relay OPEL FRONTERA 1998 Owner's Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 821 of 6000

5A–11 BRAKE CONTROL SYSTEM

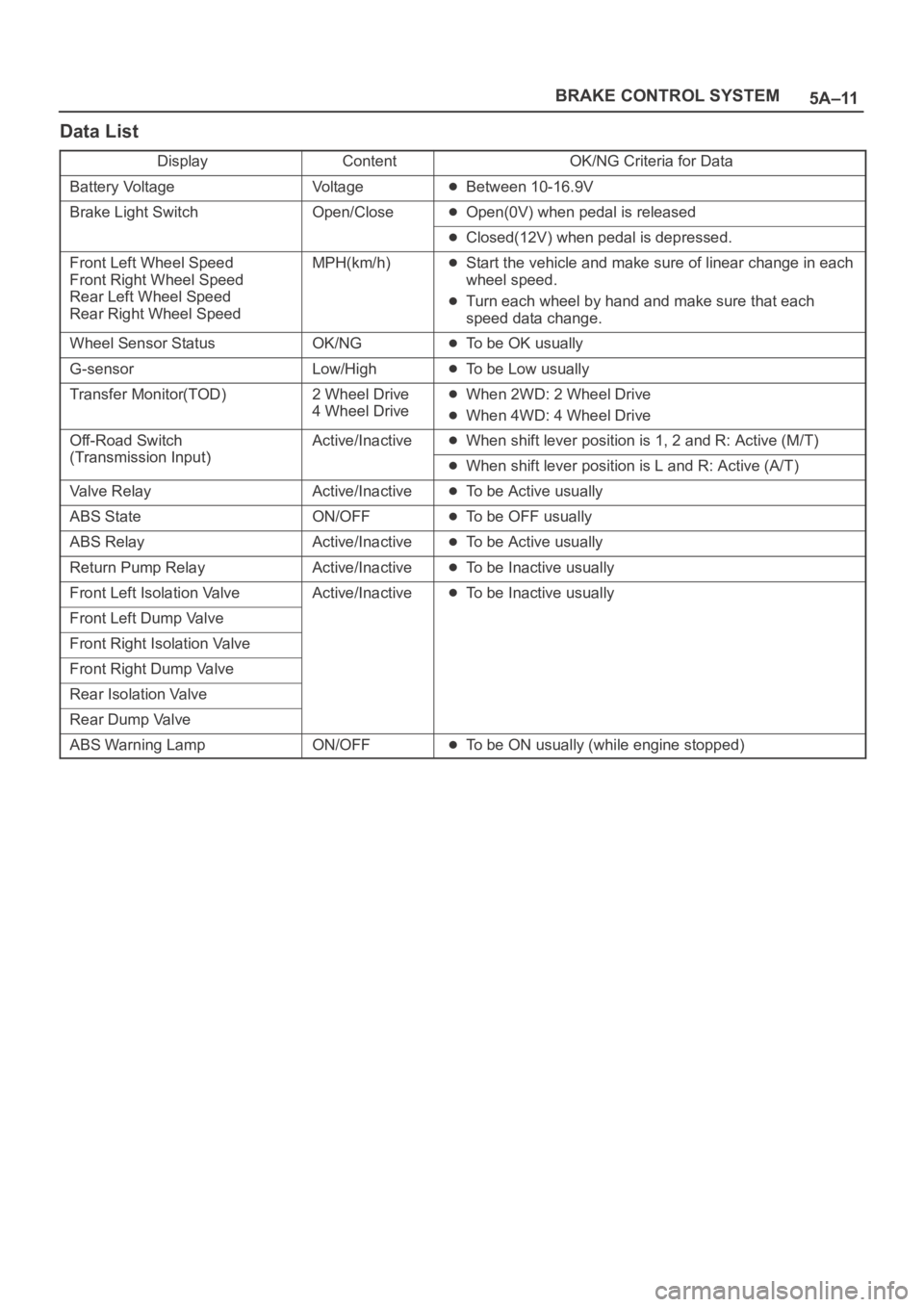

Data List

DisplayContentOK/NG Criteria for Data

Battery VoltageVo l t a g eBetween 10-16.9V

Brake Light SwitchOpen/CloseOpen(0V) when pedal is released

Closed(12V) when pedal is depressed.

Front Left Wheel Speed

Front Right Wheel Speed

Rear Left Wheel Speed

Rear Right Wheel SpeedMPH(km/h)Start the vehicle and make sure of linear change in each

wheel speed.

Turn each wheel by hand and make sure that each

speed data change.

Wheel Sensor StatusOK/NGTo be OK usually

G-sensorLow/HighTo be Low usually

Transfer Monitor(TOD)2 Wheel Drive

4 Wheel DriveWhen 2WD: 2 Wheel Drive

When 4WD: 4 Wheel Drive

Off-Road Switch

(Transmission Input)

Active/InactiveWhen shift lever position is 1, 2 and R: Active (M/T)

(Transmission Input)When shift lever position is L and R: Active (A/T)

Valve RelayActive/InactiveTo be Active usually

ABS StateON/OFFTo be OFF usually

ABS RelayActive/InactiveTo be Active usually

Return Pump RelayActive/InactiveTo be Inactive usually

Front Left Isolation ValveActive/InactiveTo be Inactive usually

Front Left Dump Valve

Front Right Isolation Valve

Front Right Dump Valve

Rear Isolation Valve

Rear Dump Valve

ABS Warning LampON/OFFTo be ON usually (while engine stopped)

Page 830 of 6000

5A–20

BRAKE CONTROL SYSTEM

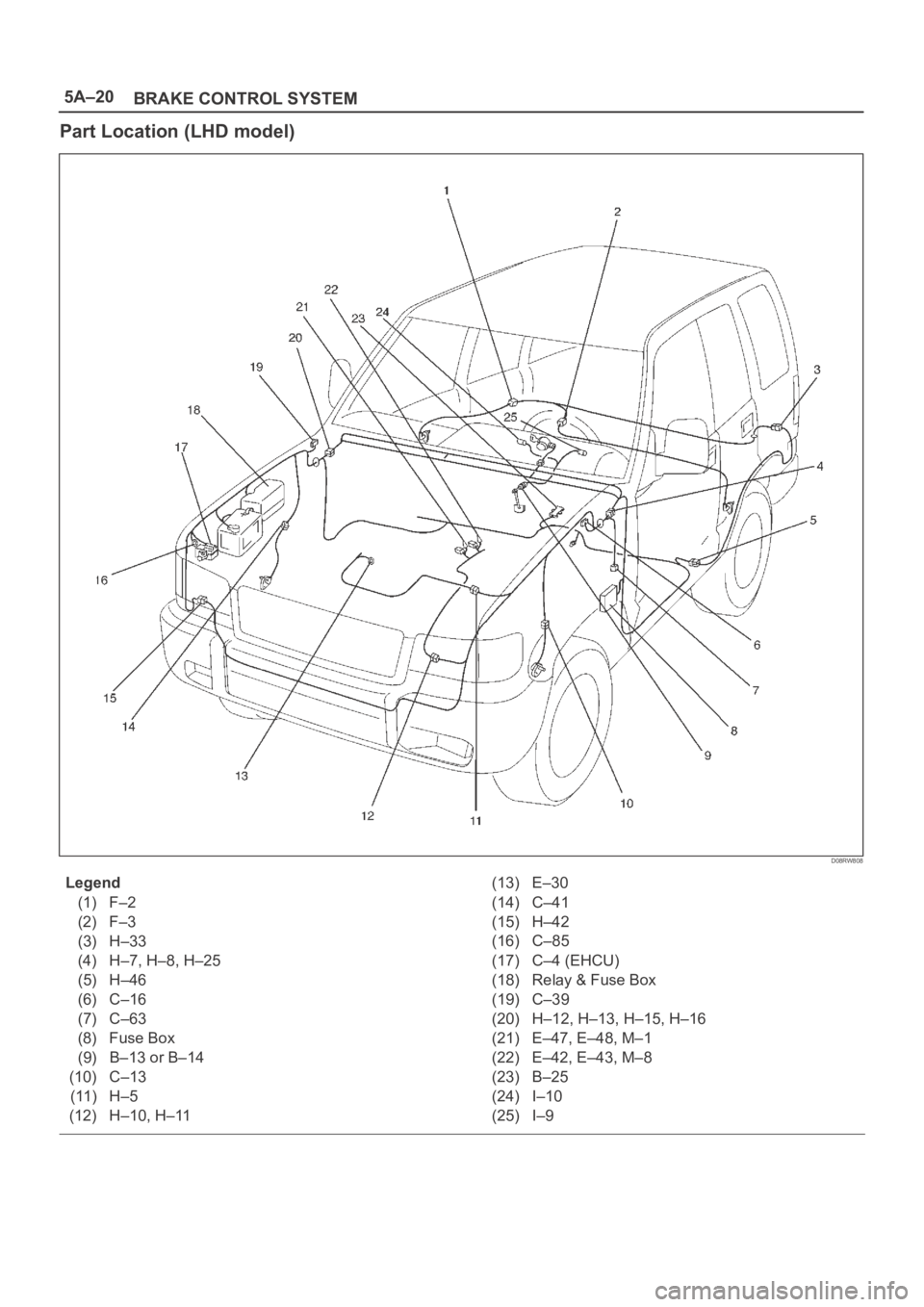

Part Location (LHD model)

D08RW808

Legend

(1) F–2

(2) F–3

(3) H–33

(4) H–7, H–8, H–25

(5) H–46

(6) C–16

(7) C–63

(8) Fuse Box

(9) B–13 or B–14

(10) C–13

(11) H–5

(12) H–10, H–11(13) E–30

(14) C–41

(15) H–42

(16) C–85

(17) C–4 (EHCU)

(18) Relay & Fuse Box

(19) C–39

(20) H–12, H–13, H–15, H–16

(21) E–47, E–48, M–1

(22) E–42, E–43, M–8

(23) B–25

(24) I–10

(25) I–9

Page 844 of 6000

5A–34

BRAKE CONTROL SYSTEM

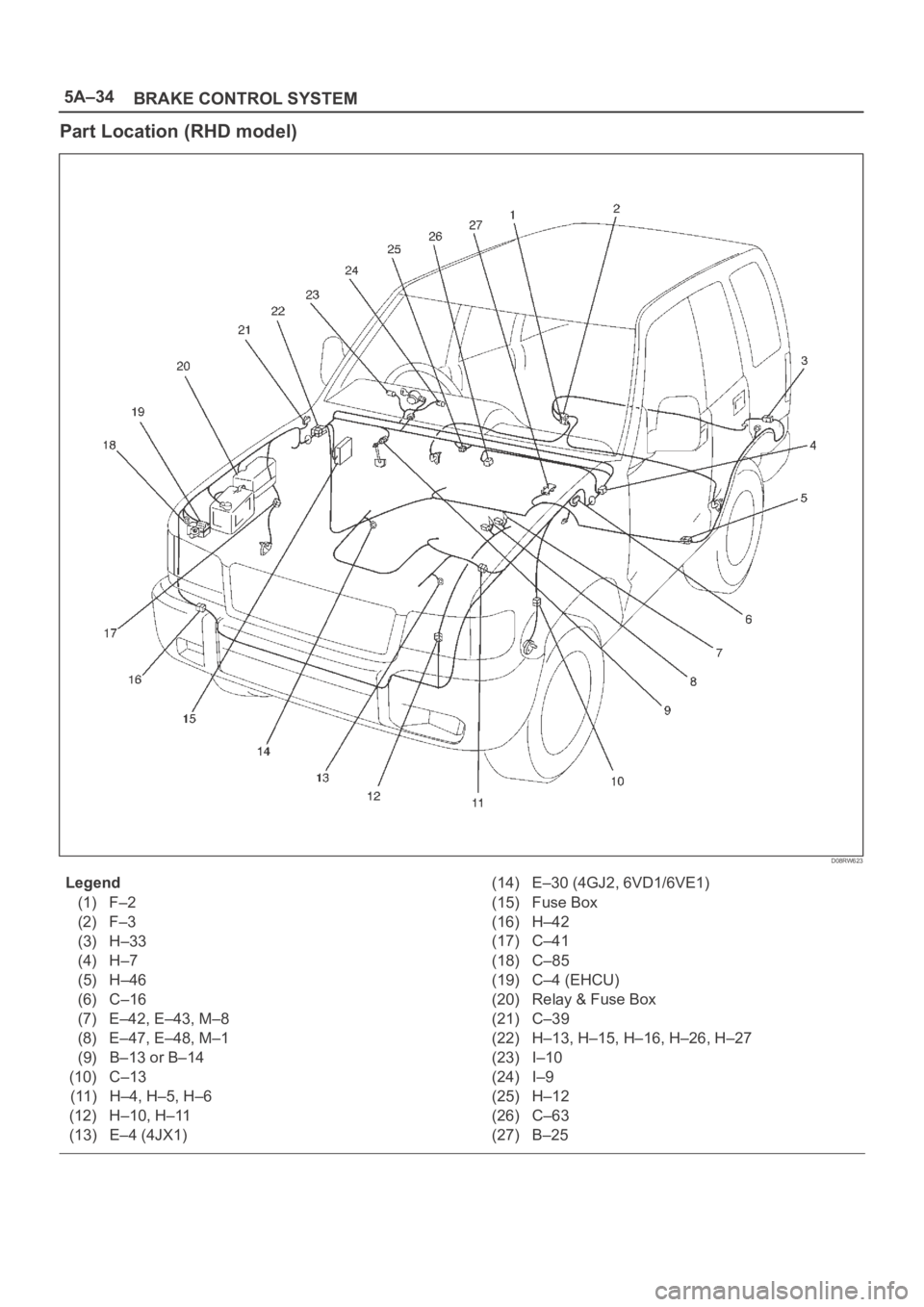

Part Location (RHD model)

D08RW623

Legend

(1) F–2

(2) F–3

(3) H–33

(4) H–7

(5) H–46

(6) C–16

(7) E–42, E–43, M–8

(8) E–47, E–48, M–1

(9) B–13 or B–14

(10) C–13

(11) H–4, H–5, H–6

(12) H–10, H–11

(13) E–4 (4JX1)(14) E–30 (4GJ2, 6VD1/6VE1)

(15) Fuse Box

(16) H–42

(17) C–41

(18) C–85

(19) C–4 (EHCU)

(20) Relay & Fuse Box

(21) C–39

(22) H–13, H–15, H–16, H–26, H–27

(23) I–10

(24) I–9

(25) H–12

(26) C–63

(27) B–25

Page 849 of 6000

5A–39 BRAKE CONTROL SYSTEM

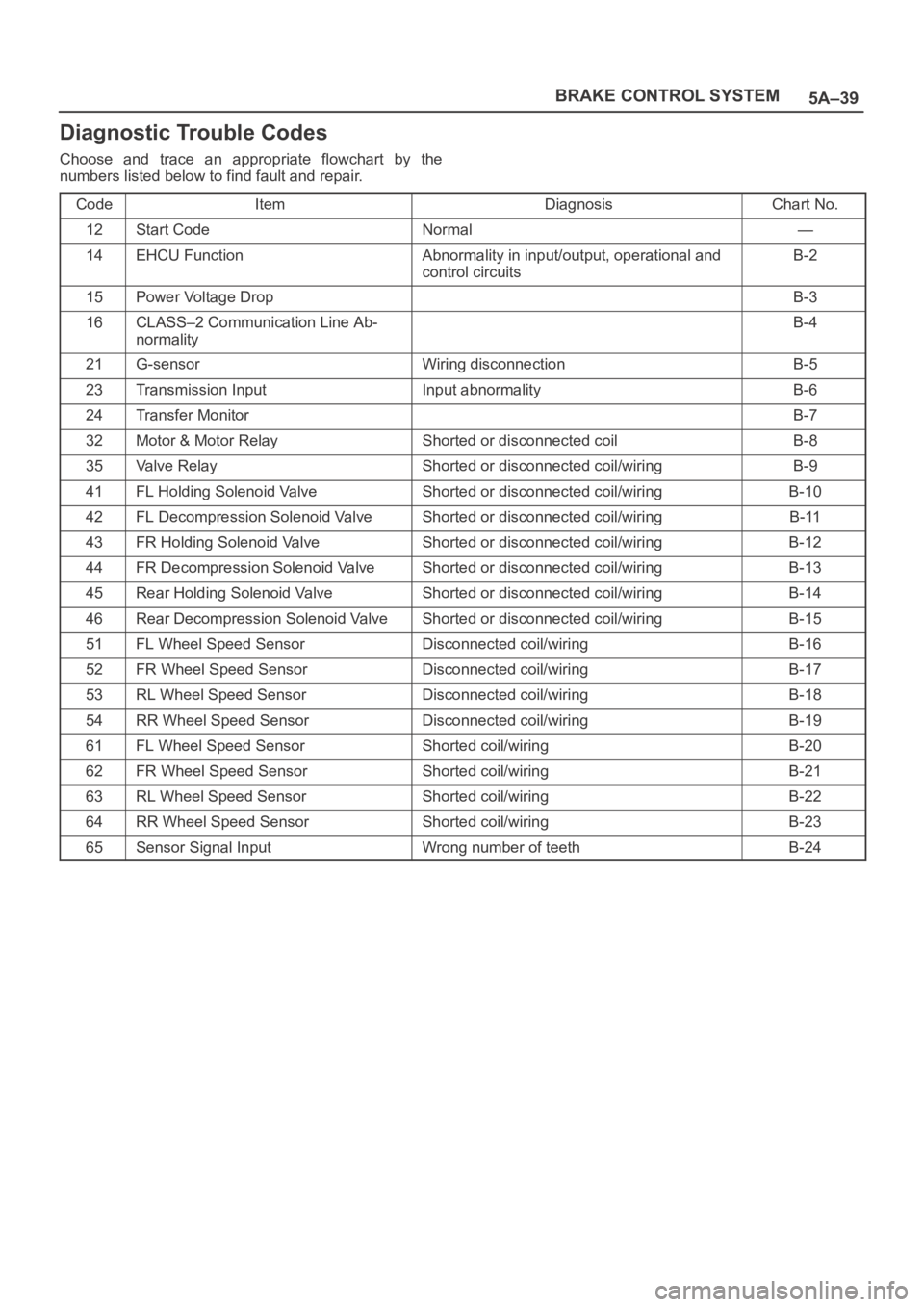

Diagnostic Trouble Codes

Choose and trace an appropriate flowchart by the

numbers listed below to find fault and repair.

Code

ItemDiagnosisChart No.

12Start CodeNormal—

14EHCU FunctionAbnormality in input/output, operational and

control circuitsB-2

15Power Voltage DropB-3

16CLASS–2 Communication Line Ab-

normalityB-4

21G-sensorWiring disconnectionB-5

23Transmission InputInput abnormalityB-6

24Transfer MonitorB-7

32Motor & Motor RelayShorted or disconnected coilB-8

35Valve RelayShorted or disconnected coil/wiringB-9

41FL Holding Solenoid ValveShorted or disconnected coil/wiringB-10

42FL Decompression Solenoid ValveShorted or disconnected coil/wiringB-11

43FR Holding Solenoid ValveShorted or disconnected coil/wiringB-12

44FR Decompression Solenoid ValveShorted or disconnected coil/wiringB-13

45Rear Holding Solenoid ValveShorted or disconnected coil/wiringB-14

46Rear Decompression Solenoid ValveShorted or disconnected coil/wiringB-15

51FL Wheel Speed SensorDisconnected coil/wiringB-16

52FR Wheel Speed SensorDisconnected coil/wiringB-17

53RL Wheel Speed SensorDisconnected coil/wiringB-18

54RR Wheel Speed SensorDisconnected coil/wiringB-19

61FL Wheel Speed SensorShorted coil/wiringB-20

62FR Wheel Speed SensorShorted coil/wiringB-21

63RL Wheel Speed SensorShorted coil/wiringB-22

64RR Wheel Speed SensorShorted coil/wiringB-23

65Sensor Signal InputWrong number of teethB-24

Page 857 of 6000

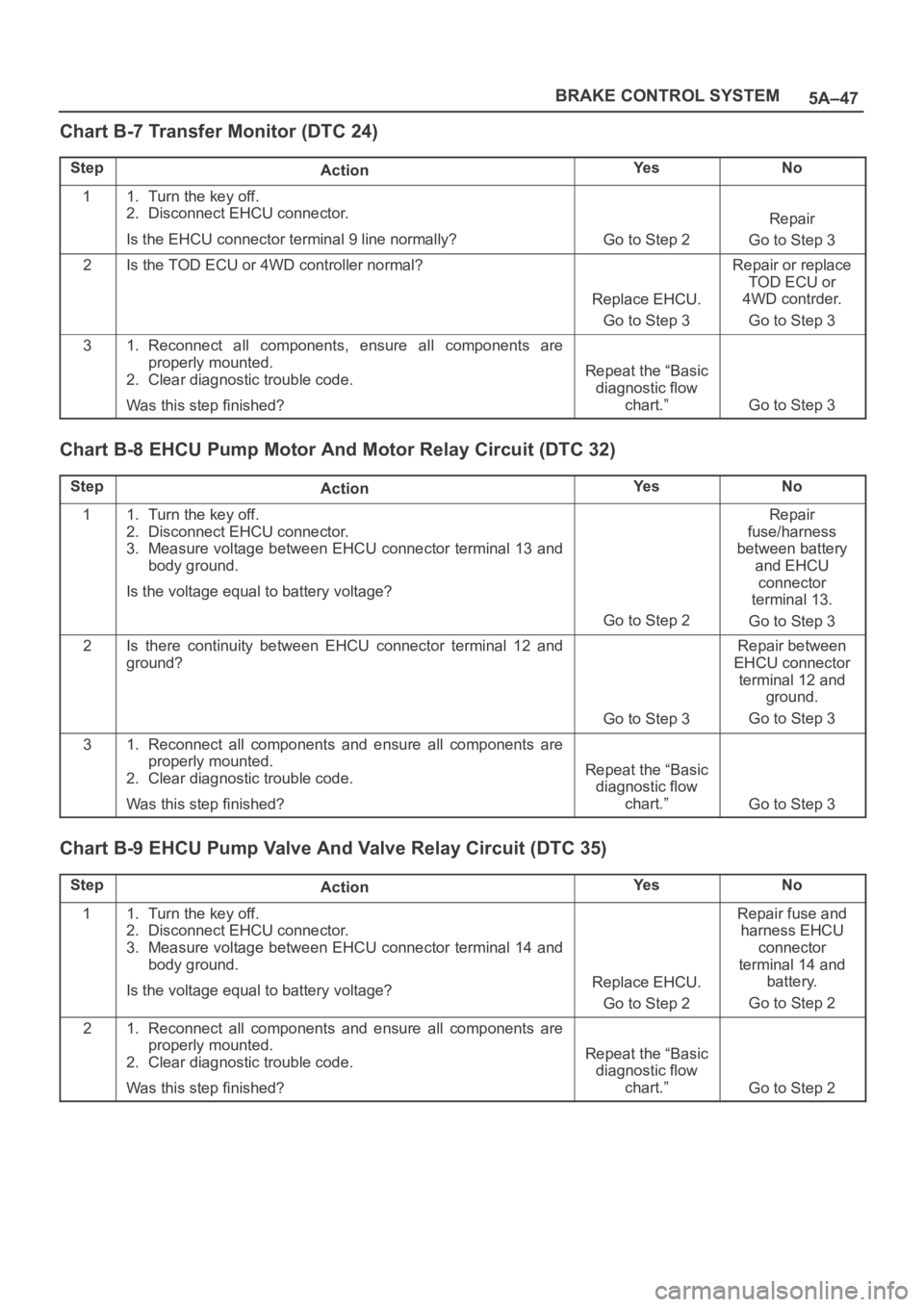

5A–47 BRAKE CONTROL SYSTEM

Chart B-7 Transfer Monitor (DTC 24)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

Is the EHCU connector terminal 9 line normally?

Go to Step 2

Repair

Go to Step 3

2Is the TOD ECU or 4WD controller normal?

Replace EHCU.

Go to Step 3

Repair or replace

TOD ECU or

4WD contrder.

Go to Step 3

31. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart B-8 EHCU Pump Motor And Motor Relay Circuit (DTC 32)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure voltage between EHCU connector terminal 13 and

body ground.

Is the voltage equal to battery voltage?

Go to Step 2

Repair

fuse/harness

between battery

and EHCU

connector

terminal 13.

Go to Step 3

2Is there continuity between EHCU connector terminal 12 and

ground?

Go to Step 3

Repair between

EHCU connector

terminal 12 and

ground.

Go to Step 3

31. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 3

Chart B-9 EHCU Pump Valve And Valve Relay Circuit (DTC 35)

StepActionYe sNo

11. Turn the key off.

2. Disconnect EHCU connector.

3. Measure voltage between EHCU connector terminal 14 and

body ground.

Is the voltage equal to battery voltage?

Replace EHCU.

Go to Step 2

Repair fuse and

harness EHCU

connector

terminal 14 and

battery.

Go to Step 2

21. Reconnect all components and ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat the “Basic

diagnostic flow

chart.”

Go to Step 2

Page 961 of 6000

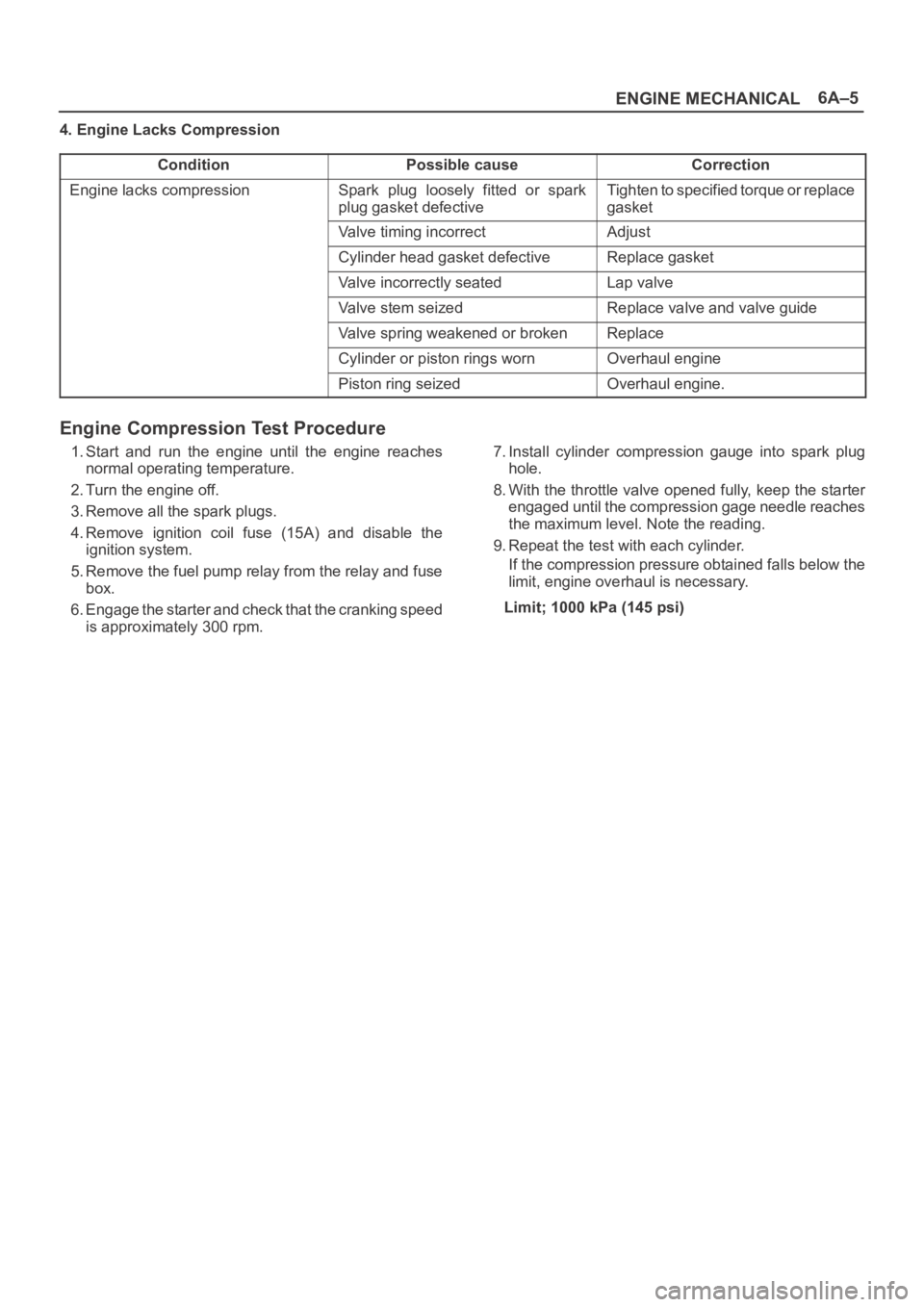

6A–5

ENGINE MECHANICAL

4. Engine Lacks Compression

Condition

Possible causeCorrection

Engine lacks compressionSpark plug loosely fitted or spark

plug gasket defectiveTighten to specified torque or replace

gasket

Valve timing incorrectAdjust

Cylinder head gasket defectiveReplace gasket

Valve incorrectly seatedLap valve

Valve stem seizedReplace valve and valve guide

Valve spring weakened or brokenReplace

Cylinder or piston rings wornOverhaul engine

Piston ring seizedOverhaul engine.

Engine Compression Test Procedure

1. Start and run the engine until the engine reaches

normal operating temperature.

2. Turn the engine off.

3. Remove all the spark plugs.

4. Remove ignition coil fuse (15A) and disable the

ignition system.

5. Remove the fuel pump relay from the relay and fuse

box.

6. Engage the starter and check that the cranking speed

is approximately 300 rpm.7. Install cylinder compression gauge into spark plug

hole.

8. With the throttle valve opened fully, keep the starter

engaged until the compression gage needle reaches

the maximum level. Note the reading.

9. Repeat the test with each cylinder.

If the compression pressure obtained falls below the

limit, engine overhaul is necessary.

Limit; 1000 kPa (145 psi)

Page 962 of 6000

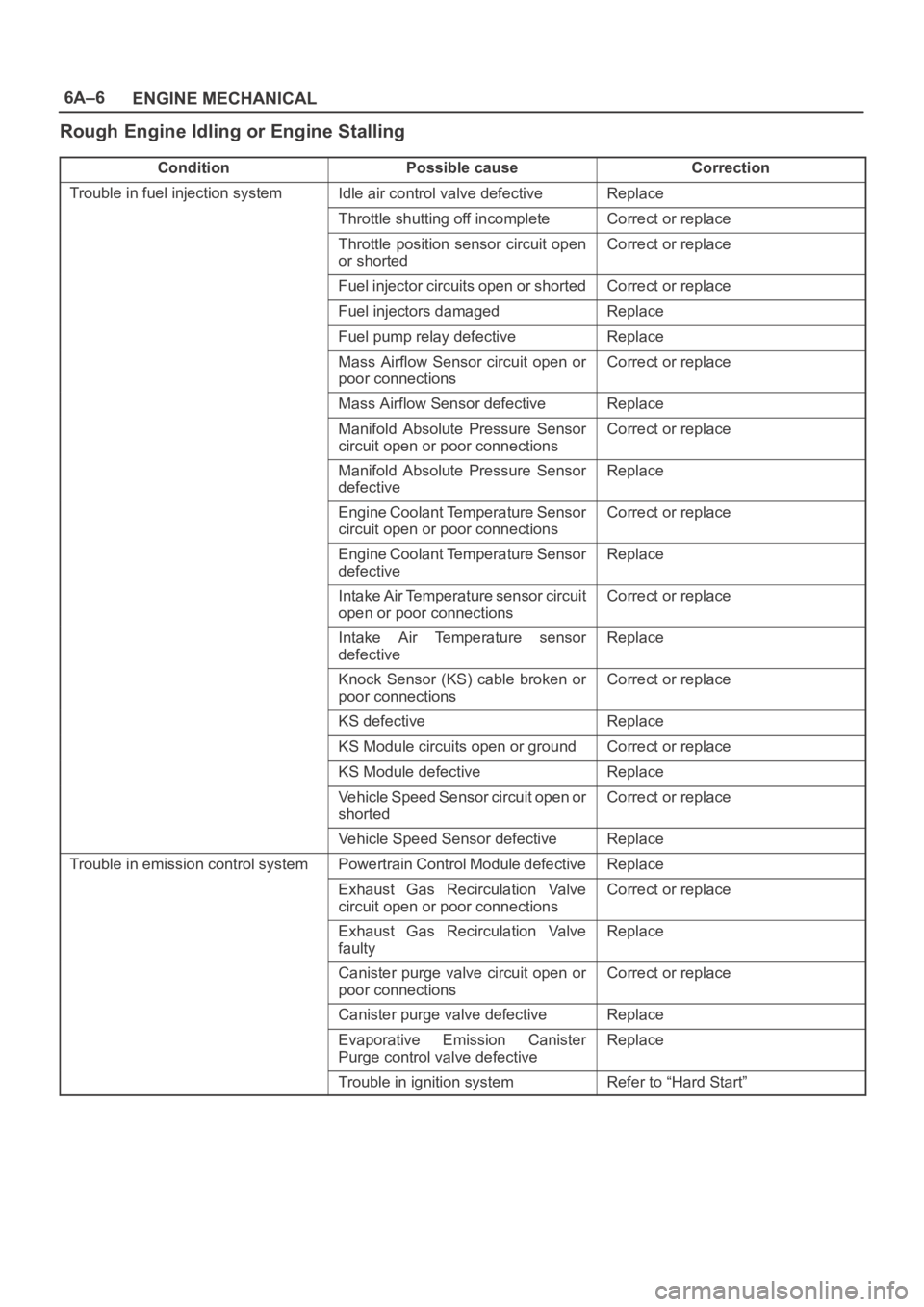

6A–6

ENGINE MECHANICAL

Rough Engine Idling or Engine Stalling

ConditionPossible causeCorrection

Trouble in fuel injection systemIdle air control valve defectiveReplace

Throttle shutting off incompleteCorrect or replace

Throttle position sensor circuit open

or shortedCorrect or replace

Fuel injector circuits open or shortedCorrect or replace

Fuel injectors damagedReplace

Fuel pump relay defectiveReplace

Mass Airflow Sensor circuit open or

poor connectionsCorrect or replace

Mass Airflow Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or poor connectionsCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature Sensor

circuit open or poor connectionsCorrect or replace

Engine Coolant Temperature Sensor

defectiveReplace

Intake Air Temperature sensor circuit

open or poor connectionsCorrect or replace

Intake Air Temperature sensor

defectiveReplace

Knock Sensor (KS) cable broken or

poor connectionsCorrect or replace

KS defectiveReplace

KS Module circuits open or groundCorrect or replace

KS Module defectiveReplace

Vehicle Speed Sensor circuit open or

shortedCorrect or replace

Vehicle Speed Sensor defectiveReplace

Trouble in emission control systemPowertrain Control Module defectiveReplace

Exhaust Gas Recirculation Valve

circuit open or poor connectionsCorrect or replace

Exhaust Gas Recirculation Valve

faultyReplace

Canister purge valve circuit open or

poor connectionsCorrect or replace

Canister purge valve defectiveReplace

Evaporative Emission Canister

Purge control valve defectiveReplace

Trouble in ignition systemRefer to “Hard Start”

Page 969 of 6000

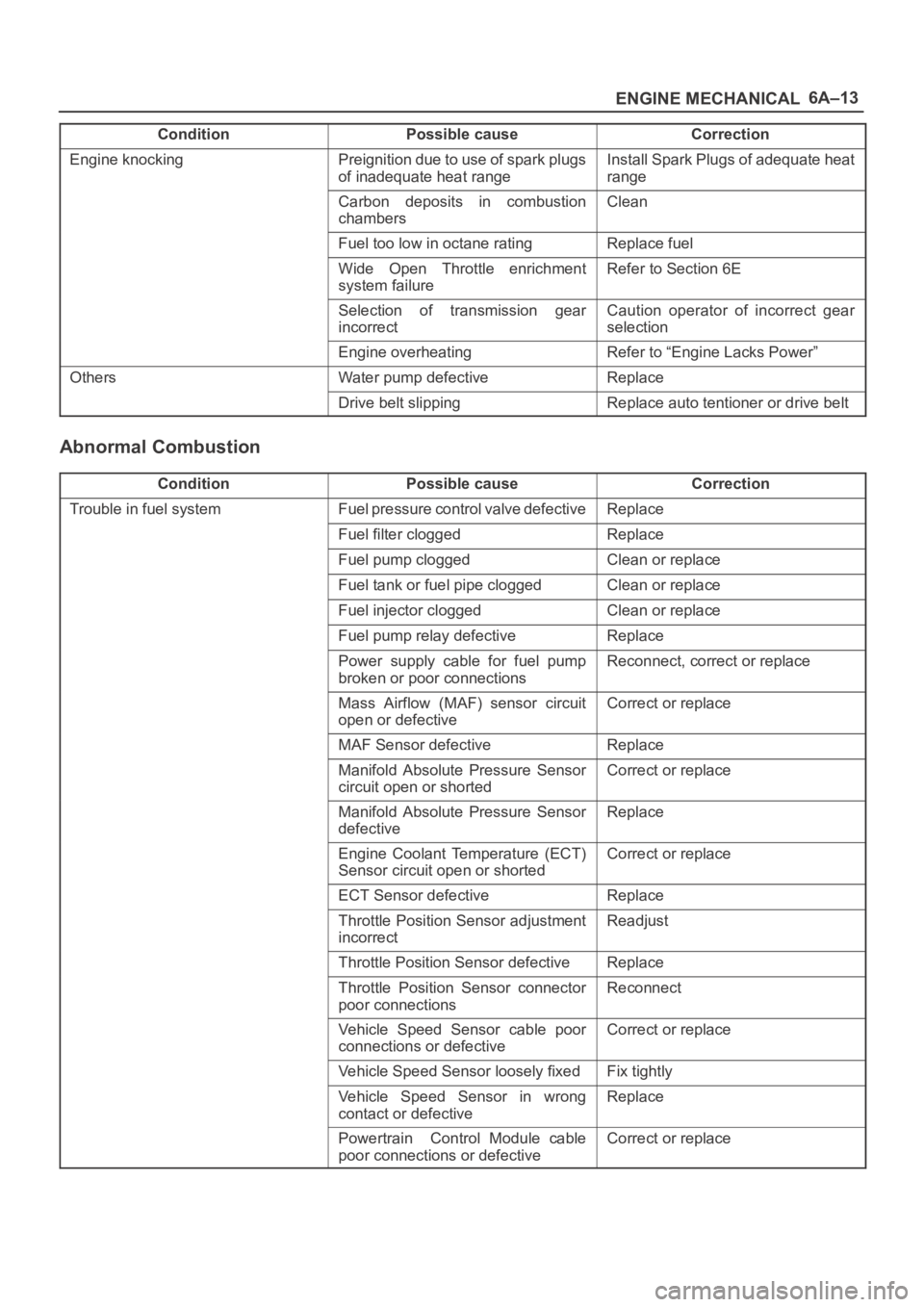

6A–13

ENGINE MECHANICAL

Condition CorrectionPossible cause

Engine knockingPreignition due to use of spark plugs

of inadequate heat rangeInstall Spark Plugs of adequate heat

range

Carbon deposits in combustion

chambersClean

Fuel too low in octane ratingReplace fuel

Wide Open Throttle enrichment

system failureRefer to Section 6E

Selection of transmission gear

incorrectCaution operator of incorrect gear

selection

Engine overheatingRefer to “Engine Lacks Power”

OthersWater pump defectiveReplace

Drive belt slippingReplace auto tentioner or drive belt

Abnormal Combustion

ConditionPossible causeCorrection

Trouble in fuel systemFuel pressure control valve defectiveReplace

Fuel filter cloggedReplace

Fuel pump cloggedClean or replace

Fuel tank or fuel pipe cloggedClean or replace

Fuel injector cloggedClean or replace

Fuel pump relay defectiveReplace

Power supply cable for fuel pump

broken or poor connectionsReconnect, correct or replace

Mass Airflow (MAF) sensor circuit

open or defectiveCorrect or replace

MAF Sensor defectiveReplace

Manifold Absolute Pressure Sensor

circuit open or shortedCorrect or replace

Manifold Absolute Pressure Sensor

defectiveReplace

Engine Coolant Temperature (ECT)

Sensor circuit open or shortedCorrect or replace

ECT Sensor defectiveReplace

Throttle Position Sensor adjustment

incorrectReadjust

Throttle Position Sensor defectiveReplace

Throttle Position Sensor connector

poor connectionsReconnect

Vehicle Speed Sensor cable poor

connections or defectiveCorrect or replace

Vehicle Speed Sensor loosely fixedFix tightly

Vehicle Speed Sensor in wrong

contact or defectiveReplace

Powertrain Control Module cable

poor connections or defectiveCorrect or replace

Page 1068 of 6000

6C–1

ENGINE FUEL

ENGINE

ENGINE FUEL

CONTENTS

Service Precaution 6C–1. . . . . . . . . . . . . . . . . . . . . .

General Description 6C–2. . . . . . . . . . . . . . . . . . . . .

Fuel Metering 6C–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 6C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter and Associated Parts 6C–4. . . . . . . . .

Removal 6C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 6C–5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

In–Tank Fuel Filter 6C–5. . . . . . . . . . . . . . . . . . . . .

Fuel Pump Flow Test 6C–5. . . . . . . . . . . . . . . . . . .

Fuel Pump 6C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pump and Associated Parts 6C–6. . . . . . . .

Removal 6C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pump Relay 6C–7. . . . . . . . . . . . . . . . . . . . . . . .

General Description 6C–7. . . . . . . . . . . . . . . . . . . . .

Fuel Tank 6C–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fuel Tank and Associated Parts 6C–7. . . . . . . . .

Removal 6C–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tube / Quick – Connect Fittings 6C–8. . . . . . .

Precautions 6C–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cautions During Work 6C–8. . . . . . . . . . . . . . . . . .

Removal 6C–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reuse of Quick–Connector 6C–10. . . . . . . . . . . . . . .

Assembling Advice 6C–10. . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge Unit 6C–11. . . . . . . . . . . . . . . . . . . . . . . .

Fuel Gauge Unit and Associated Parts 6C–11. . .

Removal 6C–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6C–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filler Cap 6C–12. . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 6C–12. . . . . . . . . . . . . . . . . . . . .

Inspection 6C–12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 6C–12. . . . . . . . . . . . .

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

Page 1072 of 6000

6C–5

ENGINE FUEL

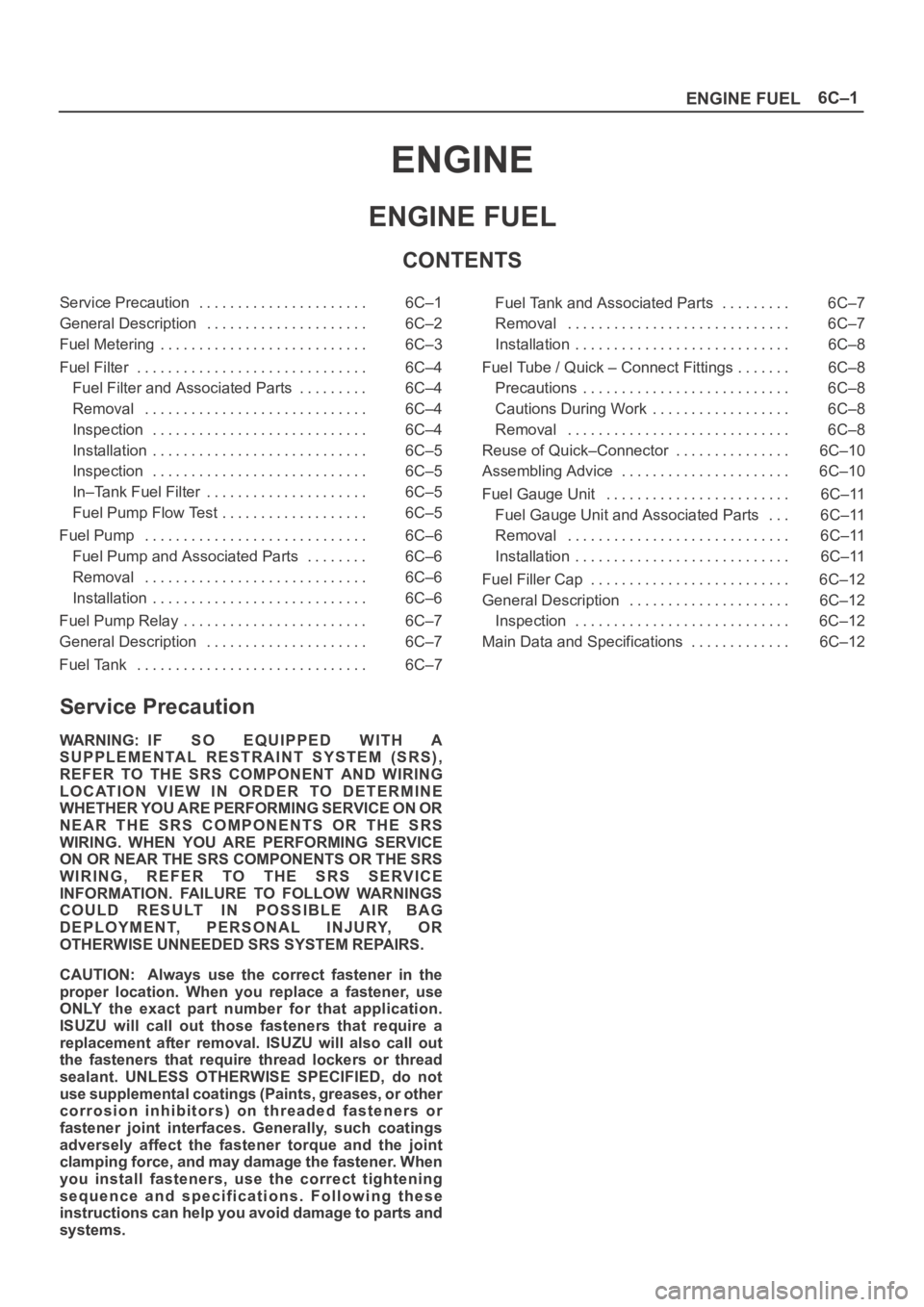

Installation

1. Install the fuel filter in the proper direction.

2. Install fuel filter holder fixing bolt.

3. Connect fuel hoses on engine side(1) and fuel tank

side(2).

041RW001

4. Install fuel filler cap

5. Connect the battery ground cable.

Inspection

After installation, start engine and check for fuel leakage.

In–Tank Fuel Filter

The filter is located on the lower end of fuel pickup tube in

the fuel tank. It prevents dirt from entering the fuel pipe

and also stops water unless the filter is completely

submerged in the water. It is a self cleaning type, not

requiring scheduled maintenance. Excess water and

sediment in the tank restricts fuel supply to the engine,

resulting in engine stoppage. In such a case, the tank

must be cleaned thoroughly.

Fuel Pump Flow Test

If reduction of fuel supply is suspected, perform the

following checks:

1. Make sure that there is fuel in the tank.

2. With the engine running, check the fuel feed pipe and

hose from fuel tank to injector for evidence of

leakage. Retighten, if pipe or hose connection is

loose. Also, check pipes and hoses for squashing or

clogging.

3. Insert the hose from fuel feed pipe into a clean

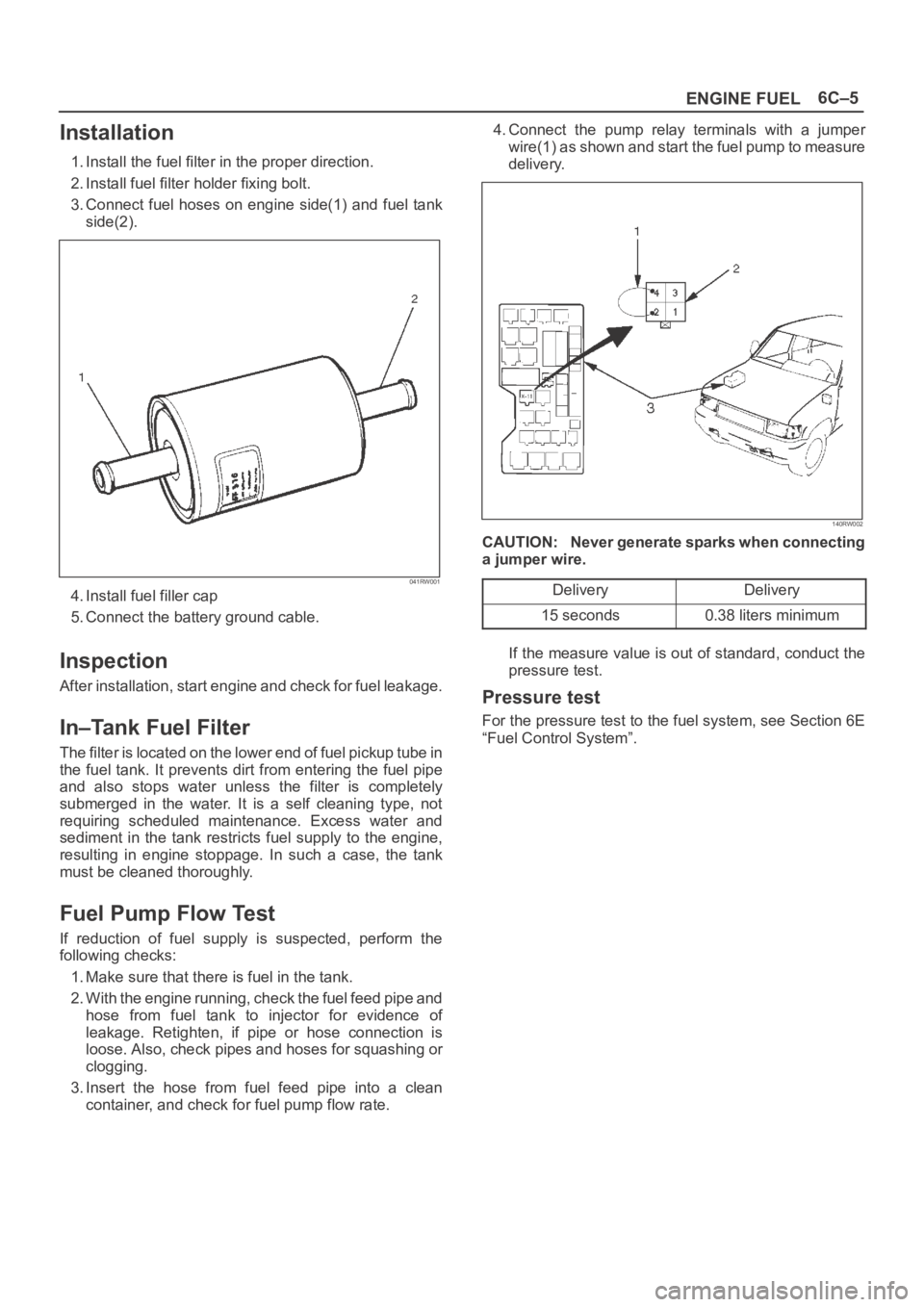

container, and check for fuel pump flow rate.4. Connect the pump relay terminals with a jumper

wire(1) as shown and start the fuel pump to measure

delivery.

140RW002

CAUTION: Never generate sparks when connecting

a jumper wire.

Delivery

Delivery

15 seconds0.38 liters minimum

If the measure value is out of standard, conduct the

pressure test.

Pressure test

For the pressure test to the fuel system, see Section 6E

“Fuel Control System”.