weight OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4999 of 6000

6E–342

ENGINE DRIVEABILITY AND EMISSIONS

PCM to calculate true sequential multiport fuel injection

(SFI). Loss of this signal will set a DTC P0341. If the CMP

signal is lost while the engine is running, the fuel injection

system will shift to a calculated sequential fuel injection

based on the last fuel injection pulse, and the engine will

continue to run. The engine can be restarted and will run

in the calculated sequential mode as long as the fault is

present, with a 1-in-6 chance of being correct.

Clear Flood Mode

Clear a flooded engine by pushing the accelerator pedal

down all the way. The PCM then de-energizes the fuel

injectors. The PCM holds the fuel injectors de-energized

as long as the throttle remains above 80% and the engine

speed is below 800 RPM. If the throttle position becomes

less than 80%, the PCM again begins to pulse the

injectors “ON” and “OFF,” allowing fuel into the cylinders.

Deceleration Mode

The PCM reduces the amount of fuel injected when it

detects a decrease in the throttle position and the air flow.

When deceleration is very fast, the PCM may cut off fuel

completely for short periods.

Engine Speed/Vehicle Speed/Fuel Disable

Mode

The PCM monitors engine speed. It turns off the fuel

injectors when the engine speed increase above 6400

RPM. The fuel injectors are turned back on when engine

speed decreases below 6150 RPM.

Fuel Cutoff Mode

No fuel is delivered by the fuel injectors when the ignition

is “OFF.” This prevents engine run-on. In addition, the

PCM suspends fuel delivery if no reference pulses are

detected (engine not running) to prevent engine flooding.

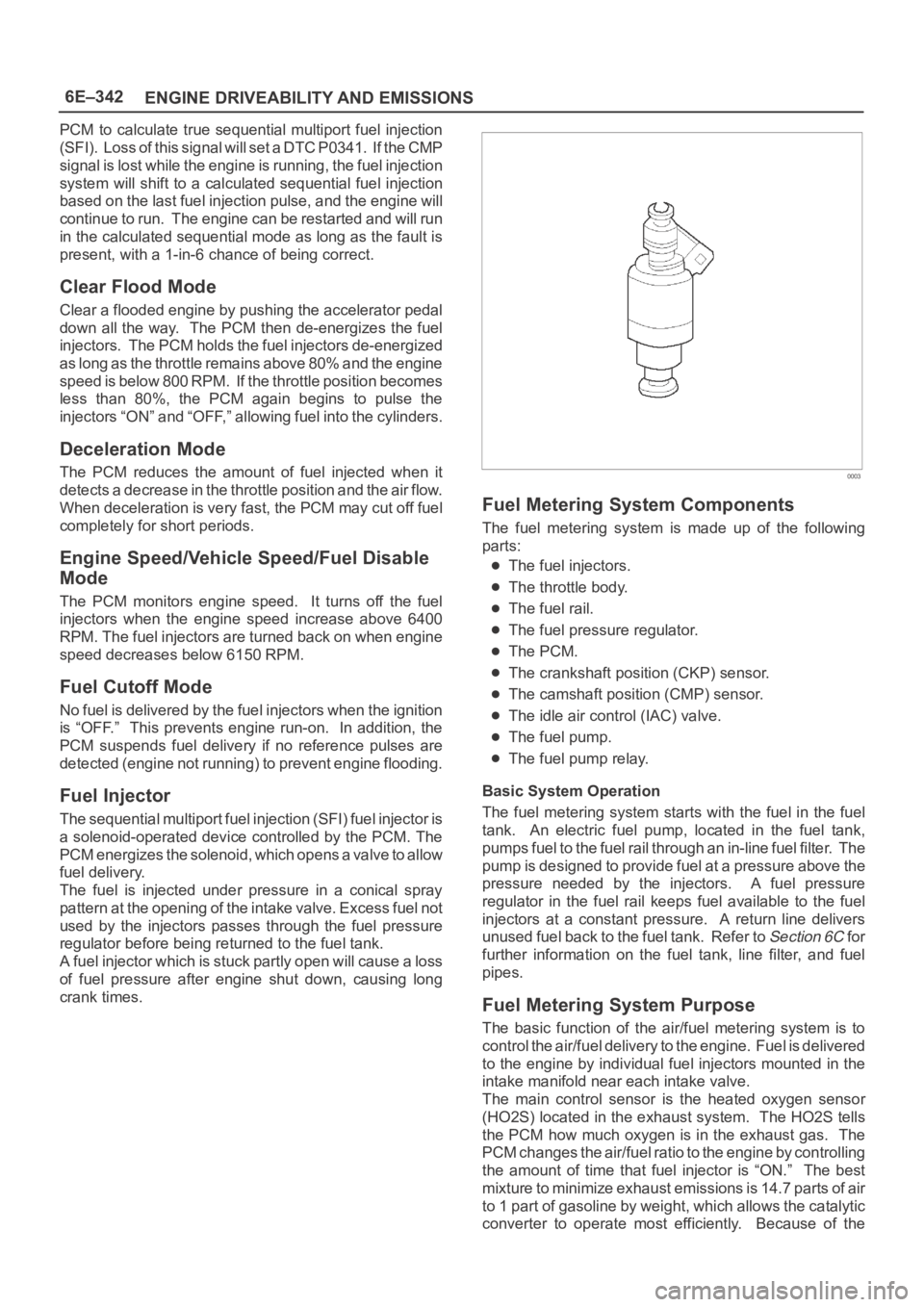

Fuel Injector

The sequential multiport fuel injection (SFI) fuel injector is

a solenoid-operated device controlled by the PCM. The

PCM energizes the solenoid, which opens a valve to allow

fuel delivery.

The fuel is injected under pressure in a conical spray

pattern at the opening of the intake valve. Excess fuel not

used by the injectors passes through the fuel pressure

regulator before being returned to the fuel tank.

A fuel injector which is stuck partly open will cause a loss

of fuel pressure after engine shut down, causing long

crank times.

0003

Fuel Metering System Components

The fuel metering system is made up of the following

parts:

The fuel injectors.

The throttle body.

The fuel rail.

The fuel pressure regulator.

The PCM.

The crankshaft position (CKP) sensor.

The camshaft position (CMP) sensor.

The idle air control (IAC) valve.

The fuel pump.

The fuel pump relay.

Basic System Operation

The fuel metering system starts with the fuel in the fuel

tank. An electric fuel pump, located in the fuel tank,

pumps fuel to the fuel rail through an in-line fuel filter. The

pump is designed to provide fuel at a pressure above the

pressure needed by the injectors. A fuel pressure

regulator in the fuel rail keeps fuel available to the fuel

injectors at a constant pressure. A return line delivers

unused fuel back to the fuel tank. Refer to

Section 6C f o r

further information on the fuel tank, line filter, and fuel

pipes.

Fuel Metering System Purpose

The basic function of the air/fuel metering system is to

control the air/fuel delivery to the engine. Fuel is delivered

to the engine by individual fuel injectors mounted in the

intake manifold near each intake valve.

The main control sensor is the heated oxygen sensor

(HO2S) located in the exhaust system. The HO2S tells

the PCM how much oxygen is in the exhaust gas. The

PCM changes the air/fuel ratio to the engine by controlling

the amount of time that fuel injector is “ON.” The best

mixture to minimize exhaust emissions is 14.7 parts of air

to 1 part of gasoline by weight, which allows the catalytic

converter to operate most efficiently. Because of the

Page 5276 of 6000

ENGINE MECHANICAL 6A – 3

SERVICE INFORMATION

MAIN DATA AND SPECIFICATION

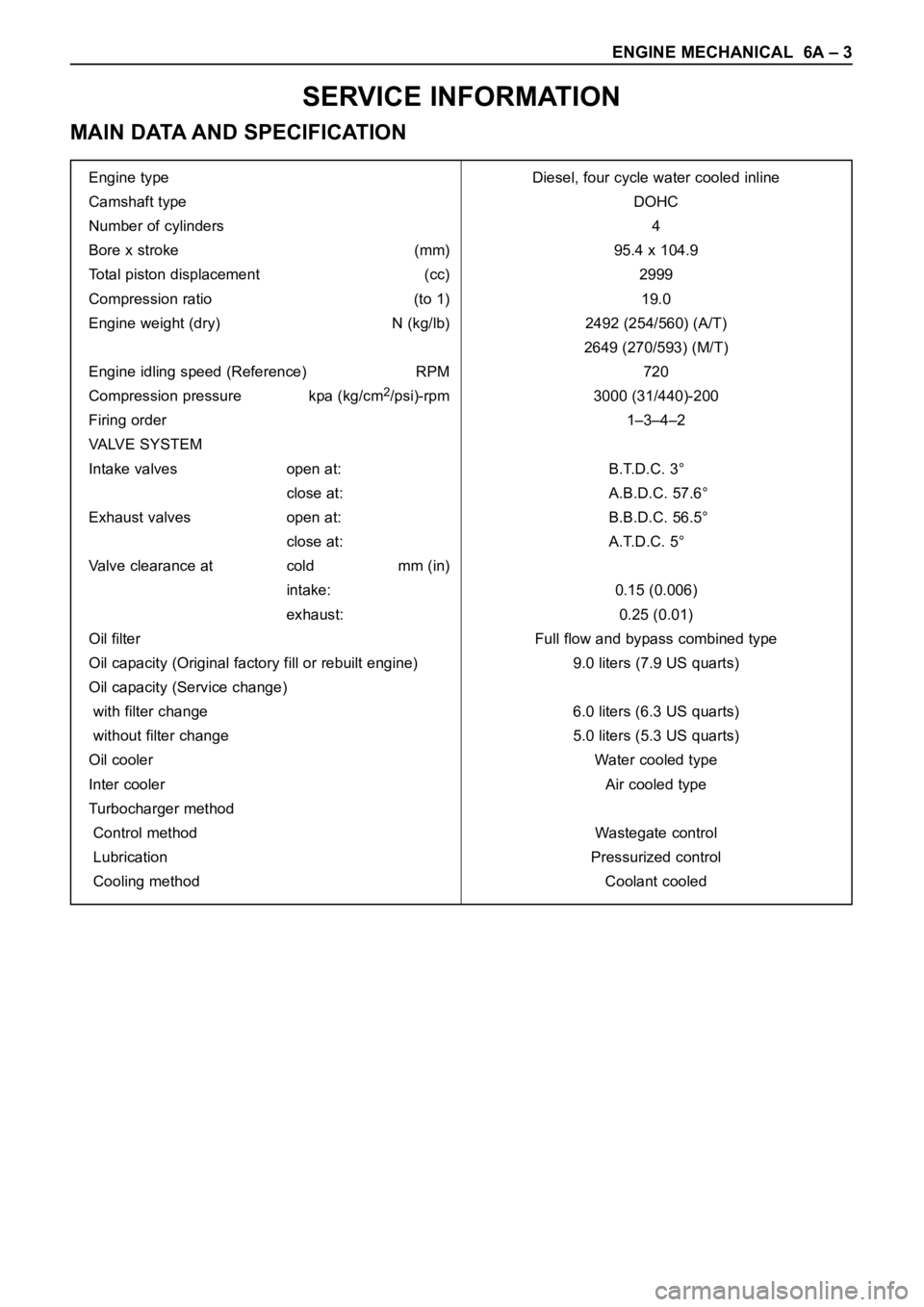

Engine type Diesel, four cycle water cooled inline

Camshaft type DOHC

Number of cylinders 4

Bore x stroke (mm) 95.4 x 104.9

Total piston displacement (cc) 2999

Compression ratio (to 1) 19.0

Engine weight (dry) N (kg/lb) 2492 (254/560) (A/T)

2649 (270/593) (M/T)

Engine idling speed (Reference) RPM 720

Compression pressure kpa (kg/cm

2/psi)-rpm 3000 (31/440)-200

Firing order 1–3–4–2

VALVE SYSTEM

Intake valves open at: B.T.D.C. 3°

close at: A.B.D.C. 57.6°

Exhaust valves open at: B.B.D.C. 56.5°

close at: A.T.D.C. 5°

Valve clearance at cold mm (in)

intake: 0.15 (0.006)

exhaust: 0.25 (0.01)

Oil filter Full flow and bypass combined type

Oil capacity (Original factory fill or rebuilt engine) 9.0 liters (7.9 US quarts)

Oil capacity (Service change)

with filter change 6.0 liters (6.3 US quarts)

without filter change 5.0 liters (5.3 US quarts)

Oil cooler Water cooled type

Inter cooler Air cooled type

Turbocharger method

Control method Wastegate control

Lubrication Pressurized control

Cooling method Coolant cooled

Page 5277 of 6000

6A – 4 ENGINE MECHANICAL

Engine Cooling

Starting System

Cooling system Coolant forced circulation

Radiator (2 tube in row) Tube type corrugated

Heat radiation capacity J/h (kcal/h) 318 x 10

6(76000)

Heat radiation area m

2(ft2) 15.63 (1.454)

Front area m

2(ft2) 0.309 (2.029)

Dry weight N (kg/lb) 83 (8.5/18.7)

Radiator cap

Valve opening pressure kPa (kg/cm

2psi) 93.3 – 122.7 (0.95 – 1.25/13.5 – 17.8)

Coolant capacity lit (Imp.qt./US qt.) M/T 2.5 (2.2/2.6) A/T 2.4 (2.1/2.5)

Coolant pump Centrifugal impeller type

Pulley ratio 1.2

Coolant total capacity lit (Imp.qt./US qt.) 9.3 (8.2/9.8)

Model HITACHI S14-0

Rating

Voltage V 12

Output kW 2.8

Time sec 30

Number of teeth of pinion 9

Rotating direction (as viewed from pinion) Clockwise

Weight (approx.) N(kg/lb) 49 (5.0/11)

No-load characteristics

Voltage/current V/A 11/160 or less

Speed rpm 4000 or more

Load characteristics

Voltage/current V/A 8.76/300

Torque Nꞏm(kgꞏm/lbꞏft) 7.4 (0.75/5.4) or more

Speed rpm 1700 or more

Locking characteristics

Voltage/current V/A 2.5/1100 or less

Torque Nꞏm(kgꞏm/lbꞏft) 18.6 (1.9/14) or more

Page 5278 of 6000

ENGINE MECHANICAL 6A – 5

Charging System

Model (HITACHI) LR160-734B LR170 – 760 LR190 – 750B

Rated voltage V 12

Rated output A 60 70 90

Rotation direction

Clockwise

(As viewed from pulled)

Pulley effective diameter mm (in) 60 (2.36) 69 (2.72)

Weight N (kg/lb) 41 (4.2/9.3) 52 (5.3/11.7)

Page 5358 of 6000

ENGINE MECHANICAL 6A – 85

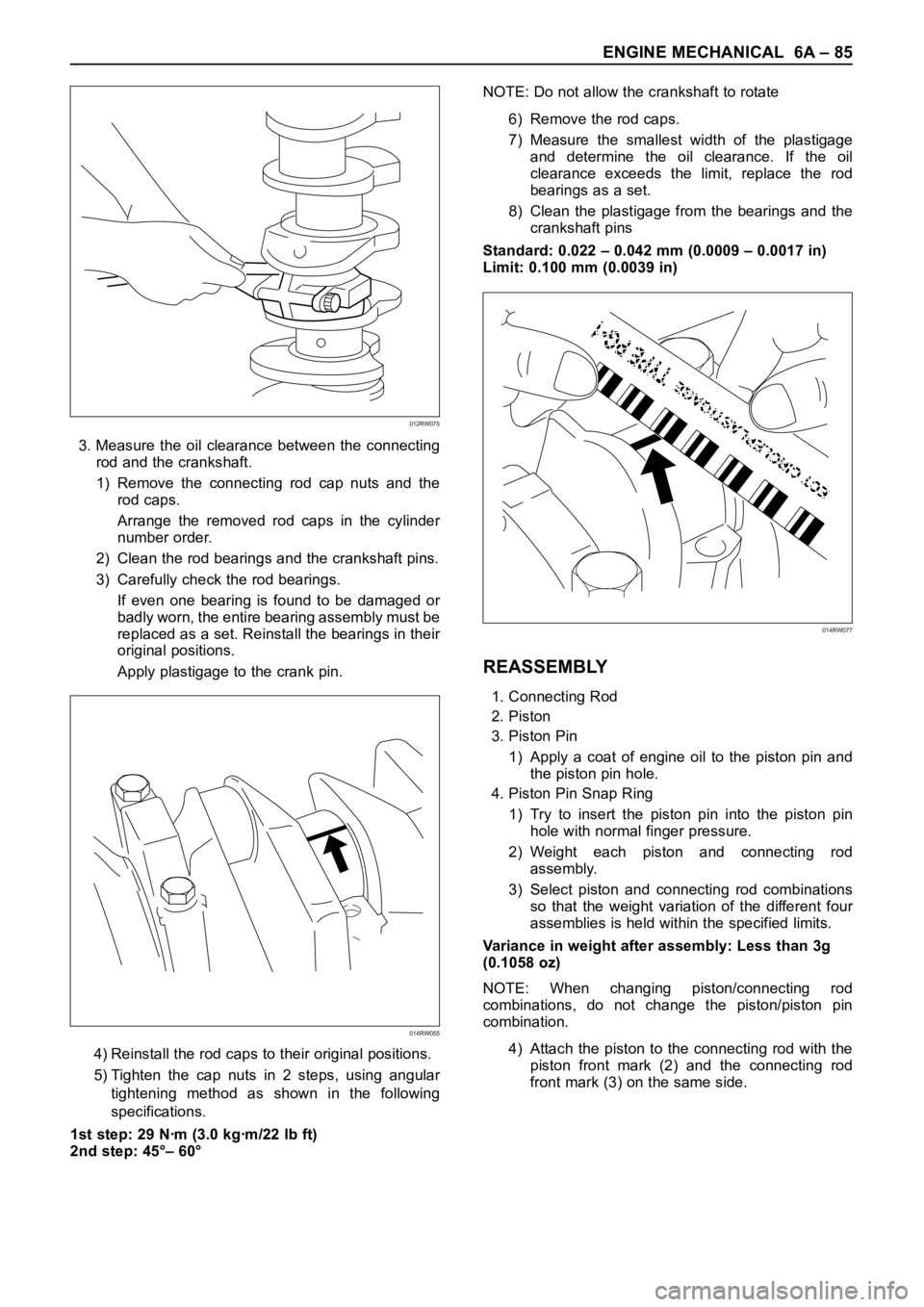

3. Measure the oil clearance between the connecting

rod and the crankshaft.

1) Remove the connecting rod cap nuts and the

rod caps.

Arrange the removed rod caps in the cylinder

number order.

2) Clean the rod bearings and the crankshaft pins.

3) Carefully check the rod bearings.

If even one bearing is found to be damaged or

badly worn, the entire bearing assembly must be

replaced as a set. Reinstall the bearings in their

original positions.

Apply plastigage to the crank pin.

4) Reinstall the rod caps to their original positions.

5) Tighten the cap nuts in 2 steps, using angular

tightening method as shown in the following

specifications.

1st step: 29 Nꞏm (3.0 kgꞏm/22 lb ft)

2nd step: 45°– 60°NOTE: Do not allow the crankshaft to rotate

6) Remove the rod caps.

7) Measure the smallest width of the plastigage

and determine the oil clearance. If the oil

clearance exceeds the limit, replace the rod

bearings as a set.

8) Clean the plastigage from the bearings and the

crankshaft pins

Standard: 0.022 – 0.042 mm (0.0009 – 0.0017 in)

Limit: 0.100 mm (0.0039 in)

REASSEMBLY

1. Connecting Rod

2. Piston

3. Piston Pin

1) Apply a coat of engine oil to the piston pin and

the piston pin hole.

4. Piston Pin Snap Ring

1) Try to insert the piston pin into the piston pin

hole with normal finger pressure.

2) Weight each piston and connecting rod

assembly.

3) Select piston and connecting rod combinations

so that the weight variation of the different four

assemblies is held within the specified limits.

Variance in weight after assembly: Less than 3g

(0.1058 oz)

NOTE: When changing piston/connecting rod

combinations, do not change the piston/piston pin

combination.

4) Attach the piston to the connecting rod with the

piston front mark (2) and the connecting rod

front mark (3) on the same side.

014RW055

012RW075

014RW077

Page 5745 of 6000

7A–56

AUTOMATIC TRANSMISSION (4L30–E)

Ensure free rotation of pump using 5–8840–2273–0

(J–23082–01) oil pump rotation tool.

241RW010

38. Overdrive clutch end play measurement.

1. Fit 5–8840–2271–0 (J–25022) and

5–8840–0618–0 (J–24773–1) turbine shaft puller

on turbine shaft.

2. Position axial play checking tool on converter

housing mating face.

3. Pull turbine shaft upwards with puller until first

resistance is met. (due to weight of overdrive

assembly).

4. Maintain shaft in this position and set indicator to

zero.

5. Pull turbine shaft further upwards with puller.

Read end play shown on indicator.

End play: 0.1mm – 0.8mm (0.004 in – 0.031in)6. Remove axial play checking tool and puller.

NOTE: If end play is not correct, repeat selective washer

selection.

252RW010

39. Inspect extension housing oil seal and replace if

necessary, using 5–8840–2282–0 (J–36797)

extension housing oil seal installer.

Rotate transmission to horizontal position, with

valve body side down.

Inspect parking wheel seal ring. Replace if

necessary.

Install wheel parking lock assembly (35).

40. Install speed wheel (36) and snap ring (37).

NOTE: Use extra long, needle-nose pliers.

41. Install gasket onto extension assembly with a thin

coating of oil.

Install extension housing assembly (38), and align

parking pawl shaft.

Install actuator assembly into extension assembly.

Install seven 8 mm hexagon socket head screws.

To r q u e : 3 2 N

m (3.3 kgꞏm/24 lb ft)

42. Inspect speed sensor O–ring. Replace if necessary.

Install speed sensor assembly (39) and 10 mm

screw.

To r q u e : 9 N

m (0.9 kgꞏm/78 lb in)