battery location OPEL FRONTERA 1998 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1981 of 6000

6E–88

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1194 (Flash DTC 61)

Rail Pressure System Low Voltage

060RW134

Circuit Description

The rail pressure (RP) sensor responds to changes in oil

rail pressure.

The ECM monitors the RP signals for voltages outside the

normal range of the RP sensor. If the ECM detects a RP

signal voltage that is excessively low, DTC P1194 will be

set.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1194 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Check for intermittent codes.

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P1194 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently,

performing the DTC P1194 Diagnostic Chart may isolate

the cause of the fault.

Page 1983 of 6000

6E–90

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

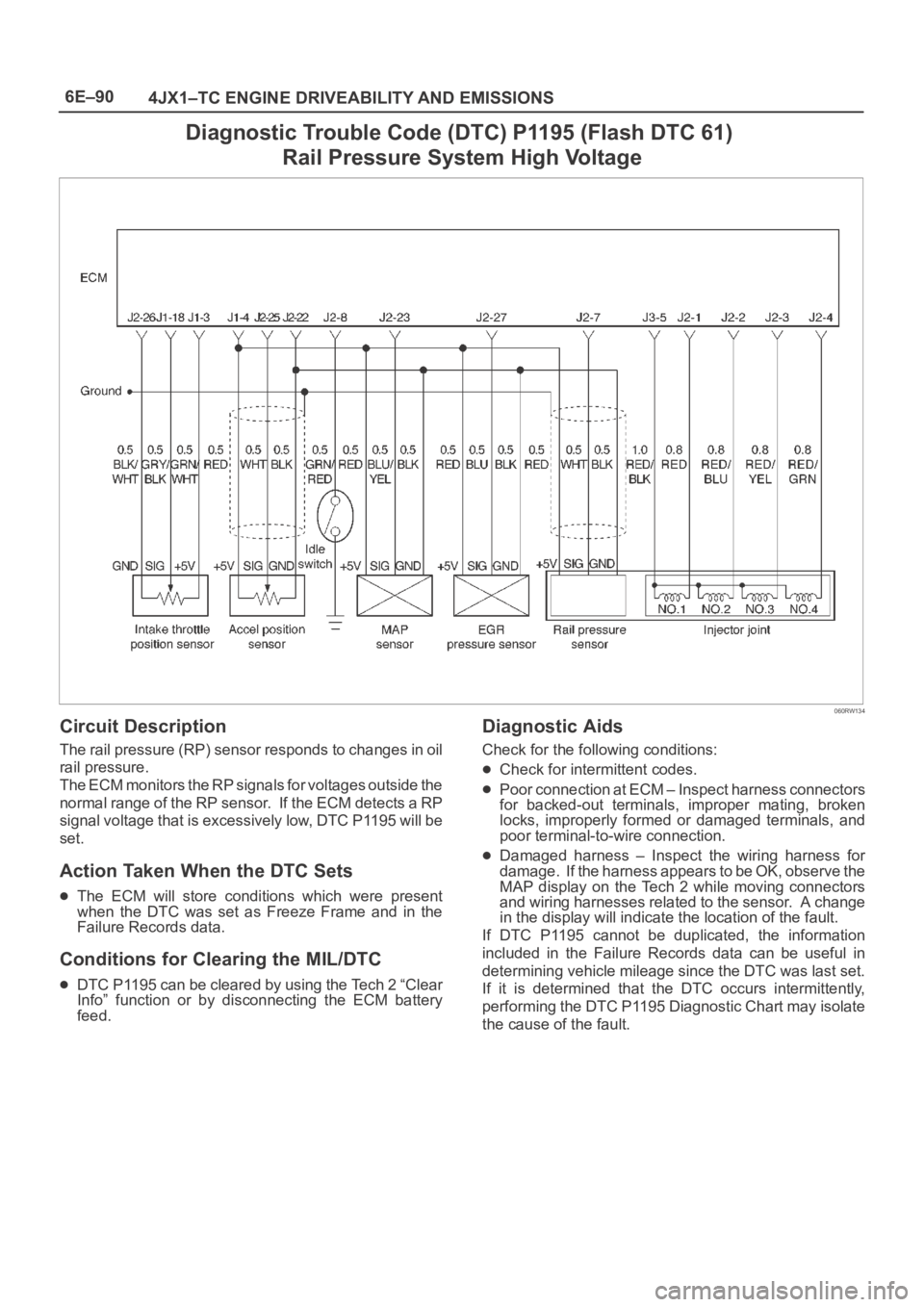

Diagnostic Trouble Code (DTC) P1195 (Flash DTC 61)

Rail Pressure System High Voltage

060RW134

Circuit Description

The rail pressure (RP) sensor responds to changes in oil

rail pressure.

The ECM monitors the RP signals for voltages outside the

normal range of the RP sensor. If the ECM detects a RP

signal voltage that is excessively low, DTC P1195 will be

set.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1195 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Check for intermittent codes.

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

If DTC P1195 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently,

performing the DTC P1195 Diagnostic Chart may isolate

the cause of the fault.

Page 1986 of 6000

6E–93 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Circuit Description

The rail pressure control valve (RPCV) is built in the high

pressure oil circuit.

RPCV is an important device which is used to control oil

pressure in the HEUI system.

The circuit receives current through Engine 15A fuse from

the battery, current flowing in the order of RPCV.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1196 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Rail Pressure Control display on the Tech 2 while

moving connectors and wiring harnesses related to the

Rail Pressure Control. A change in the Rail Pressure

Control display will indicate the location of the fault.

If DTC P1196 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Verifies that the fault is present.

DTC P1196 – RP System High Warning

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Engine is running.

2. Observe the “Rail Pressure Control” display on the

Te c h 2 .

Is the action correct?

—Go to Step 4Go to Step 3

3Replace the RPCV.

Is the action complete?

—Verify repairGo to Step 4

41. Engine is running.

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “ DTC” info for DTC P1196.

Does the Tech 2 indicate DTC P1196 failed this

ignition?

—Go to Step 5—

51. Check the 2 way valve.

2. Observe the “RP Control” display on the Tech 2.

Is the action correct?

—Go to Step 4Go to Step 6

6Replace the 2 way valve.

Is the action complete?

—Verify repair—

Page 1987 of 6000

6E–94

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0197 (Flash DTC 16)

Oil Temp Sensor Low Voltage

060RW129

Circuit Description

The engine oil temperature (OT) sensor is a thermistor

mounted in the oil rail. The Engine Control Module ECM

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine oil is cold, the

sensor (thermistor) resistance is high, therefore the ECM

will measure a high signal voltage. As the engine oil

warms, the sensor resistance becomes lower, and the OT

signal voltage measured at the ECM drops.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0197 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

OT display on the Tech 2 while moving connectors and

wiring harnesses related to the OT sensor. A change

in the OT display will indicate the location of the fault.

If DTC P0197 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.

Page 1989 of 6000

6E–96

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0198 (Flash DTC 16)

Oil Temp Sensor High Voltage

060RW129

Circuit Description

The engine oil temperature (OT) sensor is a thermistor

mounted in the oil rail. The Engine Control Module ECM

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine oil is cold, the

sensor (thermistor) resistance is high, therefore the ECM

will measure a high signal voltage. As the engine oil

warms, the sensor resistance becomes lower, and the OT

signal voltage measured at the ECM drops.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0198 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

OT display on the Tech 2 while moving connectors and

wiring harnesses related to the OT sensor. A change

in the OT display will indicate the location of the fault.

If DTC P0198 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.

Page 2000 of 6000

6E–107 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0217 (Flash DTC 22)

High Coolant Temp Waring

060RW129

Circuit Description

The engine coolant temperature (ECT) sensor is a

thermistor mounted on a coolant crossover pipe at the

rear of the engine. The Engine Control Module ECM

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine coolant is cold,

the sensor (thermistor) resistance is high, therefore the

ECM will measure a high signal voltage. As the engine

coolant warms, the sensor resistance becomes lower,

and the ECT signal voltage measured at the ECM drops.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0217 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, brokenlocks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the ECT sensor. A

change in the ECT display will indicate the location of

the fault.

If DTC P0217 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Verifies that the fault is present.

3. If DTC P0117 can be repeated only by duplicating

the Failure Records conditions, refer to the

“Temperature vs. Resistance Values” table. The

table may be used to test the ECT sensor at various

temperatures to evaluate the possibility of a

“shifted” sensor that may be shorted above or below

a certain temperature. If this is the case, replace

the ECT sensor. If the ECT sensor appears to be

OK, the fault is intermittent; refer to

Diagnostic Aids.

Page 2007 of 6000

6E–114

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0336 (Flash DTC 43)

CKP (Crank Position) Sensor Out of Synchro

060RW133

Circuit Description

The CKP reference signal is produced by the crankshaft

position (CKP) sensor. During one crankshaft revolution,

crankshaft pulses will be produced. The Engine Control

Module ECM uses the CKP reference signal to calculate

engine RPM and crankshaft position. If the ECM receives

an incorrect number of pulses on the CKP reference

circuit, DTC P0336 will set.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0336 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside the

insulation. Check for:

Poor connection – Inspect the ECM harness and

connectors for improper mating, broken locks,

improperly formed or damaged terminals, and poor

terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, disconnect

the ECM, turn the ignition on and observe a voltmeter

connected to the CKP reference circuit at the ECM

harness connector while moving connectors and

wiring harnesses related to the ECM. A change in

voltage will indicate the location of the fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 2009 of 6000

6E–116

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0337 (Flash DTC 43)

CKP (Crank Position) Sensor No Signal

060RW133

Circuit Description

The CKP reference signal is produced by the crankshaft

position (CKP) sensor. During one crankshaft revolution,

CKP crankshaft reference pulses will be produced. The

Engine Control Module ECM uses the CKP reference

signal to calculate engine RPM and crankshaft position. If

the ECM does not receive pulses on the CKP reference

circuit, DTC P0337 will set.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0337 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside the

insulation. Check for:

Poor connection – Inspect the ECM harness and

connectors for improper mating, broken locks,

improperly formed or damaged terminals, and poor

terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, disconnect

the ECM, turn the ignition on and observe a voltmeter

connected to the CKP reference circuit at the ECM

harness connector while moving connectors and

wiring harnesses related to the ICM. A change in

voltage will indicate the location of the fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Page 2012 of 6000

6E–119 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0341 (Flash DTC 41)

CMP (Cam Position) Sensor Out of Synchro

060RW133

Circuit Description

The CMP signal is produced by the camshaft position

(CMP) sensor pulses when the engine is running and

crankshaft position (CKP) sync pulses are also being

received. The Engine Control Module ECM uses the

CMP signal pulses to initiate sequential fuel injection. If

the ECM receives an incorrect number of pulses on the

CMP reference circuit, DTC P0341 will set.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0341 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed–through wire insulation or a wire broken inside the

insulation. Check for:

Poor connection — Inspect the ECM harness and

connectors for improper mating, broken locks,improperly formed or damaged terminals, and poor

terminal-to-wire connection.

Damaged harness — Inspect the wiring harness for

damage. If the harness appears to be OK, disconnect

the ECM, turn the ignition on and observe a voltmeter

connected to the CMP signal circuit at the ECM

harness connector while moving connectors and

wiring harnesses related to the ICM and the CMP

sensor. A change in voltage will indicate the location

of the fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Ensures that the fault is present.

12.Determines whether the fault is being caused by a

missing camshaft magnet or a faulty sensor. The

voltage measured in this step should read around 4

volts, toggling to near 0 volts when the CMP sensor

interfaces with the camshaft magnet.

Page 2015 of 6000

6E–122

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0342 (Flash DTC 41)

CMP (Cam Position) Sensor No Signal

060RW133

Circuit Description

The CMP signal produced by the camshaft position

(CMP) sensor pulses when the engine is running and

crankshaft position (CKP) synchro pulses are also being

received. The hall type CMP sensor and the CKP sensor

share 5 V and ground connections at the Engine Control

Module ECM. The third wire at the sensor is a signal

c i r c u i t t o t h e E C M . T h e E C M u s e s t h e C M P s i g n a l p u l s e s

to initiate sequential fuel injection. If the ECM does not

receive pulses on the CMP reference circuit, DTC P0342

will set.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0342 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside the

insulation. Check for:

Poor connection – Inspect the ECM harness and

connectors for improper mating, broken locks,

improperly formed or damaged terminals, and poor

terminal to wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, disconnect

the ECM, turn the ignition on and observe a voltmeter

connected to the CMP signal circuit at the ECM

harness connector while moving connectors and

wiring harnesses related to the ICM and the CMP

sensor. A change in voltage will indicate the location

of the fault.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Ensures that the fault is present.

14.Determines whether the fault is being caused by a

missing camshaft magnet or a faulty ECM. The

voltage measured in this step should read around 4

volts, toggling to near 0 volts when the CMP sensor

interfaces with the camshaft magnet.