check oil OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5673 of 6000

6G – 6 ENGINE LUBRICATION

OIL COOLER ASSEMBLY

REMOVAL

1. Disconnect battery ground cable.

2. Drain engine coolant.

3. Remove front exhaust pipe.

4. Remove heat protector.

5. Remove exhaust valve assembly.

6. Oil cooler assembly.

1) Remove water hose from water inlet and outlet

side.

2) Cloth should be put under the oil cooler to

prevent oil from flowing out.

3) Loosen fixing bolt then remove oil cooler

assembly.

Legend

(1) Oil cooler assembly

(2) Oil filter assembly

INSPECTION AND REPAIR

1. Inspect for corrosion, wear, and breaks on the oil

cooler core.

2. If a problem is found on the oil cooler core, the oil

cooler assembly must be replaced.

INSTALLATION

1. Oil cooler assembly

1) Tighten oil cooler fixing bolt to the specified

torque and install water hoses.

Torque: 29 Nꞏm (3.0 kgꞏm / 21.7 lb ft)

2. Install exhaust valve assembly to turbocharger

assembly and tighten to the specified torque.

Torque: 27 Nꞏm (2.7 kgꞏm / 19.5 lb ft)3. Install front exhaust pipe to the exhaust valve.

To r q u e :

67 Nꞏm (6.8 kgꞏ.m / 49.2 lb ft)

(At exhaust valve side)

43 Nꞏm (4.4 kgꞏm / 32 lb ft)

(At center exhaust pipe side)

4. Install heater protector.

5. Fill engine coolant.

6. Connect battery ground cable.

7. Start engine and carefully check for leakage of oil

and coolant.

OIL COOLER SPECIFICATIONS

OIL FILTER

REMOVAL

1. Put container under the oil filter to prevent oil from

the oil filter from flowing out.

2. Use filter wrench to remove oil filter.

Filter wrench: 5-8840-0203-0

INSTALLATION

1. Apply engine oil thinly to oil filter O-ring.

2. Tighten oil filter by hand until O-ring comes in

contact with the sealing surface.

3. Use filter wrench to tighten oil filter one turn and 1/8

turn.

4. Start engine and carefully check for oil leakage from

oil filter.

SUB OIL FILTER

The sub oil filter requires no servicing until the

replacement interval is reached.

The element is designed to provide special filtering

efficiency until it becomes due for replacement.

It is recommended to check and replace the sub oil filter

when the engine is being overhauled or if it is broken

inside the engine.

1

2

050RW009

Page 5676 of 6000

ENGINE SPEED CONTROL 6H – 3

REMOVAL

1. For vehicle with MT

1) Remove harness connector from accelerator

pedal sensor.

2) Remove accelerator pedal assembly from

chassis.

2. For vehicle with A/T

1) Remove A/T control cable from accelerator

pedal assembly.

2) Remove harness connector from accelerator

pedal sensor.

3) Remove accelerator pedal assembly from

chassis.

INSPECTION AND REPAIR

1. Check moving condition of accelerator pedal, if not

smooth working, apply oil to the pivot etc.

2. Check tightening condition of accelerator sensor, if

not completely tightened, it should be tightened

additionally.

INSTALLATION

The installation for both MT and A/T vehicles follows the

reverse manner of removal.

ENGINE SPEED CONTROL

Page 5683 of 6000

6J – 6 INDUCTION

Legend

(1) Pressure gauge

(2) Waste gate control rod

4) Check for cracks or breaks on the hose, if a

problem is found, the hose must be replaced.

CAUTION: Do not apply more than 120 Kpa (900

mmHg / 18.7 PSi) to waste gate actuator.

INSTALLATION

1. Install turbocharger assembly to exhaust manifold,

tighten to the specified torque.

Torque: 27 Nꞏm (2.7 kgꞏm / 19.5 lb ft)2. Install exhaust valve assembly to outlet of

turbocharger, tighten bolts to the specified torque.

Torque: 27 Nꞏm (2.7 kgꞏm / 19.5 lb ft)

3. Install heat protector.

4. Water inlet pipe.

1) Tighten water inlet pipe with new gasket.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

5. Oil drain pipe.

1) Tighten oil drain pipe with new gasket.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

6. Oil inlet pipe.

1) Apply about 100 cc engine oil to turbocharger

housing before installing the oil pipe.

2) Turn the turbine shaft by hand to lubricate the

bearing.

3) Install the oil inlet pipe with a new gasket, tighten

bolt to the specified torque.

Torque: 22 Nꞏm (2.2 kgꞏm / 15.9 lb ft) For M10

Torque: 54 Nꞏm (5.5 kgꞏm / 39.8 lb ft) For M14

2

1

036RW011

036RW005

036RW006

Page 5687 of 6000

6J – 10 INDUCTION

INTAKE MANIFOLD

REMOVAL

1. Drain engine coolant and remove water hose from

thermostat housing

2. Remove intercooler assembly.

3. Remove bracket fixing bolt of oil level gauge guide

tube.

4. Remove PCV hose.

5. Remove hoses from EGR valve, EGR vacuum

sensor and outlet of heater unit.

6. Disconnect harness connector from MAP sensor,

EGR vacuum sensor, ETC sensor, Water

temperature unit, IAT sensor and EVRV.

7. Remove high pressure oil pipe.

8. Remove two way check valve.

9. Remove fuel pipe.

10. Remove fixing bolts and nuts of intake manifold,

remove intake manifold assembly.

Legend

(1) Intake manifold

(2) Fixing portion of throttle valve

(3) EGR passage

(4) EGR valve

2

3

4

1

Legend

(1) Intake Manifold

(2) Throttle Valve Assembly

(3) EGR Valve

(4) Gasket

025RW022

3124

025RW031

Page 5688 of 6000

INDUCTION 6J – 11

INSPECTION AND RAPAIR

1. Visually check for cracks/clogs inside intake

manifold.

2. If foreign material is observed, it should be taken

out, and if there are some cracks on the intake

manifold, it must be replaced.

INSTALLATION

1. Install the intake manifold assembly, tighten bolts

and to the specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft) for bolt

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft) for nut

2. Install fuel pipe.

Torque: 4 Nꞏm (0.4 kgꞏm / 2.9 lb ft) for M16 nut

(Apply engine oil)

Torque: 13 Nꞏm (1.3 kgꞏm / 9.4 lb ft) for M10 cap nut

Torque: 14 Nꞏm (1.4 kgꞏm / 10 lb ft) for M10

(Apply engine oil)

3. Install two way check valve.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft)

4. Fill with about 300 cc of engine oil from the high

pressure oil pipe installation port of the oil rail using

an oil filler.

If assembled without filling the oil rail with oil, the

time for engine starting will be longer.

5. Install high pressure oil pipe, then tighten sleeve nut

to the specified torque.

Torque: 29 Nꞏm (3.0 kgꞏm / 21.7 lb ft)

6. Reconnect harness connector to MAP sensor, EGR

vacuum sensor, ETC sensor, Water thermo unit,

IAT sensor and EVRV sensor.

7. Install hoses to EGR valve, EGR vacuum sensor

and Water outlet of heater.

8. Connect PCV hose.

9. Install oil level gauge guide and fix it.

10. Install intercooler assembly.

Refer to “Intercooler” in this manual.

11. Install water hose to thermostat housing and fill with

engine coolant.

Model of Turbocharger IHI RHF5

Turbine Maximum Speed 180,000 rpm

Maximum Inlet Gas Temperature 800 °C (1472 °F)

Vibration Peak (G) criteria Maximum 4 (G) at Turbine Rotor Speed 140,000 rpm

Tolerance Limit of Compressor Blade Height Less then 0.5 mm (0.0197 in)

MAIN DATA AND SPECIFICATIONS

Page 5690 of 6000

7A–1 AUTOMATIC TRANSMISSION (4L30–E)

TRANSMISSION

AUTOMATIC TRANSMISSION (4L30–E)

CONTENTS

Service Precaution 7A–3. . . . . . . . . . . . . . . . . . . . . .

Construction 7A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Range Reference Chart 7A–4. . . . . . . . . . . . . . . . . .

Normal Operation Of 2000 4L30–E

Transmission 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosis 7A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Driver Information 7A–5. . . . . . . . . . . . . . . . . . . . . . .

General Diagnosis Procedure 7A–8. . . . . . . . . . . . .

Preliminary Inspection Chart 7A–9. . . . . . . . . . . . . .

Checking Transmission Fluid Level and

Condition 7A–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Driving 7A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis Check Trans

Indicator Chart 7A–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical / Hydraulic Diagnosis

Symptoms Index 7A–13. . . . . . . . . . . . . . . . . . . . . . . .

Stall Test 7A–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Pressure Test 7A–23. . . . . . . . . . . . . . . . . . . . . .

Shift Speed Chart (V6 3.2L 6VD1 Model) 7A–24. . .

Shift Speed Chart (V6 3.5L 6VE1 Model) 7A–26. .

Lockup Speed Chart (V6 3.2L 6VD1 Model) 7A–28

Lockup Speed Chart (V6 3.5L 6VE1 Model) 7A–28

Changing Transmission Fluid 7A–29. . . . . . . . . . . . .

Selector Lever 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 7A–29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mode Switch 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (With Transfer Case) 7A–33. . . . . . . .

Transmission And Associated Parts 7A–33. . . . . .

Removal 7A–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Main Case Valve Body) 7A–39. . . . . . . . .

Removal 7A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Solenoid (Adapter Case Valve Body) 7A–40. . . . . . .

Removal 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–40. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Main Case) 7A–41. . . . . . . .

Removal 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Body Assembly (Adapter Case) 7A–43. . . . . .

Removal 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . Installation 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powertrain Control Module (PCM) 7A–43. . . . . . . . .

Removal 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Sensor (Extension Housing) 7A–44. . . . . . . .

Removal 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Oil Temperature Sensor

(Adapter Case) 7A–44. . . . . . . . . . . . . . . . . . . . . . . . .

Removal 7A–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Oil Seal (Converter Housing) 7A–45. . . . . . . .

Removal 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal (Extension Housing) 7A–46. . . . . . . . .

Removal 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission (4L30–E) 7A–46. . . . . . . . . . . . . . . . . .

Disassembly 7A–46. . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly 7A–50. . . . . . . . . . . . . . . . . . . . . . . . . .

Converter Housing And Oil Pump Assembly 7A–60

Disassembled View 7A–60. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–60. . . . . . . . . . . . . . . . . .

Reassembly 7A–60. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembled View 7A–61. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–61. . . . . . . . . . . . . . . . . .

Reassembly 7A–61. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Case Valve Body 7A–62. . . . . . . . . . . . . . . . . . .

Disassembled View 7A–62. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–62. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–63. . . . . . . . . . . . . . . . . .

Reassembly 7A–63. . . . . . . . . . . . . . . . . . . . . . . . . .

Adapter Case Valve Body 7A–64. . . . . . . . . . . . . . . .

Disassembled View 7A–64. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–64. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–64. . . . . . . . . . . . . . . . . .

Reassembly 7A–64. . . . . . . . . . . . . . . . . . . . . . . . . .

Third Clutch And Sprag Unit 7A–65. . . . . . . . . . . . . .

Disassembled View 7A–65. . . . . . . . . . . . . . . . . . . .

Disassembly 7A–65. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection And Repair 7A–66. . . . . . . . . . . . . . . . . .

Page 5694 of 6000

7A–5 AUTOMATIC TRANSMISSION (4L30–E)

Normal Operation Of 2000 4L30–E

Tr a n s m i s s i o n

Torque Converter Clutch (TCC)

Application Conditions:

The TCC is normally applied in 2nd, 3rd and 4th gears

only when all of the following conditions exist:

— The engine coolant temperature is above 70

C

(158

F).

— The brake pedal is released.

— The shift pattern requests TCC apply.

Moreover, TCC is always applied in 2nd, 3rd and 4th

gears when the transmission oil temperature is above

135

C (275F).

This mode should be canceled at 125

C (257F).

ATF Warning Lamp

The ATF warning lamp will be constantly on (not flashing)

if the transmission oil temperature is above 145

C

(293

F).

The ATF warning lamp goes off again when the

transmission oil temperature is below 125

C (257F).

Special Shift Pattern When The Engine Is

Cold:

A special shift pattern is activated when the engine

coolant temperature is below 70

C (158F). (3–4 shifts,

for example, are delayed for small throttle openings and

will occur a few MPH higher.)

Diagnosis

Introduction

The systematic troubleshooting information covered by

this Section offers a practical and systematic approach to

diagnosing 4L30–E transmission, using information that

can be obtained from road tests, electrical diagnosis, oil

pressure checks or noise evaluation.

The key to correcting a complaint is to make use of all of

the available symptoms and logically letting them direct

you to the cause.

When dealing with automatic transmission complaints, it

is best to gather as many symptoms as possible before

making the decision to remove the transmission from the

vehicle.

Frequently, the correction of the complaint does not

require removal of the transmission from the vehicle.

Driver Information

To analyze the problem fill out a complete description of

the owner’s complaint.

Please draw a circle around the right information and

complete the following form. (The next page is an

example of a completed form). You can draw a circle

around many numbers if you are not sure.

Page 5699 of 6000

7A–10

AUTOMATIC TRANSMISSION (4L30–E)

Checking Transmission Fluid Level

and Condition

Checking fluid level and condition (color and odor) at

regular intervals will provide early diagnosis information

about the transmission. This information may be used to

correct a condition that, if not detected early, could result

in major transmission repairs.

IMPORTANT:When new, automatic transmission fluid

is red in color. As the vehicle is driven, the transmission

fluid will begin to look darker in color. The color may

eventually appear light brown.

A dark brown color with burnt odor may indicate

excessive fluid deterioration and signal a need for fluid

change.

Fluid Level

When adding or changing fluid, use only DEXRON –III.

Refer to Maintenance and Lubrication in General

Information section for maintenance information and

servicing interval.

CAUTION: DO NOT OVERFILL.

Overfilling will cause foaming, loss of fluid, abnor-

mal shifting and possible damage to the transmis-

sion.

1. Park the vehicle on level ground and apply the parking

brake firmly.

2. Check fluid level with engine running at idle.

NOTE: Be sure that transmission fluid temperature is

below 30

C (86F).

3. Move the selector lever through all gear ranges.

4. Move the selector lever to “Park”.

5. Let engine idle for 3 minutes and open the overfill

screw (1).

6. Add released transmission fluid until it flows out over

the overfill screw opening.

7. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached, then close the

overfill screw (1).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.NOTE: Check transmission fluid temperature with scan

tool.

Minimum fluid level

57C (135F)

Maximum fluid level

32C (90F)

242RW003

CAUTION: Do not open overfill screw with engine

stopped.

CAUTION: DO NOT CHECK FLUID LEVEL UNDER

THESE CONDITIONS:

Immediately after driving at sustained highway

speeds.

In heavy city traffic during hot weather.

If vehicle is towing a trailer.

If the vehicle has been operated under these conditions,

shut the engine off and allow the vehicle to “cool” for thirty

(30) minutes. After the cool down period, restart the

vehicle and continue from step 2 above.

Page 5707 of 6000

7A–18

AUTOMATIC TRANSMISSION (4L30–E)

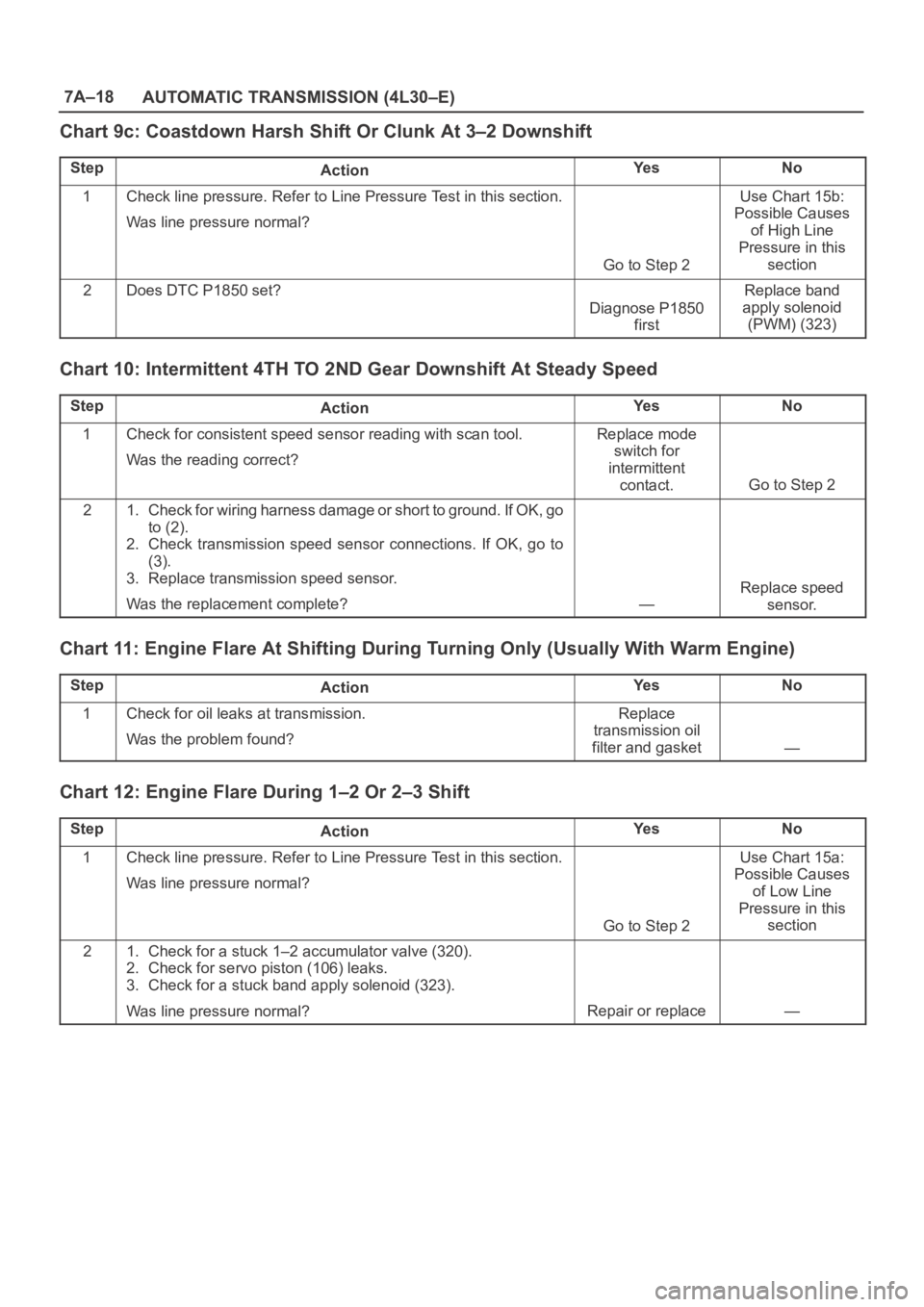

Chart 9c: Coastdown Harsh Shift Or Clunk At 3–2 Downshift

StepActionYe sNo

1Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15b:

Possible Causes

of High Line

Pressure in this

section

2Does DTC P1850 set?

Diagnose P1850

first

Replace band

apply solenoid

(PWM) (323)

Chart 10: Intermittent 4TH TO 2ND Gear Downshift At Steady Speed

StepActionYe sNo

1Check for consistent speed sensor reading with scan tool.

Was the reading correct?Replace mode

switch for

intermittent

contact.

Go to Step 2

21. Check for wiring harness damage or short to ground. If OK, go

to (2).

2. Check transmission speed sensor connections. If OK, go to

(3).

3. Replace transmission speed sensor.

Was the replacement complete?

—

Replace speed

sensor.

Chart 11: Engine Flare At Shifting During Turning Only (Usually With Warm Engine)

StepActionYe sNo

1Check for oil leaks at transmission.

Was the problem found?Replace

transmission oil

filter and gasket

—

Chart 12: Engine Flare During 1–2 Or 2–3 Shift

StepActionYe sNo

1Check line pressure. Refer to Line Pressure Test in this section.

Was line pressure normal?

Go to Step 2

Use Chart 15a:

Possible Causes

of Low Line

Pressure in this

section

21. Check for a stuck 1–2 accumulator valve (320).

2. Check for servo piston (106) leaks.

3. Check for a stuck band apply solenoid (323).

Was line pressure normal?

Repair or replace—

Page 5708 of 6000

7A–19 AUTOMATIC TRANSMISSION (4L30–E)

Chart 13: Shudder Only During Torque Converter Clutch (TCC) Applying

StepActionYe sNo

11. TCC shudder is one of the most commonly misdiagnosed

conditions in an automatic transmission. The key to

diagnosing TCC shudder is to note when it happens and under

what conditions. Once the TCC has been fully applied, it is

nearly impossible to make it shudder. TCC shudder (short

burst of noise normally less than 1 second) will only occur

during clutch applying. It is not a steady state condition.

2. Drive until whole drivetrain is at normal operating temperature.

– On 4WD vehicles, the test must be performed with transfer

case selector lever in “2H” position.

– Shudder is a short burst of noise normally less than 1 second

in duration, and can be induced by the following maneuver:

3. From coast condition at 50 mph in “D” range (Normal mode),

depress the throttle to 1/4-1/3 throttle. If present, shudder will

occur within 5 seconds together with TCC application.(The

scan tool may be used to determine the exact time of TCC

applying)

Was the problem found?

Replace

transmission fluid

and filter (remove

both pans) and

flush cooler lines.

Replace

converter

assembly and

O-ring on turbine

shaft

Perform

mechanical

inspection of

other drivetrain

components.

Chart 14: Possible Causes Of Transmission Noise

CAUTION: Before checking transmission for what

is believed to be transmission noise, ensure

presence and positioning of insulating plugs, pads

etc. Also make sure that noise does not come from

other drivetrain components.

Condition

Possible causeCorrection

Whine or BuzzOil level lowFill with ATF, check for external

leaks.

Plugged or restricted oil filterInspect oil filter.

Replace oil filter or ATF as necessary.

Damaged oil filter gasketReplace oil filter gasket.

Knocking noise from front of

transmission

Loose bolts (Converter to flex plate)Tighten to specifications.

transmission.Cracked or broken flex plateReplace flex plate.

Converter damagedReplace converter.

Knocking noise while driving, mostly

on acceleration.Transmission mount loose or brokenTighten mount bolts or replace

transmission mount.

Cooler line mounts loose or brokenTighten or replace cooler line

mounts.

Cooler lines touching body or frameRepair or replace as necessary.

Knocking noise when vehicle is

stationary

Loose flex plate mounting boltsTighten to specifications.

stationary.Cracked or broken flex plateReplace flex plate.

Damaged converterReplace converter.