set clock OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 450 of 6000

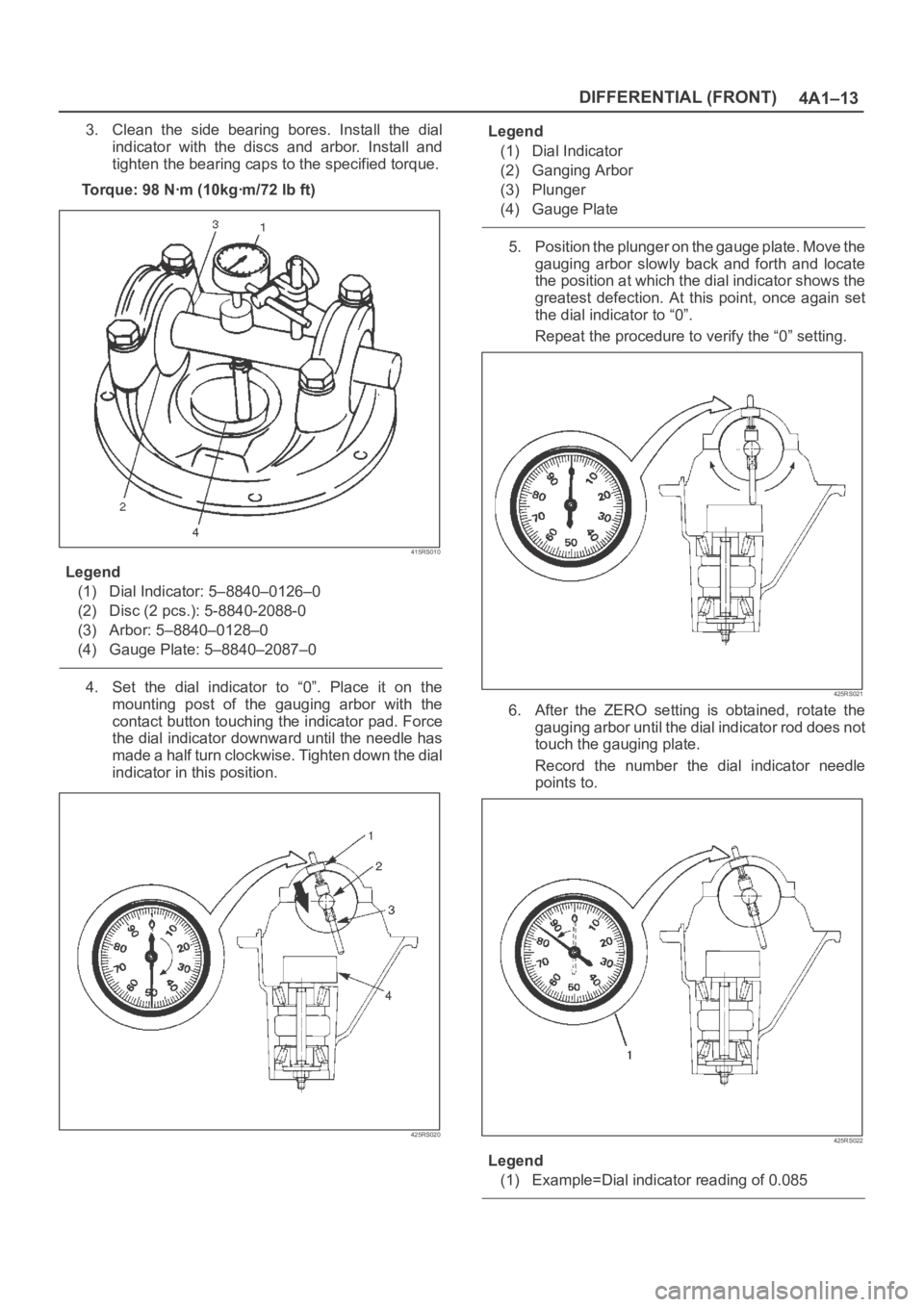

4A1–13 DIFFERENTIAL (FRONT)

3. Clean the side bearing bores. Install the dial

indicator with the discs and arbor. Install and

tighten the bearing caps to the specified torque.

To r q u e : 9 8 N ꞏm ( 1 0 k g ꞏm / 7 2 l b f t )

415RS010

Legend

(1) Dial Indicator: 5–8840–0126–0

(2) Disc (2 pcs.): 5-8840-2088-0

(3) Arbor: 5–8840–0128–0

(4) Gauge Plate: 5–8840–2087–0

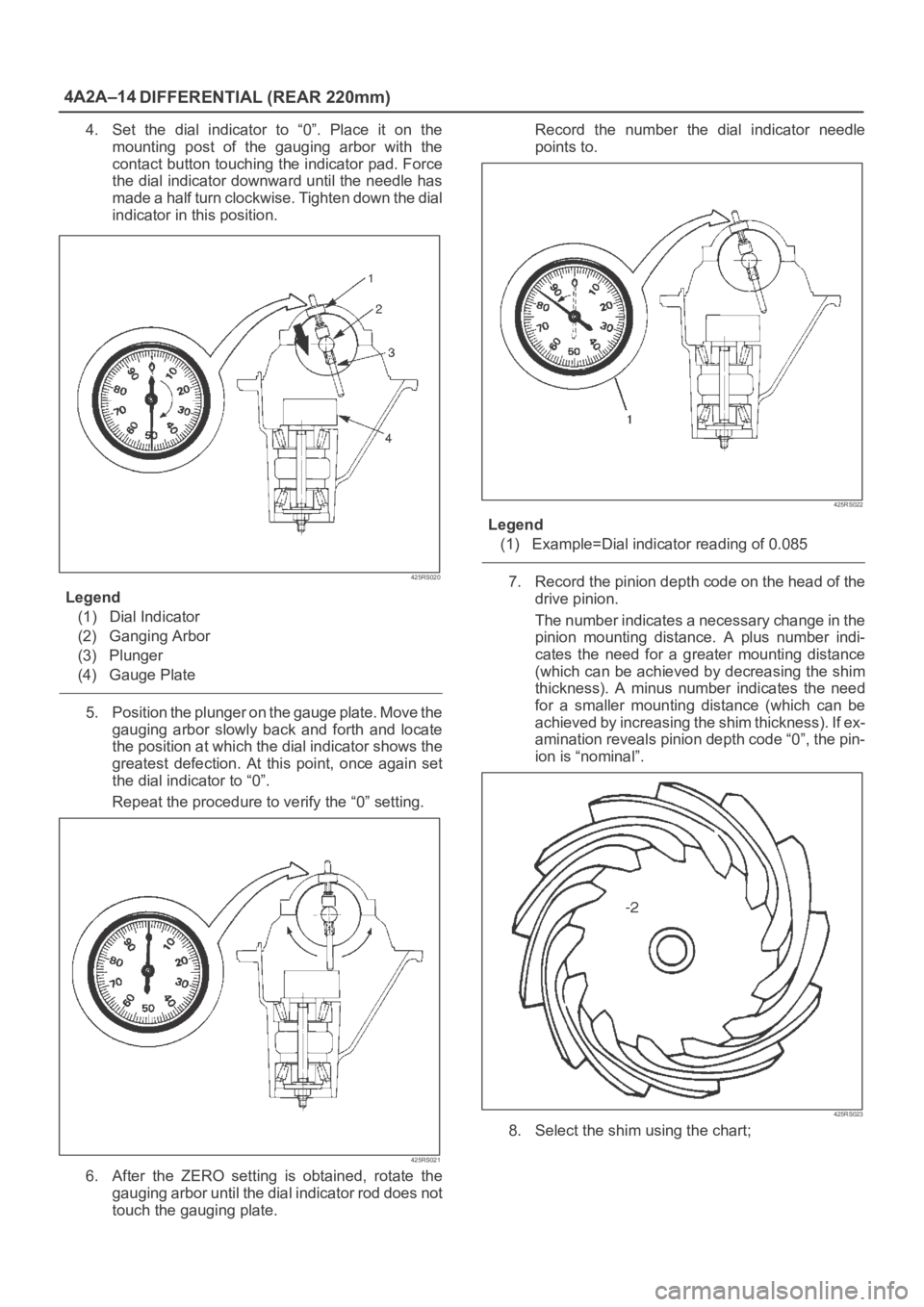

4. Set the dial indicator to “0”. Place it on the

mounting post of the gauging arbor with the

contact button touching the indicator pad. Force

the dial indicator downward until the needle has

made a half turn clockwise. Tighten down the dial

indicator in this position.

425RS020

Legend

(1) Dial Indicator

(2) Ganging Arbor

(3) Plunger

(4) Gauge Plate

5. Position the plunger on the gauge plate. Move the

gauging arbor slowly back and forth and locate

the position at which the dial indicator shows the

greatest defection. At this point, once again set

the dial indicator to “0”.

Repeat the procedure to verify the “0” setting.

425RS021

6. After the ZERO setting is obtained, rotate the

gauging arbor until the dial indicator rod does not

touch the gauging plate.

Record the number the dial indicator needle

points to.

425RS022

Legend

(1) Example=Dial indicator reading of 0.085

Page 481 of 6000

4A2A–14

DIFFERENTIAL (REAR 220mm)

4. Set the dial indicator to “0”. Place it on the

mounting post of the gauging arbor with the

contact button touching the indicator pad. Force

the dial indicator downward until the needle has

made a half turn clockwise. Tighten down the dial

indicator in this position.

425RS020

Legend

(1) Dial Indicator

(2) Ganging Arbor

(3) Plunger

(4) Gauge Plate

5. Position the plunger on the gauge plate. Move the

gauging arbor slowly back and forth and locate

the position at which the dial indicator shows the

greatest defection. At this point, once again set

the dial indicator to “0”.

Repeat the procedure to verify the “0” setting.

425RS021

6. After the ZERO setting is obtained, rotate the

gauging arbor until the dial indicator rod does not

touch the gauging plate.Record the number the dial indicator needle

points to.

425RS022

Legend

(1) Example=Dial indicator reading of 0.085

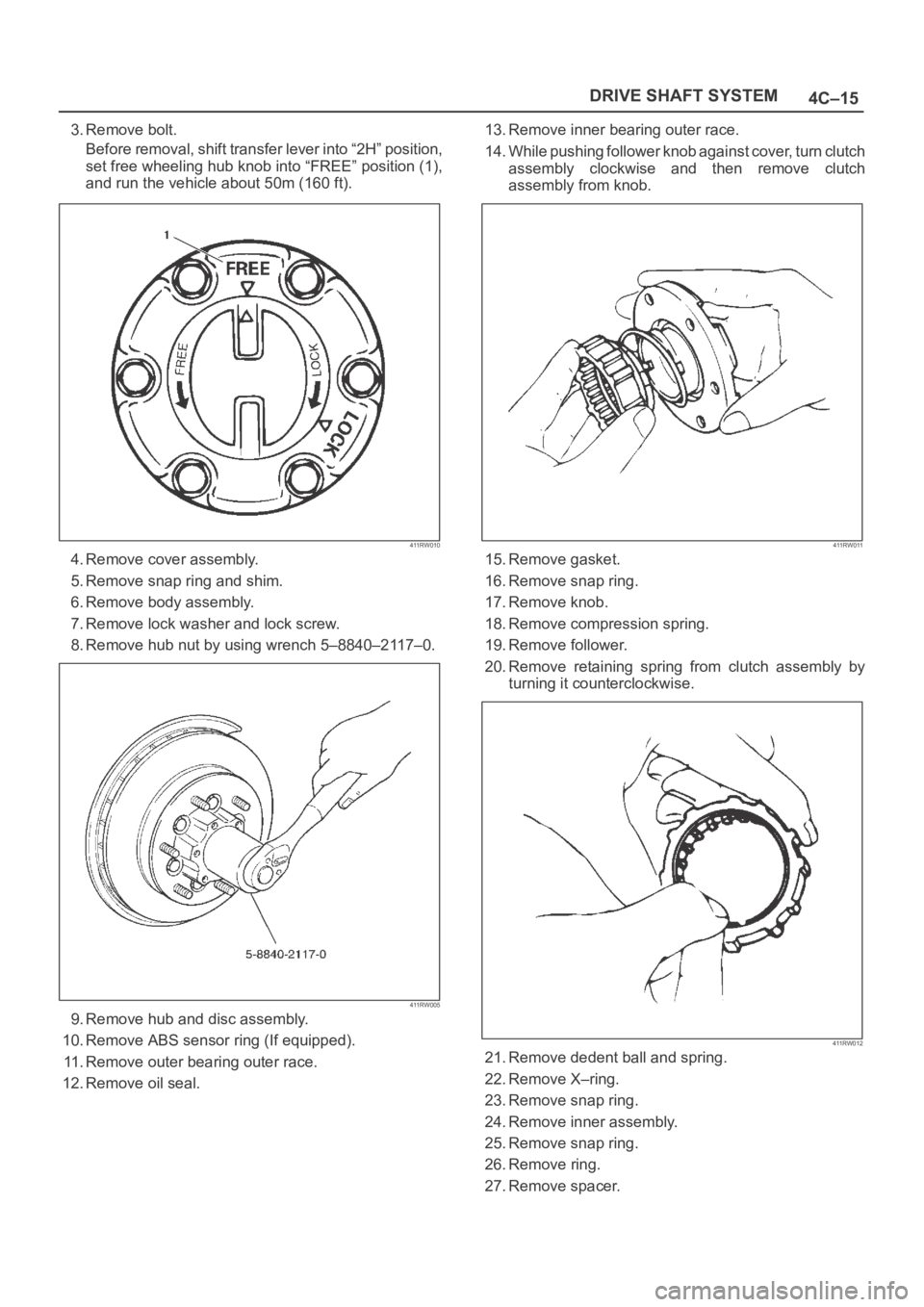

7. Record the pinion depth code on the head of the

drive pinion.

The number indicates a necessary change in the

pinion mounting distance. A plus number indi-

cates the need for a greater mounting distance

(which can be achieved by decreasing the shim

thickness). A minus number indicates the need

for a smaller mounting distance (which can be

achieved by increasing the shim thickness). If ex-

amination reveals pinion depth code “0”, the pin-

ion is “nominal”.

425RS023

8. Select the shim using the chart;

Page 517 of 6000

4A2B–14DIFFERENTIAL (REAR 244mm)

4. Set the dial indicator 5–8840–0126–0 to “0”.

Place it on the mounting post of the gauging arbor

with the contact button touching the indicator pad.

Force the dial indicator downward until the needle

has made a half turn clockwise. Tighten down the

dial indicator in this position.

425RS020

Legend

(1) Dial Indicator

(2) Ganging Arbor

(3) Plunger

(4) Gauge Plate

5. Position the plunger on the gauge plate. Move the

gauging arbor slowly back and forth and locate

the position at which the dial indicator shows the

greatest defection. At this point, once again set

the dial indicator to “0”. Repeat the procedure to

verify the “0” setting.

425RS021

6. After the ZERO setting is obtained, rotate the

gauging arbor until the dial indicator rod does not

touch the gauging plate. Record the number the

dial indicator needle points to.

425RS022

Legend

(1) Example=Dial indicator reading od 0.085

7. Record the pinion depth code on the head of the

drive pinion. The number indicates a necessary

change in the pinion mounting distance. A plus

number indicates the need for a greater mounting

distance (which can be achieved by decreasing

the shim thickness). A minus number indicates

the need for a smaller mounting distance (which

can be achieved by increasing the shim

thickness). If examination reveals pinion depth

code “0”, the pinion is “nominal”.

425RS023

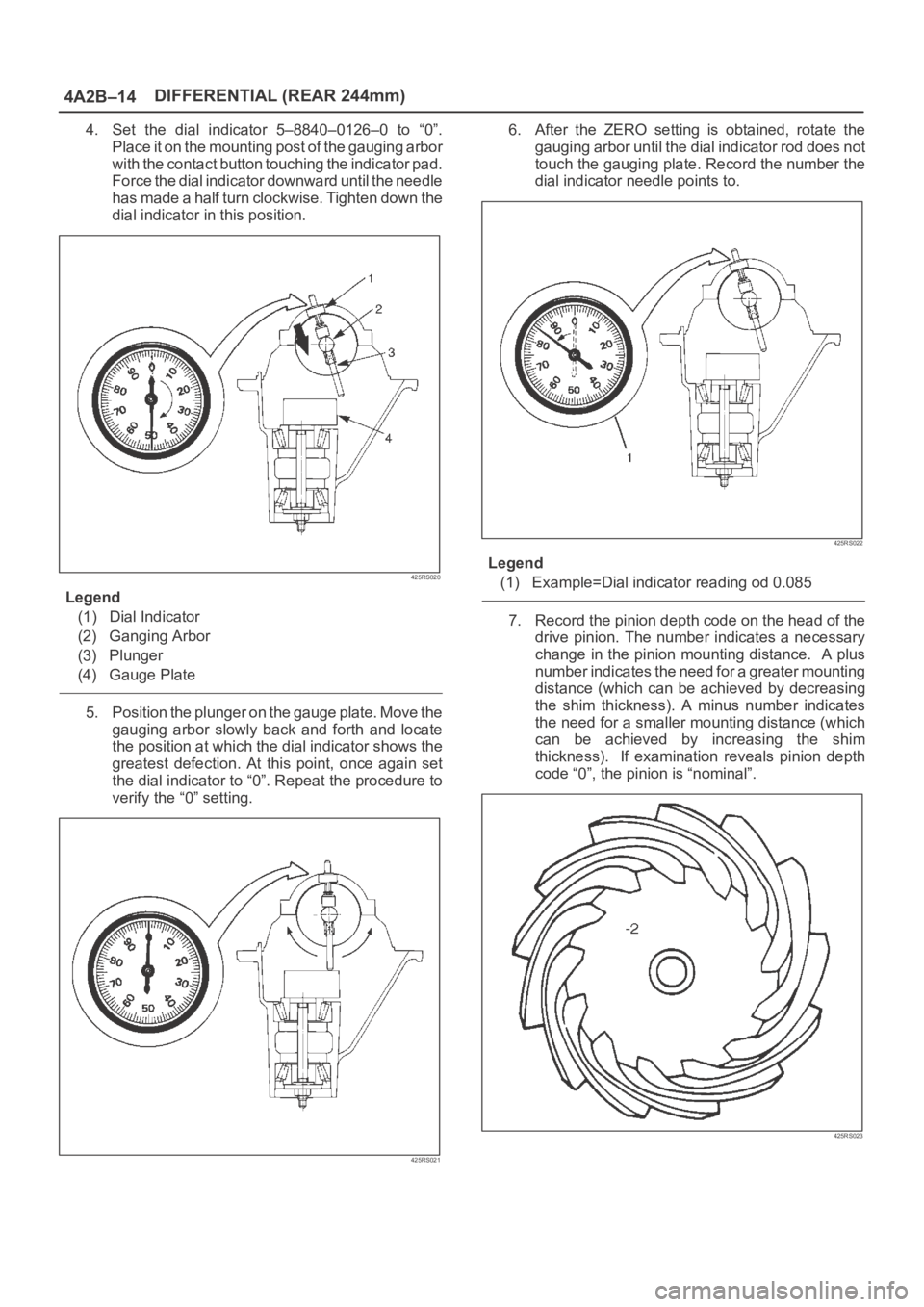

Page 681 of 6000

4C–15 DRIVE SHAFT SYSTEM

3. Remove bolt.

Before removal, shift transfer lever into “2H” position,

set free wheeling hub knob into “FREE” position (1),

and run the vehicle about 50m (160 ft).

411RW010

4. Remove cover assembly.

5. Remove snap ring and shim.

6. Remove body assembly.

7. Remove lock washer and lock screw.

8. Remove hub nut by using wrench 5–8840–2117–0.

411RW005

9. Remove hub and disc assembly.

10. Remove ABS sensor ring (If equipped).

11. Remove outer bearing outer race.

12. Remove oil seal.13. Remove inner bearing outer race.

14. While pushing follower knob against cover, turn clutch

assembly clockwise and then remove clutch

assembly from knob.

411RW011

15. Remove gasket.

16. Remove snap ring.

17. Remove knob.

18. Remove compression spring.

19. Remove follower.

20. Remove retaining spring from clutch assembly by

turning it counterclockwise.

411RW012

21. Remove dedent ball and spring.

22. Remove X–ring.

23. Remove snap ring.

24. Remove inner assembly.

25. Remove snap ring.

26. Remove ring.

27. Remove spacer.

Page 987 of 6000

6A–31

ENGINE MECHANICAL

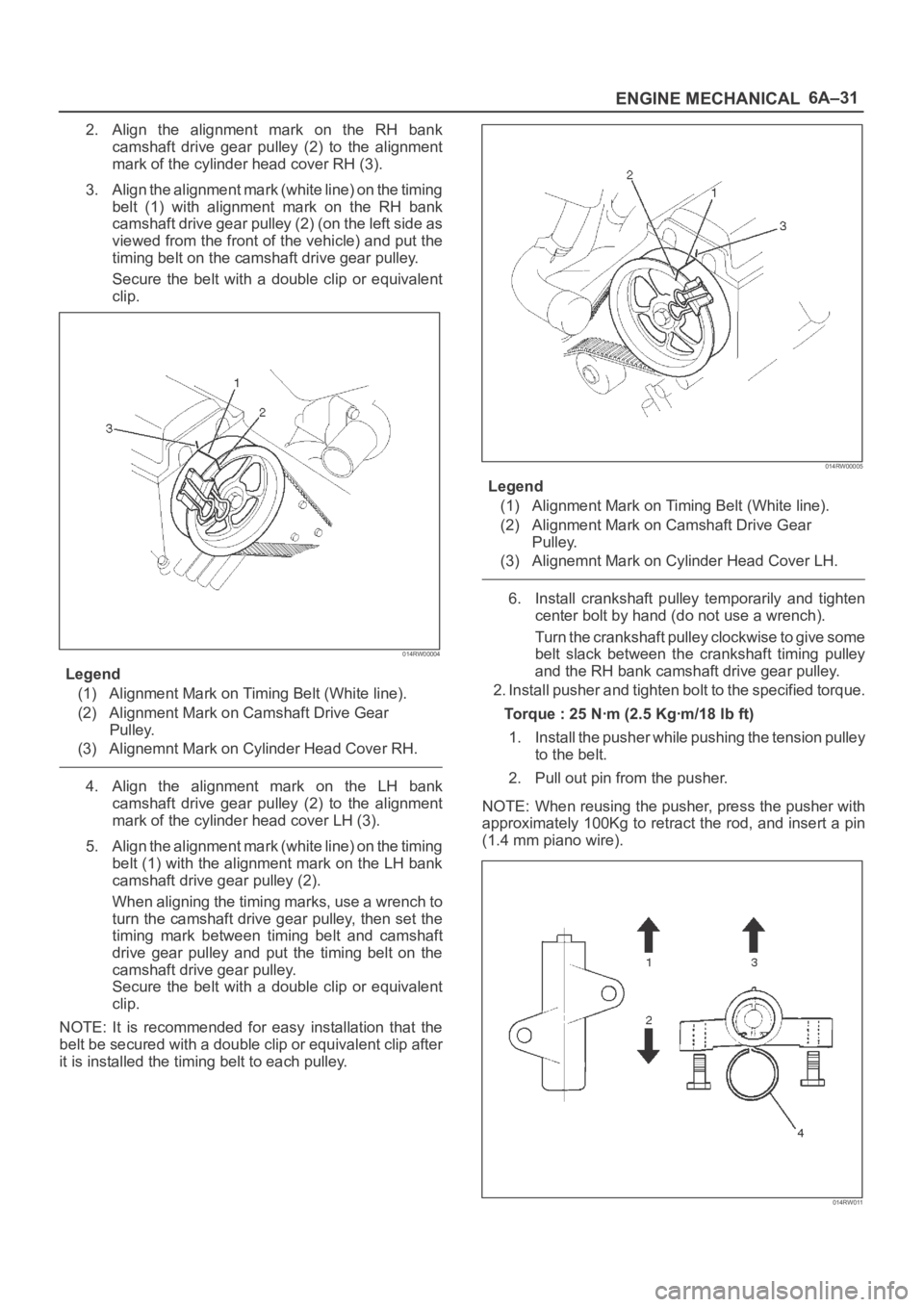

2. Align the alignment mark on the RH bank

camshaft drive gear pulley (2) to the alignment

mark of the cylinder head cover RH (3).

3. Align the alignment mark (white line) on the timing

belt (1) with alignment mark on the RH bank

camshaft drive gear pulley (2) (on the left side as

viewed from the front of the vehicle) and put the

timing belt on the camshaft drive gear pulley.

Secure the belt with a double clip or equivalent

clip.

014RW00004

Legend

(1) Alignment Mark on Timing Belt (White line).

(2) Alignment Mark on Camshaft Drive Gear

Pulley.

(3) Alignemnt Mark on Cylinder Head Cover RH.

4. Align the alignment mark on the LH bank

camshaft drive gear pulley (2) to the alignment

mark of the cylinder head cover LH (3).

5. Align the alignment mark (white line) on the timing

belt (1) with the alignment mark on the LH bank

camshaft drive gear pulley (2).

When aligning the timing marks, use a wrench to

turn the camshaft drive gear pulley, then set the

timing mark between timing belt and camshaft

drive gear pulley and put the timing belt on the

camshaft drive gear pulley.

Secure the belt with a double clip or equivalent

clip.

NOTE: It is recommended for easy installation that the

belt be secured with a double clip or equivalent clip after

it is installed the timing belt to each pulley.

014RW00005

Legend

(1) Alignment Mark on Timing Belt (White line).

(2) Alignment Mark on Camshaft Drive Gear

Pulley.

(3) Alignemnt Mark on Cylinder Head Cover LH.

6. Install crankshaft pulley temporarily and tighten

center bolt by hand (do not use a wrench).

Turn the crankshaft pulley clockwise to give some

belt slack between the crankshaft timing pulley

and the RH bank camshaft drive gear pulley.

2. Install pusher and tighten bolt to the specified torque.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

1. Install the pusher while pushing the tension pulley

to the belt.

2. Pull out pin from the pusher.

NOTE: When reusing the pusher, press the pusher with

approximately 100Kg to retract the rod, and insert a pin

(1.4 mm piano wire).

014RW011

Page 1375 of 6000

6E–258

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1625 PCM Unexpected Reset

Circuit Description

The powertrain control module (PCM) monitors

unexpected PCM reset. This will not turn on MIL light on,

only records code DTC P1625.

Conditions for Setting the DTC

Clock or COP reset.

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store conditions which were present

when the DTC was set as Failure Records only. This

information will not be stored as Freeze Frame data.

Conditions for Clearing the MIL/DTC

DTC P1625 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

P1625 alone stored does not need diagnosis. Clear

DTC code.

Page 2522 of 6000

CLUTCH7C–13

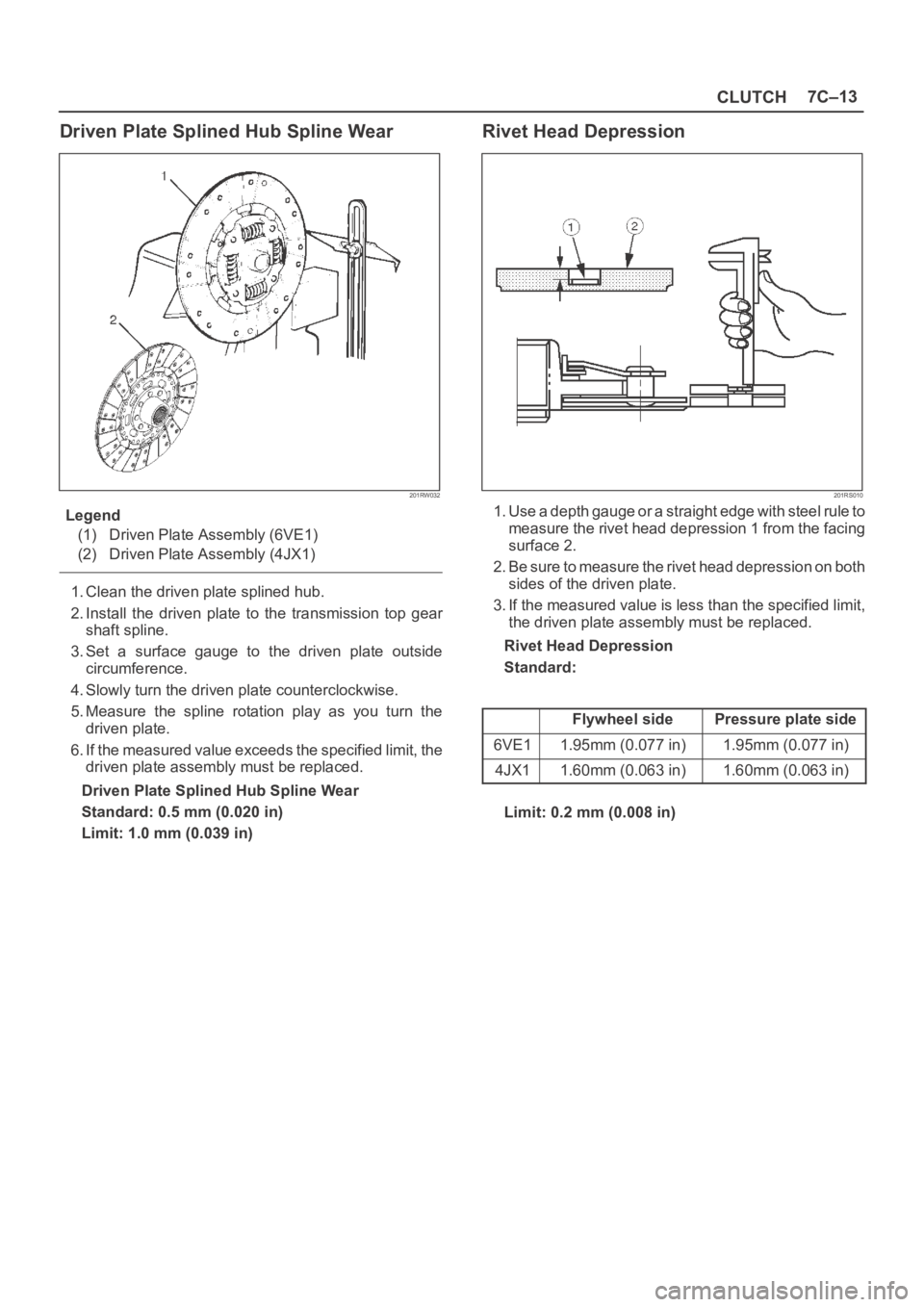

Driven Plate Splined Hub Spline Wear

201RW032

Legend

(1) Driven Plate Assembly (6VE1)

(2) Driven Plate Assembly (4JX1)

1. Clean the driven plate splined hub.

2. Install the driven plate to the transmission top gear

shaft spline.

3. Set a surface gauge to the driven plate outside

circumference.

4. Slowly turn the driven plate counterclockwise.

5. Measure the spline rotation play as you turn the

driven plate.

6. If the measured value exceeds the specified limit, the

driven plate assembly must be replaced.

Driven Plate Splined Hub Spline Wear

Standard: 0.5 mm (0.020 in)

Limit: 1.0 mm (0.039 in)

Rivet Head Depression

201RS010

1. Use a depth gauge or a straight edge with steel rule to

measure the rivet head depression 1 from the facing

surface 2.

2. Be sure to measure the rivet head depression on both

sides of the driven plate.

3. If the measured value is less than the specified limit,

the driven plate assembly must be replaced.

Rivet Head Depression

Standard:

Flywheel sidePressure plate side

6VE11.95mm (0.077 in)1.95mm (0.077 in)

4JX11.60mm (0.063 in)1.60mm (0.063 in)

Limit: 0.2 mm (0.008 in)

Page 2557 of 6000

8A–18LIGHTING SYSTEM

Lighting Switch (Combination Switch)

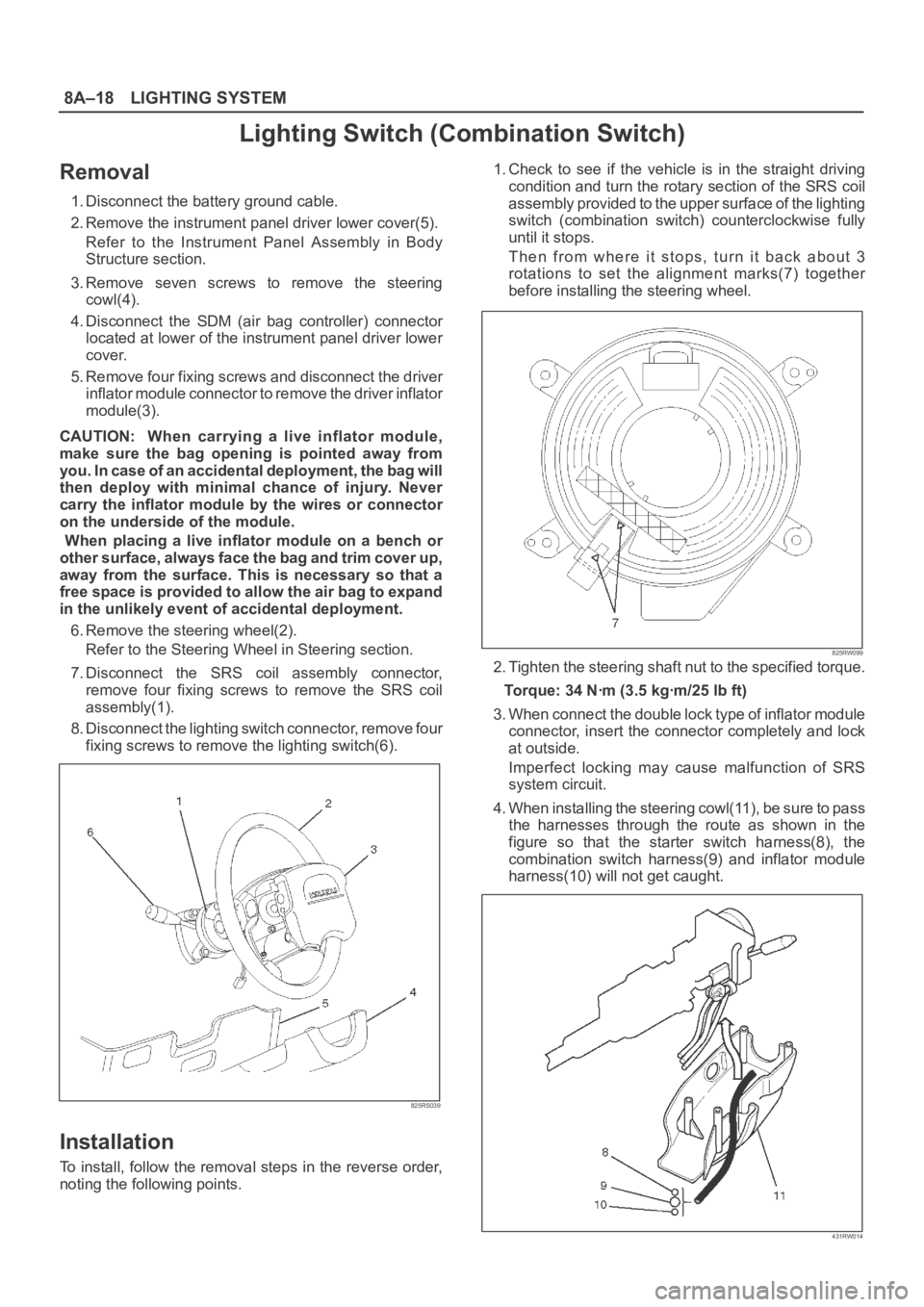

Removal

1. Disconnect the battery ground cable.

2. Remove the instrument panel driver lower cover(5).

Refer to the Instrument Panel Assembly in Body

Structure section.

3. Remove seven screws to remove the steering

cowl(4).

4. Disconnect the SDM (air bag controller) connector

located at lower of the instrument panel driver lower

cover.

5. Remove four fixing screws and disconnect the driver

inflator module connector to remove the driver inflator

module(3).

CAUTION: When carrying a live inflator module,

make sure the bag opening is pointed away from

y o u . I n c a s e o f a n a c c i d e n t a l d e p l o y m e n t , t h e b a g w i l l

then deploy with minimal chance of injury. Never

carry the inflator module by the wires or connector

on the underside of the module.

When placing a live inflator module on a bench or

other surface, always face the bag and trim cover up,

away from the surface. This is necessary so that a

free space is provided to allow the air bag to expand

in the unlikely event of accidental deployment.

6. Remove the steering wheel(2).

Refer to the Steering Wheel in Steering section.

7. Disconnect the SRS coil assembly connector,

remove four fixing screws to remove the SRS coil

assembly(1).

8. Disconnect the lighting switch connector, remove four

fixing screws to remove the lighting switch(6).

825RS039

Installation

To install, follow the removal steps in the reverse order,

noting the following points.1. Check to see if the vehicle is in the straight driving

condition and turn the rotary section of the SRS coil

assembly provided to the upper surface of the lighting

switch (combination switch) counterclockwise fully

until it stops.

Then from where it stops, turn it back about 3

rotations to set the alignment marks(7) together

before installing the steering wheel.

825RW099

2. Tighten the steering shaft nut to the specified torque.

Torque: 34 Nꞏm (3.5 kgꞏm/25 lb ft)

3. When connect the double lock type of inflator module

connector, insert the connector completely and lock

at outside.

Imperfect locking may cause malfunction of SRS

system circuit.

4. When installing the steering cowl(11), be sure to pass

the harnesses through the route as shown in the

figure so that the starter switch harness(8), the

combination switch harness(9) and inflator module

harness(10) will not get caught.

431RW014

Page 3329 of 6000

SEATS8G–17

Disassembly (Split Type)

1. Remove the back board.

Remove the clips and the back board.

2. Remove the device cover.

3. Remove the release knob.

Turn the knob counterclockwise to remove it.

4. Remove the release rod.

Disconnect the rod from the linkage bush.

5. Remove the reclining device.

755RS004

6. Remove the connecting shaft.

7. Remove the seat back assembly.

8. Remove the pillow assembly.

Turn up the seat back trim cover and slit the pad

from the back around to the place where the lock

spring(2) of the guide bush(1) is.

Then insert a finger through the slit and pull out the

pillow while you are pressing down on the lock spring.

755RS017

9. Remove the band hook cover.

10. Remove the armrest assembly.

Turn up the seat back trim cover and remove the

fixing nuts.

11. Remove the armrest set bracket.

12. Remove the armrest board.

13. Remove the trim cover.

Remove the trim cover fixing hog rings from the

backside of the seat back.

With close attention paid to the hog rings and the

wire which connect the trim cover and the pad and

frame assembly, remove the trim cover while

turning it up.

14. Remove the pad & frame assembly.

15. Remove the seat cushion assembly.

16. Remove the seat lock cover.

17. Remove the rear seat belt buckle and lock assembly.

18. Remove the mounting bracket.

19. Remove the return spring.

20. Remove the spring collar.

21. Remove the trim cover.

Remove the hog rings and pull the trim cover out

from the frame assembly groove.

With close attention paid to the hog rings and the

wire which connect the trim cover and the pad &

frame assembly, remove the trim cover while

turning it up.

22. Remove the frame assembly.

23. Remove the pad assembly.

24. Remove the stopper rubber.

Page 3331 of 6000

SEATS8G–19

Disassembled View (Short Wheel Base)

755RW036

Legend

(1) Back Board

(2) Release Knob

(3) Release Rod

(4) Device Cover

(5) Reclining Device

(6) Linkage Bush

(7) Pillow Assembly

(8) Pad & Frame Assembly

(9) Armrest Board

(10) Clip

(11) Band Hook Cover

(12) Trim Cover(13) Armrest Set Bracket

(14) Bush

(15) Armrest Assembly

(16) Trim Cover

(17) Mounting Bracket

(18) Frame Assembly

(19) Stopper Rubber

(20) Pad Assembly

(21) Seat Lock Cover

(22) Rear seat Belt Bukle and Lock Assembly

(23) Seat Cushion Assembly

(24) Free Hinge Cover

(25) Seat Back Assembly

Disassembly

1. Remove the back board.

Remove the clips and the back board.2. Remove the device cover.

3. Remove the release knob.Turn the knob counterclockwise to remove it.