light OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5368 of 6000

ENGINE MECHANICAL 6A – 95

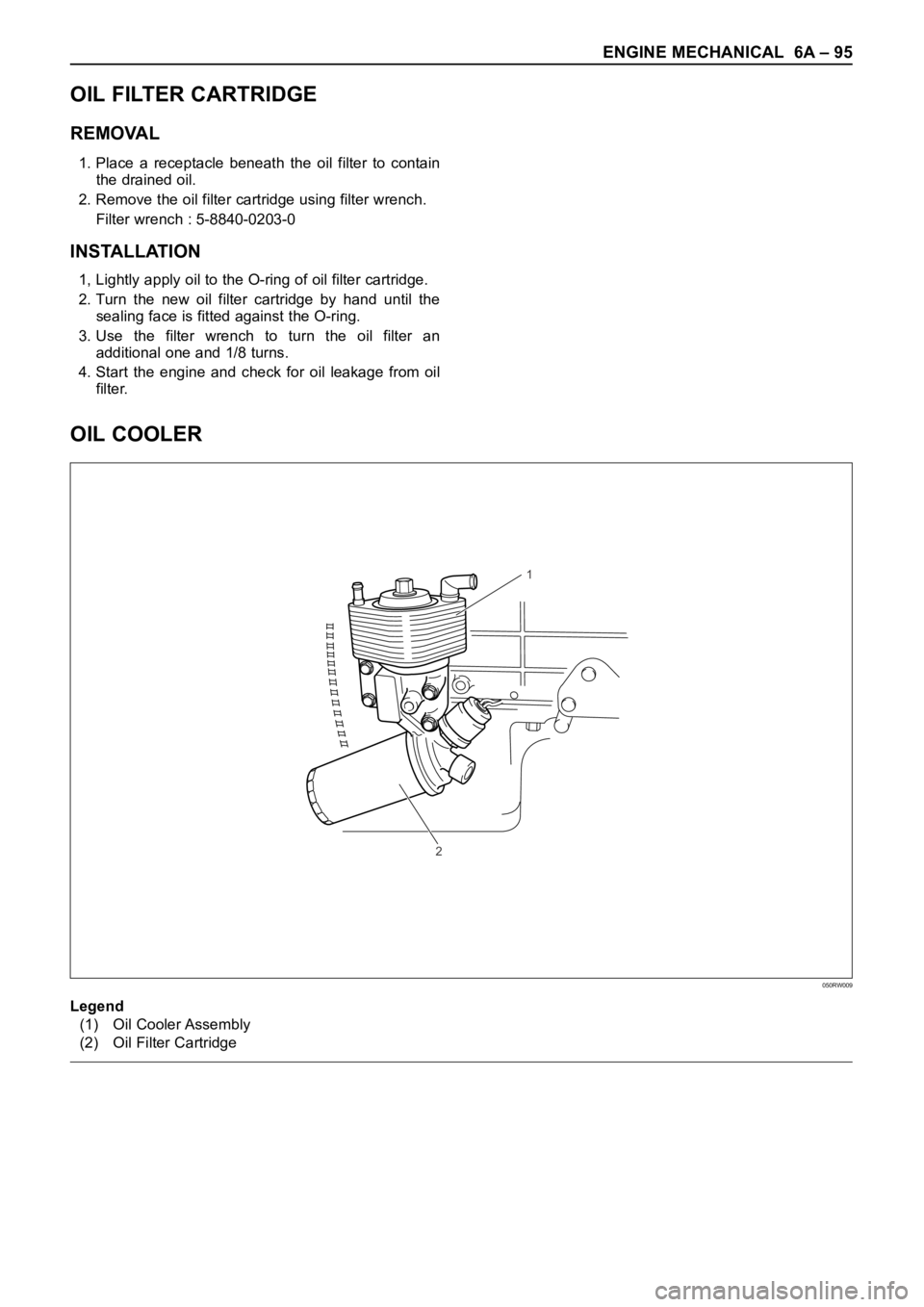

OIL COOLER

1

2

050RW009

Legend

(1) Oil Cooler Assembly

(2) Oil Filter Cartridge

OIL FILTER CARTRIDGE

REMOVAL

1. Place a receptacle beneath the oil filter to contain

the drained oil.

2. Remove the oil filter cartridge using filter wrench.

Filter wrench : 5-8840-0203-0

INSTALLATION

1, Lightly apply oil to the O-ring of oil filter cartridge.

2. Turn the new oil filter cartridge by hand until the

sealing face is fitted against the O-ring.

3. Use the filter wrench to turn the oil filter an

additional one and 1/8 turns.

4. Start the engine and check for oil leakage from oil

filter.

Page 5389 of 6000

6C – 8 ENGINE FUEL

ON-VEHICLE SERVICE

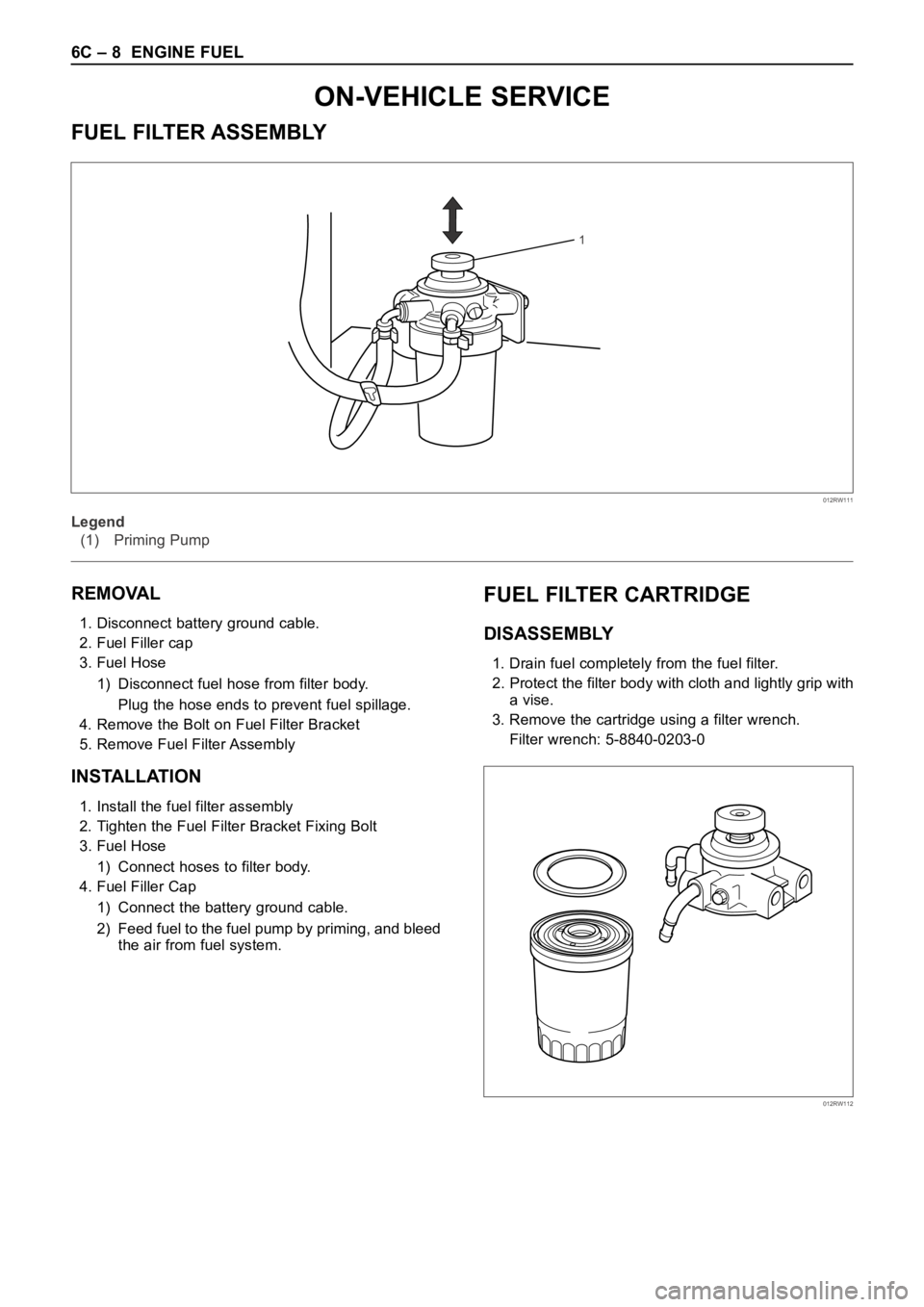

FUEL FILTER ASSEMBLY

REMOVAL

1. Disconnect battery ground cable.

2. Fuel Filler cap

3. Fuel Hose

1) Disconnect fuel hose from filter body.

Plug the hose ends to prevent fuel spillage.

4. Remove the Bolt on Fuel Filter Bracket

5. Remove Fuel Filter Assembly

INSTALLATION

1. Install the fuel filter assembly

2. Tighten the Fuel Filter Bracket Fixing Bolt

3. Fuel Hose

1) Connect hoses to filter body.

4. Fuel Filler Cap

1) Connect the battery ground cable.

2) Feed fuel to the fuel pump by priming, and bleed

the air from fuel system.

FUEL FILTER CARTRIDGE

DISASSEMBLY

1. Drain fuel completely from the fuel filter.

2. Protect the filter body with cloth and lightly grip with

a vise.

3. Remove the cartridge using a filter wrench.

Filter wrench: 5-8840-0203-0

1

Legend

(1) Priming Pump

012RW111

012RW112

Page 5390 of 6000

ENGINE FUEL 6C – 9

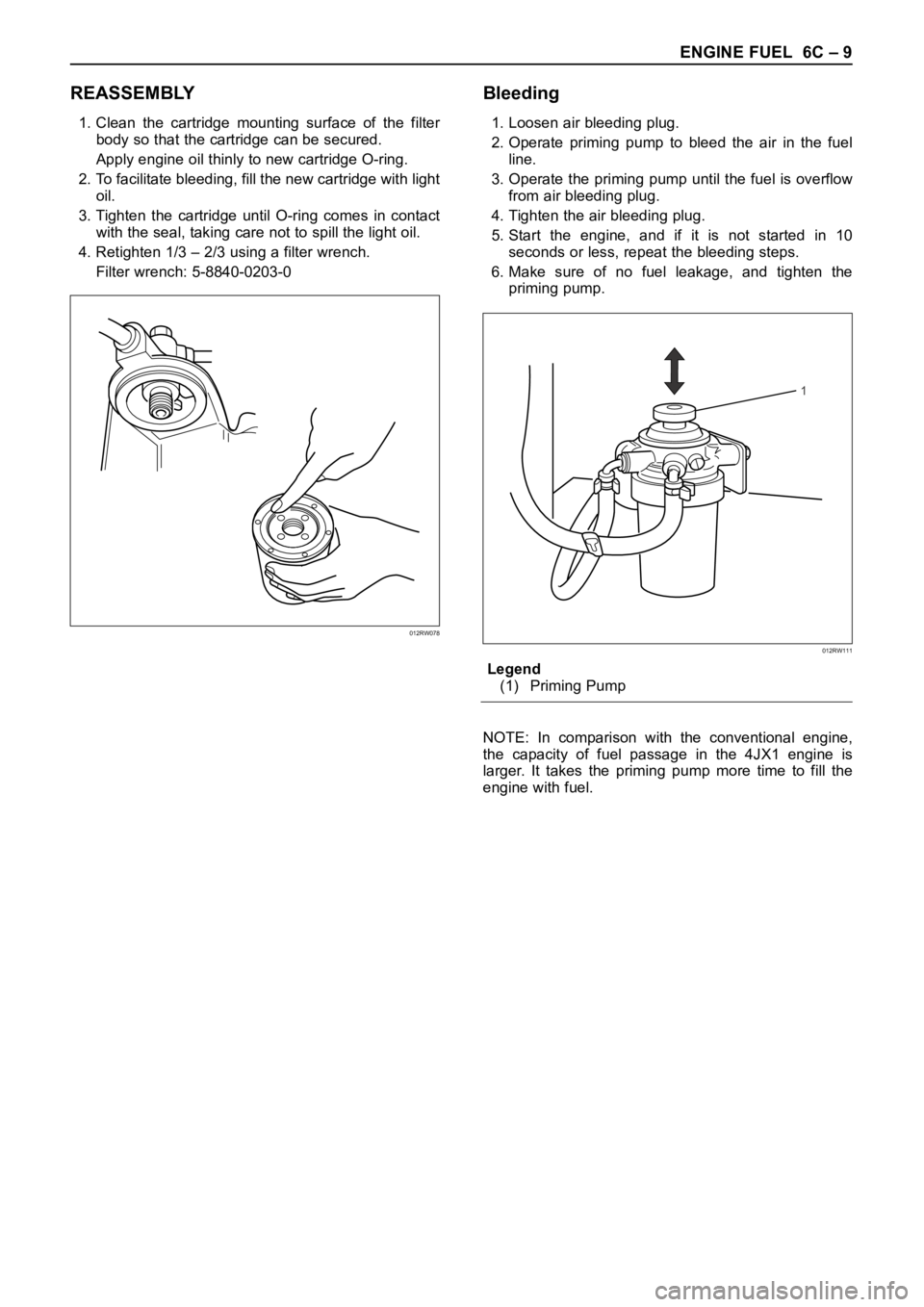

REASSEMBLY

1. Clean the cartridge mounting surface of the filter

body so that the cartridge can be secured.

Apply engine oil thinly to new cartridge O-ring.

2. To facilitate bleeding, fill the new cartridge with light

oil.

3. Tighten the cartridge until O-ring comes in contact

with the seal, taking care not to spill the light oil.

4. Retighten 1/3 – 2/3 using a filter wrench.

Filter wrench: 5-8840-0203-0

Bleeding

1. Loosen air bleeding plug.

2. Operate priming pump to bleed the air in the fuel

line.

3. Operate the priming pump until the fuel is overflow

from air bleeding plug.

4. Tighten the air bleeding plug.

5. Start the engine, and if it is not started in 10

seconds or less, repeat the bleeding steps.

6. Make sure of no fuel leakage, and tighten the

priming pump.

Legend

(1) Priming Pump

NOTE: In comparison with the conventional engine,

the capacity of fuel passage in the 4JX1 engine is

larger. It takes the priming pump more time to fill the

engine with fuel.

012RW078

1

012RW111

Page 5404 of 6000

ENGINE ELECTRICAL 6D – 1

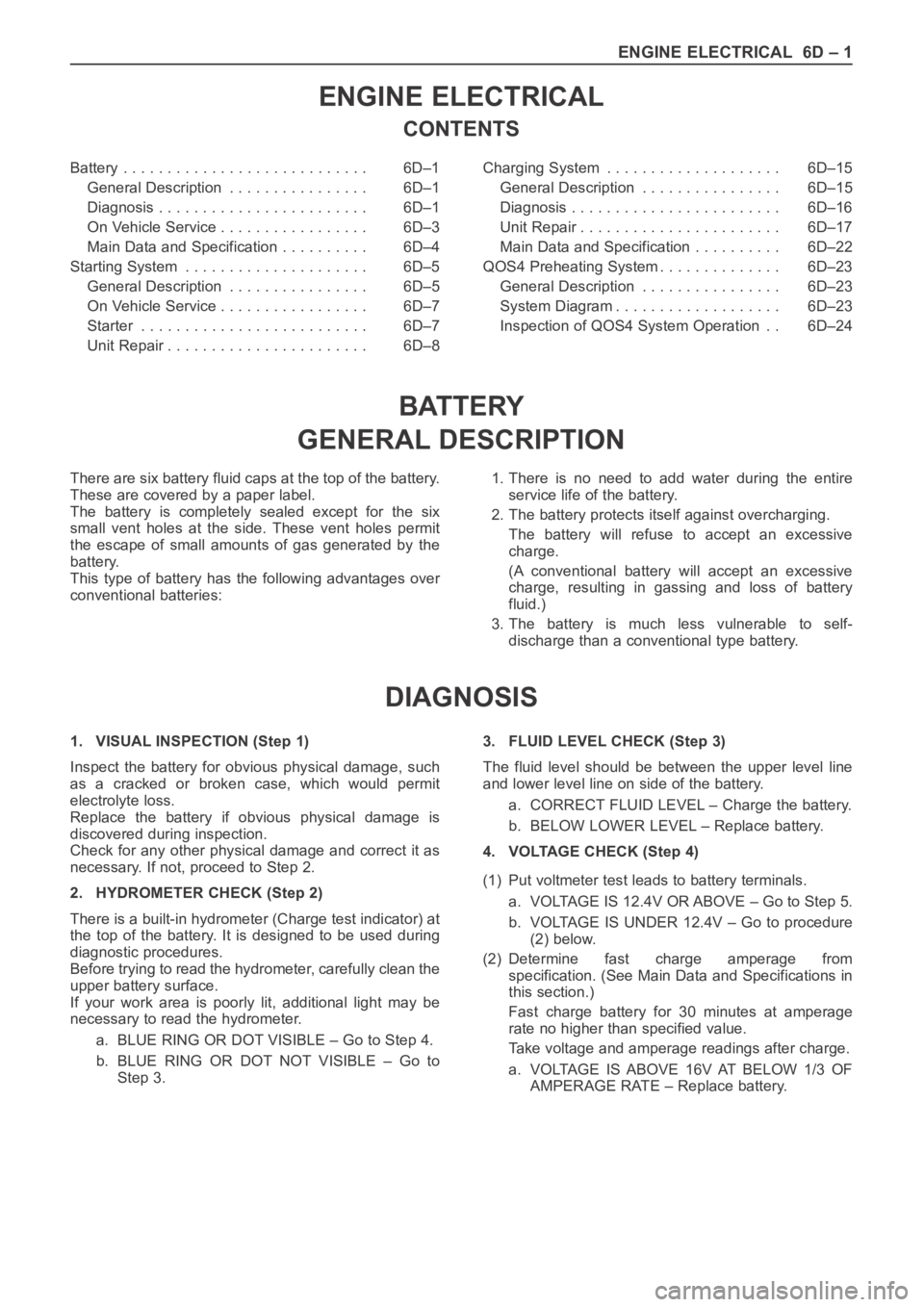

ENGINE ELECTRICAL

CONTENTS

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6D–1

General Description . . . . . . . . . . . . . . . . 6D–1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . 6D–1

On Vehicle Service . . . . . . . . . . . . . . . . . 6D–3

Main Data and Specification . . . . . . . . . . 6D–4

Starting System . . . . . . . . . . . . . . . . . . . . . 6D–5

General Description . . . . . . . . . . . . . . . . 6D–5

On Vehicle Service . . . . . . . . . . . . . . . . . 6D–7

Starter . . . . . . . . . . . . . . . . . . . . . . . . . . 6D–7

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 6D–8Charging System . . . . . . . . . . . . . . . . . . . . 6D–15

General Description . . . . . . . . . . . . . . . . 6D–15

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . 6D–16

Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 6D–17

Main Data and Specification . . . . . . . . . . 6D–22

QOS4 Preheating System . . . . . . . . . . . . . . 6D–23

General Description . . . . . . . . . . . . . . . . 6D–23

System Diagram . . . . . . . . . . . . . . . . . . . 6D–23

Inspection of QOS4 System Operation . . 6D–24

BATTERY

GENERAL DESCRIPTION

DIAGNOSIS

There are six battery fluid caps at the top of the battery.

These are covered by a paper label.

The battery is completely sealed except for the six

small vent holes at the side. These vent holes permit

the escape of small amounts of gas generated by the

battery.

This type of battery has the following advantages over

conventional batteries:1. There is no need to add water during the entire

service life of the battery.

2. The battery protects itself against overcharging.

The battery will refuse to accept an excessive

charge.

(A conventional battery will accept an excessive

charge, resulting in gassing and loss of battery

fluid.)

3. The battery is much less vulnerable to self-

discharge than a conventional type battery.

1. VISUAL INSPECTION (Step 1)

Inspect the battery for obvious physical damage, such

as a cracked or broken case, which would permit

electrolyte loss.

Replace the battery if obvious physical damage is

discovered during inspection.

Check for any other physical damage and correct it as

necessary. If not, proceed to Step 2.

2. HYDROMETER CHECK (Step 2)

There is a built-in hydrometer (Charge test indicator) at

the top of the battery. It is designed to be used during

diagnostic procedures.

Before trying to read the hydrometer, carefully clean the

upper battery surface.

If your work area is poorly lit, additional light may be

necessary to read the hydrometer.

a. BLUE RING OR DOT VISIBLE – Go to Step 4.

b. BLUE RING OR DOT NOT VISIBLE – Go to

Step 3.3. FLUID LEVEL CHECK (Step 3)

The fluid level should be between the upper level line

and lower level line on side of the battery.

a. CORRECT FLUID LEVEL – Charge the battery.

b. BELOW LOWER LEVEL – Replace battery.

4. VOLTAGE CHECK (Step 4)

(1) Put voltmeter test leads to battery terminals.

a. VOLTAGE IS 12.4V OR ABOVE – Go to Step 5.

b. VOLTAGE IS UNDER 12.4V – Go to procedure

(2) below.

(2) Determine fast charge amperage from

specification. (See Main Data and Specifications in

this section.)

Fast charge battery for 30 minutes at amperage

rate no higher than specified value.

Take voltage and amperage readings after charge.

a. VOLTAGE IS ABOVE 16V AT BELOW 1/3 OF

AMPERAGE RATE – Replace battery.

Page 5406 of 6000

ENGINE ELECTRICAL 6D – 3

ON-VEHICLE SERVICE

BATTERY CHARGING

Observe the following safety precautions when

charging the battery:

1. Never attempt to charge the battery when the fluid

level is below the lower level line on the side of the

battery. In this case, the battery must be replaced.

2. Pay close attention to the battery during the

charging procedure.

Battery charging should be discontinued or the rate

of charge reduced if the battery feels hot to the

touch.

Battery charging should be discontinued or the rate

of charge reduced if the battery begins to gas or

spew electrolyte from the vent holes.

3. In order to more easily view the hydrometer blue

dot or ring, it may be necessary to jiggle or tilt the

battery.

4. Battery temperature can have a great effect on

battery charging capacity.

5. The sealed battery used on this vehicle may be

either quick-charged or slow-charged in the same

manner as other batteries.

Whichever method you decide to use, be sure that

you completely charge the battery. Never partially

charge the battery.

JUMP STARTING

JUMP STARTING WITH AN AUXILIARY

(BOOSTER) BATTERY

CAUTION: Never push or tow the vehicle in an

attempt to start it. Serious damage to the emission

system as well as other vehicle parts will result.

Treat both the discharged battery and the booster

battery with great care when using jumper cables.

Carefully follow the jump starting procedure, being

careful at all times to avoid sparking.

WARNING: Failure to carefully follow the jump

starting procedure could result in the following:

1. Serious personal injury, particularly to your

eyes.

2. Property damage from a battery explosion,

battery acid, or an electrical fire.

3. Damage to the electronic components of one or

both vehicles.

Never expose the battery to an open flame or electrical

spark. Gas generated by the battery may catch fire or

explode. Remove any rings, watches, or other jewelry

before working around the battery. Protect your eyes by

wearing an approved set of goggles.

Never allow battery fluid to come in contact with your

eyes or skin.

Never allow battery fluid to come in contact with fabrics

or painted surfaces.

Battery fluid is a highly corrosive acid.Should battery fluid come in contact with your eyes,

skin, fabric, or a painted surface, immediately and

thoroughly rinse the affected area with clean tap water.

Never allow metal tools or jumper cables to come in

contact with the positive battery terminal, or any other

metal surface of the vehicle. This will protect against a

short circuit.

Always keep batteries out of the reach of young

children.

JUMP STARTING PROCEDURE

1. Set the vehicle parking brake.

If the vehicle is equipped with an automatic

transmission, place the selector lever in the “PARK”

position.

If the vehicle is equipped with a manual

transmission place the shift lever in the “NEUTRAL”

position.

Turn “OFF” the ignition.

Turn “OFF” all lights and any other accessory

requiring electrical power.

2. Look at the built-in hydrometer.

If the indication area of the built-in hydrometer is

completely clear, do not try to jump start.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery.

Attach the other end of the same cable to the

positive terminal of the discharged battery.

Do not allow the vehicles to touch each other.

This will cause a ground connection, effectively

neutralizing the charging procedure.

Be sure that the booster battery has a 12 volt rating.

4. Attach one end of the remaining cable to the

negative terminal of the booster battery.

Attach the other end of the same cable to a solid

engine ground (such as the A/C compressor

bracket or the generator mounting bracket) of the

vehicle with the discharged battery.

This ground connection must be at least 450 mm

(18 in) from the battery of the vehicle whose battery

is being charged.

WARNING: Never attach the end of the jumper

cable directly to the negative terminal of the dead

battery.

5. Start the engine of the vehicle with the good battery.

Make sure that all unnecessary electrical

accessories have been turned “OFF”.

6. Start the engine of the vehicle with the dead battery.

7. To remove the jumper cables, follow the above

directions in the reverse order.

Be sure to first disconnect the negative cable from

the vehicle with the discharged battery.

Page 5427 of 6000

6D – 24 ENGINE ELECTRICAL

1 Inspection on Quick Heating Operation

1. Disconnect ECT-sensor connection on the

thermostat housing

Legend

(1) ECT Sensor

(2) EVRV

2. Connect the circuit tester between glow plug and

engine earth.

3. Inspect the following items with starter switch set to

ON position (but do not start the engine).

1) The glow indicator shall light for about 5 sec.

2) The circuit tester shall indicate power supply

voltage for 9 – 13 sec.

If above specifications are not satisfied, inspect

wire harness, glow relay and ECT-sensor. If

satisfied, inspect glow plug.2 Inspection on Afterglow Operation

1. Disconnect ECT-sensor connection on the

thermostat housing

Legend

(1) ECT Sensor

(2) EVRV

2. Connect the circuit tester between glow plug and

engine earth.

3. Inspect the following item with the engine started.

1) The circuit tester shall indicate about 7 volts

after 360 seconds of engine start.

If above specifications are not satisfied, inspect

battery voltage, engine earth, wiring harness,

glow plug, and ECM.

12

060RW166

065RW035

12

060RW166

065RW035

INSPECTION ON QOS4 SYSTEM OPERATION

Page 5452 of 6000

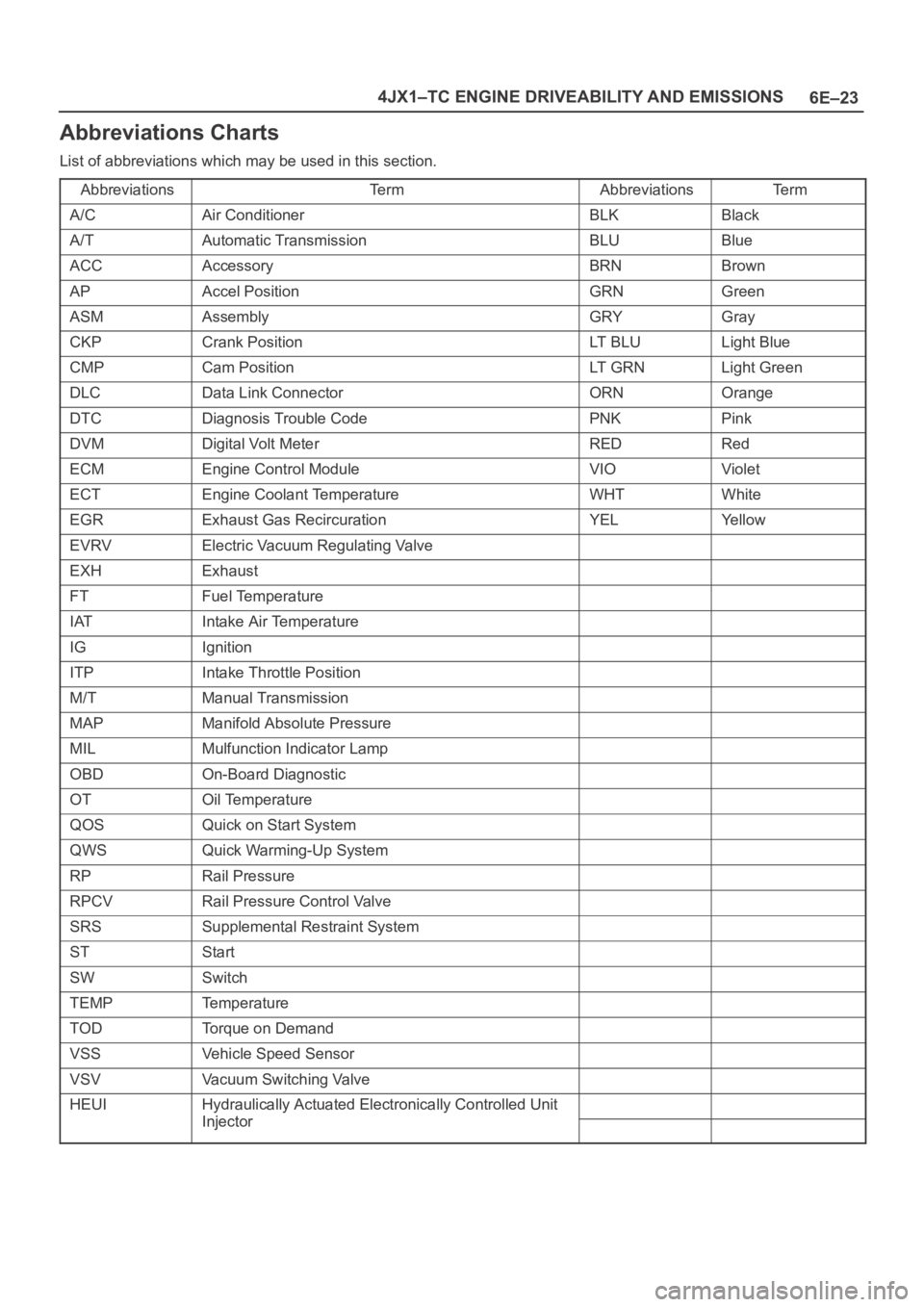

6E–23 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Abbreviations Charts

List of abbreviations which may be used in this section.

Abbreviations

Te r mAbbreviationsTe r m

A/CAir ConditionerBLKBlack

A/TAutomatic TransmissionBLUBlue

ACCAccessoryBRNBrown

APAccel PositionGRNGreen

ASMAssemblyGRYGray

CKPCrank PositionLT B L ULight Blue

CMPCam PositionLT G R NLight Green

DLCData Link ConnectorORNOrange

DTCDiagnosis Trouble CodePNKPink

DVMDigital Volt MeterREDRed

ECMEngine Control ModuleVIOViolet

ECTEngine Coolant TemperatureWHTWhite

EGRExhaust Gas RecircurationYELYe l l o w

EVRVElectric Vacuum Regulating Valve

EXHExhaust

FTFuel Temperature

IATIntake Air Temperature

IGIgnition

ITPIntake Throttle Position

M/TManual Transmission

MAPManifold Absolute Pressure

MILMulfunction Indicator Lamp

OBDOn-Board Diagnostic

OTOil Temperature

QOSQuick on Start System

QWSQuick Warming-Up System

RPRail Pressure

RPCVRail Pressure Control Valve

SRSSupplemental Restraint System

STStart

SWSwitch

TEMPTemperature

TODTorque on Demand

VSSVehicle Speed Sensor

VSVVacuum Switching Valve

HEUIHydraulically Actuated Electronically Controlled Unit

InjectorInjector

Page 5460 of 6000

6E–31 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

060RW120

Menu

The following table shows, which functions are used

the available equipment versions.

F0: Diagnostic Trouble Codes

F0: Read DTC Info Ordered By Priority

F1: Read DTC Info As Stored By ECU

F2: Clear DTC Information

F3: Freeze Frame / Failure Records

F1: Data Display

F2: Snapshot

F3: Actuator Tests

F0: Checklight

F1: Glow Time Lamp

F2: EGR Switching Valve

F3: Exhaust Switching Valve 1

F4: Exhaust Switching Valve 2

F4: Miscellaneous Tests

F0: Throttle Motor Control

F1: Rail Pressure Control

F2: EGR Regulating Valve Control

F3: Rail Pressure Control Valve

F4: Injector Balance Test

F5: Programming

F0: Injector Calibration

(F1: Rail Pressure Calibration)

Page 5473 of 6000

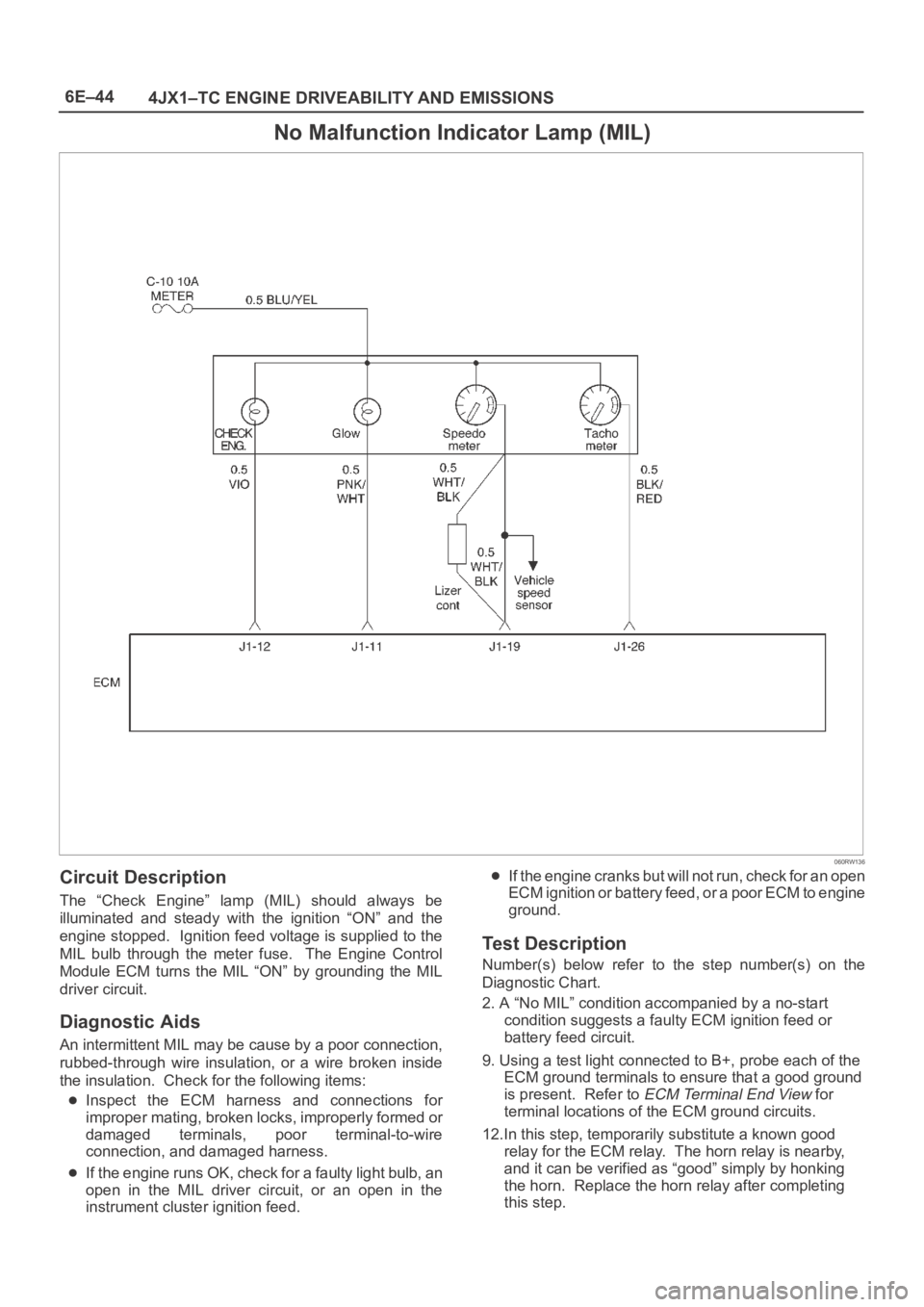

6E–44

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

No Malfunction Indicator Lamp (MIL)

060RW136

Circuit Description

The “Check Engine” lamp (MIL) should always be

illuminated and steady with the ignition “ON” and the

engine stopped. Ignition feed voltage is supplied to the

MIL bulb through the meter fuse. The Engine Control

Module ECM turns the MIL “ON” by grounding the MIL

driver circuit.

Diagnostic Aids

An intermittent MIL may be cause by a poor connection,

rubbed-through wire insulation, or a wire broken inside

the insulation. Check for the following items:

Inspect the ECM harness and connections for

improper mating, broken locks, improperly formed or

damaged terminals, poor terminal-to-wire

connection, and damaged harness.

If the engine runs OK, check for a faulty light bulb, an

open in the MIL driver circuit, or an open in the

instrument cluster ignition feed.

If the engine cranks but will not run, check for an open

ECM ignition or battery feed, or a poor ECM to engine

ground.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. A “No MIL” condition accompanied by a no-start

condition suggests a faulty ECM ignition feed or

battery feed circuit.

9. Using a test light connected to B+, probe each of the

ECM ground terminals to ensure that a good ground

is present. Refer to

ECM Terminal End View for

terminal locations of the ECM ground circuits.

12.In this step, temporarily substitute a known good

relay for the ECM relay. The horn relay is nearby,

and it can be verified as “good” simply by honking

the horn. Replace the horn relay after completing

this step.

Page 5474 of 6000

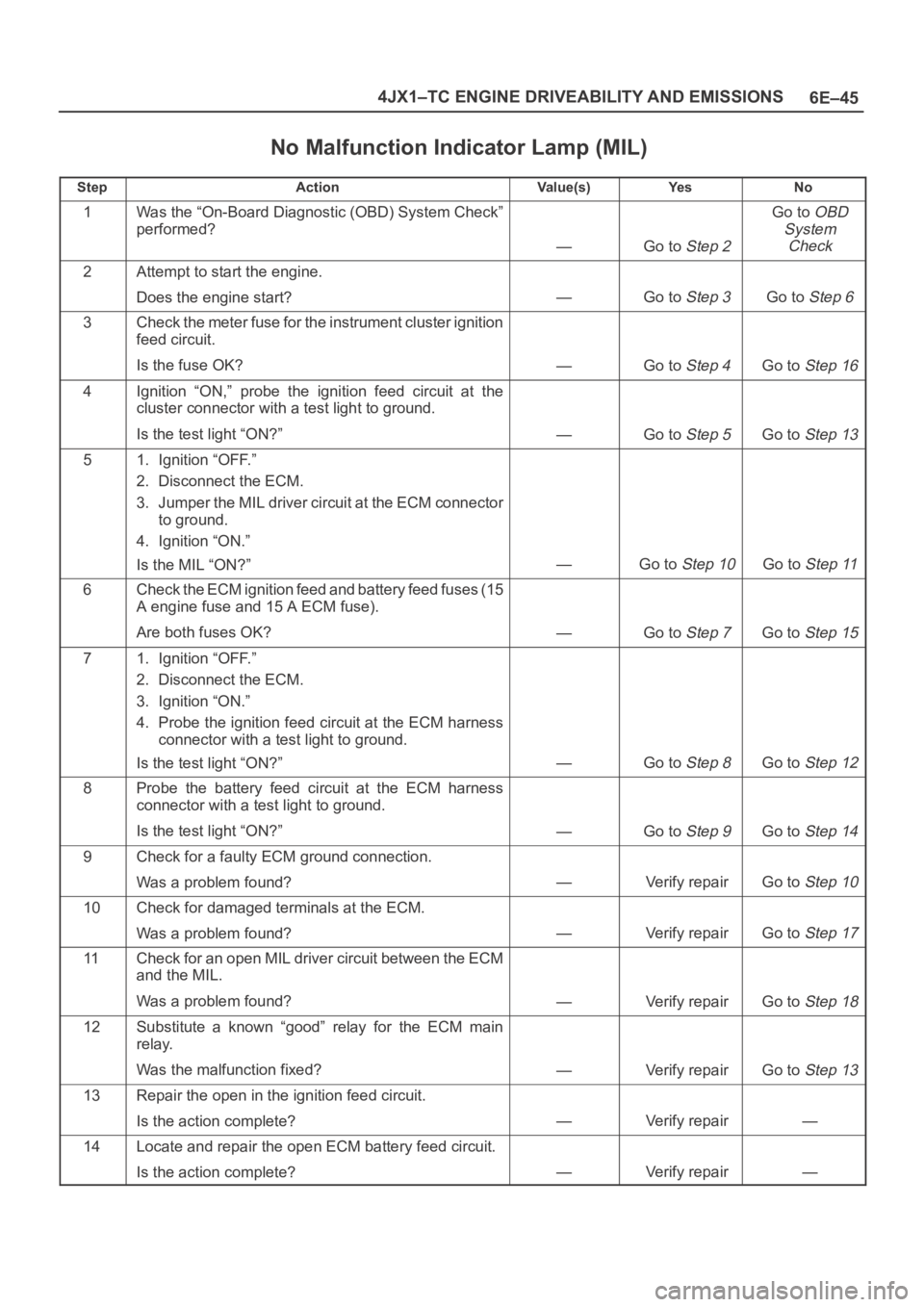

6E–45 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

No Malfunction Indicator Lamp (MIL)

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Attempt to start the engine.

Does the engine start?

—Go to Step 3Go to Step 6

3Check the meter fuse for the instrument cluster ignition

feed circuit.

Is the fuse OK?

—Go to Step 4Go to Step 16

4Ignition “ON,” probe the ignition feed circuit at the

cluster connector with a test light to ground.

Is the test light “ON?”

—Go to Step 5Go to Step 13

51. Ignition “OFF.”

2. Disconnect the ECM.

3. Jumper the MIL driver circuit at the ECM connector

to ground.

4. Ignition “ON.”

Is the MIL “ON?”

—Go to Step 10Go to Step 11

6Check the ECM ignition feed and battery feed fuses (15

A engine fuse and 15 A ECM fuse).

Are both fuses OK?

—Go to Step 7Go to Step 15

71. Ignition “OFF.”

2. Disconnect the ECM.

3. Ignition “ON.”

4. Probe the ignition feed circuit at the ECM harness

connector with a test light to ground.

Is the test light “ON?”

—Go to Step 8Go to Step 12

8Probe the battery feed circuit at the ECM harness

connector with a test light to ground.

Is the test light “ON?”

—Go to Step 9Go to Step 14

9Check for a faulty ECM ground connection.

Was a problem found?

—Verify repairGo to Step 10

10Check for damaged terminals at the ECM.

Was a problem found?

—Verify repairGo to Step 17

11Check for an open MIL driver circuit between the ECM

and the MIL.

Was a problem found?

—Verify repairGo to Step 18

12Substitute a known “good” relay for the ECM main

relay.

Was the malfunction fixed?

—Verify repairGo to Step 13

13Repair the open in the ignition feed circuit.

Is the action complete?

—Verify repair—

14Locate and repair the open ECM battery feed circuit.

Is the action complete?

—Verify repair—