transmission OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1215 of 6000

6E–98

ENGINE DRIVEABILITY AND EMISSIONS

Exhaust Gas Recirculation (EGR) System Check

StepActionVa l u e ( s )Ye sNo

1Check the EGR valve for looseness.

Is the EGR valve Loose?

—Go to Step 2Go to Step 3

2Tighten the EGR valve.

Is the action complete?

—Verify repair—

31. Place the transmission selector in Park or Neutral.

2. Start the engine and idle until warm.

3. Using Tech 2, command EGR “50% ON.”

Does the engine idle rough and lose RPMs?

—

EGR system

working

properly. No

problem

found.

Go to Step 4

41. Engine “OFF.”

2. Ignition “ON.”

3. Using a test light to ground, check the EGR harness

between the EGR valve and the ignition feed.

Does the test light illuminate?

—Go to Step 6Go to Step 5

5Repair the EGR harness ignition feed.

Was the problem corrected?

—Verify repairGo to Step 6

61. Remove the EGR valve.

2. Visually and physically inspect the EGR valve

pintle, valve passages and adapter for excessive

deposits, obstructions or any restrictions.

Does the EGR valve have excessive deposits,

obstructions or any restrictions?

—Go to Step 7Go to Step 8

7Clean or replace EGR system components as

necessary.

Was the problem corrected?

—Verify repairGo to Step 8

81. Ground the EGR valve metal case to battery (–).

2. Using Tech 2, command EGR “ON” and observe the

EGR valve pintle for movement.

Does the EGR valve pintle move according to

command?

—Go to Step 9

Go to DTC

P1406 chart

91. Remove the EGR inlet and outlet pipes from the

intake and exhaust manifolds.

2. Visually and physically inspect manifold EGR ports

and EGR inlet and outlet pipes for blockage or

restriction caused by excessive deposits or other

damage.

Do the manifold EGR ports or inlet and outlet pipes

have excessive deposits, obstructions, or any

restrictions?

—Go to Step 10

EGR system

working

properly. No

problem

found.

10Clean or replace EGR system components as

necessary.

Is the action complete?

—Verify repair—

Page 1229 of 6000

6E–112

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0107 MAP Sensor Circuit Low Voltage

D06RW102

Circuit Description

The manifold absolute pressure (MAP) sensor responds

to changes in intake manifold pressure (vacuum). The

MAP sensor signal voltage to the powertrain control

module (PCM) varies from below 2 volts at idle (high

vacuum) to above 4 volts with the ignition “ON,” engine

not running or at wide-open throttle (low vacuum).

The MAP sensor is used to determine manifold pressure

changes while the exhaust gas recirculation (EGR) flow

test diagnostic is being run (refer to

DTC P0401), to

determine engine vacuum level for some other

diagnostics and to determine barometric pressure

(BARO). The PCM monitors the MAP signals for voltages

outside the normal range of the MAP sensor. If the PCM

detects a MAP signal voltage that is excessively low, DTC

P0107 will be set.

Conditions for Setting the DTC

No TP sensor DTCs present.

Engine is running.

Throttle angle is above 1% if engine speed is less than

1000 RPM.

Throttle angle is above 2% if engine speed is above

1000 RPM.

The MAP sensor indicates manifold absolute pressure

at or below 11 kPa for a total of approximately 10

seconds over a 16-second period.

Ignition voltage more than 11 volts.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will default to a BARO value of 79.3 kPa.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0107 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

Check for intermittent codes.

The MAP sensor shares a 5 Volt reference with the

Rough Road Sensor. If these codes are also set, it

could indicate a problem with the 5 Volt reference

circuit .

The MAP sensor shares a ground with the Rough Road

Sensor, the ECT sensor, and the Transmission Fluid

Temperature sensor.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

MAP display on the Tech 2 while moving connectors

Page 1244 of 6000

6E–127 ENGINE DRIVEABILITY AND EMISSIONS

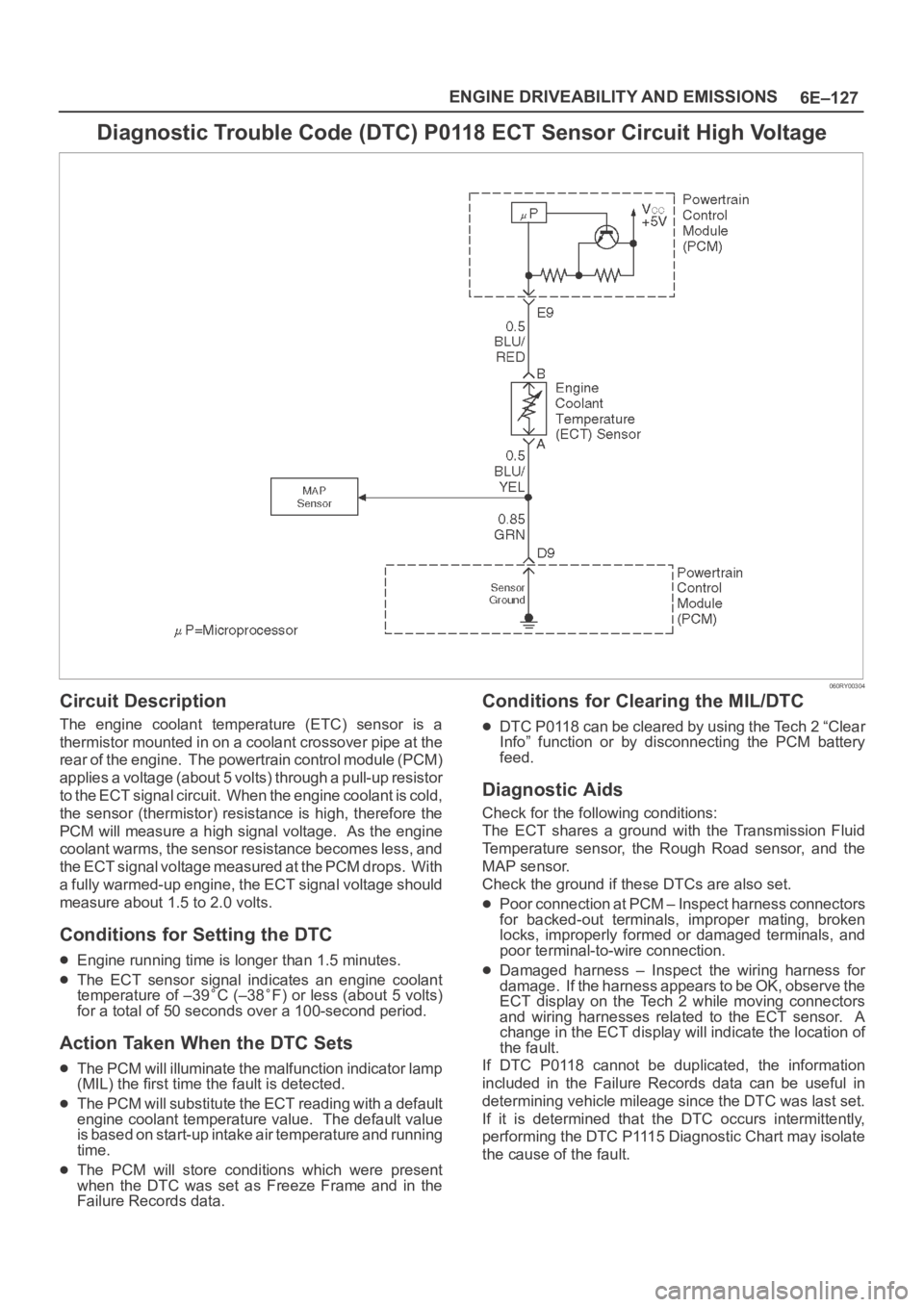

Diagnostic Trouble Code (DTC) P0118 ECT Sensor Circuit High Voltage

060RY00304

Circuit Description

The engine coolant temperature (ETC) sensor is a

thermistor mounted in on a coolant crossover pipe at the

rear of the engine. The powertrain control module (PCM)

applies a voltage (about 5 volts) through a pull-up resistor

to the ECT signal circuit. When the engine coolant is cold,

the sensor (thermistor) resistance is high, therefore the

PCM will measure a high signal voltage. As the engine

coolant warms, the sensor resistance becomes less, and

the ECT signal voltage measured at the PCM drops. With

a fully warmed-up engine, the ECT signal voltage should

measure about 1.5 to 2.0 volts.

Conditions for Setting the DTC

Engine running time is longer than 1.5 minutes.

The ECT sensor signal indicates an engine coolant

temperature of –39C (–38F) or less (about 5 volts)

for a total of 50 seconds over a 100-second period.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will substitute the ECT reading with a default

engine coolant temperature value. The default value

is based on start-up intake air temperature and running

time.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0118 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

Check for the following conditions:

The ECT shares a ground with the Transmission Fluid

Temperature sensor, the Rough Road sensor, and the

MAP sensor.

Check the ground if these DTCs are also set.

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the ECT sensor. A

change in the ECT display will indicate the location of

the fault.

If DTC P0118 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently,

performing the DTC P1115 Diagnostic Chart may isolate

the cause of the fault.

Page 1271 of 6000

6E–154

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0171 Fuel Trim System Lean Bank 1

D06RW030

Circuit Description

To provide the best possible combination of driveability,

fuel economy, and emission control, a “closed loop”

air/fuel metering system is used. While in “closed loop,”

the powertrain control module (PCM) monitors the Bank 1

HO2S 1 and Bank 2 HO2S 1 signals and adjusts fuel

delivery based upon the HO2S signal voltages. A change

made to fuel delivery will be indicated by the long and

short term fuel trim values which can be monitored with a

Tech 2. Ideal fuel trim values are around 0%; if the HO2S

signals are indicating a lean condition the PCM will add

fuel, resulting in fuel trim values above 0%. If a rich

condition is detected, the fuel trim values will be below

0%, indicating that the PCM is reducing the amount of fuel

delivered. If an excessively lean condition is detected on

Bank 1, the PCM will set DTC P0171.

The PCM’s maximum authority to control long term fuel

trim allows a range between –15% (automatic

transmission) or –12% (manual transmission) and +20%.

The PCM monitors fuel trim under various enginespeed/load fuel trim cells before determining the status of

the fuel trim diagnostic.

Conditions for Setting the DTC

No Tech 2 test is being run.

None of the following: EGR DTCs, HO2S DTCs,

(response, transition, open, low volts, no activity), MAF

DTCs, TP sensor DTCs, MAP DTCs, IAT DTCs,

canister purge DTCs, EVAP DTCs, injector circuit

DTCs, or misfire DTCs.

Engine coolant temperature is between 25C (77F)

and 100C (212F).

Intake air temperature is between –40C (–40F) and

120C (248F).

Manifold absolute pressure is between 24 kPa and 99

kPa.

Throttle angle is steady below 95%.

Vehicle speed is below 136 km/h (85 mph).

Engine speed is between 400 and 6,000 RPM.

Barometric pressure is greater than 72.5 kPa.

Page 1275 of 6000

6E–158

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0172 Fuel Trim System Rich Bank 1

D06RW030

Circuit Description

To provide the best possible combination of driveability,

fuel economy, and emission control, a “closed loop”

air/fuel metering system is used. While in “closed loop,”

the powertrain control module (PCM) monitors the Bank 1

heated oxygen sensors (HO2S) 1 and Bank 2 HO2S 1

signals and adjusts fuel delivery based upon the HO2S

signal voltages. A change made to fuel delivery will be

indicated by the long and short term fuel trim values which

can be monitored with a Tech 2. Ideal fuel trim values are

around 0%; if the HO2S signals are indicating a lean

condition the PCM will add fuel, resulting in fuel trim

values above 0%. If a rich condition is detected, the fuel

trim values will be below 0%, indicating that the PCM is

reducing the amount of fuel delivered. If an excessively

rich condition is detected on Bank 1, the PCM will set DTC

P0172.

The PCM’s maximum authority to control long term fuel

trim allows a range between –15% (automatic

transmission) or –12 (manual transmission) and +20%.The PCM’s maximum authority to control short term fuel

trim allows a range between –11% and +20%. The PCM

monitors fuel trim under various engine speed/load fuel

trim cells before determining the status of the fuel trim

diagnostic.

Conditions for Setting the DTC

No Tech 2 test is being run.

None of the following was set: EGR DTCs, HO2S

DTCs, (response, transition, open, low volts, no

activity), MAF DTCs, TPS DTCs, MAP DTCs, IAT

DTCs, canister purge DTCs, EVAP DTCs, injector

circuit DTCs, or misfire DTCs.

Engine coolant temperature is between 25C (77F)

and 100C (212F).

Intake air temperature is between –40C (–40F) and

120

C (248F).

Manifold absolute pressure is between 24 kPa and 99

kPa.

Throttle angle is steady below 95%.

Page 1279 of 6000

6E–162

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0174 Fuel Trim System Lean Bank 2

D06RW031

Circuit Description

To provide the best possible combination of driveability,

fuel economy, and emission control, a “closed loop”

air/fuel metering system is used. While in “closed loop,”

the powertrain control module (PCM) monitors the Bank 1

HO2S 1 and Bank 2 HO2S 1 signals and adjusts fuel

delivery based upon the HO2S signal voltages. A change

made to fuel delivery will be indicated by the long and

short term fuel trim values which can be monitored with a

Tech 2. Ideal fuel trim values are around 0%; if the HO2S

signals are indicating a lean condition the PCM will add

fuel, resulting in fuel trim values above 0%. If a rich

condition is detected, the fuel trim values will be below

0%, indicating that the PCM is reducing the amount of fuel

delivered. If an excessively lean condition is detected on

Bank 2, the PCM will set DTC P0174.

The PCM’s maximum authority to control long term fuel

trim allows a range between –15%(automatic

transmission) or –12%(manual transmission) and +20%.

The PCM monitors fuel trim under various enginespeed/load fuel trim cells before determining the status of

the fuel trim diagnostic.

Conditions for Setting the DTC

No Tech 2 test is being run.

None of the following DTCs are set: idle system, EGR,

HO2S, (response, transition, open, low volts, no

activity), MAF, TP sensor, MAP, IAT, canister purge,

EVAP, injector circuit, or misfire.

Engine coolant temperature is between 25C (77F)

and 100C (212F).

Intake air temperature is between –40C (–40F) and

120C (248F).

Manifold absolute pressure is between 24 kPa and 99

kPa.

Throttle angle is steady below 95%.

Vehicle speed is below 136 km/h (85 mph).

Engine speed is between 400 and 6,000 RPM.

Barometric pressure is greater than 72.5 kPa.

Mass air flow is between 2 g/second and 200 g/second.

Page 1283 of 6000

6E–166

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0175 Fuel Trim System Rich Bank 2

D06RW031

Circuit Description

To provide the best possible combination of driveability,

fuel economy, and emission control, a “closed loop”

air/fuel metering system is used. While in “closed loop,”

the powertrain control module (PCM) monitors the Bank 1

HO2S 1 and Bank 2 HO2S 1 signals and adjusts fuel

delivery based upon the HO2S signal voltages. A change

made to fuel delivery will be indicated by the long and

short term fuel trim values which can be monitored with a

Tech 2. Ideal fuel trim values are around 0%; if the HO2S

signals are indicating a lean condition the PCM will add

fuel, resulting in fuel trim values above 0%. If a rich

condition is detected, the fuel trim values will be below

0%, indicating that the PCM is reducing the amount of fuel

delivered. If an excessively rich condition is detected on

Bank 2, the PCM will set DTC P0175.

The PCM’s maximum authority to control long term fuel

trim allows a range between –15%(automatic

transmission) or –12%(manual transmission) and +20%.

The PCM’s maximum authority to control short term fueltrim allows a range between –11% and +20%. The PCM

monitors fuel trim under various engine speed/load fuel

trim cells before determining the status of the fuel trim

diagnostic.

Conditions for Setting the DTC

No Tech 2 test is being run.

None of the following DTCs are set: idle system, EGR,

HO2S, (response, transition, open, low volts, no

activity), MAF, TPS, MAP, IAT, canister purge, EVAP,

injector circuit, or misfire.

Engine coolant temperature is between 25C (77F)

and 100C (212F).

Intake air temperature is between –40C (–40F) and

120

C (248F).

Manifold absolute pressure is between 24 kPa and 99

kPa.

Throttle angle is steady below 95%.

Vehicle speed is below 136 km/h (85 mph).

Engine speed is between 400 and 6,000 RPM.

Page 1351 of 6000

6E–234

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0502 VSS Circuit Low Input

D06RW019

Circuit Description

The vehicle speed sensor has a magnet rotated by the

transmission output shaft. Attached to the sensor is a hall

effect circuit the interacts with the magnetic field treated

by the rotating magnet. A 12-volt operating supply for the

speed sensor hall circuit is supplied from the meter fuse.

The VSS pulses to ground the 9-volt signal sent from the

powertrain control module (PCM) on the reference circuit.

The PCM interprets vehicle speed by the number of

pulses to ground per second on the reference circuit.

Conditions for Setting the DTC

Engine is running.

Engine coolant temperature is above 60C (140F).

Engine speed is between 1800 RPM and 2500 RPM.

Throttle angle is between 10% and 40%.

Engine load is greater than 50 kPa.

MAP sensor indicates greater than 50 kPa manifold

pressure.

PCM detects no VSS signal for 12.5 seconds over a

period of 25 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0502 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

10. To avoid backprobing the VSS and possibly

damaging a seal or terminal, the VSS output can be

tested at the point where the transmission harness

connects to the engine harness. Power and ground

are applied by jumpers to the VSS through the

connectors which are located just in front of the air

cleaner assembly. The VSS signal is monitored

with a DVM as the rear driveshaft turns. The

wheels can be turned to rotate the driveshaft, or in

2-wheels-drive vehicles the driveshaft can be turned

directly.

12. The speedometer-to-PCM VSS signal wire is

spliced to a wire leading to the cruise control

module. If a short to ground or voltage is indicated

between the PCM and speedometer, it could be on

the cruise control circuit if the vehicle is equipped

with cruise control.

Page 1353 of 6000

6E–236

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0502 – VSS Circuit Low Input

StepNo Ye s Va l u e ( s ) Action

101. Ignition “OFF.”

2. Disconnect the MAF sensor and remove the air

cleaner assembly and filter element to gain access

to the 16-way black connector located immediately

to the rear of the left front headlamp. The connector

attaches the VSS wires from the transmission

harness to the left-side engine harness.

3. Disconnect the black 16-way connector.

4. Select a terminal adapter from kit J 35616 that can

be used with a jumper to supply B+ to the blue wire

with a yellow tracer (transmission side of the

connector).

5. Use another terminal adapter to attach a voltmeter

to the light-green wire with a w h i l e t r a c e r ( n e x t t o t h e

wire in the previous step.)

6. Disconnect the blue connector next to the black

16-way connector, and locate the black/red tracer

wire at one corner of the blue connector. The

black/red wire is the VSS ground. Use a terminal

adapter to attach a jumper to ground to the

black/red VSS ground wire at the transmission side

of the blue connector.

7. Raise the rear wheels off the ground with

transmission in neutral.

Does the DVM toggle back and forth between 0.6 V and

10 V as the wheels (and driveshaft) are rotated?

—Go to Step 11Go to Step 12

11Replace the VSS.

Is the action complete?

—Verify repair—

12Check for an open or short between the PCM and the

speedometer.

Was a problem found?

—Verify repairGo to Step 13

13Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1357 of 6000

6E–240

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0601 PCM Memory

Circuit Description

The powertrain control module (PCM) used in this vehicle

utilizes an electrically erasable programmable read-only

memory (EEPROM). The EEPROM contains program

information and the calibrations required for engine,

transmission, and powertrain diagnostics operation.

Unlike the PROM used in past applications, the EEPROM

is not replaceable.

Conditions for Setting the DTC

The PCM detects an internal program fault (check sum

error).

Action Taken When the DTC Sets

The PCM will not illuminate the malfunction indicator

lamp (MIL).

The PCM will store conditions which were present

when the DTC was set in the Failure Records data only.

Conditions for Clearing the MIL/DTC

DTC P0601 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

DTC P0601 indicates that the contents of the

EEPROM have changed since the PCM was

programmed. The only possible repair is PCM

replacement.

DTC P0601 – PCM Memory

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—