air condition OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 2315 of 6000

7A1–70

TRANSMISSION CONTROL SYSTEM (4L30–E)

DTC P1850 Brake Band Apply Solenoid Malfunction (Cont’d)

StepNo Ye s Action

23The wiring harness between the PCM connector terminal J1–A16

and the 16–way connector terminal H53–13 is open.

Was a problem found and corrected?

Go to Step 26—

24The wiring harness between the transmission 16–way connector

terminal H53–13 and the transmission main case connector

terminal M7–2(B) is open.

Was a problem found and corrected?

Go to Step 26—

25Check every connection at the PCM.

If OK, replace the PCM. Refer to Powertrain Control Module

(PCM) in Automatic Transmission (4L30–E) section.

Is the replacement complete?

Go to Step 26—

261. After the repair is complete, use the scan tool to select “DTC”,

then “Clear Info” function and ensure the following conditions

are met:

The brake band apply solenoid is commanded “on” and the

volts drop to zero.

The brake band apply solenoid is commanded “off” and the

volts increase to B+.

2. Review the scan tool “DTC Info”.

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1

Repair verified

Exit DTC table

Page 2318 of 6000

TRANSMISSION CONTROL SYSTEM (4L30–E)7A1–73

DTC P1860 TCC Solenoid Electrical (Cont’d)

StepNo Ye s Action

12The wiring harness between PCM connector terminal J2–D2 and

transmission 16–way connector terminal H53–8 is shorted to

ground.

Was a problem found and corrected?

Go to Step 20—

13The wiring harness between transmission 16–way connector

H–53 and adapter case connector M–6 is shorted to ground.

Was a problem found and corrected?

Go to Step 20—

14The TCC solenoid is faulty, or the internal wiring harness from t h e

TCC solenoid is shorted to ground.

Was a problem found and corrected?

Go to Step 20—

15The wiring harness between PCM connector terminal J2–D2 and

transmission 16–way connector terminal H53–8 is open.

Was a problem found and corrected?

Go to Step 20—

16The wiring harness between transmission 16–way connector

terminal H53–8 and adapter case terminal M6–4(A) is open.

Was a problem found and corrected?

Go to Step 20—

17The TCC solenoid is faulty, or the internal wiring harness from t h e

TCC solenoid is open.

Was a problem found and corrected?

Go to Step 20—

18Check every connection at the PCM.

If OK, replace the PCM. Refer to Powertrain Control Module

(PCM) in Automatic Transmission (4L30–E) section.

Is the replacement complete?

Go to Step 20—

19Check the PCM connector terminal J2–D2, transmission 16–way

connector terminal H53–8 and transmission adapter case

connector terminal M6–4(A).

Was a problem found and corrected?

Go to Step 20—

201. After the repair is complete, use the scan tool to select “DTC”,

then “Clear Info” function and ensure the following conditions

are met:

The TCC solenoid is commanded “on” and the volts increase

to B+.

The TCC solenoid is commanded “off” and the volts drop to

zero.

2. Review the scan tool “DTC Info”.

Has the last test failed or is the current DTC displayed?

Begin diagnosis

again

Go to Step 1

Repair verified

Exit DTC table

Page 2322 of 6000

7B–4MANUAL TRANSMISSION

Diagnosis

ConditionPossible causeCorrection

Abnormal noiseFlywheel pilot bearing wornReplace

Bearings worn or broken (Mainshaft,

counter shaft, and transfer shaft)Replace

Gear tooth contact surfaces worn or

scuffed (Mainshaft, counter shaft,

reverse idler gear and transfer gears)Replace

Splines worn (Mainshaft,

synchronizer clutch hub)Replace

Gear or bearing thrust face seizedReplace

Lack of backlash between meshing

gearsReplace

Hard ShiftingImproper clutch pedal free playReadjust

Change lever sliding portions wornRepair or replace

Regrease

Shift block, shift rod and/or control

box sliding faces wornReplace

Shift arm and synchronizer sleeve

groove wornReplace worn parts

Thrust washer, collar, and/or gear

thrust faces worn (Mainshaft and

counter shaft thrust play)Replace worn parts

Synchronizer parts wornReplace

Walking or Jumping out of gearDetent ball wornReplace

Detent spring weakened or brokenReplace

Shift rod and/or control box sliding

faces wornReplace

Shift arm and synchronizer sleeve

groove wornReplace worn parts

Thrust washer, collar, and/or gear

thrust faces worn (Mainshaft and

counter shaft thrust play)Replace worn parts

Bearings worn or brokenReplace

Splines worn (Mainshaft,

synchronizer hub)Replace

Synchronizer spring weakened or

brokenReplace

Oil leakageLoose drain plug(s) and/or filler

plug(s)Tighten

Replenish oil

Defective or improperly installed

gasket(s)Replace

Oil seal worn or scratchedReplace

Page 2517 of 6000

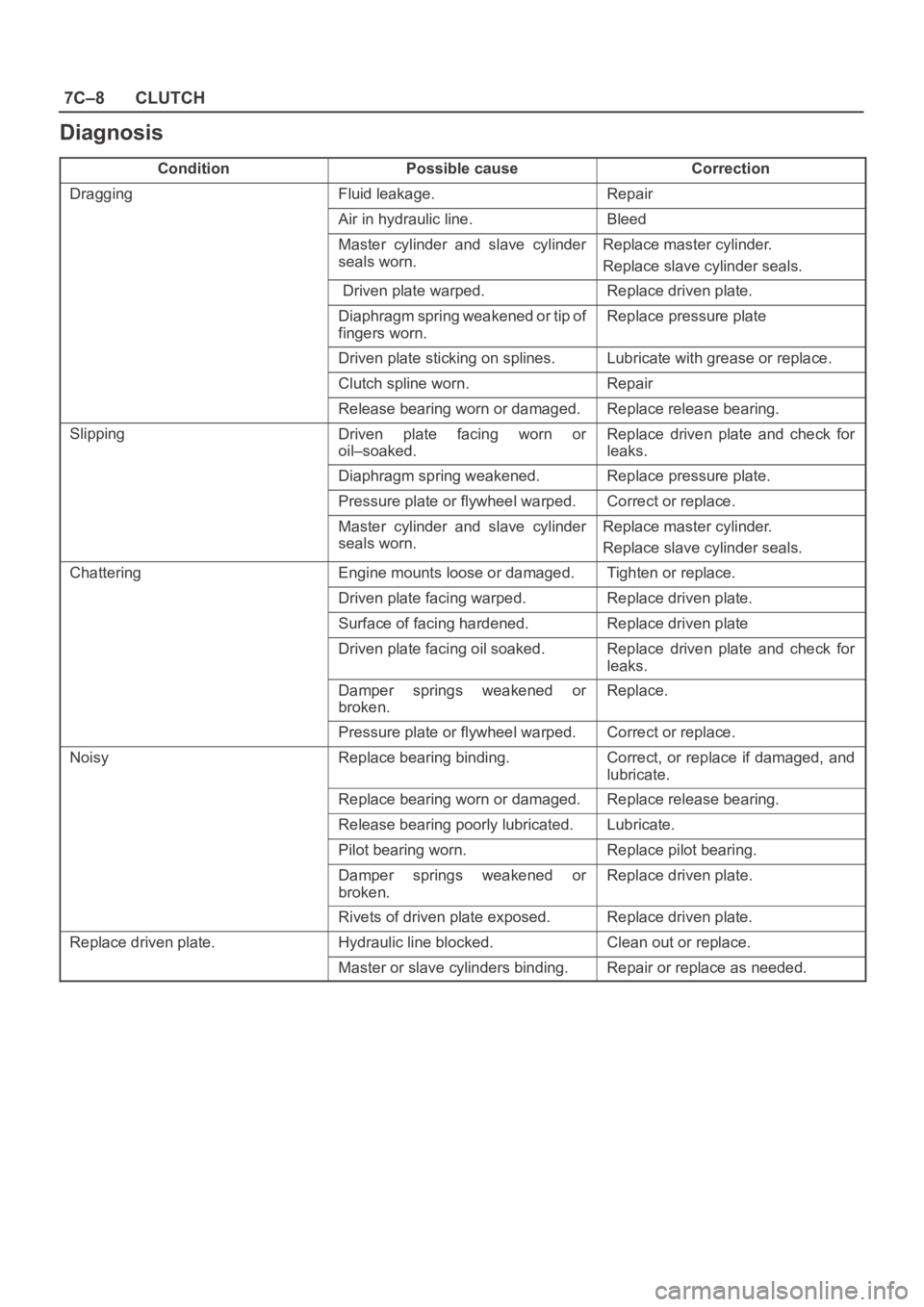

7C–8CLUTCH

Diagnosis

ConditionPossible causeCorrection

DraggingFluid leakage.Repair

Air in hydraulic line.Bleed

Master cylinder and slave cylinder

seals worn. Replace master cylinder.

Replace slave cylinder seals.

Driven plate warped.Replace driven plate.

Diaphragm spring weakened or tip of

fingers worn. Replace pressure plate

Driven plate sticking on splines.Lubricate with grease or replace.

Clutch spline worn. Repair

Release bearing worn or damaged.Replace release bearing.

SlippingDriven plate facing worn or

oil–soaked.Replace driven plate and check for

leaks.

Diaphragm spring weakened.Replace pressure plate.

Pressure plate or flywheel warped.Correct or replace.

Master cylinder and slave cylinder

seals worn.Replace master cylinder.

Replace slave cylinder seals.

ChatteringEngine mounts loose or damaged.Tighten or replace.

Driven plate facing warped.Replace driven plate.

Surface of facing hardened.Replace driven plate

Driven plate facing oil soaked. Replace driven plate and check for

leaks.

Damper springs weakened or

broken. Replace.

Pressure plate or flywheel warped.Correct or replace.

NoisyReplace bearing binding.Correct, or replace if damaged, and

lubricate.

Replace bearing worn or damaged. Replace release bearing.

Release bearing poorly lubricated. Lubricate.

Pilot bearing worn.Replace pilot bearing.

Damper springs weakened or

broken.Replace driven plate.

Rivets of driven plate exposed.Replace driven plate.

Replace driven plate.Hydraulic line blocked.Clean out or replace.

Master or slave cylinders binding.Repair or replace as needed.

Page 2519 of 6000

7C–10CLUTCH

5. Mark the flywheel, clutch cover and pressure plate lug

for alignment when installing.

6. Remove the release bearing (3) from the

transmission case .

7. Remove the shift fork snap pin.

8. Remove the shift fork pin and shift fork (4) from the

front cover.

9. Remove the front cover bolts.

10. Remove the front cover (5) from the transmission

case.

220RW088

11. Remove flywheel assembly and crankshaft bearing.

Do not remove except for replacement.

12. Use the remover 5–8840–2000–0 (J–5822) and

sliding hammer 5–8840–0019–0 (J–23907) to

remove the crankshaft bearing

015RW053

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, or any other abnormal condition are found

through inspection.

Pressure Plate Assembly

201RS002

1. Visually check the pressure plate friction surface for

excessive wear and heat cracks.

2. If excessive wear or deep heat cracks are present,

the pressure plate must be replaced.

Pressure Plate Warpage

201RS003

Page 2557 of 6000

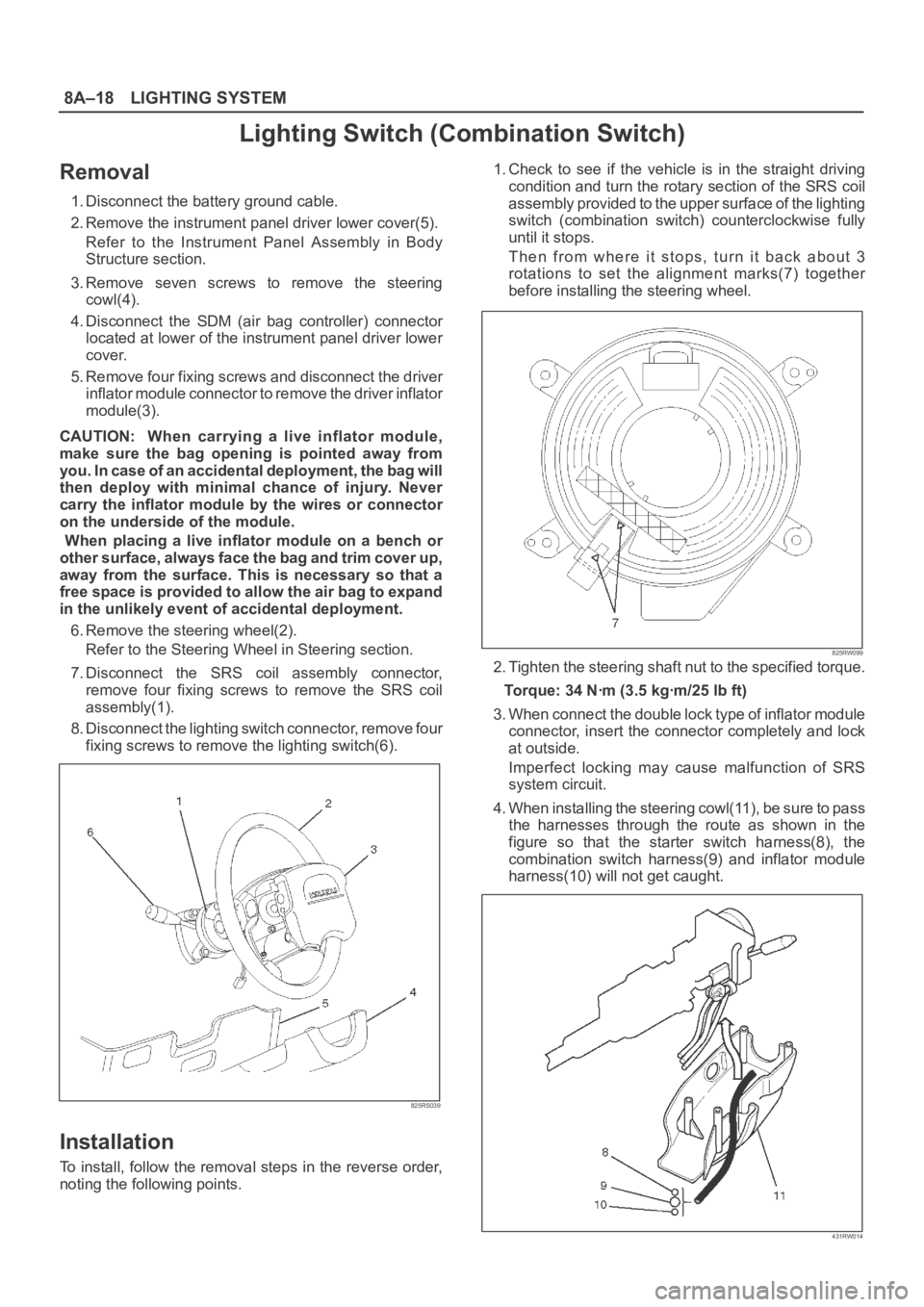

8A–18LIGHTING SYSTEM

Lighting Switch (Combination Switch)

Removal

1. Disconnect the battery ground cable.

2. Remove the instrument panel driver lower cover(5).

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove seven screws to remove the steering

cowl(4).

4. Disconnect the SDM (air bag controller) connector

located at lower of the instrument panel driver lower

cover.

5. Remove four fixing screws and disconnect the driver

inflator module connector to remove the driver inflator

module(3).

CAUTION: When carrying a live inflator module,

make sure the bag opening is pointed away from

y o u . I n c a s e o f a n a c c i d e n t a l d e p l o y m e n t , t h e b a g w i l l

then deploy with minimal chance of injury. Never

carry the inflator module by the wires or connector

on the underside of the module.

When placing a live inflator module on a bench or

other surface, always face the bag and trim cover up,

away from the surface. This is necessary so that a

free space is provided to allow the air bag to expand

in the unlikely event of accidental deployment.

6. Remove the steering wheel(2).

Refer to the Steering Wheel in Steering section.

7. Disconnect the SRS coil assembly connector,

remove four fixing screws to remove the SRS coil

assembly(1).

8. Disconnect the lighting switch connector, remove four

fixing screws to remove the lighting switch(6).

825RS039

Installation

To install, follow the removal steps in the reverse order,

noting the following points.1. Check to see if the vehicle is in the straight driving

condition and turn the rotary section of the SRS coil

assembly provided to the upper surface of the lighting

switch (combination switch) counterclockwise fully

until it stops.

Then from where it stops, turn it back about 3

rotations to set the alignment marks(7) together

before installing the steering wheel.

825RW099

2. Tighten the steering shaft nut to the specified torque.

Torque: 34 Nꞏm (3.5 kgꞏm/25 lb ft)

3. When connect the double lock type of inflator module

connector, insert the connector completely and lock

at outside.

Imperfect locking may cause malfunction of SRS

system circuit.

4. When installing the steering cowl(11), be sure to pass

the harnesses through the route as shown in the

figure so that the starter switch harness(8), the

combination switch harness(9) and inflator module

harness(10) will not get caught.

431RW014

Page 2609 of 6000

Circuit Breaker

The circuit breaker is a protective device designed to

open the circuit when a current load is in excess of rated

breaker capacity. If there is a short or other type of

overload condition in the circuit, the excessive current will

open the circuit between the circuit breaker terminals.

The reset knob (1) pops out when the circuit is open. Push

the reset knob in place to restore the circuit after repairing

it.

Relay

Battery and load location may require that a switch be

placed some distance from either component. This

means a longer wire and a higher voltage drop (1).

The installation of a relay between the battery and the

load reduces the voltage drop (2).

Because the switch controls the relay, amperage through

the switch can be reduced.

LOAD

12LOAD

RELAY

D08RW404

1

Page 3245 of 6000

8F–50BODY STRUCTURE

7. Remove instrument panel driver lower cover

assembly.

Remove the engine hood opener fixing screws.

Remove the 2 fixing screws (2), 1 fixing bolt (3), and

1 clip (4). Pull out the fasteners at the 4 positions

(1).

740RW105

8. Remove driver knee bolster assembly (W/SRS).

Remove the 6 fixing nuts.

740RW122

9. Remove front defroster grille.

Pry 8 claws on the front side toward you side (room

side) and raise the grille upward.

10. Remove instrument panel assembly.

Remove the 2 fixing bolts on the SRS adjust bracket

and the cross beam under the passenger inflator

module (W/SRS).

CAUTION: For precautions on installation or

removal of SRS — air bag system, refer to

Supplemental RestraintSystem (SRS) — AIR BAG in

Restraint section.

827RW031

Disconnect the 3 air conditioner control cables on

the unit side.

Remove the instrument harness connectors (5

connectors on the drivers side and 3 connectors on

the passenger side), the passenger inflator module

connector, the radio antenna cable plug, and the

ground cable fixing bolt on the center bracket.

Remove the 4 bolts (4) and the 2 nuts (3) under the

instrument panel assembly, and the upper left and

the upper right bolts (2) and the center nut (1).

Page 3248 of 6000

8F–53 BODY STRUCTURE

Installation

To install, follow the removal steps in the reverse order.

Order Of Removal/Installation Steps For Each Item

Removal Item

Removal ProcedureRemoval Step

Front console assem-

blyShift knob (M/T), Power & Winter SW (A/T), Transfer knob, Seat

heater/Miller SW conn. and 4 screws1, 2

Lower cluster assem-

bly3 screws, Ciger lighter conn. and Ashtray illumination conn.13

Glove box2 screws4

Instrument panel pas-

senger lower cover7 screws and 1 clip15

Passenger knee bol-

ster reinforcement4 nuts and 4 bolts16

Instrument panel driver

lower coverEngine hood opening fixing screw, 2 screws, 1 bolt, 1 clip and fasten-

ers at 4 positions13, 7

Driver knee bolster6 nuts13, 7, 8

Front defroster grilleClaws at 8 positions9

Instrument panel as-

sembly2 bolts (SRS adjust bracket cross beam), A/C control cable (Unit

side at 3 position), Instrument harness connector (Driver side 5 posi-

tion, assist side 3 position), SRS module conn., Radio antenna jack,

Earth cable, 9 bolts and 3 nuts110

Passenger inflator

module4 nuts (SRS moduleInstrument panel), 2 nuts 0 and 2 washers

(SRS module

support bracket) and 2 clips

16, 11

Instrument panel clus-

ter5 Screws, fastener at 4 position and each SW conn.13, 7, 12

Meter assembly4 screws and connectors13, 7, 12, 13

A/C control panel as-

sembly4 screws and connectors13, 7, 12, 14

Radio assembly2 screws13, 15

Vent duct assembly5 screws110, 16

Instrument harness as-

sembly4 screws, fasteners at 4 position, and clips at 7 position110, 17

Side defroster grille18

M/T = Manual Transmission

A/T = Automatic Transmission

SRS = Supplemental Restraint System

A/C = Air Conditioning

Page 3439 of 6000

SUPPLEMENTAL RESTRAINT SYSTEM 9J–2

General Description

CAUTION: When fasteners are removed, always

reinstall them at the same location from which they

were removed. If a fastener needs to be replaced, use

the correct part number fastener for that application.

If the correct part number fastener is not available, a

fastener of equal size and strength (or stronger) may

be used. Fasteners that are not reused, and those

requiring thread locking compound will be called

out. The correct torque value must be used when

installing fasteners that require it. If the above

conditions are not followed, parts or system damage

could result.

Restraint Devices

827RW006

Legend

(1) Deployed Air Bag

(2) Knee Bolster

(3) Seat Belt

The Supplemental Restraint System (SRS) helps

supplement the protection offered by the driver and front

passenger seat belts by deploying an air bag from the

center of the steering wheel and from the top of the right

side of the instrument panel.

The air bag deploys when the vehicle is involved in a

frontal crash of sufficient force up to 30 degrees off the

centerline of the vehicle. To further absorb the crash

energy there is a knee bolster located beneath the

instrument panel for both the driver and passenger, and

the steering column is collapsible.

827RW005