lock OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 660 of 6000

4B2–89 DRIVE LINE CONTROL SYSTEM (TOD)

StepNo Ye s Action

131. Apply the brake and fully turn the steering to the left (or right)

end, and start the creep run.

Does the voltage between terminals 4 and 20 range between 0.1

and 1.0V?Repair the

transfer

assembly.

Go to Step 16The ECU has

failed. Replace

the ECU.

Go to Step 16

141. Shift the transfer lever to the high (TOD) position.

2. Fully turn the steering to the left (or right) end, and select the D

range and start the creep run.

Does the voltage between terminals 4 and 20 range between 0.1

and 1.0V?

Go to Step 15 Go to Step 13

151. Select the 4WD SW to the 2WD position.

2. Jack up the right front wheel.

Does the front tire rotate smoothly?

Repair the

transfer

assembly.

Go to Step 16

The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 16

16Check that all the parts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow”.

Return to Step 16

*NOTE: Before checking this item, run the vehicle more

than 10 meters with the steering wheel in straight position

so that the 4L mechanical lock sleeve can be released

certainly.

Page 667 of 6000

4C–1 DRIVE SHAFT SYSTEM

DRIVELINE/AXLE

DRIVE SHAFT SYSTEM

CONTENTS

Service Precaution 4C–2. . . . . . . . . . . . . . . . . . . . . .

General Description 4C–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 4C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Shaft 4C–4. . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Shaft and Associated Parts 4C–4. . . .

Removal 4C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–5. . . . . . . . . . . . . . . . . .

Oil Seal Replacement 4C–6. . . . . . . . . . . . . . . . . .

Installation 4C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 4C–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Hub and Disc (with Shift on the Fly) 4C–9. .

Disassembled View 4C–9. . . . . . . . . . . . . . . . . . . .

Disassembly 4C–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–10. . . . . . . . . . . . . . . . . .

Reassembly 4C–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Hub and Disc with Manual Locking Hub 4C–14

Disassembled View 4C–14. . . . . . . . . . . . . . . . . . . .

Disassembly 4C–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–16. . . . . . . . . . . . . . . . . .

Reassembly 4C–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–20. . . . . . . . . . . . .

Special Tools 4C–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Drive Shaft Joint 4C–22. . . . . . . . . . . . . . . . . . .

Front Drive Shaft Joints Replacement 4C–22. . . .

Front Axle Drive Shaft 4C–23. . . . . . . . . . . . . . . . . . .

Front Axle Drive Shaft and Associated

Parts 4C–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–25. . . . . . . . . . . . . . . . . .

Bushing Replacement 4C–25. . . . . . . . . . . . . . . . . . Reassembly 4C–26. . . . . . . . . . . . . . . . . . . . . . . . . .

Shift On The Fly System 4C–28. . . . . . . . . . . . . . . . .

Shift On The Fly System and Associated

Parts 4C–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–30. . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–35. . . . . . . . . . .

Special Tools 4C–36. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Propeller Shaft 4C–37. . . . . . . . . . . . . . . . . . . . .

General Description 4C–37. . . . . . . . . . . . . . . . . . . . .

Front Propeller Shaft and Associated Parts 4C–38

Removal 4C–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4C–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly (Except TOD 4

4) 4C–40. . . . . . . . .

Universal Joint Disassembly 4C–41. . . . . . . . . . . .

Inspection and Repair 4C–42. . . . . . . . . . . . . . . . . .

Universal Joint Reassembly 4C–45. . . . . . . . . . . . .

Reassembly (Except TOD 4

4) 4C–46. . . . . . . . . .

Main Data and Specifications 4C–47. . . . . . . . . . .

Rear Propeller Shaft 4C–48. . . . . . . . . . . . . . . . . . . . .

General Description 4C–48. . . . . . . . . . . . . . . . . . . . .

Rear Propeller Shaft and Associated Parts 4C–48

Removal 4C–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4C–49. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–50. . . . . . . . . . . . . . . . . . . . . . . . . .

Universal Joint Disassembly 4C–51. . . . . . . . . . . .

Inspection and Repair 4C–52. . . . . . . . . . . . . . . . . .

Universal Joint Reassembly 4C–53. . . . . . . . . . . . .

Reassembly 4C–54. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–55. . . . . . . . . . .

Page 668 of 6000

4C–2

DRIVE SHAFT SYSTEM

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

This publication contains essential removal, installation,

adjustment and maintenance procedures.

The front axle utilizes a central disconnect type front

axle/transfer case system.

The drive axles are completely flexible assemblies,

consisting of inner and outer constant velocity (CV) drive

shaft joints connected by an axle shaft.

For description of propeller shaft and universal joint, refer

to Front/Rear Propeller Shaft in this section.

Page 670 of 6000

4C–4

DRIVE SHAFT SYSTEM

Rear Axle Shaft

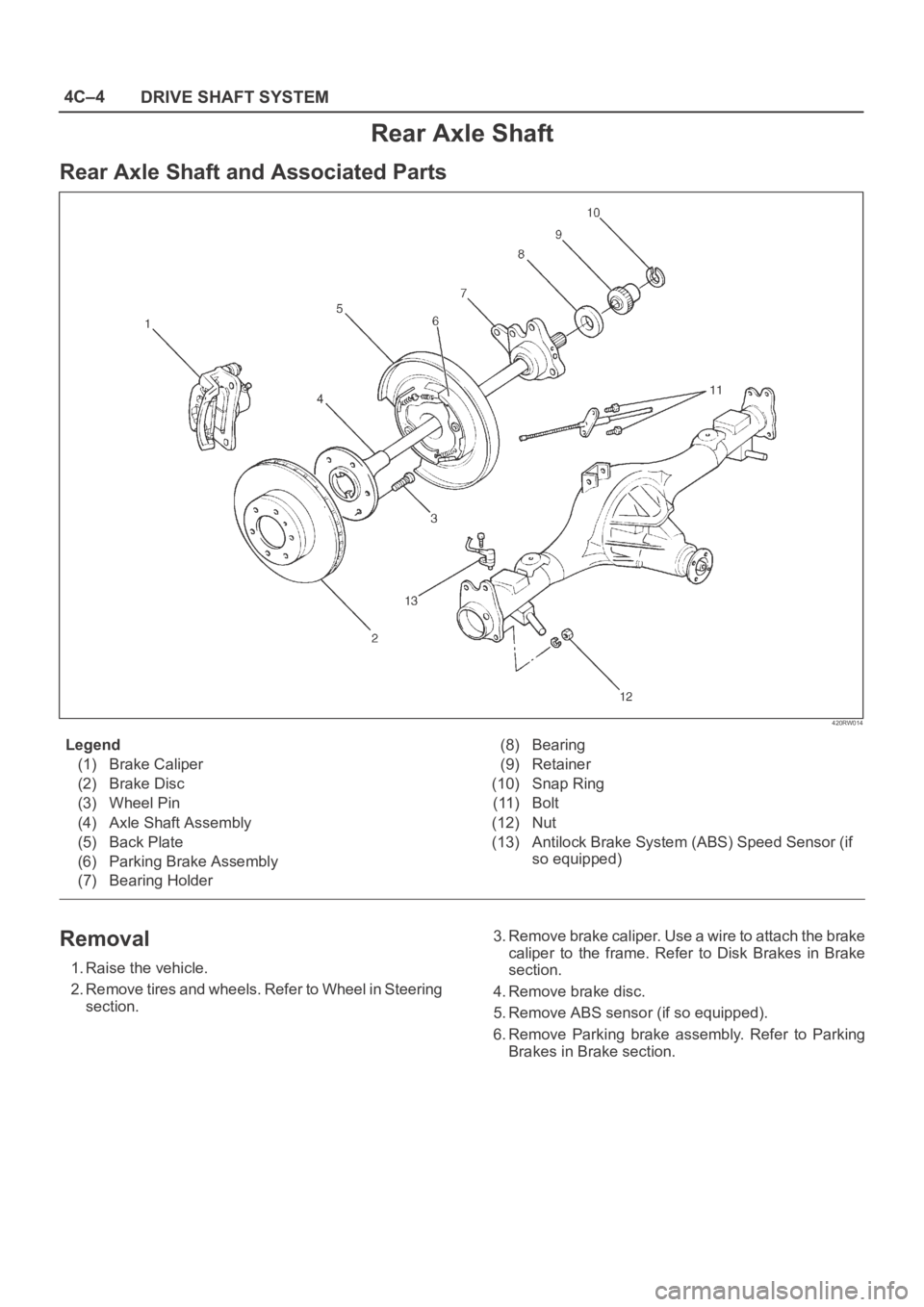

Rear Axle Shaft and Associated Parts

420RW014

Legend

(1) Brake Caliper

(2) Brake Disc

(3) Wheel Pin

(4) Axle Shaft Assembly

(5) Back Plate

(6) Parking Brake Assembly

(7) Bearing Holder(8) Bearing

(9) Retainer

(10) Snap Ring

(11) Bolt

(12) Nut

(13) Antilock Brake System (ABS) Speed Sensor (if

so equipped)

Removal

1. Raise the vehicle.

2. Remove tires and wheels. Refer to Wheel in Steering

section.3. Remove brake caliper. Use a wire to attach the brake

caliper to the frame. Refer to Disk Brakes in Brake

section.

4. Remove brake disc.

5. Remove ABS sensor (if so equipped).

6. Remove Parking brake assembly. Refer to Parking

Brakes in Brake section.

Page 673 of 6000

4C–7 DRIVE SHAFT SYSTEM

9. Fix the parking brake cable mounting bolt (Behind the

back plate).

10. Install parking brake assembly, refer to Parking

Brakes in Brake section.

11. Install antilock brake system sensor (if so equipped).

12. Install brake disc.

13. Install brake caliper, refer to Disk Brakes in Brake

section.

Page 675 of 6000

4C–9 DRIVE SHAFT SYSTEM

Front Hub and Disc (with Shift on the Fly)

Disassembled View

411RW001

Legend

(1) Bolt

(2) Cap

(3) Snap Ring and Shim

(4) Hub Flange

(5) Lock Washer and Lock Screw

(6) Hub Nut(7) Outer Bearing

(8) Bolt

(9) Hub and Disc Assembly

(10) Wheel Pin

(11) ABS Sensor Ring (If equipped)

(12) Inner Bearing

(13) Oil Seal

Disassembly

1. Before disassembly, select the 2WD position.

2. Jack up the front of vehicle and support frame with

jack stands.3. Remove the disc brake caliper assembly and hang it

on the frame with wires. Refer to Front Disc Brake

Caliper Assembly in Brakes section.

4. Remove bolt.

5. Remove cap.

6. Remove snap ring and shim.

7. Remove hub flange.

Page 676 of 6000

4C–10

DRIVE SHAFT SYSTEM

8. Remove lock washer and lock screw.

9. Use wrench 5–8840–2117–0, remove hub nut.

411RW005

10. Remove hub and disc assembly.

11. Remove ABS sensor ring (If equipped).

12. Remove outer bearing.

13. Remove oil seal.

14. Remove inner bearing.

15. Remove bolt , if necessary, replace the wheel pin in

the following manner.

Apply a scribe mark(1) to disc to hub.

Clamp the hub and disc assembly in a vise, using

protective pads. Remove the 6 disc–to–hub

retaining bolts.

411RS003

Place hub on a suitable work surface and remove

the studs by using a hammer.

411RS004

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

Hub

Hub bearing oil seal

Knuckle spindle

Disc

Caliper

Shift on the fly system parts (Cap, Hub flange, Shim,

Snap ring)

ABS sensor ring (If equipped)

For inspection and servicing of disc caliper and related

parts, refer to Brakes section.

Page 677 of 6000

4C–11 DRIVE SHAFT SYSTEM

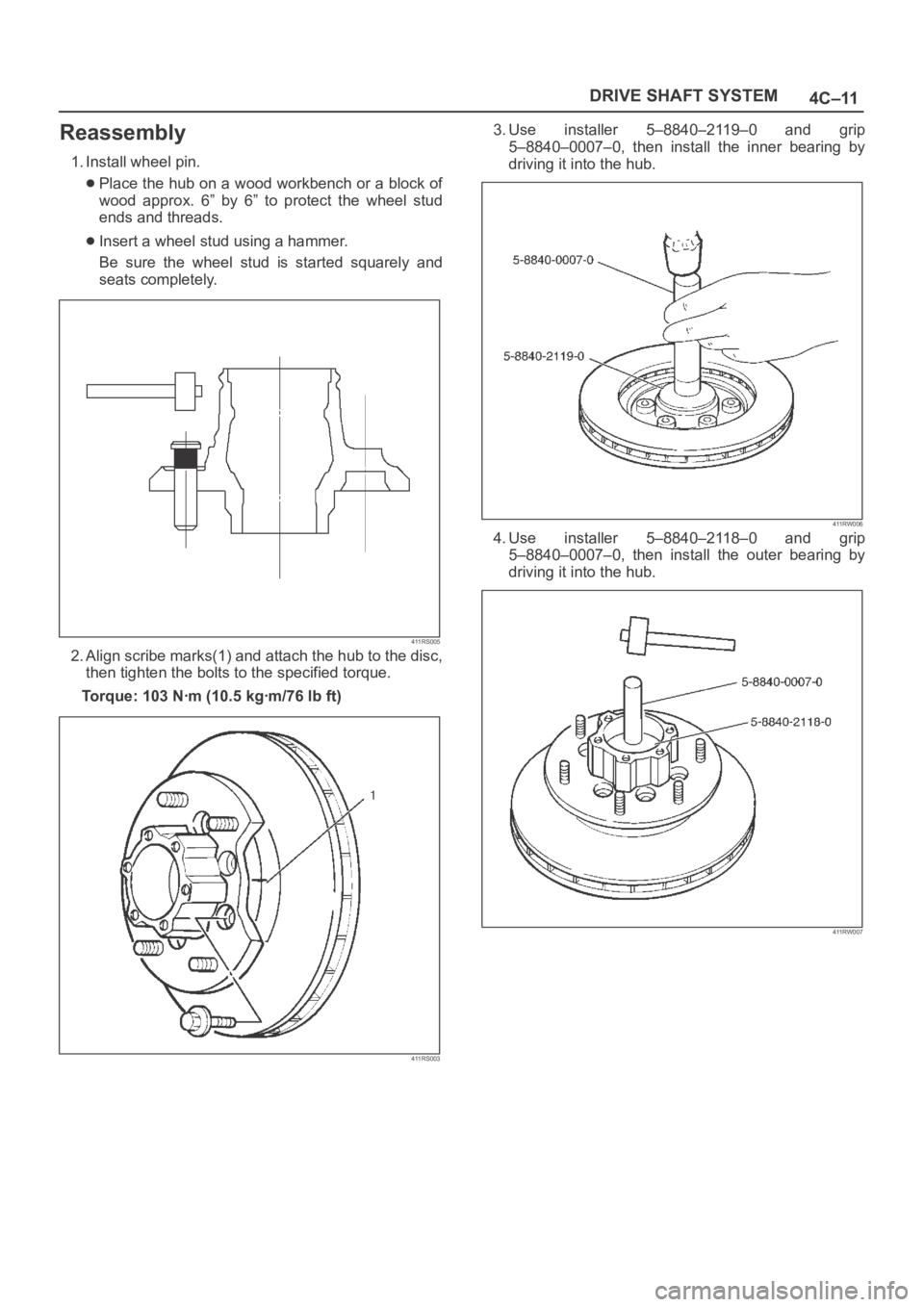

Reassembly

1. Install wheel pin.

Place the hub on a wood workbench or a block of

wood approx. 6” by 6” to protect the wheel stud

ends and threads.

Insert a wheel stud using a hammer.

Be sure the wheel stud is started squarely and

seats completely.

411RS005

2. Align scribe marks(1) and attach the hub to the disc,

then tighten the bolts to the specified torque.

Torque: 103 Nꞏm (10.5 kgꞏm/76 lb ft)

411RS003

3. Use installer 5–8840–2119–0 and grip

5–8840–0007–0, then install the inner bearing by

driving it into the hub.

411RW006

4. Use installer 5–8840–2118–0 and grip

5–8840–0007–0, then install the outer bearing by

driving it into the hub.

411RW007

Page 679 of 6000

4C–13 DRIVE SHAFT SYSTEM

9. Install lock washer and lock screw in the following

manner.

Turn the side with larger diameter of the tapered

bore to the vehicle outer side, then attach the

washer.

If the bolt holes in the lock plate are not aligned with

the corresponding holes in the nut, reverse the lock

plate.

If the bolt holes are still out of alignment, turn in the

nut just enough to obtain alignment.

Screw is to be fastened tightly so its head may

come lower than the surface of the washer.

411RS012

10. Apply adhesive (LOCTITE 515 or equivalent) to both

joining flange faces then install hub flange.

11. Install snap ring and shim.

Adjust the clearance between the free wheeling hub

body and the snap ring.

Clearance: 0 mm–0.3 mm (0 in–0.012 in)

Shims Available: 0.2 mm, 0.3 mm, 0.5 mm,

1.0 mm (0.008 in, 0.012 in, 0.020 in, 0.039 in)

411RW002

12. Install hub cap.

13. Tighten the bolts to the specified torque.

Torque: 59 Nꞏm (6.0 kgꞏm/43 lb ft)

Page 680 of 6000

4C–14

DRIVE SHAFT SYSTEM

Front Hub and Disc with Manual Locking Hub

Disassembled View

411RW009

Legend

(1) Bolt

(2) Cover Assembly

(3) Gasket

(4) Knob

(5) X–ring

(6) Detent Ball and Spring

(7) Snap Ring

(8) Clutch Assembly

(9) Compression Spring

(10) Follower

(11) Retaining Spring

(12) Snap Ring and Shim(13) Body Assembly

(14) Inner Assembly

(15) Spacer

(16) Ring

(17) Snap Ring

(18) Snap Ring

(19) Lock Washer and Lock Screw

(20) Hub Nut

(21) Hub and Disc Assembly

(22) Outer Bearing Outer Race

(23) ABS Sensor Ring (if so equipped)

(24) Inner Bearing Outer Race

(25) Oil Seal

Disassembly

1. Before disassembly, jack up the front of vehicle and

support frame with jack stands.2. Remove the disc brake caliper assembly and hang it

on the frame with wires. Refer to Front Disk Brake

Caliper Assembly in Brakes section.