key battery OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1873 of 6000

6D – 6 ENGINE ELECTRICAL

RELATION BETWEEN STARTER SWITCH AND STARTER

M

Key

PositionB1 B2 ACCIG1 IG2 ST

LOCKKey

Removed

Inserted OFF

ACC

ON

START

BSBattery

+-

2

17

3

4

5

6

Legend

(1) Starter Switch

(2) To Generator

(3) To QOS4 Control(4) Starter Relay

(5) Immobilizer Relay (for Europe)

(6) Magnetic Switch

(7) Battery

065R200029

Page 1921 of 6000

6E–28

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

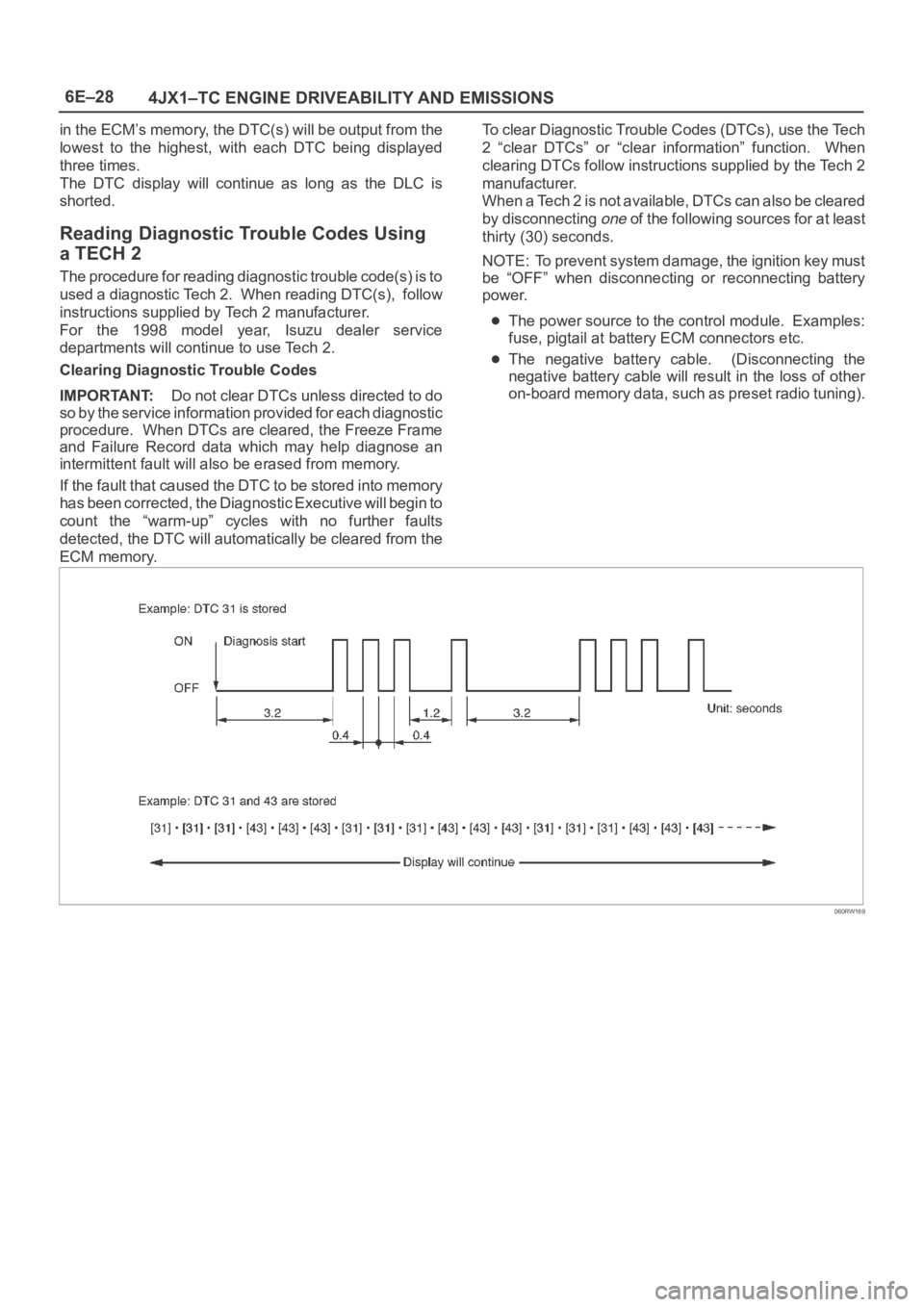

in the ECM’s memory, the DTC(s) will be output from the

lowest to the highest, with each DTC being displayed

three times.

The DTC display will continue as long as the DLC is

shorted.

Reading Diagnostic Trouble Codes Using

a TECH 2

The procedure for reading diagnostic trouble code(s) is to

used a diagnostic Tech 2. When reading DTC(s), follow

instructions supplied by Tech 2 manufacturer.

For the 1998 model year, Isuzu dealer service

departments will continue to use Tech 2.

Clearing Diagnostic Trouble Codes

IMPORTANT:Do not clear DTCs unless directed to do

so by the service information provided for each diagnostic

procedure. When DTCs are cleared, the Freeze Frame

and Failure Record data which may help diagnose an

intermittent fault will also be erased from memory.

If the fault that caused the DTC to be stored into memory

has been corrected, the Diagnostic Executive will begin to

count the “warm-up” cycles with no further faults

detected, the DTC will automatically be cleared from the

ECM memory.To clear Diagnostic Trouble Codes (DTCs), use the Tech

2 “clear DTCs” or “clear information” function. When

clearing DTCs follow instructions supplied by the Tech 2

manufacturer.

When a Tech 2 is not available, DTCs can also be cleared

by disconnecting

one of the following sources for at least

thirty (30) seconds.

NOTE: To prevent system damage, the ignition key must

be “OFF” when disconnecting or reconnecting battery

power.

The power source to the control module. Examples:

fuse, pigtail at battery ECM connectors etc.

The negative battery cable. (Disconnecting the

negative battery cable will result in the loss of other

on-board memory data, such as preset radio tuning).

060RW169

Page 1968 of 6000

6E–75 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0123 (Flash DTC 21)

AP Sensor High Voltage

060RW134

Circuit Description

The accelerator position (AP) sensor circuit provides a

voltage signal that changes relative to throttle blade

angle.

The TP signal is one of the most important inputs used by

the Engine Control Module ECM for fuel volume control

and many of the ECM-controlled outputs.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0123 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, brokenlocks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

AP sensor display on the Tech 2 while moving

connectors and wiring harnesses related to the TP

sensor. A change in the display will indicate the

location of the fault.

Faulty AP sensor – With the ignition key “ON,” engine

“OFF,” observe the AP sensor display on the Tech 2

while slowly depressing the accelerator to wide open

throttle. If a voltage over 4.88 volts is seen at any point

in normal accelerator travel, replace the AP sensor.

If DTC P0123 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Test Description

Number (s) below refer to the step number(s) on the

Diagnostic Chart.

8. Components that share the AP sensor 5 volt reference

“A” circuit include the following device:

Page 2039 of 6000

6E–146

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1486 (Flash DTC 74)

ITP (Intake Throttle Position) Sensor High Voltage

060RW134

Circuit Description

The intake throttle position (ITP) sensor circuit provides a

voltage signal that changes relative to throttle blade

angle.

Action Taken When the DTC Sets

The ECM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1486 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ITP sensor display on the Tech 2 while moving

connectors and wiring harnesses related to the TP

sensor. A change in the display will indicate the

location of the fault.

Faulty TP sensor – With the ignition key “ON,” engine

“OFF,” observe the TP sensor display on the Tech 2

while slowly depressing the accelerator to wide open

throttle.

If DTC P1486 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

Page 2182 of 6000

7A–28

AUTOMATIC TRANSMISSION (4L30–E)

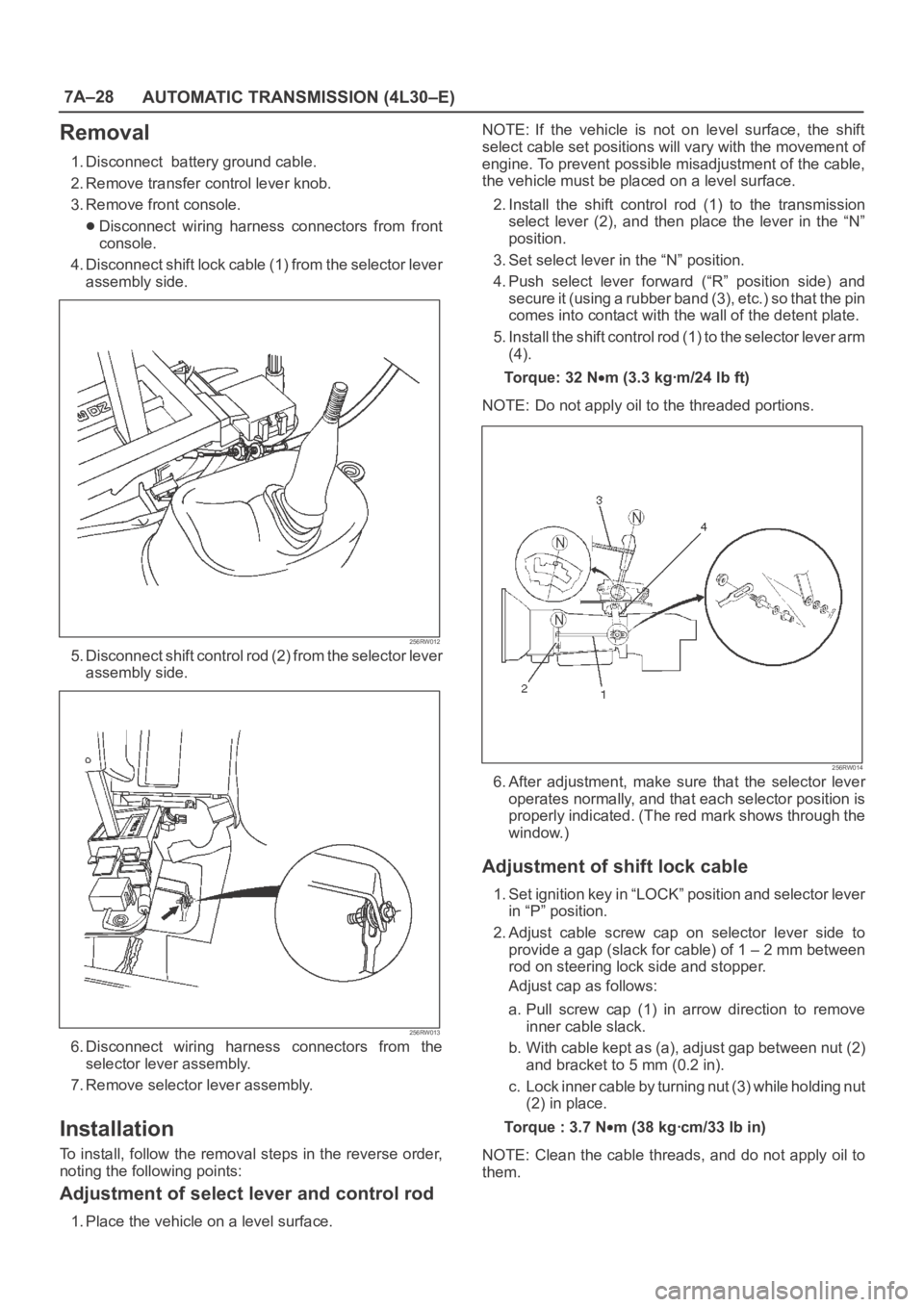

Removal

1. Disconnect battery ground cable.

2. Remove transfer control lever knob.

3. Remove front console.

Disconnect wiring harness connectors from front

console.

4. Disconnect shift lock cable (1) from the selector lever

assembly side.

256RW012

5. Disconnect shift control rod (2) from the selector lever

assembly side.

256RW013

6. Disconnect wiring harness connectors from the

selector lever assembly.

7. Remove selector lever assembly.

Installation

To install, follow the removal steps in the reverse order,

noting the following points:

Adjustment of select lever and control rod

1. Place the vehicle on a level surface.NOTE: If the vehicle is not on level surface, the shift

select cable set positions will vary with the movement of

engine. To prevent possible misadjustment of the cable,

the vehicle must be placed on a level surface.

2. Install the shift control rod (1) to the transmission

select lever (2), and then place the lever in the “N”

position.

3. Set select lever in the “N” position.

4. Push select lever forward (“R” position side) and

s e c u r e i t ( u s i n g a r u b b e r b a n d ( 3 ) , e t c . ) s o t h a t t h e p i n

comes into contact with the wall of the detent plate.

5. Install the shift control rod (1) to the selector lever arm

(4).

To r q u e : 3 2 N

m (3.3 kgꞏm/24 lb ft)

NOTE: Do not apply oil to the threaded portions.

256RW014

6. After adjustment, make sure that the selector lever

operates normally, and that each selector position is

properly indicated. (The red mark shows through the

window.)

Adjustment of shift lock cable

1. Set ignition key in “LOCK” position and selector lever

in “P” position.

2. Adjust cable screw cap on selector lever side to

provide a gap (slack for cable) of 1 – 2 mm between

rod on steering lock side and stopper.

Adjust cap as follows:

a. Pull screw cap (1) in arrow direction to remove

inner cable slack.

b. With cable kept as (a), adjust gap between nut (2)

and bracket to 5 mm (0.2 in).

c. Lock inner cable by turning nut (3) while holding nut

(2) in place.

Torque : 3.7 N

m (38 kgꞏcm/33 lb in)

NOTE: Clean the cable threads, and do not apply oil to

them.

Page 2183 of 6000

7A–29 AUTOMATIC TRANSMISSION (4L30–E)

256RW015

3. Check the shift lock operation:

a. Selector lever should not move out of “P” position

with ignition key in “Lock” position.

b. Selector lever can be moved out of “P” position with

ignition key in “ON” position only when brake pedal

is depressed.

c. Ignition key can be turned to “LOCK” position only

when selector lever is in “P” position (key can be

pulled out).

If (a) and (c) fail, readjust cable. If (b) fails, readjust

connector wiring and brake pedal switch.

Mode Switch

Removal

1. Place selector lever in neutral.

2. Disconnect battery ground cable.

3. Remove mode switch cover (1).

4. Disconnect selector lever (2) from the mode switch.

5. Disconnect transmission harness from the mode

switch connector (3).

6. Remove bracket with mode switch connector from

the transmission case.

7. Remove mode switch connector (3) from the bracket

(4).

8. Remove two mode switch bolts and nut then remove

mode switch (5).

210RW008

Installation

To install, follow the removal steps in the reverse order,

noting the following points;

1. Torque

Mode switch bolt: 13 N

m(1.3kgꞏm/113lbin)

Selector lever nut: 23 N

m (2.3 kgꞏm/17 lb ft)

2. Mode switch setting procedure

Perform either of the following adjustment

procedures:

Procedure 1

a. Place selector lever in neutral.

b. Remove selector lever from the mode switch.

c. Remove the mode switch cover.

d. Loosen the two 10 mm screws.

e. Rotate the mode switch until the slot in the mode

switch housing aligns with the selector shaft

bushing, and insert a 3/32 in. (2.4 mm) drill bit or

punch (1) into the slot.

f. Tighten the screws to 13 Nꞏm (1.3 kgꞏm/113 lb in).

g. After completing adjustment, snap the mode

switch cover into place.

h. Reinstall the selector lever.

Page 2564 of 6000

LIGHTING SYSTEM8A–25

Seat Heater Switch

Removal

1. Disconnect the battery ground cable.

2. Remove four fixing screws and disconnect the switch

connectors to remove the front console assembly(4).

3. Push the lock from the back side of the front console

assembly to remove the seat heater switch(5).

825RW025

Installation

To install, follow the removal steps in the reverse order,

noting the following point.

1. Push the switch with your fingers until it locks

securely.

Key Remind Switch (Starter Switch)

Removal and Installation

Refer to the removal and installation on steps of the

Starter Switch in this section.

Page 2647 of 6000

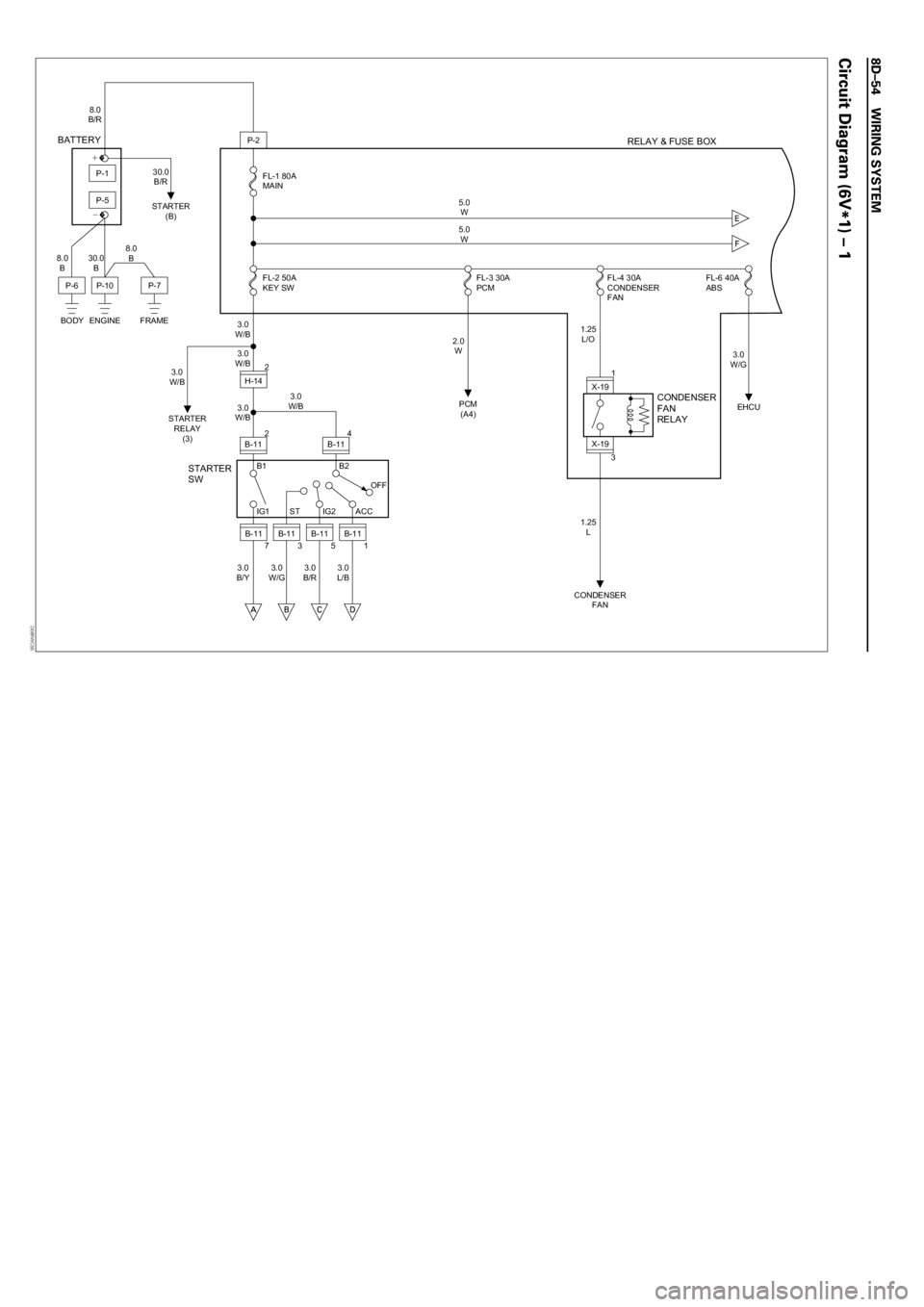

3

P-2

H-142

2

B-11

P-10P-7

PCM

(A4)

CONDENSER

FANEHCU STARTER

(B)

STARTER

RELAY

(3)

P-6

BODY ENGINE FRAME

BATTERY

STARTER

SWRELAY & FUSE BOX

CONDENSER

FAN

RELAY

FL-2 50A

KEY SWFL-3 30A

PCMFL-4 30A

CONDENSER

FANFL-6 40A

ABS FL-1 80A

MAIN 8.0

B/R

8.0

B30.0

B8.0

B30.0

B/R

3.0

W/B

3.0

W/B

3.0

W/B

3.0

B/Y3.0

W/G3.0

B/R3.0

L/B2.0

W1.25

L/O

1.25

L3.0

W/G

3.0

W/B5.0

W

5.0

W

3.0

W/B

B-11IG1 ST IG2 ACC B1

7B-11

3B-11

5B-11

1

B2

OFF 4

B-11

P-5

P-1�+

�−

X-191

X-19

D08RWC56.

Page 2652 of 6000

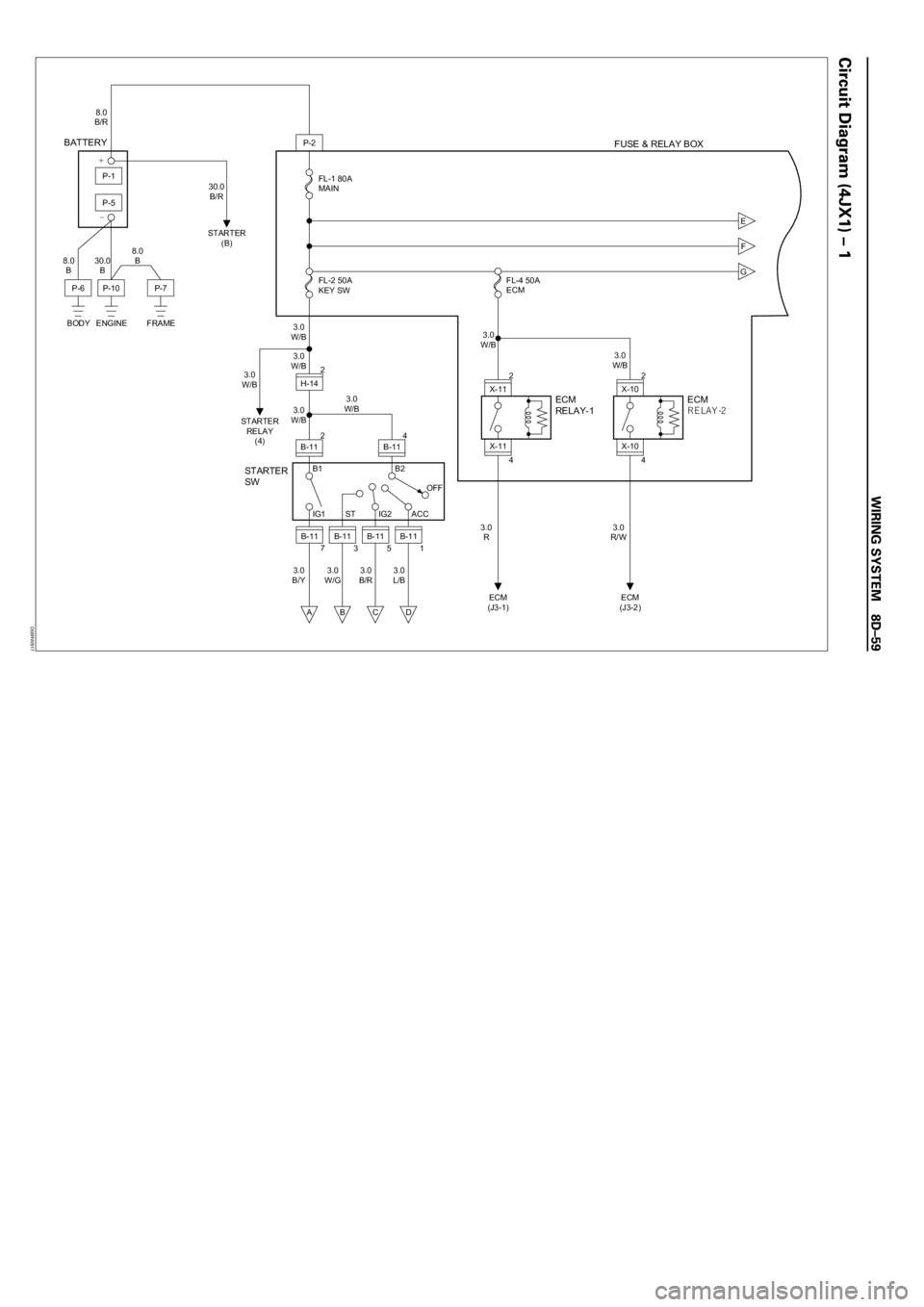

P-2

H-142

2

B-11

P-10P-7

STARTER

RELAY

(4)

P-6

BODY ENGINE FRAME

BATTERY

STARTER

SWFUSE & RELAY BOX

FL-2 50A

KEY SW FL-1 80A

MAIN 8.0

B/R

8.0

B30.0

B8.0

B

3.0

W/B

3.0

W/B

3.0

W/B

3.0

B/Y3.0

W/G3.0

B/R3.0

L/B 3.0

W/B 3.0

W/B 30.0

B/R

B-11IG1 ST IG2 ACC B1

7

E

F

G

A

B-11

3

B

B-11

5

C

B-11

1

D

B2

OFF 4

B-11

STARTER

(B)

P-5

P-1+

−

X-112

4

X-11

ECM

(J3-1)

ECM

RELAY-1

FL-4 50A

ECM

3.0

R 3.0

W/B

X-102

4

X-10

ECM

(J3-2)

ECM

RELAY-2

3.0

R/W3.0

W/B

D08RWB17

Page 2653 of 6000

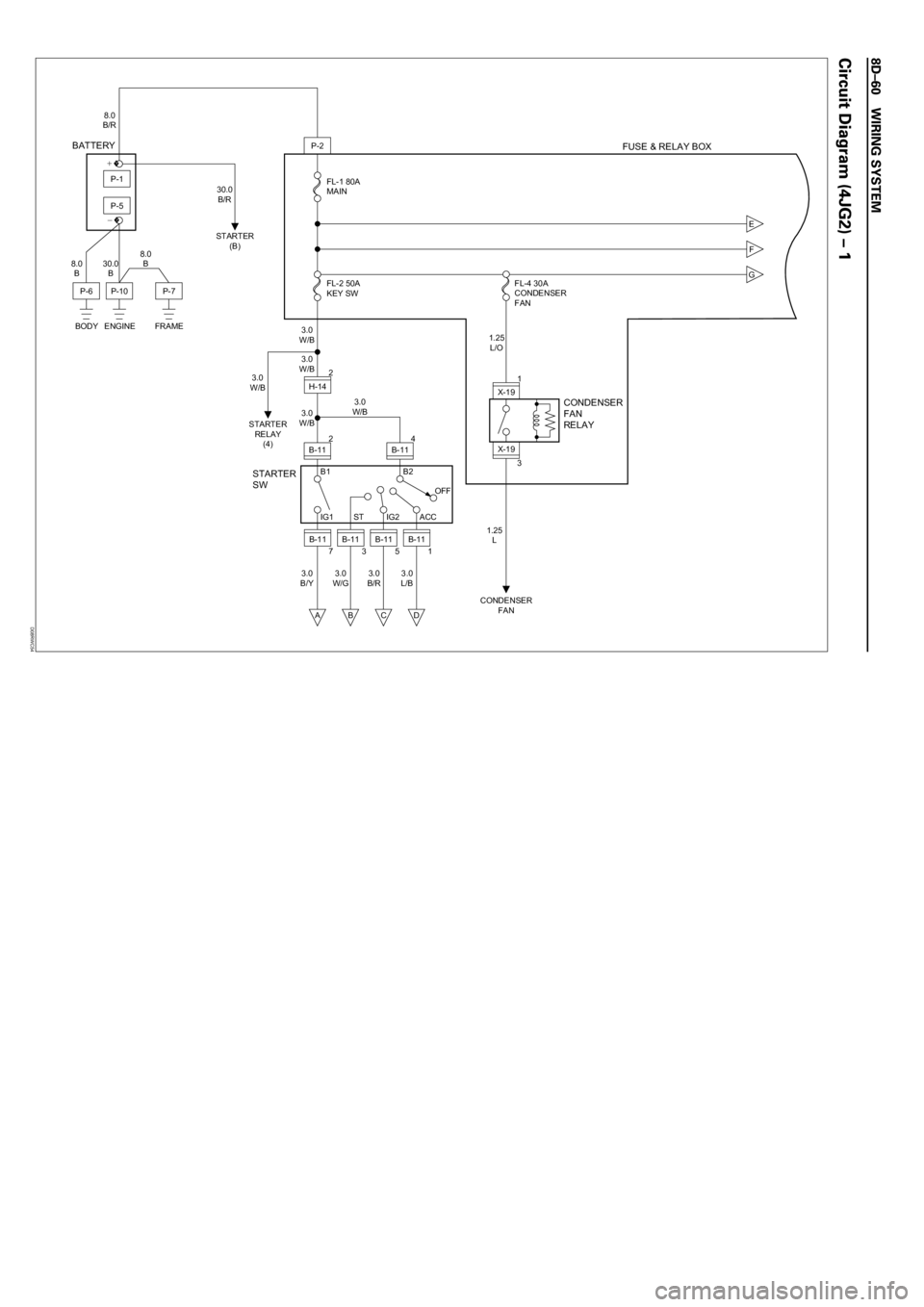

P-2

H-142

2

B-11

P-10P-7

STARTER

RELAY

(4)

P-6

BODY ENGINE FRAME

BATTERY

STARTER

SWFUSE & RELAY BOX

FL-2 50A

KEY SW FL-1 80A

MAIN 8.0

B/R

8.0

B30.0

B8.0

B

3.0

W/B

3.0

W/B

3.0

W/B

3.0

B/Y3.0

W/G3.0

B/R3.0

L/B 3.0

W/B 3.0

W/B 30.0

B/R

B-11IG1 ST IG2 ACC B1

7

E

F

G

A

B-11

3

B

B-11

5

C

B-11

1

D

B2

OFF 4

B-11

STARTER

(B)

P-5

P-1�+

�−

X-191

3

X-19

CONDENSER

FAN

CONDENSER

FAN

RELAY

FL-4 30A

CONDENSER

FAN

1.25

L 1.25

L/O

D08RWC54