reset OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 5286 of 6000

ENGINE MECHANICAL 6A – 13

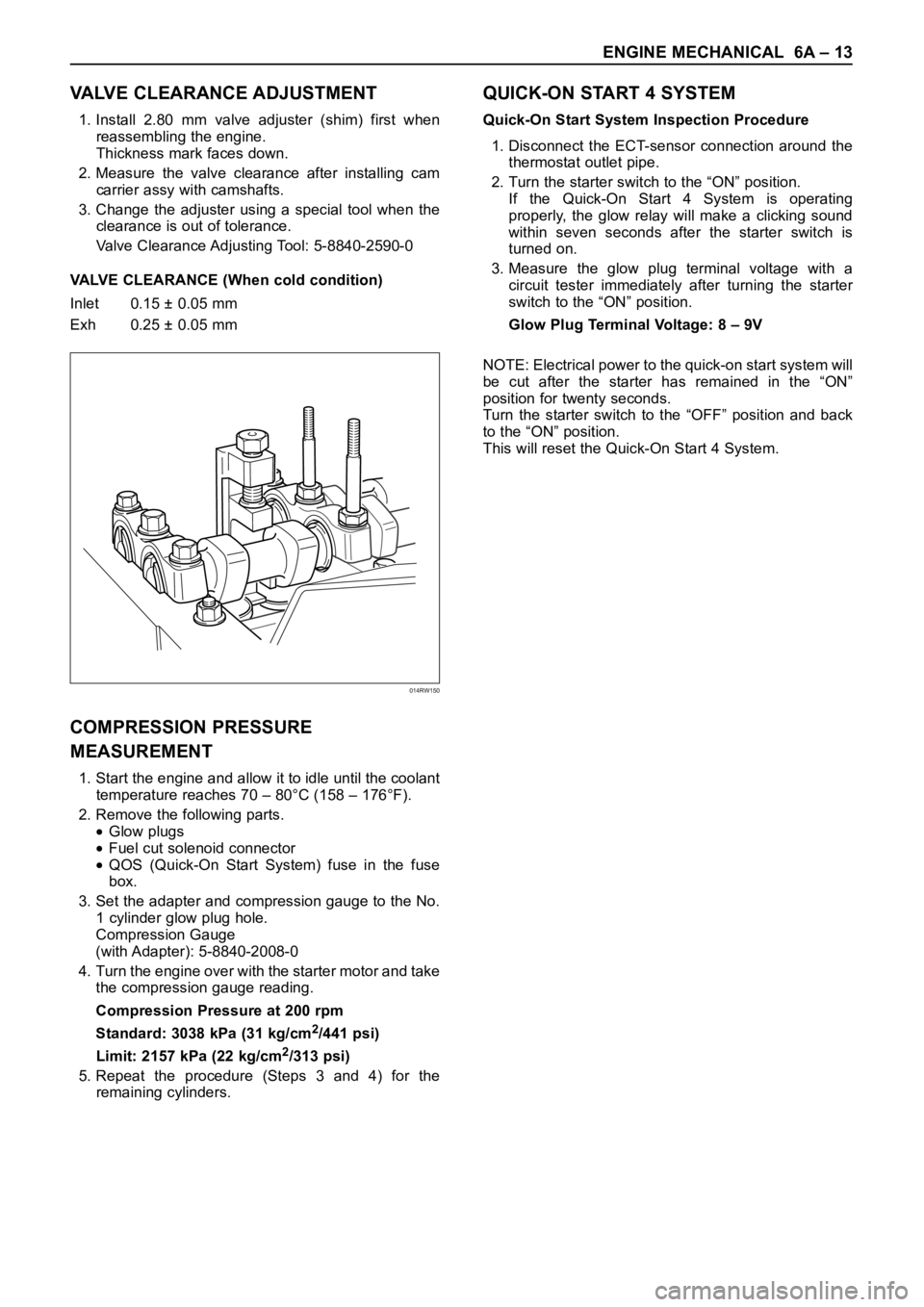

VALVE CLEARANCE ADJUSTMENT

1. Install 2.80 mm valve adjuster (shim) first when

reassembling the engine.

Thickness mark faces down.

2. Measure the valve clearance after installing cam

carrier assy with camshafts.

3. Change the adjuster using a special tool when the

clearance is out of tolerance.

Valve Clearance Adjusting Tool: 5-8840-2590-0

VALVE CLEARANCE (When cold condition)

Inlet 0.15 ± 0.05 mm

Exh 0.25 ± 0.05 mm

COMPRESSION PRESSURE

MEASUREMENT

1. Start the engine and allow it to idle until the coolant

temperature reaches 70 – 80°C (158 – 176°F).

2. Remove the following parts.

Glow plugs

Fuel cut solenoid connector

QOS (Quick-On Start System) fuse in the fuse

box.

3. Set the adapter and compression gauge to the No.

1 cylinder glow plug hole.

Compression Gauge

(with Adapter): 5-8840-2008-0

4. Turn the engine over with the starter motor and take

the compression gauge reading.

Compression Pressure at 200 rpm

Standard: 3038 kPa (31 kg/cm

2/441 psi)

Limit: 2157 kPa (22 kg/cm

2/313 psi)

5. Repeat the procedure (Steps 3 and 4) for the

remaining cylinders.

QUICK-ON START 4 SYSTEM

Quick-On Start System Inspection Procedure

1. Disconnect the ECT-sensor connection around the

thermostat outlet pipe.

2. Turn the starter switch to the “ON” position.

If the Quick-On Start 4 System is operating

properly, the glow relay will make a clicking sound

within seven seconds after the starter switch is

turned on.

3. Measure the glow plug terminal voltage with a

circuit tester immediately after turning the starter

switch to the “ON” position.

Glow Plug Terminal Voltage: 8 – 9V

NOTE: Electrical power to the quick-on start system will

be cut after the starter has remained in the “ON”

position for twenty seconds.

Turn the starter switch to the “OFF” position and back

to the “ON” position.

This will reset the Quick-On Start 4 System.

014RW150

Page 5457 of 6000

6E–28

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

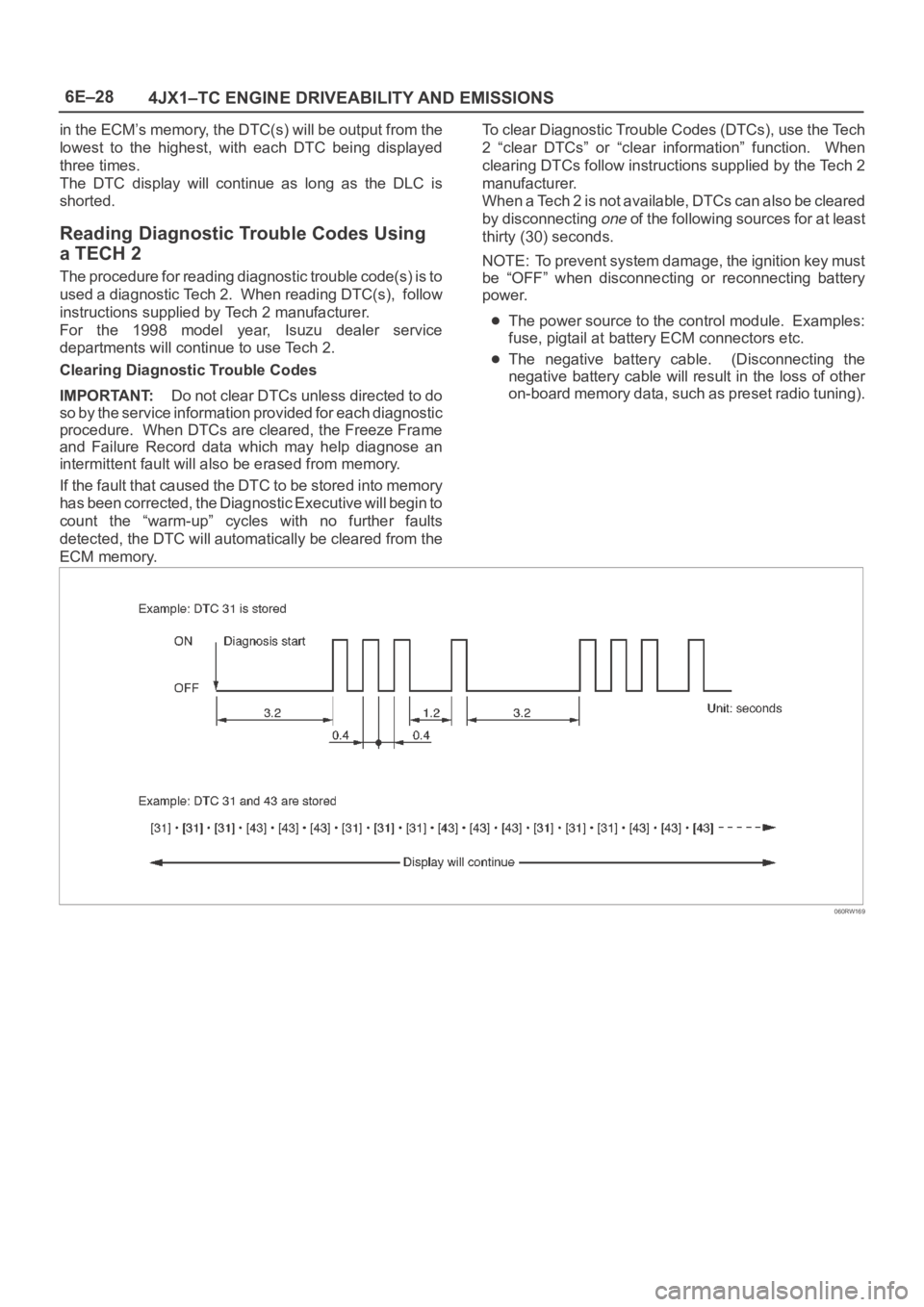

in the ECM’s memory, the DTC(s) will be output from the

lowest to the highest, with each DTC being displayed

three times.

The DTC display will continue as long as the DLC is

shorted.

Reading Diagnostic Trouble Codes Using

a TECH 2

The procedure for reading diagnostic trouble code(s) is to

used a diagnostic Tech 2. When reading DTC(s), follow

instructions supplied by Tech 2 manufacturer.

For the 1998 model year, Isuzu dealer service

departments will continue to use Tech 2.

Clearing Diagnostic Trouble Codes

IMPORTANT:Do not clear DTCs unless directed to do

so by the service information provided for each diagnostic

procedure. When DTCs are cleared, the Freeze Frame

and Failure Record data which may help diagnose an

intermittent fault will also be erased from memory.

If the fault that caused the DTC to be stored into memory

has been corrected, the Diagnostic Executive will begin to

count the “warm-up” cycles with no further faults

detected, the DTC will automatically be cleared from the

ECM memory.To clear Diagnostic Trouble Codes (DTCs), use the Tech

2 “clear DTCs” or “clear information” function. When

clearing DTCs follow instructions supplied by the Tech 2

manufacturer.

When a Tech 2 is not available, DTCs can also be cleared

by disconnecting

one of the following sources for at least

thirty (30) seconds.

NOTE: To prevent system damage, the ignition key must

be “OFF” when disconnecting or reconnecting battery

power.

The power source to the control module. Examples:

fuse, pigtail at battery ECM connectors etc.

The negative battery cable. (Disconnecting the

negative battery cable will result in the loss of other

on-board memory data, such as preset radio tuning).

060RW169

Page 5470 of 6000

6E–41 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

EGR (Exhaust Gas Recirculation)

Diagnosis

A diagnosis of the EGR system is covered by DTC

P1403.

EGR VSV circuit diagnosis is covered by DTC P1404.

EGR pressure sensor diagnosis is covered by DTC

P405 and/or P406.

EGR EVRV circuit diagnosis is covered by DTC

P1405. Refer to the DTC charts.

Tech 2 Data Definitions and Ranges

A/C CLUTCH–Tech 2 Displays ON or OFF–

Indicates whether the A/C has commanded the A/C

clutch ON.

MAP kPa — Tech 2 Range 10-105 kPa/0.00-5.00

Vo l t s —

The manifold absolute pressure reading is determined

from the MAP sensor signal monitored during key up and

wide open throttle (WOT) conditions. The manifold

absolute pressure is used to compensate for altitude

differences and is normally displayed around “61-104”

depending on altitude and manifold absolute pressure.

CMP ACT. COUNTER –Cam Position

DESIRED IDLE — Tech 2 Range 0-3187 RPM —

The idle speed that the ECM is commanding. The ECM

will compensate for various engine loads based on engine

coolant temperature, to keep the engine at the desired

speed.

ECT — (Engine Coolant Temperature) Tech 2

Range –40

C to 151C (–40F to 304F) —

The engine coolant temperature (ECT) is mounted in the

coolant stream and sends engine temperature

information to the ECM. The ECM applies 5 volts to the

ECT sensor circuit. The sensor is a thermistor which

changes internal resistance as temperature changes.

When the sensor is cold (high resistance), the ECM

monitors a high signal voltage and interprets that as a cold

engine. As the sensor warms (decreasing resistance),

the voltage signal will decrease and the ECM will interpret

the lower voltage as a warm engine.

ENGINE RUN TIME — Tech 2 Range

00:00:00-99:99:99 Hrs:Min:Sec —

Indicates the time elapsed since the engine was started.

If the engine is stopped, engine run time will be reset to

00:00:00.

ENGINE SPEED — Range 0-9999 RPM —

Engine speed is computed by the ECM from the 57X

reference input. It should remain close to desired idle

under various engine loads with engine idling.Air Intake Valve meter POSITION — Tech 2 Range

0-100 % —

IAT (INTAKE AIR TEMPERATURE)— Tech 2 Range

–40

C to 151C (–40F to 304F) —

The ECM converts the resistance of the intake air

temperature sensor to degrees. Intake air temperature

(IAT) is used by the ECM to adjust fuel delivery and spark

timing according to incoming air density.

MAP — Tech 2 Range 10-105 kPa (0.00-4.97 Volts)—

The manifold absolute pressure (MAP) sensor measures

the change in the boost pressure.

MIL — Tech 2 Displays ON or OFF —

Indicates the ECM commanded state of the malfunction

indicator lamp.

AP — Tech 2 Range 0%-100% —

AP (Accelerator position) angle is computed by the ECM

from the AP sensor voltage. AP angle should display

“0%” at idle and “100%” at wide open throttle.

AP SENSOR — Tech 2 Range 0.00-5.00 Volts —

The voltage being monitored by the ECM on the AP

sensor signal circuit.

VEHICLE SPEED—Tech 2 Range 0-255 km/h (0-155

mph)–

The vehicle speed sensor signal is converted into km/h

and mph for display.

Typical Scan Data Values

Use the Typical Scan Data Values Table only after the

On-Board Diagnostic System Check has been

completed, no DTC(s) were noted, and you have

determined that the on-board diagnostics are functioning

properly. Tech 2 values from a properly-running engine

may be used for comparison with the engine you are

diagnosing. The typical scan data values represent

values that would be seen on a normally-running engine.

NOTE: A Tech 2 that displays faulty data should not be

used, and the problem should be reported to the Tech 2

manufacturer. Use of a faulty Tech 2 can result in

misdiagnosis and unnecessary replacement of parts.

Only the parameters listed below are referred to in this

service manual for use in diagnosis. For further

information on using the Tech 2 to diagnose the ECM and

related sensors, refer to the applicable reference section

listed below. If all values are within the typical range

described below, refer to the

Symptoms section for

diagnosis.

Test Conditions

Engine running, lower radiator hose hot, transmission in

park or neutral, accessaries off, brake not applied and air

conditioning off.

Page 5529 of 6000

6E–100

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0201 – Injector # 1 Circuit Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0201 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0201 reset?

—Go to Step 5—

5Check the Injector test.

Does the working noise confirm?

—Go to Step 6Go to Step 7

61. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Dose DTC P0201 reset?

—Verify repairGo to Step 7

7Check for an open circuit between the injector

connector and the ECM.

Was there an open circuit?

—Go to Step 8Go to Step 9

8Repair the open circuit.

Is the action complete?

—Verify repair—

9Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repairGo to Step 10

10Replace the Injector (Refer to the Injector Group Sign

Programming).

Is the action complete?

—Verify repair—

Page 5531 of 6000

6E–102

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0202 – Injector # 2 Circuit Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0202 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0202 reset?

—Go to Step 5—

5Check the Injector test.

Does the working noise confirm?

—Go to Step 6Go to Step 7

61. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Dose DTC P0202 reset?

—Verify repairGo to Step 7

7Check for an open circuit between the injector

connector and the ECM.

Was there an open circuit?

—Go to Step 8Go to Step 9

8Repair the open circuit.

Is the action complete?

—Verify repair—

9Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repairGo to Step 10

10Replace the Injector (Refer to the Injector Group Sign

Programming).

Is the action complete?

—Verify repair—

Page 5533 of 6000

6E–104

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0203 – Injector # 3 Circuit Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0203 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0203 reset?

—Go to Step 5—

5Check the Injector test.

Does the working noise confirm?

—Go to Step 6Go to Step 7

61. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Dose DTC P0203 reset?

—Verify repairGo to Step 7

7Check for an open circuit between the injector

connector and the ECM.

Was there an open circuit?

—Go to Step 8Go to Step 9

8Repair the open circuit.

Is the action complete?

—Verify repair—

9Replace the ECM (Refer to the Data Programming in

Case of ECM change).

Is the action complete?

—Verify repairGo to Step 10

10Replace the Injector (Refer to the Injector Group Sign

Programming).

Is the action complete?

—Verify repair—

Page 5535 of 6000

6E–106

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0204 – Injector #4 Circuit Fault

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Will the engine start?

—Go to Step 3

Go to Engine

Cranks But

Will Not Run

chart

31. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Does DTC P0204 reset?

—Go to Step 5Go to Step 4

41. Review the Freeze Frame data with the ignition

“ON” and the engine “OFF” and note the

parameters.

2. Operate the vehicle within the Freeze Frame

conditions as noted.

Does P0204 reset?

—Go to Step 5—

5Check the Injector test.

Does the working noise confirm?

—Go to Step 6Go to Step 7

61. Install the Tech 2. Clear the DTC.

2. Idle the engine for one minute.

Dose DTC P0204 reset?

—Verify repairGo to Step 7

7Check for an open circuit between the injector

connector and the ECM.

Was there an open circuit?

—Go to Step 8Go to Step 9

8Repair the open circuit.

Is the action complete?

—Verify repair—

9Is the action complete?—Verify repairGo to Step 10

10Replace the Injector (Refer to the Injector Group Sign

Programming).

Is the action complete?

—Verify repair—

Page 5718 of 6000

7A–29 AUTOMATIC TRANSMISSION (4L30–E)

Changing Transmission Fluid

There is no need to change the transmission fluid unless

the transmission is used under one or more of the

following heavy duty conditions.

A. Repeated short trips

B. Driving on rough roads

C. Driving on dusty roads

D. Towing a trailer

If the vehicle is used under these conditions, change the

fluid every 20,000 miles (32,000 km).

More over, the remaining life percentage of ATF can be

estimated by using Tech 2 as an auxiliary tool to judge the

right time for ATF replacement.

The remaining life percentage is calculated from ATF’S

heat history. When it is close to 0%, ATF replacement is

recommended.

1. Place a large drain pan under the oil pan.

2. Remove the transmission oil drain screw (2) and drain

fluid.

3. Tighten drain screw (2).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)

4. Remove the transmission overfill screw (1) and fill

transmission through overfill screw opening, using

DEXRON

–III ATF.

NOTE: Add transmission fluid until it flows out over the

overfill screw opening.

5. Let engine idle until a fluid temperature between 32

C

(90

F) and 57C (135F) is reached.

6. Add transmission fluid until it flows out over the overfill

screw opening, then close the overfill screw (1).

Torque: 38 N

m (3.9 kgꞏm/28 lb ft)NOTE: To prevent fluid leaks, the overfill screw and oil

drain screws gasket must be replaced each time these

screws are removed.

NOTE: Check transmission fluid temperature with

service scan tool.

7. Reset “Oil Life Monitor” data by using Tech 2.

Refer to Tech 2 OBD II Connector in Transmission

Control System (4L30-E) Section.

242RW003

Selector Lever

Inspection

1. Make sure that when the selector lever is shifted from

“P” to “L”, a “clicking” can be felt at each shift position.

Make sure that the gear corresponds to that of the

position plate indicator.

2. Check to see if the selector lever can be shifted as

shown in illustration.

C07RW009