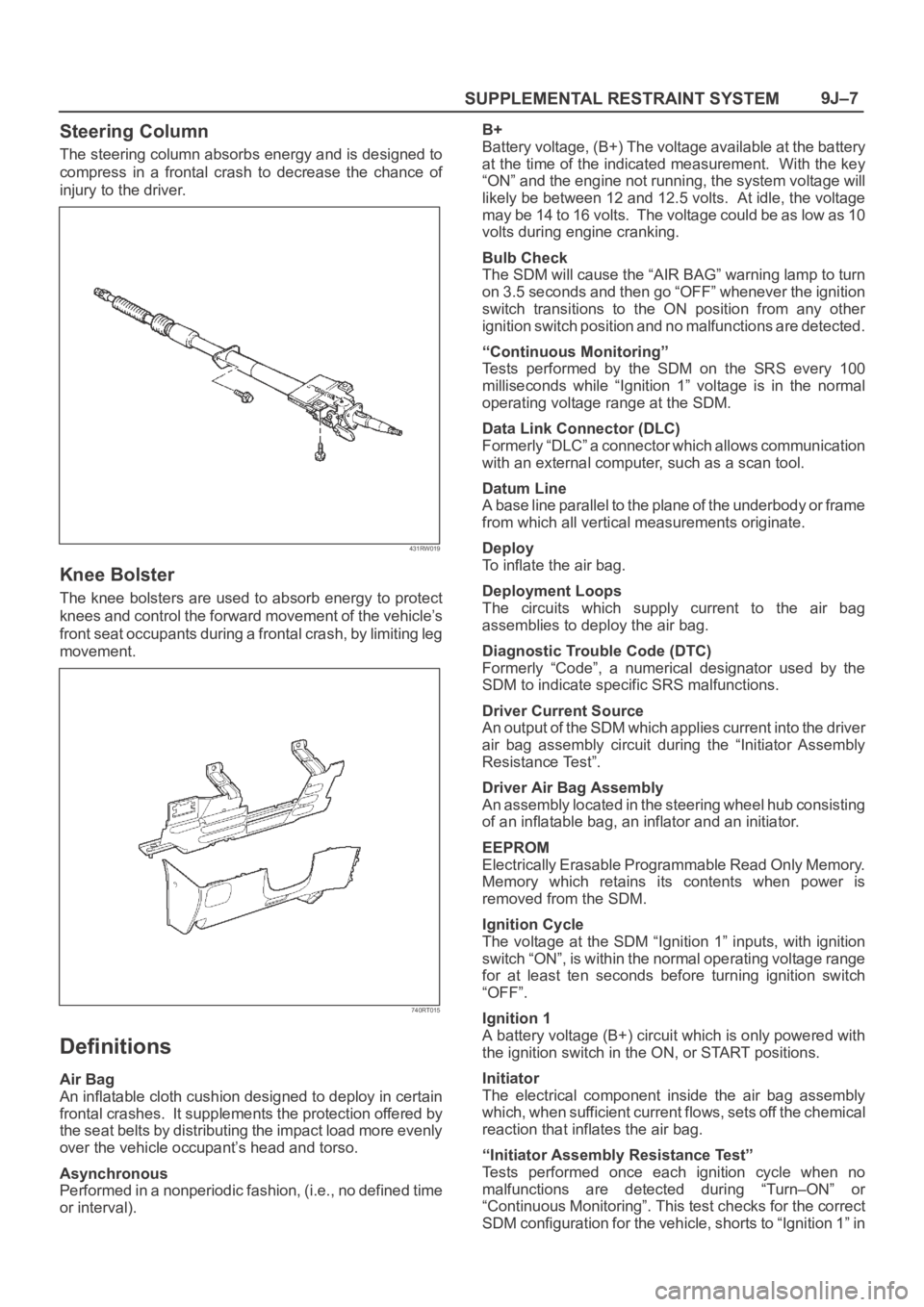

Steering Column

The steering column absorbs energy and is designed to

compress in a frontal crash to decrease the chance of

injury to the driver.

431RW019

Knee Bolster

The knee bolsters are used to absorb energy to protect

knees and control the forward movement of the vehicle’s

front seat occupants during a frontal crash, by limiting leg

movement.

740RT015

Definitions

Air Bag

An inflatable cloth cushion designed to deploy in certain

frontal crashes. It supplements the protection offered by

the seat belts by distributing the impact load more evenly

over the vehicle occupant’s head and torso.

Asynchronous

Performed in a nonperiodic fashion, (i.e., no defined time

or interval).B+

Battery voltage, (B+) The voltage available at the battery

at the time of the indicated measurement. With the key

“ON” and the engine not running, the system voltage will

likely be between 12 and 12.5 volts. At idle, the voltage

may be 14 to 16 volts. The voltage could be as low as 10

volts during engine cranking.

Bulb Check

The SDM will cause the “AIR BAG” warning lamp to turn

on 3.5 seconds and then go “OFF” whenever the ignition

switch transitions to the ON position from any other

ignition switch position and no malfunctions are detected.

“Continuous Monitoring”

Tests performed by the SDM on the SRS every 100

milliseconds while “Ignition 1” voltage is in the normal

operating voltage range at the SDM.

Data Link Connector (DLC)

Formerly “DLC” a connector which allows communication

with an external computer, such as a scan tool.

Datum Line

A base line parallel to the plane of the underbody or frame

from which all vertical measurements originate.

Deploy

To inflate the air bag.

Deployment Loops

The circuits which supply current to the air bag

assemblies to deploy the air bag.

Diagnostic Trouble Code (DTC)

Formerly “Code”, a numerical designator used by the

SDM to indicate specific SRS malfunctions.

Driver Current Source

An output of the SDM which applies current into the driver

air bag assembly circuit during the “Initiator Assembly

Resistance Test”.

Driver Air Bag Assembly

An assembly located in the steering wheel hub consisting

of an inflatable bag, an inflator and an initiator.

EEPROM

Electrically Erasable Programmable Read Only Memory.

Memory which retains its contents when power is

removed from the SDM.

Ignition Cycle

The voltage at the SDM “Ignition 1” inputs, with ignition

switch “ON”, is within the normal operating voltage range

for at least ten seconds before turning ignition switch

“OFF”.

Ignition 1

A battery voltage (B+) circuit which is only powered with

the ignition switch in the ON, or START positions.

Initiator

The electrical component inside the air bag assembly

which, when sufficient current flows, sets off the chemical

reaction that inflates the air bag.

“Initiator Assembly Resistance Test”

Tests performed once each ignition cycle when no

malfunctions are detected during “Turn–ON” or

“Continuous Monitoring”. This test checks for the correct

SDM configuration for the vehicle, shorts to “Ignition 1” in

Page 3447 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–10

Accident With Deployment – Component

Replacement And Inspections

Certain SRS components must be replaced or inspected

for damage after a frontal crash involving air bag

deployment. Those components are:

Air bag assembly

SDM

CAUTION: Refer to “SDM Replacement Guidelines”

below for important information on SDM

replacement in both deployment and non

deployment crashes.

SRS coil assembly — Inspect wiring and connector

for any signs of scorching, melting, or damage due to

excessive heat. Replace if damaged. Refer to

section “SRS Coil Assembly” in this manual.

Accident With or Without Deployment –

Component Inspection

Certain SRS system components and rotation parts must

be inspected after any crash, whether the air bag

deployed or not. Those components are:

Steering column — Refer to Inspection Required

“After an Accident” in this manual.

Knee bolsters and mounting points — Inspect for any

distortion, bending, cracking, or other damage.

I/P steering column reinforcement plate — Inspect for

any distortion, bending, cracking, or other damage.

I/P braces — Inspect for any distortion, bending,

cracking, or other damage.

Seat belts and mounting points — Refer to “Seat

Belts” in Section “Seat Belt” of this workshop manual.

SDM Replacement Guidelines

SDM replacement policy requires replacement of SDM,

after crash involving air bag deployment when “SRS

Warning Lamp” turn “ON”, “SRS Diagnosis” should be

done according to Section “Restraint Control System.”

If accident without deployment air bag, it is not necessary

replacement of SDM when do not indicate to replace the

SDM by scan tool after SRS system check.

Wiring Damage

If any SRS wire harness is damaged, it should be

replaced. Don’t repair SRS harness. It is replace only.

SRS Connector (Plastic Body And

Terminal Metal Pin) Damage

If any connector or terminal in the SRS wire harness

(except pigtails) is damaged, it should be replaced.

SRS Wire Pigtail Damage

If the wiring pigtail (a wire or wires attached directly to the

device, not by a connector) is damaged, the entire

component (with pigtail) must be replaced. Examples of

“pigtail” components are the driver air bag assembly, the

passenger air bag assembly, and the SRS coil assembly.

On–Vehicle Service

Service Precaution

WARNING: WHEN PERFORMING SERVICE ON OR

AROUND SRS COMPONENTS OR SRS WIRING,

FOLLOW THE PROCEDURES LISTED BELOW TO

TEMPORARILY DISABLE THE SRS. FAILURE TO

FOLLOW PROCEDURES COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY OR OTHERWISE UNNEEDED SRS REPAIRS.

The SDM in Driver–Passenger SRS can maintain

sufficient voltage to cause a deployment for up to 15

seconds after the ignition switch is turned “OFF,” the

battery is disconnected, or the fuse powering the SDM is

removed.

Many of the service procedures require removal of the

“C–21” fuse, and disconnection of the air bag assembly

from the deployment loop to avoid an accidental

deployment. If the air bag assembly is disconnected from

the deployment loop as noted in the “Disabling the SRS”

procedure that follows, service can begin immediately

without waiting for the 15 second time period to expire.

Disabling The SRS

Removal

Turn the ignition switch to “LOCK” and remove key.

1. Remove SRS fuse C–21, from left dash side lower

fuse block or disconnect battery.

2. Disconnect yellow 2–pin connector at the base of

steering column.

3. Remove glove box assembly, refer to “Passenger Air

Bag Assembly Replacement” in this manual.

4. Disconnect yellow 2–pin connector behind the glove

box assembly.

CAUTION: With the “C–21” fuse removed and

ignition switch “ON”, the “AIR BAG” warning lamp

will be “ON”. This is normal operation and does not

indicate an SRS malfunction.

Enabling The SRS

Installation

CAUTION: Never use the air bag assembly from

another vehicle. Use only the air bag assembly for

Trooper.

Turn ignition switch to “LOCK” and remove key.

1. Connect yellow 2–pin connector passenger air bag

assembly.

2. Install glove box assembly. Refer to “Passenger air

bag assembly replacement” in this manual.

3. Connect yellow 2–pin connector at the base of

steering column.

4. Install “AIR BAG” fuse C–21 to left dash side lower

fuse block or connect battery.

Turn ignition switch to “ON” and verify that the “AIR BAG”

warning lamp turn on 3.5 seconds and then turns “OFF.” If

it does not operate as described, perform the “SRS

Diagnostic System Check” in this manual.

Page 3460 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM9J–23

carbonate and sodium bicarbonate (baking soda).

Therefore, it is unlikely that sodium hydroxide will be

present after deployment.

(Driver air bag assembly)

After the air bag assembly has been deployed, the

surface of the air bag may contain solid particulate. This

solid particulate consists primarily of by products of the

chemical reaction, Potassium Chloride and copper metal

dust. Compounds of Potassium Borate, Strontium

Chloride, Copper Chloride, and Ammonium Chloride may

be found in amounts of about 1 % (each) of the total

particulate.

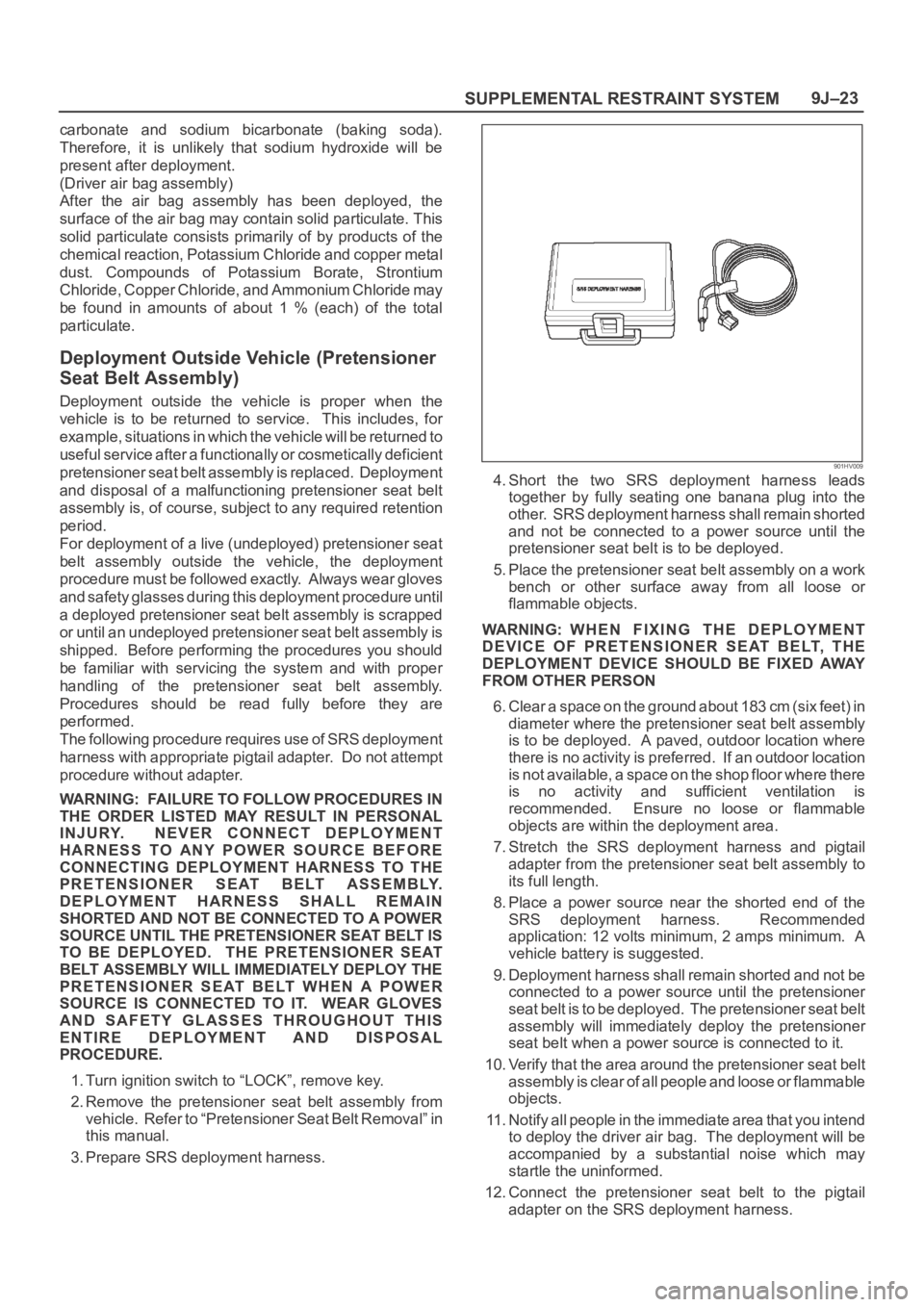

Deployment Outside Vehicle (Pretensioner

Seat Belt Assembly)

Deployment outside the vehicle is proper when the

vehicle is to be returned to service. This includes, for

example, situations in which the vehicle will be returned to

useful service after a functionally or cosmetically deficient

pretensioner seat belt assembly is replaced. Deployment

and disposal of a malfunctioning pretensioner seat belt

assembly is, of course, subject to any required retention

period.

For deployment of a live (undeployed) pretensioner seat

belt assembly outside the vehicle, the deployment

procedure must be followed exactly. Always wear gloves

and safety glasses during this deployment procedure until

a deployed pretensioner seat belt assembly is scrapped

or until an undeployed pretensioner seat belt assembly is

shipped. Before performing the procedures you should

be familiar with servicing the system and with proper

handling of the pretensioner seat belt assembly.

Procedures should be read fully before they are

performed.

The following procedure requires use of SRS deployment

harness with appropriate pigtail adapter. Do not attempt

procedure without adapter.

WARNING: FAILURE TO FOLLOW PROCEDURES IN

THE ORDER LISTED MAY RESULT IN PERSONAL

INJURY. NEVER CONNECT DEPLOYMENT

HARNESS TO ANY POWER SOURCE BEFORE

CONNECTING DEPLOYMENT HARNESS TO THE

PRETENSIONER SEAT BELT ASSEMBLY.

DEPLOYMENT HARNESS SHALL REMAIN

SHORTED AND NOT BE CONNECTED TO A POWER

SOURCE UNTIL THE PRETENSIONER SEAT BELT IS

TO BE DEPLOYED. THE PRETENSIONER SEAT

BELT ASSEMBLY WILL IMMEDIATELY DEPLOY THE

PRETENSIONER SEAT BELT WHEN A POWER

SOURCE IS CONNECTED TO IT. WEAR GLOVES

AND SAFETY GLASSES THROUGHOUT THIS

ENTIRE DEPLOYMENT AND DISPOSAL

PROCEDURE.

1. Turn ignition switch to “LOCK”, remove key.

2. Remove the pretensioner seat belt assembly from

vehicle. Refer to “Pretensioner Seat Belt Removal” in

this manual.

3. Prepare SRS deployment harness.

901HV009

4. Short the two SRS deployment harness leads

together by fully seating one banana plug into the

other. SRS deployment harness shall remain shorted

and not be connected to a power source until the

pretensioner seat belt is to be deployed.

5. Place the pretensioner seat belt assembly on a work

bench or other surface away from all loose or

flammable objects.

WARNING: WHEN FIXING THE DEPLOYMENT

DEVICE OF PRETENSIONER SEAT BELT, THE

DEPLOYMENT DEVICE SHOULD BE FIXED AWAY

FROM OTHER PERSON

6. Clear a space on the ground about 183 cm (six feet) in

diameter where the pretensioner seat belt assembly

is to be deployed. A paved, outdoor location where

there is no activity is preferred. If an outdoor location

is not available, a space on the shop floor where there

is no activity and sufficient ventilation is

recommended. Ensure no loose or flammable

objects are within the deployment area.

7. Stretch the SRS deployment harness and pigtail

adapter from the pretensioner seat belt assembly to

its full length.

8. Place a power source near the shorted end of the

SRS deployment harness. Recommended

application: 12 volts minimum, 2 amps minimum. A

vehicle battery is suggested.

9. Deployment harness shall remain shorted and not be

connected to a power source until the pretensioner

seat belt is to be deployed. The pretensioner seat belt

assembly will immediately deploy the pretensioner

seat belt when a power source is connected to it.

10. Verify that the area around the pretensioner seat belt

assembly is clear of all people and loose or flammable

objects.

11. Notify all people in the immediate area that you intend

to deploy the driver air bag. The deployment will be

accompanied by a substantial noise which may

startle the uninformed.

12. Connect the pretensioner seat belt to the pigtail

adapter on the SRS deployment harness.