wiring OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4836 of 6000

6E–179 ENGINE DRIVEABILITY AND EMISSIONS

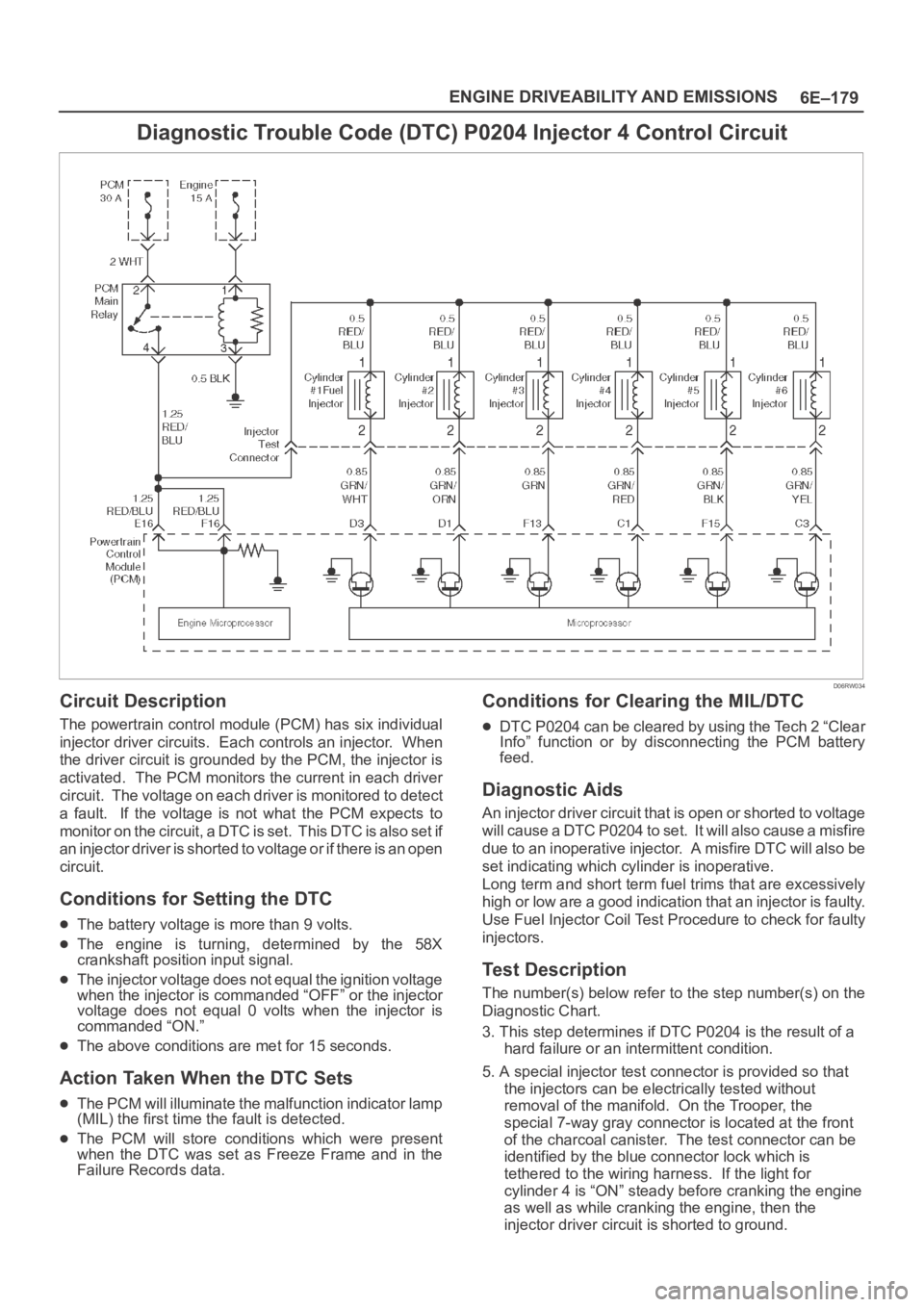

Diagnostic Trouble Code (DTC) P0204 Injector 4 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When

the driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. The voltage on each driver is monitored to detect

a fault. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by the 58X

crankshaft position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0204 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0204 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0204 is the result of a

hard failure or an intermittent condition.

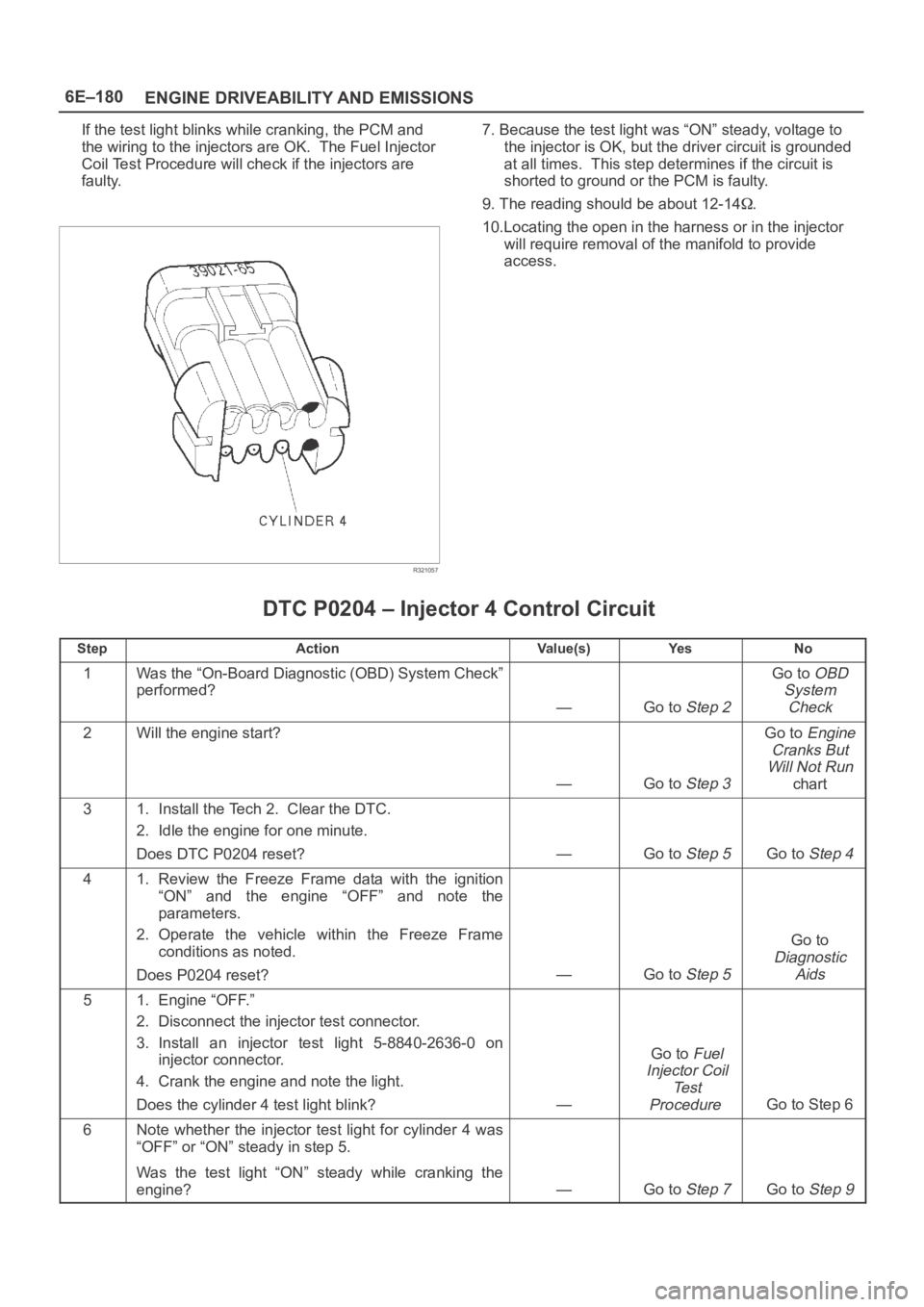

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 4 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.

Page 4837 of 6000

6E–180

ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321057

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9. The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0204 – Injector 4 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0204 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0204 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector test connector.

3. Install an injector test light 5-8840-2636-0 on

injector connector.

4. Crank the engine and note the light.

Does the cylinder 4 test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6Note whether the injector test light for cylinder 4 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 4839 of 6000

6E–182

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0205 Injector 5 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When

the driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by the 58X

crankshaft position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0205 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0205 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0205 is the result of a

hard failure or an intermittent condition.

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 5 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.

Page 4840 of 6000

6E–183 ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321058

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9. The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0205 – Injector 5 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0205 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0205 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector test connector.

3. Install an injector test light 5-8840-2636-0 on

injector connector.

4. Crank the engine and note the light.

Does the cylinder 5 test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6 Note whether the injector test light for cylinder 5 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 4842 of 6000

6E–185 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0206 Injector 6 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When

the driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. The voltage on each driver is monitored to detect

a fault. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by 58X crankshaft

position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0206 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0206 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0206 is the result of a

hard failure or an intermittent condition.

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 6 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.

Page 4843 of 6000

6E–186

ENGINE DRIVEABILITY AND EMISSIONS

If the test light blinks while cranking, the PCM and

the wiring to the injectors are OK. The Fuel Injector

Coil Test Procedure will check if the injectors are

faulty.

R321059

7. Because the test light was “ON” steady, voltage to

the injector is OK, but the driver circuit is grounded

at all times. This step determines if the circuit is

shorted to ground or the PCM is faulty.

9. The reading should be about 12-14

.

10.Locating the open in the harness or in the injector

will require removal of the manifold to provide

access.

DTC P0206 – Injector 6 Control Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0206 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0206 reset?

—Go to Step 5

Go to

Diagnostic

Aids

51. Engine “OFF.”

2. Disconnect the injector test connector.

3. Install an injector test light 5-8840-2636-0 on

injector connector.

4. Crank the engine and note the light.

Does the cylinder 6 test light blink?

—

Go to Fuel

Injector Coil

Te s t

Procedure

Go to Step 6

6Note whether the injector test light for cylinder 6 was

“OFF” or “ON” steady in step 5.

Was the test light “ON” steady while cranking the

engine?

—Go to Step 7Go to Step 9

Page 4851 of 6000

6E–194

ENGINE DRIVEABILITY AND EMISSIONS

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, disconnect

the PCM, turn the ignition on and observe a voltmeter

connected to the 58X reference circuit at the PCM

harness connector while moving connectors and

wiring harnesses related to the ICM. A change in

voltage will indicate the location of the fault.Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

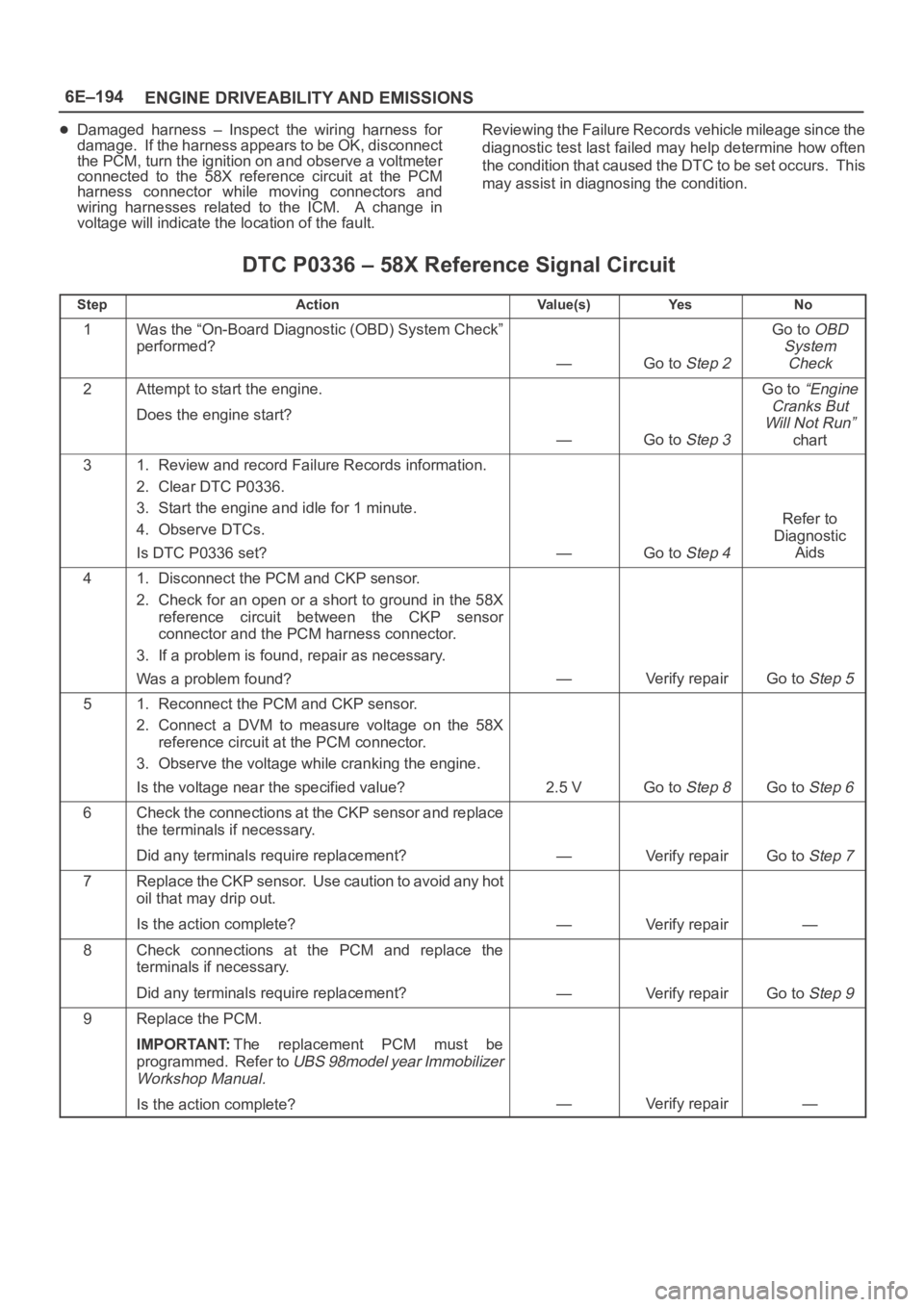

DTC P0336 – 58X Reference Signal Circuit

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Attempt to start the engine.

Does the engine start?

—Go to Step 3

Go to “Engine

Cranks But

Will Not Run”

chart

31. Review and record Failure Records information.

2. Clear DTC P0336.

3. Start the engine and idle for 1 minute.

4. Observe DTCs.

Is DTC P0336 set?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Disconnect the PCM and CKP sensor.

2. Check for an open or a short to ground in the 58X

reference circuit between the CKP sensor

connector and the PCM harness connector.

3. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 5

51. Reconnect the PCM and CKP sensor.

2. Connect a DVM to measure voltage on the 58X

reference circuit at the PCM connector.

3. Observe the voltage while cranking the engine.

Is the voltage near the specified value?

2.5 VGo to Step 8Go to Step 6

6Check the connections at the CKP sensor and replace

the terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 7

7Replace the CKP sensor. Use caution to avoid any hot

oil that may drip out.

Is the action complete?

—Verify repair—

8Check connections at the PCM and replace the

terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 9

9Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 4853 of 6000

6E–196

ENGINE DRIVEABILITY AND EMISSIONS

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, disconnect

the PCM, turn the ignition on and observe a voltmeter

connected to the 58X reference circuit at the PCM

harness connector while moving connectors and

wiring harnesses related to the ICM. A change in

voltage will indicate the location of the fault.Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

DTC P0337 – CKP Sensor Circuit Low Frequency

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Attempt to start the engine.

Does the engine start?

—Go to Step 3Go to Chart 3

31. Review and record Failure Records information.

2. Clear DTC P0337.

3. Start the engine and idle for 1 minute.

4. Observe DTCs.

Is DTC P0337 set?

—Go to Step 4

Refer to

Diagnostic

Aid

41. Disconnect the CKP sensor.

2. Ignition “ON.”

3. Using a DVM, verify that 5 V reference and ground

are being supplied at the sensor connector (PCM

side).

Are 4-6 volts and ground available at the sensor?

—Go to Step 7Go to Step 5

51. Ignition “ON.”

2. With a DVM, backprobe the PCM connector 5 V

reference and ground connections.

Are 5 V reference and ground available at the PCM?

—Go to Step 6Go to Step 11

6Check 5 V reference or ground between the CKP

sensor and PCM and repair the open circuit, short to

ground or short to voltage.

Is the action complete?

—Verify repair—

71. Ignition “OFF.”

2. Disconnect the PCM and CKP sensor.

3. Check for an open or a short to ground in the 58X

reference circuit between the CKP sensor

connector and the PCM harness connector.

4. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 8

81. Reconnect the PCM and CKP sensor.

2. Connect a DVM to measure voltage on the 58X

reference circuit at the PCM connector.

3. Observe the voltage while cranking the engine.

Is the voltage near the specified value?

2.5 VGo to Step 11Go to Step 9

9Check the connections at the CKP sensor and replace

the terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 10

10Replace the CKP sensor. Use caution and avoid hot oil

that may drip out.

Is the action complete?

—Verify repair—

Page 4856 of 6000

6E–199 ENGINE DRIVEABILITY AND EMISSIONS

Conditions for Clearing the MIL/DTC

DTC P0341 can be cleared by using Tech 2 “Clear Info”

function or by disconnecting the PCM battery feed.

Diagnostic Aids

An intermittent may be caused by a poor connection,

rubbed-through wire insulation or a wire broken inside the

insulation. Check for:

Poor connection – Inspect the PCM harness and

connectors for improper mating, broken locks,

improperly formed or damaged terminals, and poor

terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, disconnect

the PCM, turn the ignition on and observe a voltmeter

connected to the CMP signal circuit at the PCM

harness connector while moving connectors andwiring harnesses related to the ICM and the CMP

sensor. A change in voltage will indicate the location

of the fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Ensures that the fault is present.

12.Determines whether the fault is being caused by a

missing camshaft magnet or a faulty sensor. The

voltage measured in this step should read around 4

volts, toggling to near 0 volts when the CMP sensor

interfaces with the camshaft magnet.

Page 4858 of 6000

6E–201 ENGINE DRIVEABILITY AND EMISSIONS

DTC P0341 – CMP Sensor Circuit Performance

StepNo Ye s Va l u e ( s ) Action

101. Check for poor connections at the PCM.

2. If a problem is found, repair it as necessary.

Was a problem found?

—Verify repairGo to Step 11

11Backprobe the PCM connector with a DVM to monitor

voltage on the camshaft position input signal circuit

while cranking the engine with the sensor connected.

(Use rubber band, tape, or an assistant to keep the

DVM lead in contact with the sensor terminal during this

test.)

Does the voltage toggle between the specified values?

4-0 VGo to Step 15Go to Step 12

121. Remove the CMP sensor from the engine front

cover (leave the sensor wiring connected).

2. Place a magnet on the CMP sensor.

(If you use a magnet that is too small to cover the face

of the sensor, test on every part of the sensor face

because only a small area will respond to this test.)

Does the DVM display a voltage near the specified

value?

0 VGo to Step 13Go to Step 14

13Replace the faulty or missing camshaft position sensor

magnet.

Is the action complete?

—Verify repair—

14Replace the camshaft position sensor.

Is the action complete?

—Verify repair—

15Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—