lock OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 471 of 6000

4A2A–4

DIFFERENTIAL (REAR 220mm)

Axle Housing

Axle Housing and Associated Parts

420RW022

Legend

(1) Coil Spring and Insulator

(2) Axle Housing Assembly

(3) ABS Speed Sensor and Harness(if equipped)

(4) Nut

(5) Parking Brake Cable

(6) Bolt and Nut

(7) Antilock Brake System (ABS) Connector and

Bracket (if equipped)

(8) Bolt and Nut(9) Nut

(10) Differential Assembly

(11) Axle Shaft Assembly

(12) Brake Disc

(13) Brake Pipe

(14) Brake Caliper

(15) Nut

(16) Breather Hose

(17) Flare Nut

Removal

1. Raise the vehicle and support it with suitable safety

stands.

The hoist must remain under the rear axle housing.

2. Drain brake fluid. Refer to Hydraulic Brakes in Brake

section.

3. Remove rear wheels and tires. Refer to Wheel in

Suspension section.4. Remove propeller shaft. Refer to Rear Propeller

Shaft in this section.

5. Drain the rear axle oil into a proper container.

6. Remove parking brake cable, release the connection

between the cable fixing clip equalizer. Refer to

Parking Brakes in Brake section.

7. Move the clip aside and pull out the breather hose.

Page 472 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–5

8. Disconnect the ABS connectors (1) and remove the

brackets (2) attached to the frame and center link

(ABS model only).

350RS001

9. Loosen the brake tube flare nut, remove the clip and

take out the brake tube.

10. Remove the shock absorber fixing nut from the axle

housing.

11. Remove the stabilizer linkage mounting nut from the

axle housing.

12. Remove the lateral rod fixing nut from the axle

housing.

13. Remove the center link mounting bolt and nut from

the axle housing.

14. Remove the trailing link fixing bolt and nut from the

axle housing.

15. Jack down and remove the coil spring and insulator.

16. Axle housing assembly can be separated from the

vehicle on completion of steps 1 – 11.

17. Remove the brake caliper fixing bolt (3), loosen the

flare nut (1), release the clip (2) and take out the brake

caliper together with the flexible hose.

306RS001

18. Remove brake disc.

19. Remove antilock brake system speed sensor fixing

bolt and the clip and bracket on the axle housing

(ABS model only).

20. Remove the brake pipe clip and fixing bolt on the axle

housing and take out the brake pipe.

21. Remove the bearing holder fixing nut and take out the

axle shaft assembly, be sure not to damage the oil

seal by the spline of the shaft, Refer to Axle Shaft in

this section.

22. Remove differential assembly, refer to Differential

Assembly in this section.

Oil Seal Replacement

Remove the oil seal, carefully not to damage the housing,

and mount new oil seal using oil seal installer

5–8840–2294–0.

420RW028

Installation

1. Install differential assembly, refer to Differential

Assembly in this section.

2. Install axle shaft assembly then tighten the bearing

holder mounting nut to the specified torque. Be sure

not to damage the oil seal by the spline of the shaft.

Torque: 74Nꞏm (7.5kgꞏm/54lb ft)

3. Install brake pipe.

4. Connect antilock brake system (ABS) speed sensor

and harness, refer to 4–Wheel Anti–Lock Brake

System (ABS) in Brake section (ABS model only).

5. Install brake disc.

6. Install brake caliper. Refer to Disk Brakes in Brake

section.

7. Install axle housing assembly.

8. Install coil spring and insulator.

9. Install the trailing link fixing bolt and nut to the axle

housing. For the procedures in items 9–13, refer to

Suspension section.

10. Install the center link bolt and nut to the axle housing.

Page 475 of 6000

4A2A–8

DIFFERENTIAL (REAR 220mm)

Differential Assembly

Differential Assembly and Associated Parts

425RW055

Legend

(1) Bolt and Nut

(2) Axle Shaft Assembly(3) Parking Brake Cable

(4) Differential Assembly

(5) Nut

Removal

1. Jack up and support the frame with stands.

2. Remove the wheel and tire. Refer to Wheel in

Steering section.

3. Drain the differential oil.

4. Remove the propeller shaft. Refer to Rear Propeller

Shaft in this section.

5. Remove the ABS speed sensor(ABS model only).

Refer to 4–Wheel Anti–lock Brake System (ABS) in

Brake section.6. Remove the parking brake cable fastening clip and

disconnect the equalizer section. Refer to Parking

Brakes in Brake section.

7. Remove the bearing holder fixing nuts.

8. Remove axle shaft assembly, be sure not to damage

the oil seal by axle shaft.

9. Remove differential carrier mounting bolts and nuts.

10. Remove differential assembly.

Page 481 of 6000

4A2A–14

DIFFERENTIAL (REAR 220mm)

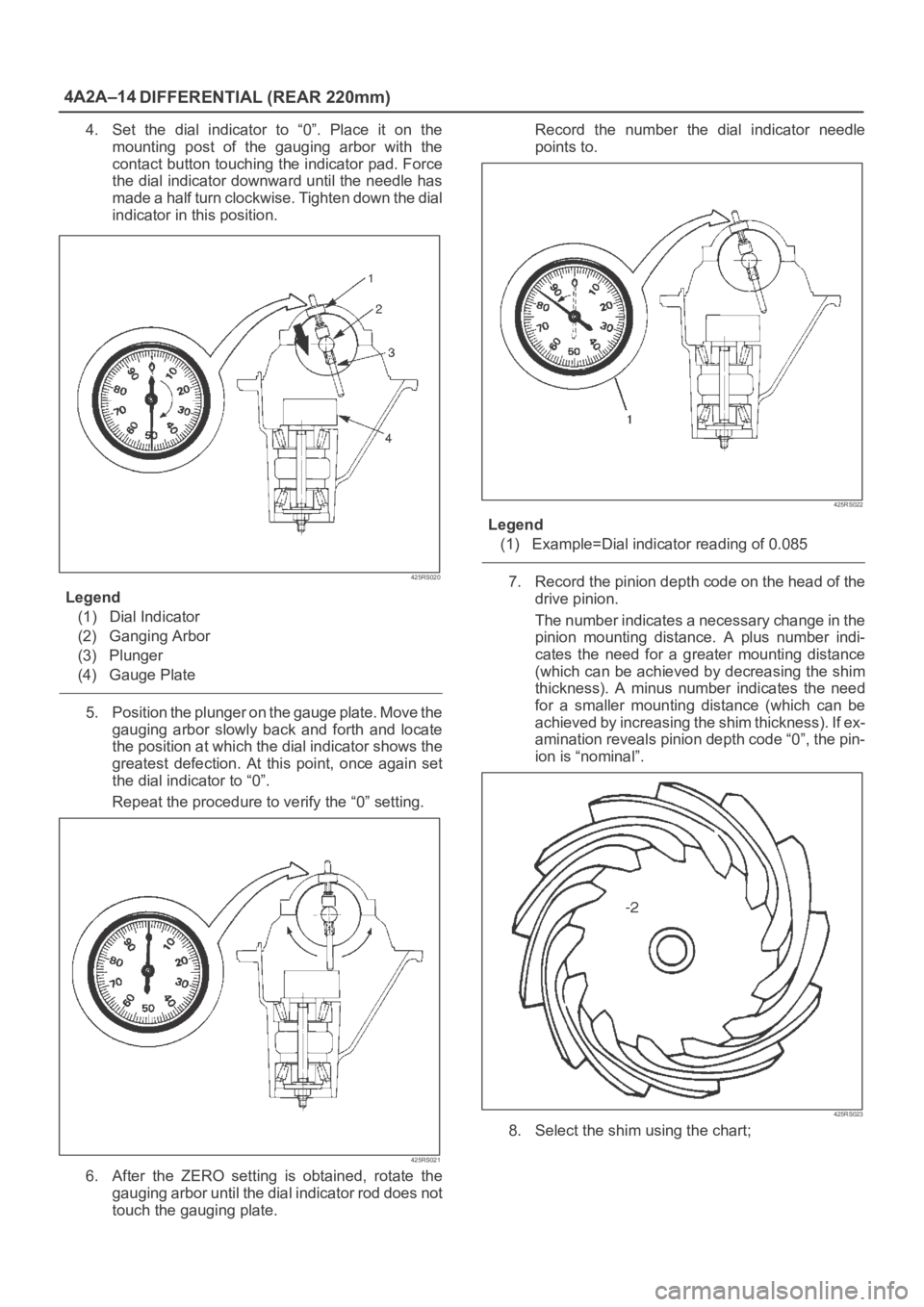

4. Set the dial indicator to “0”. Place it on the

mounting post of the gauging arbor with the

contact button touching the indicator pad. Force

the dial indicator downward until the needle has

made a half turn clockwise. Tighten down the dial

indicator in this position.

425RS020

Legend

(1) Dial Indicator

(2) Ganging Arbor

(3) Plunger

(4) Gauge Plate

5. Position the plunger on the gauge plate. Move the

gauging arbor slowly back and forth and locate

the position at which the dial indicator shows the

greatest defection. At this point, once again set

the dial indicator to “0”.

Repeat the procedure to verify the “0” setting.

425RS021

6. After the ZERO setting is obtained, rotate the

gauging arbor until the dial indicator rod does not

touch the gauging plate.Record the number the dial indicator needle

points to.

425RS022

Legend

(1) Example=Dial indicator reading of 0.085

7. Record the pinion depth code on the head of the

drive pinion.

The number indicates a necessary change in the

pinion mounting distance. A plus number indi-

cates the need for a greater mounting distance

(which can be achieved by decreasing the shim

thickness). A minus number indicates the need

for a smaller mounting distance (which can be

achieved by increasing the shim thickness). If ex-

amination reveals pinion depth code “0”, the pin-

ion is “nominal”.

425RS023

8. Select the shim using the chart;

Page 488 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–21

Differential Cage Assembly

Disassembled View

415RW034

Legend

(1) Pinion Gear

(2) Thrust Washer

(3) Side Gear

(4) Cross Pin(5) Ring Gear

(6) Bolt

(7) Differential Cage

(8) Lock Pin

Disassembly

1. Remove bolt.

2. Remove ring gear.

3. Remove lock pin, break staking on the lock pin, using

a 5 mm (0.20 in) diameter drill.

425RS042

Page 489 of 6000

4A2A–22

DIFFERENTIAL (REAR 220mm)

4. Remove the cross pin, using a soft metal rod and a

hammer.

425RS043

5. Remove pinion gear.

6. Remove side gear.

7. Remove thrust washer.

Inspection and Repair

Make necessary correction or parts replacement if wear,

damage, corrosion or any other abnormal conditions are

found through inspection.

Check the following parts:

1. Ring gear, pinion gear

2. Bearing

3. Side gear, pinion gear, cross pin

4. Differential cage, carrier

5. Thrust washer

6. Oil seal

Ring gear replacement:

1. The ring gear should always be replaced with the

drive pinion as a set.

2. Clean the ring gear threaded holes to remove the

locking agent.

3. When installing the ring gear, apply LOCTITE 271 or

equivalent to all the threaded area and half of the

unthreaded area of the bolt.

4. Discard used bolts and install new ones.

Torque: 108 Nꞏm (11.0kgꞏm/80 lb ft)5. Tighten the fixing bolts in a diagonal sequence as

illustrated.

415RW036

Clearance between the differential pinion

and the cross pin measurement:

Standard: 0.06 – 0.12 mm (0.002–0.005 in)

Limit: 0.2 mm (0.008 in)

425RS045

Page 490 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–23

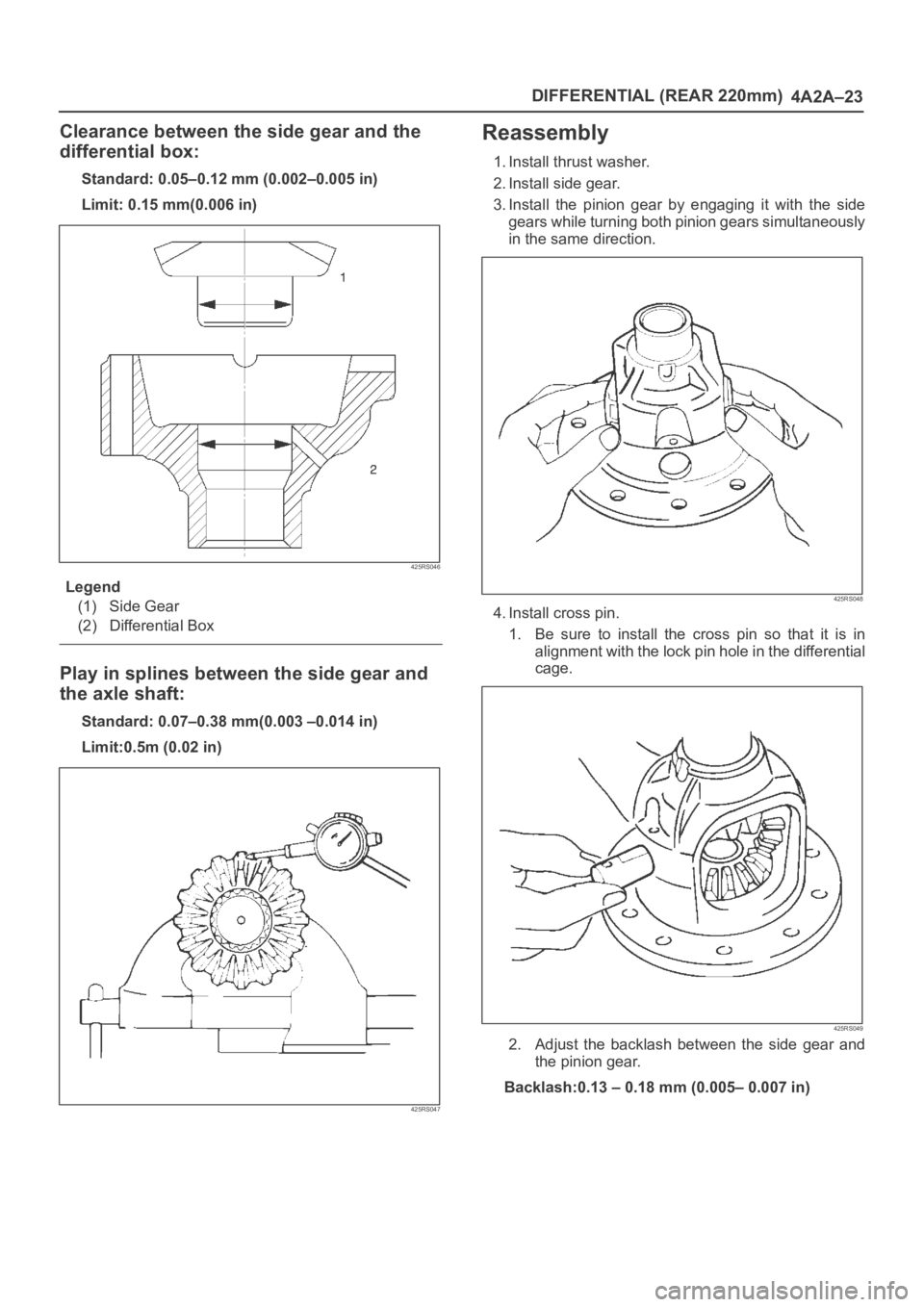

Clearance between the side gear and the

differential box:

Standard: 0.05–0.12 mm (0.002–0.005 in)

Limit: 0.15 mm(0.006 in)

425RS046

Legend

(1) Side Gear

(2) Differential Box

Play in splines between the side gear and

the axle shaft:

Standard: 0.07–0.38 mm(0.003 –0.014 in)

Limit:0.5m (0.02 in)

425RS047

Reassembly

1. Install thrust washer.

2. Install side gear.

3. Install the pinion gear by engaging it with the side

gears while turning both pinion gears simultaneously

in the same direction.

425RS048

4. Install cross pin.

1. Be sure to install the cross pin so that it is in

alignment with the lock pin hole in the differential

cage.

425RS049

2. Adjust the backlash between the side gear and

the pinion gear.

Backlash:0.13 – 0.18 mm (0.005– 0.007 in)

Page 491 of 6000

4A2A–24

DIFFERENTIAL (REAR 220mm)

Thickness of thrust washers available:

0.80 mm, 0.90 mm, 1.00 mm 1.10 mm, 1.20 mm,

1.30 mm (0.031 in, 0.035 in, 0.039 in,0.043 in,

0.047 in, 0.051 in)

425RS050

5. Install lock pin. After lock pin installation, stake the

cage to secure the lock pin.

425RS051

Legend

(1) Staked Portion

(2) Lock Pin

6. Clean the ring gear threaded holes to remove the

locking agent. When installing the ring gear, apply

LOCTITE 271 or equivalent to all the threaded area

and half of the unthreaded area of the bolt.7. Tighten the bolts in diagonal sequence as illustrated.

Torque: 108 Nꞏm (11.0kgꞏm/80 lb ft)

NOTE: Discard used bolts and install new ones.

415RW036

Page 494 of 6000

DIFFERENTIAL (REAR 220mm)

4A2A–27

Pressure ring

425RS057

Legend

(3) Sliding surface with the friction disc. When

nicks or scratches are found, polish with an oil

stone and repair on a level block using a

compound.

(4) Sliding spherical surface with the pinion gear.

(5) Sliding surface with the side gear.

(6) V–shaped groove of the pressure ring and V

–shaped section of the pinion shaft.

(7) Fitting section with the case.

(8) Face contacting the inner surface of the

differential case. Repair burrs and nicks using

an oil stone.

Thrust washer

425RS058

Legend

(9) Sliding surface with the side gear or case.

(10) Peripheral groove of the side gear.

Repair light nicks and burrs using an oil stone.

Case

425RS059

Legend

(11) Contact surface with the spring disc.

(12) Inner groove of the differential cage B.

Repair light nicks and burrs using an oil stone.

425RS060

Page 499 of 6000

4A2A–32

DIFFERENTIAL (REAR 220mm)

Main Data and Specifications

General Specifications

Rear axle

Ty p eBanjo, Semi–floating

Rear axle Size220mm(8.66in)

Gear typeHypoid

Gear ratio (to 1)4.555(6VD1,4JG2–TC)

4.777(4JG2)

Differential typeTwo pinion

Lubricant GradeGL–5: (Standard differential)

GL–5, LSD: (Limited slip differential)

Locking Differential Lubricant80W90 GL–5

(USE Limited Slip Differential Gear Lubricant or Friction

Modifier Organic Additive)

Capacity1.8liter(1.6 Imp qt/1.9 US qt)