service indicator OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2155 of 6000

7A–1 AUTOMATIC TRANSMISSION (4L30–E)

TRANSMISSION

AUTOMATIC TRANSMISSION (4L30–E)

CONTENTS

Service Precaution 7A–3. . . . . . . . . . . . . . . . . . . . . .

Construction 7A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Range Reference Chart 7A–4. . . . . . . . . . . . . . . . . .

Normal Operation Of 1998 4L30–E

Transmission 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver Information 7A–5. . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis Procedure 7A–8. . . . . . . . . . . . .

Preliminary Inspection Chart 7A–9. . . . . . . . . . . . . .

Checking Transmission Fluid Level and

Condition 7A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Driving 7A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis Check Trans

Indicator Chart 7A–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis Symptoms

Index 7A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stall Test 7A–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Pressure Test 7A–23. . . . . . . . . . . . . . . . . . . . . .

Shift Speed Chart 7A–24. . . . . . . . . . . . . . . . . . . . . . .

Lockup Speed Chart 7A–26. . . . . . . . . . . . . . . . . . . . .

Changing Transmission Fluid 7A–27. . . . . . . . . . . . .

Selector Lever 7A–27. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 7A–27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (With Transfer Case) 7A–31. . . . . . . .

Transmission And Associated Parts 7A–31. . . . . .

Removal 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Main Case Valve Body) 7A–36. . . . . . . . .

Removal 7A–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Adapter Case Valve Body) 7A–37. . . . . . .

Removal 7A–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Main Case) 7A–38. . . . . . . .

Removal 7A–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Adapter Case) 7A–40. . . . . .

Removal 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powertrain Control Module (PCM) 7A–40. . . . . . . . . Removal 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Sensor (Extension Housing) 7A–41. . . . . . . .

Removal 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Oil Temperature Sensor

(Adapter Case) 7A–41. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–42. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Oil Seal (Converter Housing) 7A–42. . . . . . . .

Removal 7A–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–42. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal (Extension Housing) 7A–43. . . . . . . . .

Removal 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (4L30–E) 7A–43. . . . . . . . . . . . . . . . . .

Disassembly 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 7A–47. . . . . . . . . . . . . . . . . . . . . . . . . .

Converter Housing And Oil Pump Assembly 7A–57

Disassembled View 7A–57. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–57. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–57. . . . . . . . . . . . . . . . . .

Reassembly 7A–57. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 7A–58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–58. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–58. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–58. . . . . . . . . . . . . . . . . .

Reassembly 7A–58. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Case Valve Body 7A–59. . . . . . . . . . . . . . . . . . .

Disassembled View 7A–59. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–59. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–60. . . . . . . . . . . . . . . . . .

Reassembly 7A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Adapter Case Valve Body 7A–61. . . . . . . . . . . . . . . .

Disassembled View 7A–61. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–61. . . . . . . . . . . . . . . . . .

Reassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Third Clutch And Sprag Unit 7A–63. . . . . . . . . . . . . .

Disassembled View 7A–63. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–63. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–64. . . . . . . . . . . . . . . . . .

Reassembly 7A–64. . . . . . . . . . . . . . . . . . . . . . . . . .

Third Clutch 7A–65. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2181 of 6000

7A–27 AUTOMATIC TRANSMISSION (4L30–E)

Changing Transmission Fluid

There is no need to change the transmission fluid unless

the transmission is used under one or more of the

following heavy duty conditions.

A. Repeated short trips

B. Driving on rough roads

C. Driving on dusty roads

D. Towing a trailer

If the vehicle is used under these conditions, change the

fluid every 20,000 miles (32,000 km.)

More over, the remaining life percentage of ATF can be

estimated by using Tech 2 as an auxiliary tool to judge the

right time for ATF replacement.

The remaining life percentage is calculated from ATF’S

heat history. When it is close to 0%, ATF replacement is

recommended.

1. Place a large drain pan under the oil pan.

2. Remove the transmission oil drain screw (2) and drain

fluid.

3. Tighten drain screw (2).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

4. Remove the transmission overfill screw (1) and fill

transmission through overfill screw opening, using

DEXRON

–III ATF.

NOTE: Add transmission fluid until it flows out over the

overfill screw opening.

5. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached.6. Add transmission fluid until it flows out over the overfill

screw opening, then close the overfill screw (1).

To r q u e : 3 8 N

m (3.9 kgꞏm/28 lb ft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.

NOTE: Check transmission fluid temperature with

service scan tool.

242RW003

Selector Lever

Inspection

1. Make sure that when the shifter control lever is shifted

from “P” to “L”, a “clicking” can be felt at each shift

position. Make sure that the gear corresponds to that

of the position plate indicator.

2. Check to see if the shifter lever can be shifted as

shown in illustration.

C07RW009

Page 2246 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–1

TRANSMISSION

TRANSMISSION CONTROL SYSTEM (4L30–E)

CONTENTS

Service Precaution 7A1–2. . . . . . . . . . . . . . . . . . . . . .

General Description 7A1–2. . . . . . . . . . . . . . . . . . . . .

Shift Control 7A1–6. . . . . . . . . . . . . . . . . . . . . . . . . .

Band Apply Control 7A1–6. . . . . . . . . . . . . . . . . . . .

Torque Converter Clutch Control 7A1–6. . . . . . . . .

Line Pressure Control 7A1–6. . . . . . . . . . . . . . . . . .

On–Board Diagnostic System 7A1–6. . . . . . . . . . .

Fail Safe Mechanism 7A1–6. . . . . . . . . . . . . . . . . . .

Torque Management Control 7A1–6. . . . . . . . . . . .

ATF Warning Control 7A1–6. . . . . . . . . . . . . . . . . . .

ABS Control (If equipped) 7A1–6. . . . . . . . . . . . . .

Winter Drive Mode 7A1–9. . . . . . . . . . . . . . . . . . . . .

Backup Mode 7A1–9. . . . . . . . . . . . . . . . . . . . . . . . .

Functions of Input / Output Components 7A1–10. .

Diagnosis 7A1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Trans Indicator 7A1–11. . . . . . . . . . . . . . . . . .

Diagnostic Check 7A1–11. . . . . . . . . . . . . . . . . . . . . .

“Check Trans” Check 7A1–12. . . . . . . . . . . . . . . . . .

Tech2 OBD II Connection 7A1–13. . . . . . . . . . . . . . .

OBD II Diagnostic Management System 7A1–18. .

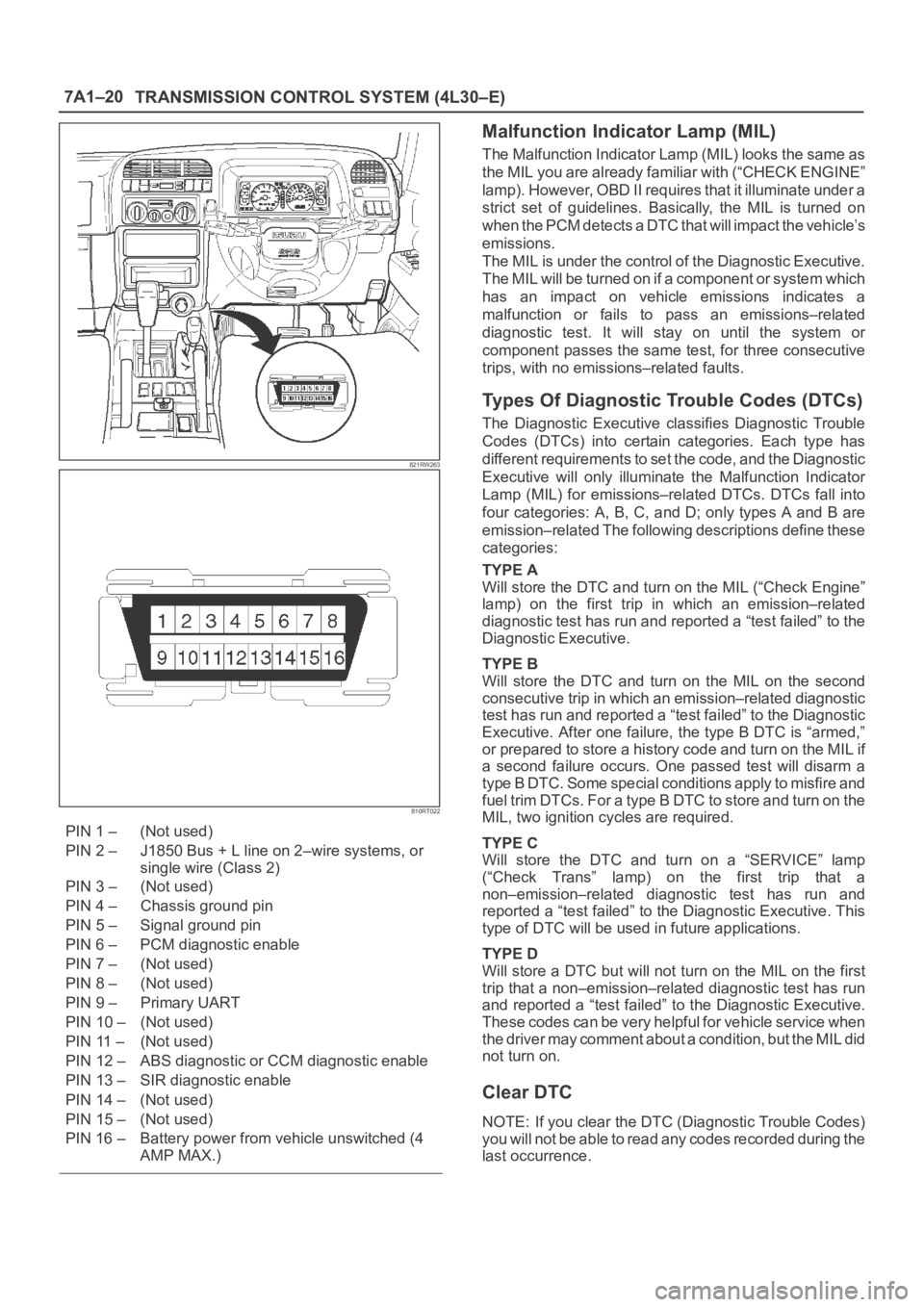

16 – Terminal Data Link Connector (DLC) 7A1–19.

Malfunction Indicator Lamp (MIL) 7A1–20. . . . . . . .

Types Of Diagnostic Trouble Codes

(DTCs) 7A1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clear DTC 7A1–20. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC Check 7A1–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

PCM Precaution 7A1–21. . . . . . . . . . . . . . . . . . . . . . .

Information On PCM 7A1–21. . . . . . . . . . . . . . . . . . .

Intermittent Conditions 7A1–21. . . . . . . . . . . . . . . . .

Transmission And PCM Identification 7A1–22. . . . .

Diagnostic Trouble Code (DTC)

Identification 7A1–24. . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0218 Transmission Fluid Over

Temperature 7A1–25. . . . . . . . . . . . . . . . . . . . . . . . . . . Conditions For Setting The DTC 7A1–25. . . . . . . . .

Action Taken When The DTC Sets 7A1–25. . . . . . .

Conditions For Clearing The DTC 7A1–25. . . . . . . .

Diagnostic Aids 7A1–25. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 7A1–25. . . . . . . . . . . . . . . . . . . . . . .

DTC P0560 System Voltage Malfunction 7A1–27. . .

DTC P0705 Transmission Range Switch

(Mode Switch) Illegal Position 7A1–30. . . . . . . . . . . .

DTC P0706 Transmission Range Switch

(Mode Switch) Performance 7A1–33. . . . . . . . . . . . . .

DTC P0712 Transmission Fluid Temperature

(TFT) Sensor Circuit Low Input 7A1–36. . . . . . . . . . .

DTC P0713 Transmission Fluid Temperature

(TFT) Sensor Circuit High Input 7A1–39. . . . . . . . . . .

DTC P0719 TCC Brake Switch Circuit High

(Stuck On) 7A1–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0722 Transmission Output Speed

Sensor (OSS) Low Input 7A1–45. . . . . . . . . . . . . . . . .

DTC P0723 Transmission Output Speed

Sensor (OSS) Intermittent 7A1–48. . . . . . . . . . . . . . .

DTC P0730 Transmission Incorrect

Gear Ratio 7A1–51. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P0748 Pressure Control Solenoid

(PCS) (Force Motor) Circuit Electrical 7A1–54. . . . .

DTC P0753 Shift Solenoid A Electrical 7A1–56. . . . .

DTC P0758 Shift Solenoid B Electrical 7A1–59. . . . .

DTC P1790 ROM Transmission Side Bad

Check Sum 7A1–63. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1792 EEPROM Transmission Side

Bad Check Sum 7A1–64. . . . . . . . . . . . . . . . . . . . . . . .

DTC P1835 Kickdown Switch Always On 7A1–65. . .

DTC P1850 Brake Band Apply Solenoid

Malfunction 7A1–67. . . . . . . . . . . . . . . . . . . . . . . . . . . .

DTC P1860 TCC Solenoid Electrical 7A1–71. . . . . . .

Page 2265 of 6000

7A1–20

TRANSMISSION CONTROL SYSTEM (4L30–E)

821RW263

810RT022

PIN 1 – (Not used)

PIN 2 – J1850 Bus + L line on 2–wire systems, or

single wire (Class 2)

PIN 3 – (Not used)

PIN 4 – Chassis ground pin

PIN 5 – Signal ground pin

PIN 6 – PCM diagnostic enable

PIN 7 – (Not used)

PIN 8 – (Not used)

PIN 9 – Primary UART

PIN 10 – (Not used)

PIN 11 – (Not used)

PIN 12 – ABS diagnostic or CCM diagnostic enable

PIN 13 – SIR diagnostic enable

PIN 14 – (Not used)

PIN 15 – (Not used)

PIN 16 – Battery power from vehicle unswitched (4

AMP MAX.)

Malfunction Indicator Lamp (MIL)

The Malfunction Indicator Lamp (MIL) looks the same as

the MIL you are already familiar with (“CHECK ENGINE”

lamp). However, OBD II requires that it illuminate under a

strict set of guidelines. Basically, the MIL is turned on

when the PCM detects a DTC that will impact the vehicle’s

emissions.

The MIL is under the control of the Diagnostic Executive.

The MIL will be turned on if a component or system which

has an impact on vehicle emissions indicates a

malfunction or fails to pass an emissions–related

diagnostic test. It will stay on until the system or

component passes the same test, for three consecutive

trips, with no emissions–related faults.

Types Of Diagnostic Trouble Codes (DTCs)

The Diagnostic Executive classifies Diagnostic Trouble

Codes (DTCs) into certain categories. Each type has

different requirements to set the code, and the Diagnostic

Executive will only illuminate the Malfunction Indicator

Lamp (MIL) for emissions–related DTCs. DTCs fall into

four categories: A, B, C, and D; only types A and B are

emission–related The following descriptions define these

categories:

TYPE A

Will store the DTC and turn on the MIL (“Check Engine”

lamp) on the first trip in which an emission–related

diagnostic test has run and reported a “test failed” to the

Diagnostic Executive.

TYPE B

Will store the DTC and turn on the MIL on the second

consecutive trip in which an emission–related diagnostic

test has run and reported a “test failed” to the Diagnostic

Executive. After one failure, the type B DTC is “armed,”

or prepared to store a history code and turn on the MIL if

a second failure occurs. One passed test will disarm a

type B DTC. Some special conditions apply to misfire and

fuel trim DTCs. For a type B DTC to store and turn on the

MIL, two ignition cycles are required.

TYPE C

Will store the DTC and turn on a “SERVICE” lamp

(“Check Trans” lamp) on the first trip that a

non–emission–related diagnostic test has run and

reported a “test failed” to the Diagnostic Executive. This

type of DTC will be used in future applications.

TYPE D

Will store a DTC but will not turn on the MIL on the first

trip that a non–emission–related diagnostic test has run

and reported a “test failed” to the Diagnostic Executive.

These codes can be very helpful for vehicle service when

the driver may comment about a condition, but the MIL did

not turn on.

Clear DTC

NOTE: If you clear the DTC (Diagnostic Trouble Codes)

you will not be able to read any codes recorded during the

last occurrence.

Page 3178 of 6000

METER AND GAUGE8E–1

METER AND GAUGE

CONTENTS

Service Precaution 8E–1. . . . . . . . . . . . . . . . . . . . . .

General Description 8E–1. . . . . . . . . . . . . . . . . . . . .

Meter Assembly 8E–2. . . . . . . . . . . . . . . . . . . . . . . . .

General Description 8E–2. . . . . . . . . . . . . . . . . . . . .

Layout for Meters/Gauges, Warning Lights,

Indicator Lights and Illumination Lights 8E–2. . .

Table for Meter/Gauge Connector Terminal

Connections 8E–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warning Light Bulb, Indicator Light Bulb,

Illumination Light Bulb, A/T Indicator

Light Bulb 8E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . Vehicle Speed Sensor 8E–15. . . . . . . . . . . . . . . . . . .

Removal 8E–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank Unit 8E–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8E–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi Meter 8E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ambient Sensor 8E–16. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8E–16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 8E–17. . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

The circuit consists of the starter switch, meter assembly,

vehicle speed sensor, transmission switch, lighting

switch, turn signal switch, thermo unit, oil pressure unit,

Powertrain Control Module (PCM), fuel tank unit, 4WD

switch, oil pressure switch, parking brake switch, brake

fluid switch, seat belt switch, illumination controller, multi

meter and ambient sensor.

Page 3340 of 6000

SECURITY AND LOCKS8H–1

BODY AND ACCESSORIES

SECURITY AND LOCKS

CONTENTS

Service Precaution 8H–2. . . . . . . . . . . . . . . . . . . . . .

Front Door Lock Assembly 8H–2. . . . . . . . . . . . . . .

Front Door Lock Assembly and

Associated Parts 8H–2. . . . . . . . . . . . . . . . . . . . . .

Removal 8H–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8H–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Outside Handle and Door Lock Cylinder 8H–4

Front Outside Handle, Door Lock Cylinder

and Associated Parts 8H–4. . . . . . . . . . . . . . . . . .

Removal 8H–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8H–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Door Lock Assembly 8H–7. . . . . . . . . . . . . . . .

Rear Door Lock Assembly and Associated

Parts 8H–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 8H–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8H–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Outside Handle 8H–9. . . . . . . . . . . . . . . . . . . .

Rear Outside Handle and Associated Parts 8H–9

Removal 8H–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8H–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Door Inside Lock Knob Link 8H–10. . . . . . . . . .

Removal 8H–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8H–10. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Inside Lock Knob 8H–11. . . . . . . . . . . . . . . . . . .

Removal 8H–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8H–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Door Inside Handle 8H–11. . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 8H–11. . . . . . . . . . . . . . .

Tailgate Lock Assembly (LH) 8H–12. . . . . . . . . . . . . .

Tailgate Lock Assembly (LH) and

Associated Parts 8H–12. . . . . . . . . . . . . . . . . . . . . .

Removal 8H–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8H–13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tailgate Lock Assembly (RH) 8H–14. . . . . . . . . . . . .

Tailgate Lock Assembly (RH) and

Associated Parts 8H–14. . . . . . . . . . . . . . . . . . . . . .

Removal 8H–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8H–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tailgate Inside Lock Knob 8H–15. . . . . . . . . . . . . . . .

Removal 8H–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 8H–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tailgate Inside Handle 8H–16. . . . . . . . . . . . . . . . . . .

Parts Location 8H–16. . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 8H–16. . . . . . . . . . . . . . .

Tailgate Outside Handle and/or Tailgate

Lock Cylinder 8H–17. . . . . . . . . . . . . . . . . . . . . . . . . .

Tailgate Outside Handle and/or Tailgate

Lock Cylinder and Associated Parts 8H–17. . . . .

Removal 8H–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8H–18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key 8H–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Coding 8H–19. . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Styles 8H–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Door Lock System 8H–20. . . . . . . . . . . . . . . .

General Description 8H–20

. . . . . . . . . . . . . . . . . . . . . .

Front Door Lock Actuator Removal 8H–20. . . . . .

Front Door Lock Actuator Installation 8H–20. . . . .

Rear Door Lock Actuator Removal 8H–20. . . . . . .

Rear Door Lock Actuator Installation 8H–21. . . . .

Tailgate Lock Actuator Removal 8H–21. . . . . . . . .

Tailgate Lock Actuator Installation 8H–21. . . . . . .

Anti-theft System 8H–22. . . . . . . . . . . . . . . . . . . . . . . .

General Description 8H–22. . . . . . . . . . . . . . . . . . . . . .

Anti-theft & Keyless Entry Control Unit

Removal 8H–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Anti-theft & Keyless Entry Control Unit

Installation 8H–22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Anti-theft Indicator Removal 8H–22. . . . . . . . . . . . .

Anti-theft Indicator Installation 8H–23. . . . . . . . . . .

Anti-theft Horn Removal 8H–23. . . . . . . . . . . . . . . .

Anti-Theft Horn Installation 8H–23. . . . . . . . . . . . . .

Engine Hood Switch Removal 8H–23. . . . . . . . . . .

Engine Hood Switch Installation 8H–23. . . . . . . . .

Keyless Entry System 8H–24. . . . . . . . . . . . . . . . . . . .

ID Code Registration 8H–24. . . . . . . . . . . . . . . . . . .

Answer Back (Anti–theft Horn Operation)

Change Mode 8H–26. . . . . . . . . . . . . . . . . . . . . . . .

Anti–theft & Keyless Entry Control

Unit/Transmitter Replacement 8H–27. . . . . . . . . .

Main Data and Specifications 8H–28. . . . . . . . . . . . .

Page 3552 of 6000

10A–1

CRUISE CONTROL SYSTEM

CONTROL SYSTEM

CRUISE CONTROL SYSTEM

CONTENTS

Service Precaution 10A–1. . . . . . . . . . . . . . . . . . . . . .

General Description 10A–1. . . . . . . . . . . . . . . . . . . . .

Diagnosis 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Brake Switch 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Switch 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 10A–3. . . . . . . . . . . . . . .

Adjustment 10A–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Starter Switch 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Control Main Switch 10A–5. . . . . . . . . . . . . . . Removal 10A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Control Switch (Combination Switch) 10A–5

Removal and Installation 10A–5. . . . . . . . . . . . . . .

Cruise Control Unit 10A–6. . . . . . . . . . . . . . . . . . . . . .

Removal 10A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cruise Actuator 10A–7. . . . . . . . . . . . . . . . . . . . . . . . .

Actuator Cable Diagram (LHD) 10A–7. . . . . . . . . .

Actuator Cable Diagram (RHD) 10A–7. . . . . . . . . .

Removal 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 10A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal and Installation 10A–8. . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

The cruise control keeps the vehicle running at a fixed

speed until a signal canceling this fixed speed is received .

When the main switch “AUTO CRUISE” is turned on with

the vehicle in the running mode, the battery voltage is

applied to the control unit. When a signal from the control

switch is input to the control unit while the vehicle is in this

state, the cruise control actuator is activated to operate

the system. Also, while the system is operating, the

“AUTO CRUISE” indicator light in the meter assembly

lights up.

1. SET/COAST Switch Function

1.Set Function: When the SET/COAST switch is

pressed and released with the main switch on, the

speed at which the vehicle is running at that moment

is stored in the memory, and the vehicle automatically

runs at the stored speed.

2.Coast-down Function: When the SET/COAST

switch is kept on while the vehicle in running, the

vehicle decelerates during that time. The speed at

which vehicle is running when the control switch is

turned off is stored in the memory, and the vehicle

automatically returns to the stored speed.

3.Tap-down Function: When the SET/COAST switch

is turned on and off instantaneously while the vehicle

is running, the vehicle decelerates a mile for each

on/off operation. The vehicle speed at which the

vehicle was running when the SET/COAST was

turned off last is stored in the memory, and the vehicle

automatically returns to this stored speed.

Page 4046 of 6000

4B1–1 DRIVE LINE CONTROL SYSTEM (SHIFT ON THE FLY)

DRIVELINE/AXLE

DRIVELINE CONTROL SYSTEM (SHIFT ON THE FLY)

CONTENTS

Service Precaution 4B1–1. . . . . . . . . . . . . . . . . . . . . .

Shift on the Fly System (Lever Type) 4B1–2. . . . . . .

Outline of Shift on the Fly System

(Lever Type) 4B1–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift on the Fly Vacuum Piping and Electric

Equipment (For Lever Control Type) 4B1–3. . . . . .

Vacuum Piping Diagram 4B1–3. . . . . . . . . . . . . . . .

Inspection and Repair 4B1–4. . . . . . . . . . . . . . . . . .

Shift on the Fly System (Push Button Type) 4B1–7.

Outline of Shift on the Fly System

(Push Button Type) 4B1–7. . . . . . . . . . . . . . . . . . . . Functions of Indicator Lamp 4B1–11. . . . . . . . . . . . . . .

Diagnosis 4B1–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Axle Diagnosis 4B1–30. . . . . . . . . . . . . . . . . . .

Shift on the Fly Vacuum Piping and Electric

Equipment (For Push Button Type) 4B1–32. . . . . . . .

Vacuum Piping Diagram 4B1–32. . . . . . . . . . . . . . . .

Inspection and Repair 4B1–33. . . . . . . . . . . . . . . . . .

4WD Control Unit (For Push Button Type) 4B1–36. .

4WD Control Unit Associated Parts 4B1–36. . . . . .

Removal 4B1–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4B1–37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 4084 of 6000

4B2–1 DRIVE LINE CONTROL SYSTEM (TOD)

DRIVELINE/AXLE

DRIVELINE CONTROL SYSTEM (TOD)

CONTENTS

Service Precaution 4B2–1. . . . . . . . . . . . . . . . . . . . . .

General Description 4B2–2. . . . . . . . . . . . . . . . . . . . .

System Components 4B2–4. . . . . . . . . . . . . . . . . . . .

Parts Location 4B2–4. . . . . . . . . . . . . . . . . . . . . . . .

Functions of Indicator Lamp 4B2–8. . . . . . . . . . . . . .

Diagnosis 4B2–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Diagnostic Flow Chart 4B2–17. . . . . . . . . . . . . .

Parts Location 4B2–18. . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram 4B2–22. . . . . . . . . . . . . . . . . . . . . . . . . Connector List 4B2–34. . . . . . . . . . . . . . . . . . . . . . . . . .

Checking Failed Pin 4B2–36. . . . . . . . . . . . . . . . . . . . .

Checking Failed TOD Control Unit Pin 4B2–39. . . . .

Diagnostic Trouble Codes 4B2–43. . . . . . . . . . . . . . . .

Diagnosis from Trouble Codes 4B2–44. . . . . . . . . . . .

Trouble Diagnosis Depending on The Status

of TOD Indicator 4B2–74. . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis from Symptom 4B2–114. . . . . . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 4621 of 6000

6D1–2

ENGINE ELECTRICAL

Battery

General Description

There are six battery fluid caps on top of the battery.

These are covered by a paper label.

The battery is completely sealed except for the six small

vent holes on the side. These vent holes permit the

escape of small amounts of gas generated by the battery.

This type of battery has the following advantages over

conventional batteries:

1. There is no need to add water during the entire

service life of the battery.

2. The battery protects itself against overcharging.

The battery will refuse to accept an extensive charge.

(A conventional battery will accept an excessive

charge, resulting in gassing and loss of battery fluid.)

3. The battery is much less vulnerable to self discharge

than a conventional type battery.

Diagnosis

1. Visual Inspection

Inspect the battery for obvious physical damage, such as

a cracked or broken case, which would permit electrolyte

loss.

Replace the battery if obvious physical damage is

discovered during inspection.

Check for any other physical damage and correct it as

necessary.

2. Hydrometer Check

There is a built–in hydrometer (Charge test indicator(1))

at the top of the battery. It is designed to be used during

diagnostic procedures.

Before trying to read the hydrometer, carefully clean the

upper battery surface.

If your work area is poorly lit, additional light may be

necessary to read the hydrometer.

a. BLUE RING OR DOT VISIBLE(5) – Go to Step 4.

b . B L U E R I N G O R D O T N O T V I S I B L E ( 4 ) – G o t o S t e p

3.

061RW001

3. Fluid Level Check

The fluid level should be between the upper level line(2)

and lower level line(3) on side of battery.

a. CORRECT FLUID LEVEL – Charge the battery.

b. BELOW LOWER LEVEL – Replace battery.

061RW001

4. Voltage Check

1. Put voltmeter test leads to battery terminals.

a. VOLTAGE IS 12.4V OR ABOVE – Go to Step 5.

b. VOLTAGE IS UNDER 12.4V – Go to procedure (2)

below.

2. Determine fast charge amperage from specification.

(See Main Data and Specifications in this section).

Fast charge battery for 30 minutes at amperage rate

no higher than specified value.

Take voltage and amperage readings after charge.

a. VOLTAGE IS ABOVE 16V AT BELOW 1/3 OF

AMPERAGE RATE – Replace battery.

b. VOLTAGE IS ABOVE 16V AT ABOVE 1/3 OF

AMPERAGE RATE – Drop charging voltage to

15V and charge for 10 – 15 hours. Then go to Step

5.

c. VOLTAGE IS BETWEEN 12V AND 16V –

Continue charging at the same rate for an

additional 3–1/2 hours. Then go to Step 5.

d. VOLTAGE BELOW 12V – Replace Battery.

5. Load Test

1. Connect a voltmeter and a battery load tester across

the battery terminals.

2. Apply 300 ampere load for 15 seconds to remove

surface charge from the battery. Remove load.

3. Wait 15 seconds to let battery recover. Then apply

specified load from specifications (See Main Data

and Specifications in this section).

Read voltage after 15 seconds, then remove load.