warning OPEL FRONTERA 1998 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1883 of 6000

6D – 16 ENGINE ELECTRICAL

DIAGNOSIS

GENERAL ON-VEHICLE INSPECTION

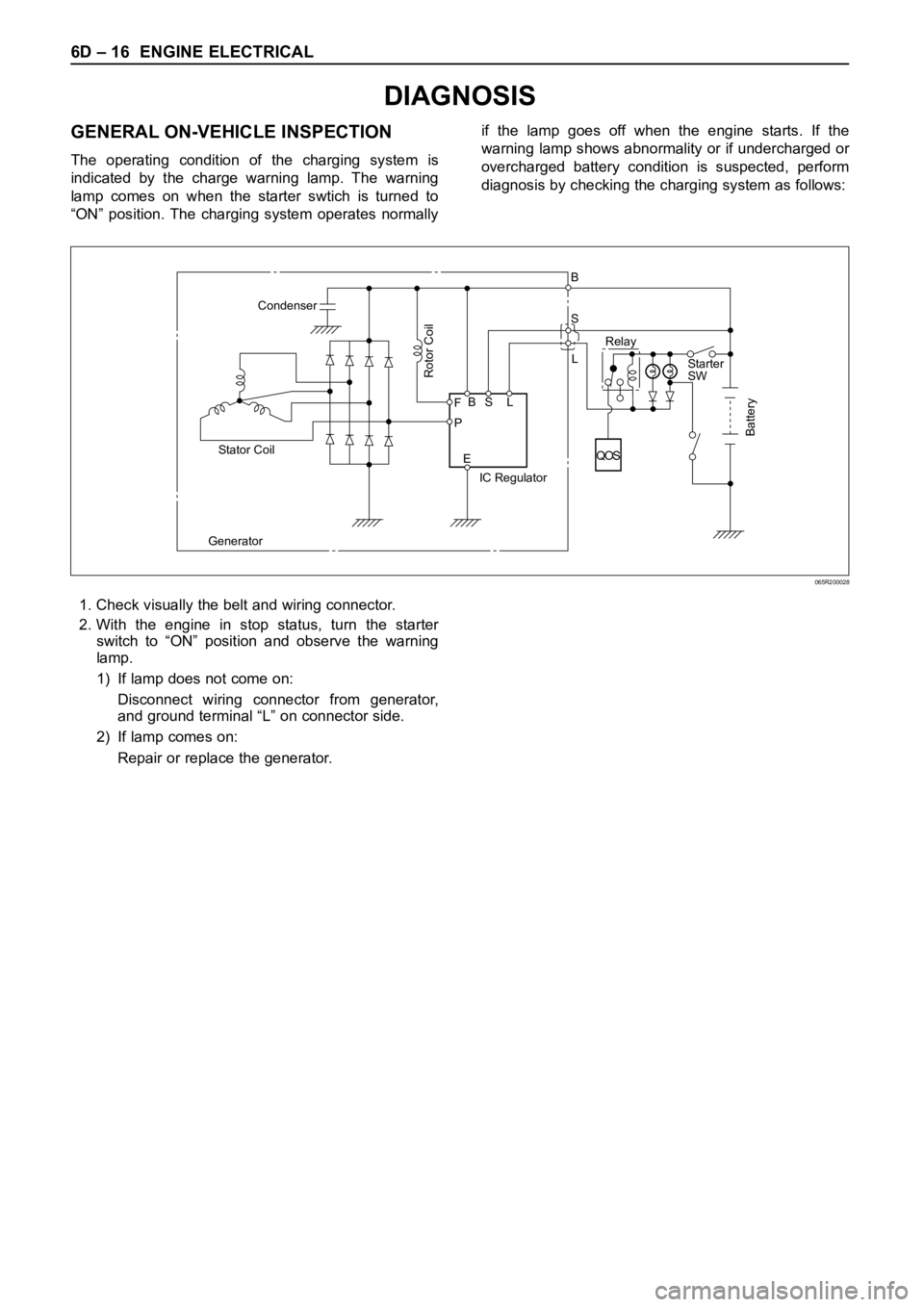

The operating condition of the charging system is

indicated by the charge warning lamp. The warning

lamp comes on when the starter swtich is turned to

“ON” position. The charging system operates normallyif the lamp goes off when the engine starts. If the

warning lamp shows abnormality or if undercharged or

overcharged battery condition is suspected, perform

diagnosis by checking the charging system as follows:

Condenser

GeneratorStator Coil

IC RegulatorStarter

SW

Rotor Coil

Battery

P F

EBS LRelay B

S

L

QOS

065R200028

1. Check visually the belt and wiring connector.

2. With the engine in stop status, turn the starter

switch to “ON” position and observe the warning

lamp.

1) If lamp does not come on:

Disconnect wiring connector from generator,

and ground terminal “L” on connector side.

2) If lamp comes on:

Repair or replace the generator.

Page 1896 of 6000

6E–3 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Action Taken When the DTC Sets 6E–90. . . . . . .

Conditions for Clearing the MIL/DTC 6E–90. . . . .

Diagnostic Aids 6E–90. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1196

(Flash DTC 62) Rail Pressure System

High Warning 6E–92. . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–93. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–93. . . . . . .

Conditions for Clearing the MIL/DTC 6E–93. . . . .

Diagnostic Aids 6E–93. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–93. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0197

(Flash DTC 16) Oil Temp Sensor Low

Voltage 6E–94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–94. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–94. . . . . . .

Conditions for Clearing the MIL/DTC 6E–94. . . . .

Diagnostic Aids 6E–94. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–95. . . . . . . . . . . . . . . . . . . . . . .

Engine Oil Temperature Sensor 6E–95. . . . . . . . .

Diagnostic Trouble Code (DTC) P0198

(Flash DTC 16) Oil Temp Sensor High

Voltage 6E–96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–96. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–96. . . . . . .

Conditions for Clearing the MIL/DTC 6E–96. . . . .

Diagnostic Aids 6E–96. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–97. . . . . . . . . . . . . . . . . . . . . . .

Engine Oil Temperature Sensor 6E–97. . . . . . . . .

Diagnostic Trouble Code (DTC) P0201

(Flash DTC 51) Injector # 1 Circuit Fault 6E–99. . .

Circuit Description 6E–99. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–99. . . . . . .

Conditions for Clearing the MIL/DTC 6E–99. . . . .

Diagnostic Aids 6E–99. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–99. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–99. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0202

(Flash DTC 52) Injector # 2 Circuit Fault 6E–101. . .

Circuit Description 6E–101. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–101. . . . . . .

Conditions for Clearing the MIL/DTC 6E–101. . . . .

Diagnostic Aids 6E–101. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–101. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–101. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0203

(Flash DTC 52) Injector # 3 Circuit Fault 6E–103. . .

Circuit Description 6E–103. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–103. . . . . . .

Conditions for Clearing the MIL/DTC 6E–103. . . . .

Diagnostic Aids 6E–103. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–103. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–103. . . . . . . . . . . . . . . . . . . . . . . . . . Diagnostic Trouble Code (DTC) P0204

(Flash DTC 54) Injector # 4 Circuit Fault 6E–105

. . .

Circuit Description 6E–105. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–105. . . . . . .

Conditions for Clearing the MIL/DTC 6E–105. . . . .

Diagnostic Aids 6E–105. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–105. . . . . . . . . . . . . . . . . . . . . . .

Injector Test 6E–105. . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0217

(Flash DTC 22) High Coolant Temp Waring 6E–107

Circuit Description 6E–107. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–107. . . . . . .

Conditions for Clearing the MIL/DTC 6E–107. . . . .

Diagnostic Aids 6E–107. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–107. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P1217

(Flash DTC 36) High Oil Temp Warning 6E–109. . . .

Circuit Description 6E–109. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–109. . . . . . .

Conditions for Clearing the MIL/DTC 6E–109. . . . .

Diagnostic Aids 6E–109. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0219

(Flash DTC 11) Engine Over Speed Warning 6E–111

Circuit Description 6E–111. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–111. . . . . . .

Conditions for Clearing the MIL/DTC 6E–111. . . . .

Diagnostic Aids 6E–111. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0336

(Flash DTC 43) CKP (Crank Position)

Sensor Out of Synchro 6E–114. . . . . . . . . . . . . . . . . .

Circuit Description 6E–114. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–114. . . . . . .

Conditions for Clearing the MIL/DTC 6E–114. . . . .

Diagnostic Aids 6E–114. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0337

(Flash DTC 43) CKP (Crank Position)

Sensor No Signal 6E–116. . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–116. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–116. . . . . . .

Conditions for Clearing the MIL/DTC 6E–116. . . . .

Diagnostic Aids 6E–116. . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0341

(Flash DTC 41) CMP (Cam Position)

Sensor Out of Synchro 6E–119. . . . . . . . . . . . . . . . . .

Circuit Description 6E–119. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–119. . . . . . .

Conditions for Clearing the MIL/DTC 6E–119. . . . .

Diagnostic Aids 6E–119. . . . . . . . . . . . . . . . . . . . . . . .

Test Description 6E–119. . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Trouble Code (DTC) P0342

(Flash DTC 41) CMP (Cam Position)

Sensor No Signal 6E–122. . . . . . . . . . . . . . . . . . . . . . .

Circuit Description 6E–122. . . . . . . . . . . . . . . . . . . . .

Action Taken When the DTC Sets 6E–122. . . . . . .

Conditions for Clearing the MIL/DTC 6E–122. . . . .

Page 1947 of 6000

6E–54

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

ECM Diagnostic Trouble Codes

The following table lists the diagnostic trouble codes

supported a Tech 2 and to flash.If any DTCs not listedhere are displayed by a Tech 2, the Tech 2 data may be

faulty; notify the Tech 2 manufacturer of any DTCs

displayed that are not included in the following table.

ECM Diagnostic Trouble Codes

DTC

using a

Te c h 2

Flash DTCDescriptionMIL

P010734MAP Sensor Low VoltageON

P010834MAP Sensor High VoltageON

P011223Intake Air temp Sensor Low VoltageON

P011323Intake Air temp Sensor High VoltageON

P011714Engine Coolant Temp Sensor Low VoltageON

P011814Engine Coolant Temp Sensor High VoltageON

P012133Accel Position Sensor RationalityON

P012221Accel Position Sensor Low VoltageON

P012321Accel Position Sensor High VoltageON

P018215Fuel Temp Sensor Low VoltageON

P018315Fuel Temp Sensor High VoltageON

P019263Rail Pressure Sensor Low VoltageON

P019363Rail Pressure Sensor High VoltageON

P119364RPCV Circuit Open/Short—

P119461Rail Pressure System Low VoltageON

P119561Rail Pressure System High VoltageON

P119662Rail Pressure System High WarningON

P019716Oil Temp sensor Low VoltageON

P019816Oil Temp sensor High VoltageON

P020151Injector #1 Circuit FaultON

P020252Injector #2 Circuit FaultON

P020353Injector #3 Circuit FaultON

P020454Injector #4 Circuit FaultON

P021722High Coolant Temp WarningON

P121736High Oil Temp WarningON

P021911Engine Over Speed WarningON

P033643Crank Position Sensor Out of SyncroON

P033743Crank Position Sensor No SignalON

P034141Cam Position Sensor Out of SyncroON

P034241Cam Position Sensor No SignalON

P038066Glow Relay Circuit Open/Short—

P038167Glow Lamp Circuit Open/Short—

P140332EGR EVRV Fault—

P140431EGR VSV Circuit—

P040526EGR Pressure Sensor Low VoltageON

P140537EGR EVRV Circuit Open/Short—

P040626EGR Pressure Sensor High VoltageON

Page 1985 of 6000

6E–92

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1196 (Flash DTC 62)

Rail Pressure System High Warning

060RW178

Legend

(1) ECM

(2) Meter Panel

(3) Battery

(4) Oil Temp Sensor

(5) Rail Pressure Sensor

(6) Glow Relay

(7) Oil Rail

(8) Tech–2

(9) A/C Comp Relay

(10) RPCV

(11) Intake Air Temp Sensor

(12) Engine Coolant Temp Sensor

(13) MAP Sensor

(14) EGR Valve

(15) EGR Pressure Sensor(16) High Pressure Oil Pump

(17) Fuel Pump

(18) VSV

(19) EXH Throttle VSV1

(20) EXH Throttle VSV2

(21) EVRV

(22) Engine Harness Connector

(23) QWS Relay

(24) AP Sensor

(25) T.O.D

(26) ECT

(27) OBD

(28) TDC

(29) Injector

(30) Edge Filter

Page 1986 of 6000

6E–93 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Circuit Description

The rail pressure control valve (RPCV) is built in the high

pressure oil circuit.

RPCV is an important device which is used to control oil

pressure in the HEUI system.

The circuit receives current through Engine 15A fuse from

the battery, current flowing in the order of RPCV.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1196 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

Rail Pressure Control display on the Tech 2 while

moving connectors and wiring harnesses related to the

Rail Pressure Control. A change in the Rail Pressure

Control display will indicate the location of the fault.

If DTC P1196 cannot be duplicated, the information

included in the Failure Records data can be useful in

determining vehicle mileage since the DTC was last set.

If it is determined that the DTC occurs intermittently.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. Verifies that the fault is present.

DTC P1196 – RP System High Warning

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Engine is running.

2. Observe the “Rail Pressure Control” display on the

Te c h 2 .

Is the action correct?

—Go to Step 4Go to Step 3

3Replace the RPCV.

Is the action complete?

—Verify repairGo to Step 4

41. Engine is running.

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “ DTC” info for DTC P1196.

Does the Tech 2 indicate DTC P1196 failed this

ignition?

—Go to Step 5—

51. Check the 2 way valve.

2. Observe the “RP Control” display on the Tech 2.

Is the action correct?

—Go to Step 4Go to Step 6

6Replace the 2 way valve.

Is the action complete?

—Verify repair—

Page 2002 of 6000

6E–109 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P1217 (Flash DTC 36)

High Oil Temp Warning

060RW129

Circuit Description

The engine oil temperature (OT) sensor is a thermistor

mounted on a oil manifold. The Engine Control Module

ECM applies a voltage (about 5 volts) through a pull-up

resistor to the OT signal circuit. When the engine oil is

cold, the sensor (thermistor) resistance is high, therefore

the ECM will measure a high signal voltage. As the

engine oil warms, the sensor resistance becomes lower,

and the OT signal voltage measured at the ECM drops.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P1217 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for the following conditions:

Poor connection at ECM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

Damaged harness – Inspect the wiring harness for

damage.

High Oil Temperature Warning may sometimes be

given due to High Coolant Temp Warning. On this

occasion, recognize DTC P0217 and give priority to

High Coolant Temp Warning.

Page 2003 of 6000

6E–110

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P1217 – High Oil Temp Warning

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

21. Ignition “ON,” engine “OFF.”

2. Observe the “Eng Cool Temp” display on the Tech 2.

Is the “Eng Cool Temp” below the specified value?

139C

(282

F)Go to Step 4Go to Step 3

31. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Using a Tech 2, monitor “ DTC” info for DTC P0217.

Does the Tech 2 indicate DTC P0217 failed this

ignition?

—Go to Step 4

Refer to

Diagnostic

Aids

41. Ignition “ON,” engine “OFF.”

2. Review and record Tech 2 Failure Records data.

3. Operate the vehicle within Failure Records

conditions as noted.

4. Using a Tech 2, monitor “ DTC” info for DTC P1217.

Does the Tech 2 indicate DTC P1217 failed this

ignition?

—Go to Step 5

Refer to

Diagnostic

Aids

51. Measure the engine oil quantity by oil level gage.

2. If the engine oil is shortage, fill up it as necessary.

Was the engine oil is shortaged?

—Verify repairGo to Step 6

6Replace the oil temp sensor.

Is the action complete?

—Verify repairGo to Step 7

7Replace the oil cooler.

Is the action complete?

—Verify repair—

Page 2004 of 6000

6E–111 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0219 (Flash DTC 11)

Engine Over Speed Warning

060RW133

Circuit Description

The CKP reference signal is produced by the crankshaft

position (CKP) sensor. During one crankshaft revolution,

CKP crankshaft reference pulses will be produced. The

Engine Control Module ECM uses the CKP reference

signal to calculate engine RPM and crankshaft position.

Action Taken When the DTC Sets

The ECM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0219 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the ECM battery

feed.

Diagnostic Aids

Check for:

Poor connection – Inspect the CKP harness and

connectors for improper mating, broken locks,

improperly formed or damaged terminals, and poor

terminal-to-wire connection.

Damaged X57 – Inspect the X57 for damage.

DTC P0219 – Engine Over Speed Warning

StepActionVa l u e ( s )Ye sNo

1Was the “On-Board Diagnostic (OBD) System Check”

performed?

—Go to Step 2

Go to OBD

System

Check

2Check the responsibility.

Was the driver responsibility?

—Go to Step 3Go to Chart 4

Page 2005 of 6000

6E–112

4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0219 – Engine Over Speed Warning

StepNo Ye s Va l u e ( s ) Action

31. Review and record Failure Records information.

2. Clear DTC P0219.

3. Start the engine and idle for 1 minute.

4. Observe DTCs.

Is DTC P0219 set?

—Go to Step 4—

4Observe the AP value displayed on the Tech 2.

Is the AP value near the specified value?(Idling 720 r.p

.m) 0 %

Go to Step 3Go to Step 5

5Observe the Engine speed displayed on the Tech 2.

Is the Engine speed near the specified value?(Idling) 720 r.

p.m

Go to Step 7Go to Step 6

61. Check the CKP sensor.

2. Ignition “ON.”

3. Using a DVM, verify that 5 V reference and ground

are being supplied at the sensor connector (ECM

side).

Are 4-6 volts and ground available at the sensor?

—Go to Step 9Go to Step 7

71. Ignition “ON.”

2. With a DVM, backprobe the ECM connector 5 V

reference and ground connections.

Are 5 V reference and ground available at the ECM?

—Go to Step 8Go to Step 13

8Check 5 V reference or ground between the CKP

sensor and ECM and repair the open circuit, short to

ground or short to voltage.

Is the action complete?

—Verify repair—

91. Ignition “OFF.”

2. Disconnect the ECM and CKP sensor.

3. Check for an open or a short to ground in the CKP

reference circuit between the CKP sensor

connector and the ECM harness connector.

4. If a problem is found, repair as necessary.

Was a problem found?

—Verify repairGo to Step 10

101. Reconnect the ECM and CKP sensor.

2. Connect a DVM to measure voltage on the CKP

reference circuit at the ECM connector.

3. Observe the voltage while cranking the engine.

Is the voltage near the specified value?

2.5 VGo to Step 13Go to Step 11

11Check the connections at the CKP sensor and replace

the terminals if necessary.

Did any terminals require replacement?

—Verify repairGo to Step 12

12Replace the CKP sensor.

Is the action complete?

—Verify repair—

13Check the connections at the ECM and replace the

terminals if necessary.

Did any terminals require replacement?

—Verify repair Go to Step 14

Page 2006 of 6000

6E–113 4JX1–TC ENGINE DRIVEABILITY AND EMISSIONS

DTC P0219 – Engine Over Speed Warning

StepNo Ye s Va l u e ( s ) Action

14Check the X57 signal plate.

Is the X57 signal plate damage?

—Go to Step 15Go to Step 3

15Replace the X57 signal plate.

Is the action complete?

—Verify repairGo to Step 2