check engine OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 4571 of 6000

6A–75

ENGINE MECHANICAL

4. Piston and connecting rod assembly (8)

Apply engine oil to the cylinder bores, the

connecting rod bearings and the crankshaft pins.

Check to see that the piston ring end gaps are

correctly positioned.

015RS019

Legend

(1) No.1 Compression Ring

(2) No.2 Compression Ring

(3) Oil Ring Side Rail Upper

(4) Oil Ring Side Rail Lower

(5) Piston Front Mark

Insert the piston/connecting rod assemblies into

each cylinder with the piston ring compressor. The

front marks must be facing the front of the engine.

Match the numbered caps with the numbers on the

connecting rods. Align the punched marks on the

connecting rods and caps.

Apply engine oil to the threads and seating faces of

the nuts.

Tighten the nuts.

Torque: 54 Nꞏm (5.5 Kgꞏm/40 lb ft)

After tightening the cap nuts, check to see that the

crankshaft rotates smoothly.

NOTE: Do not apply engine oil to the bearing back faces.

015RS020

5. Install oil gallery (7) and tighten the bolts in 2 steps, in

the order shown.

1st step: 29 Nꞏm (3.0 Kgꞏm/22 lb ft)

2nd step: 55

65

051RS009

6. Cylinder block side bolts (6)

Tighten all the bolts to the specified torque in the

order shown.

NOTE: Do not apply engine oil to the crank case side

bolts.

Torque: 39 Nꞏm (4.0 Kgꞏm/29 lb ft)

Page 4574 of 6000

6A–78

ENGINE MECHANICAL

015RS031

Remove any ridge or carbon build up from the top

end of the cylinder.

9. Remove the piston rings (8) with a piston ring

expander. Arrange the removed piston rings in the

cylinder number order.

015RS022

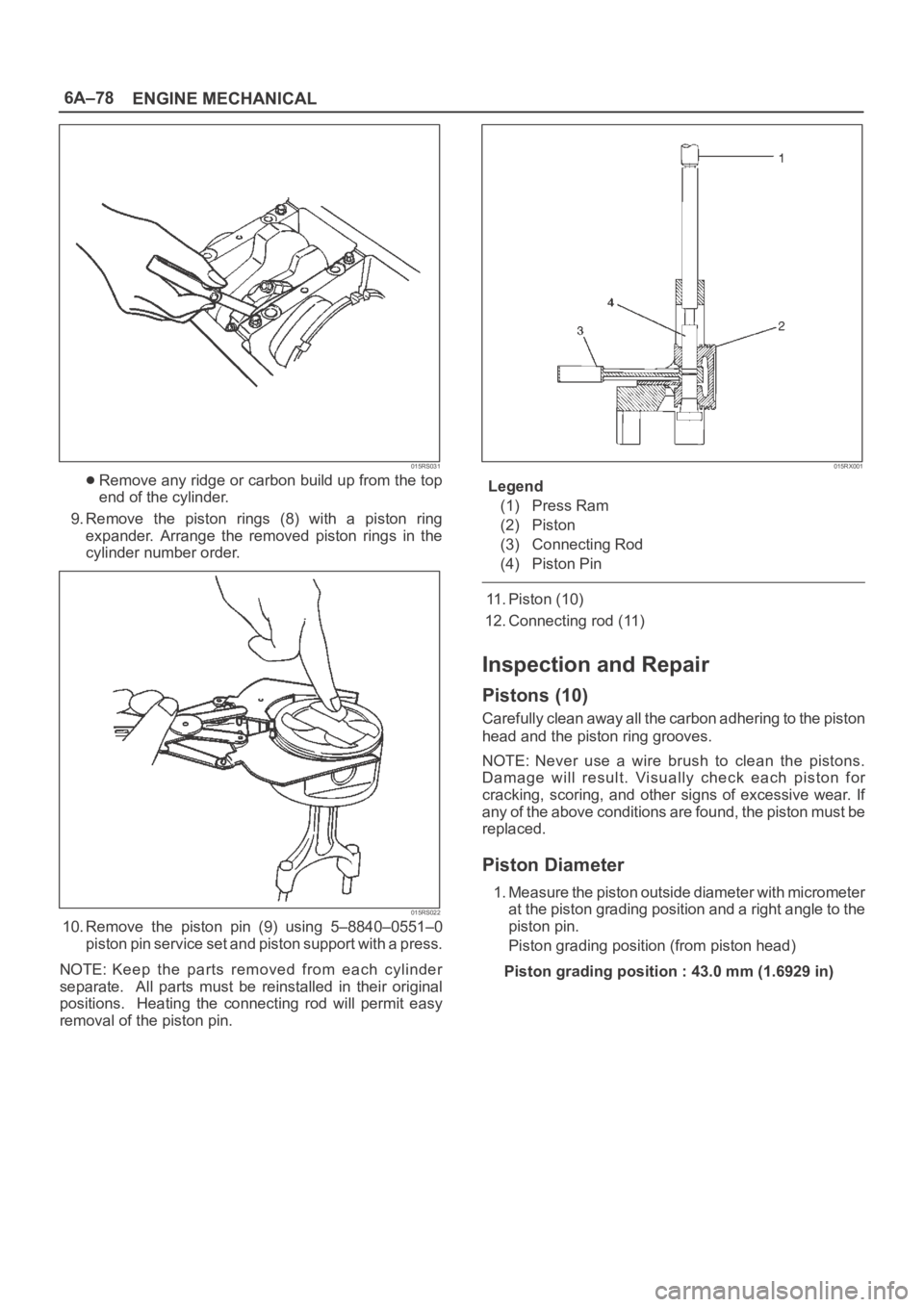

10. Remove the piston pin (9) using 5–8840–0551–0

piston pin service set and piston support with a press.

NOTE: Keep the parts removed from each cylinder

separate. All parts must be reinstalled in their original

positions. Heating the connecting rod will permit easy

removal of the piston pin.

015RX001

Legend

(1) Press Ram

(2) Piston

(3) Connecting Rod

(4) Piston Pin

11. Piston (10)

12. Connecting rod (11)

Inspection and Repair

Pistons (10)

Carefully clean away all the carbon adhering to the piston

head and the piston ring grooves.

NOTE: Never use a wire brush to clean the pistons.

Damage will result. Visually check each piston for

cracking, scoring, and other signs of excessive wear. If

any of the above conditions are found, the piston must be

replaced.

Piston Diameter

1. Measure the piston outside diameter with micrometer

at the piston grading position and a right angle to the

piston pin.

Piston grading position (from piston head)

Piston grading position : 43.0 mm (1.6929 in)

Page 4577 of 6000

6A–81

ENGINE MECHANICAL

Connecting Rods (11)

1. Check the connecting rod alignment If either the bend

or the twist exceeds the specified limit, the connecting

rod must be replaced.

Bend per 100 mm (3.937 in)

Limit: 0.15 (0.0059)

Twist per 100 mm (3.937 in)

Limit: 0.20 (0.0078)

015RS030

2. Measure the connecting rod thrust clearance. Use a

feeler gauge to measure the thrust clearance at the

large end of the connecting rod If the clearance

exceeds the specified limit, the connecting rod must

be replaced.

Standard : 0.16 mm–0.35 mm

(0.0063 in.–0.0138 in)

Limit : 0.40 mm (0.0157 in)

015RS031

3. Measure the oil clearance between the connecting

rod and the crankshaft.

1. Remove the connecting rod cap nuts and the rod

caps (12).

Arrange the removed rod caps in the cylinder

number order.

2. Clean the rod bearings and the crankshaft pins.

3. Carefully check the rod bearings. If even one

bearing is found to be damaged or badly worn, the

entire bearing assembly must be replaced as a

set. Reinstall the bearings in their original

positions. Apply plastigage to the crank pin.

015RS032

Page 4579 of 6000

6A–83

ENGINE MECHANICAL

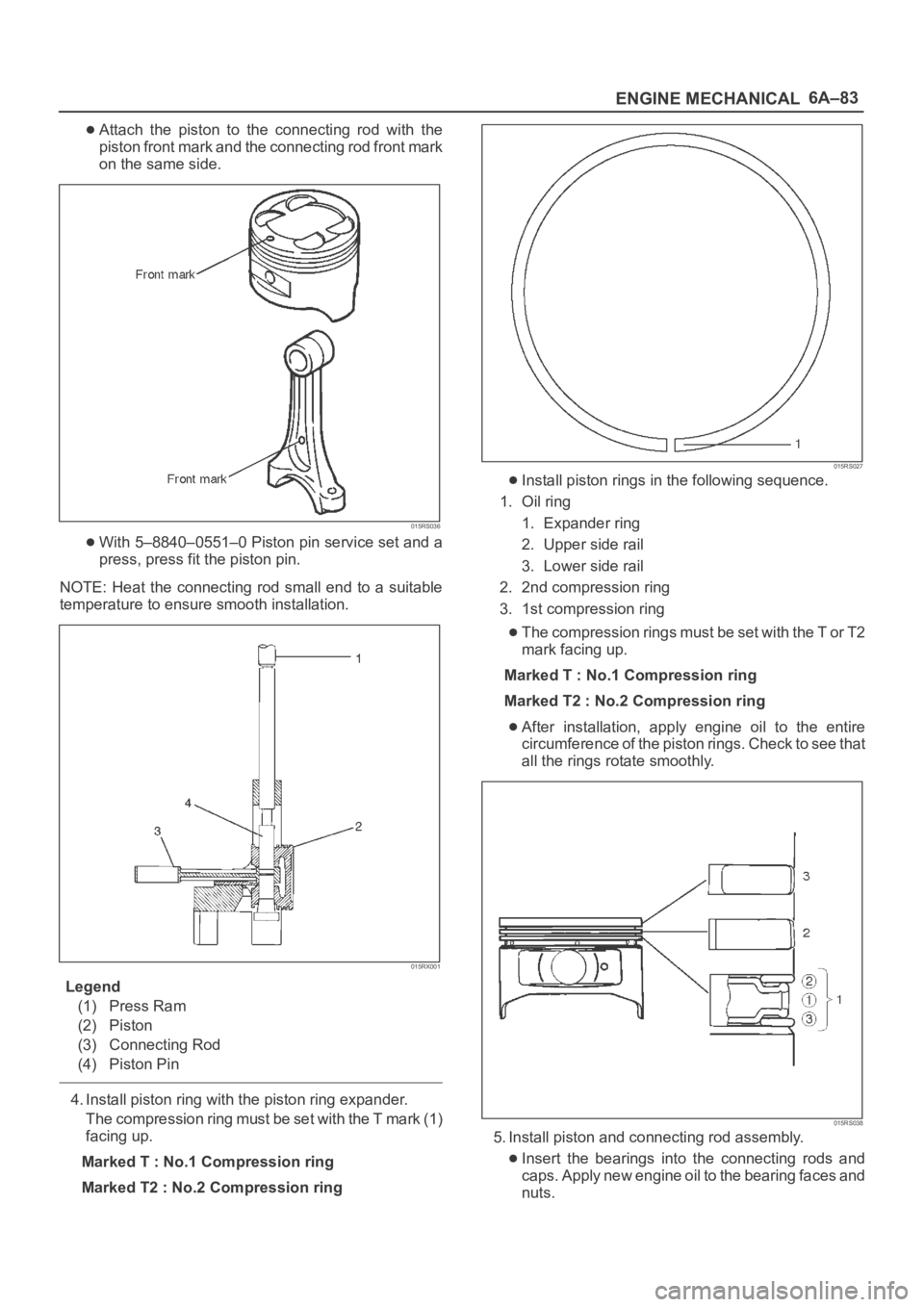

Attach the piston to the connecting rod with the

piston front mark and the connecting rod front mark

on the same side.

015RS036

With 5–8840–0551–0 Piston pin service set and a

press, press fit the piston pin.

NOTE: Heat the connecting rod small end to a suitable

temperature to ensure smooth installation.

015RX001

Legend

(1) Press Ram

(2) Piston

(3) Connecting Rod

(4) Piston Pin

4. Install piston ring with the piston ring expander.

The compression ring must be set with the T mark (1)

facing up.

Marked T : No.1 Compression ring

Marked T2 : No.2 Compression ring

015RS027

Install piston rings in the following sequence.

1. Oil ring

1. Expander ring

2. Upper side rail

3. Lower side rail

2. 2nd compression ring

3. 1st compression ring

The compression rings must be set with the T or T2

mark facing up.

Marked T : No.1 Compression ring

Marked T2 : No.2 Compression ring

After installation, apply engine oil to the entire

circumference of the piston rings. Check to see that

all the rings rotate smoothly.

015RS038

5. Install piston and connecting rod assembly.

Insert the bearings into the connecting rods and

caps. Apply new engine oil to the bearing faces and

nuts.

Page 4582 of 6000

6A–86

ENGINE MECHANICAL

11. Remove rear oil seal retainer assembly.

12. Remove main bearing cap.

13. Remove crankshaft.

14. Remove cylinder block.

Inspection and Repair

1. Remove the cylinder head gasket and any other

material adhering to the upper surface of the cylinder

block. Be very careful not to allow any material to

accidentally drop into the cylinder block. Be very

careful not to scratch the cylinder block.

2. Carefully remove the oil pump, rear oil seal retainer,

and crankcase assembly installation surface seal.

3. Wipe the cylinder block clean.

4. Visually inspect the cylinder block. If necessary, use a

flaw detector to perform a dye penetrate and

hydraulic (or air pressure) test. If cracking or other

damage is discovered, the cylinder block must either

be repaired or replaced.

Flatness

1. Using a straight–edge and feeler gauge, check that

the upper surface of the cylinder block is not warped.

CAUTION: Be very careful not to allow any material

to accidentally drop into the upper surface of the

cylinder block. Be very careful not to scratch the

upper surface of the cylinder block.

2. The cylinder block must be reground or replaced if the

warpage exceeds the limit.

Warpage

Limit : 0.15 mm (0.0059 in)

Maximum repairable limit: 0.15 mm (0.0059 in)

012RS004

Cylinder Bore

Use a cylinder gauge to measure the cylinder bore

diameter in both the axial and thrust directions. Each

measurement should be made at six points.CAUTION: Be very careful not to allow any material

to accidentally drop into the upper surface of the

cylinder block. Be very careful not to scratch the

upper surface of the cylinder block.

Cylinder Bore Inside Diameter

Limit : 93.530 (3.6823)

If the measurement exceed the specified limit, the

cylinder block must be replaced.

Diameter

Grade A : 93.400 mm–93.410 mm

(3.6772 in–3.6776 in)

Grade B : 93.411 mm–93.420 mm

(3.6776 in–3.6779 in)

Grade C : 93.421 mm–93.430 mm

(3.6780 in–3.6783 in)

012RS005

NOTE: For information on piston diameter, please refer

to the section ”Inspection of the Piston and Connecting

Rod Assembly” in this manual.

The ”Grade” mark (1) is stamped at the position

illustrated.

Page 4584 of 6000

6A–88

ENGINE MECHANICAL

015RW001

4. Install flywheel

1. Thoroughly clean and remove the oil from the

threads of crankshaft.

2. Remove the oil from the crankshaft and flywheel

mounting faces.

3. Mount the flywheel on the crankshaft and then

install the washer.

4. Holding the crankshaft stationary, tighten the

flywheel bolts in the order shown.

Torque: 54 Nꞏm (5.5 Kgꞏm/40 lb ft)

NOTE: Do not reuse the bolts and do not apply oil or

thread lock to the bolts.

015RS018

5. Install piston and connecting rod assembly.

Apply engine oil to the cylinder bores, the

connecting rod bearings and the crankshaft pins.

NOTE: Do not apply engine oil to the bearing back faces.

Check to see that the piston ring end gaps are

correctly positioned.

015RS019

Legend

(1) No.1 Compression Ring

(2) No.2 Compression Ring

(3) Oil Ring Side Rail Upper

(4) Oil Ring Side Rail Lower

(5) Piston Front Mark

Insert the piston/connecting rod assemblies into

each cylinder with the piston ring compressor.

The front marks (1) must be facing the front of the

engine.

015RS020

6. Install oil gallery and tighten the bolts in 2 steps in the

order shown.

1st step : 29 Nꞏm (3.0 Kgꞏm/22 lb ft)

2nd step : 55

65

Page 4597 of 6000

6B–4

ENGINE COOLING

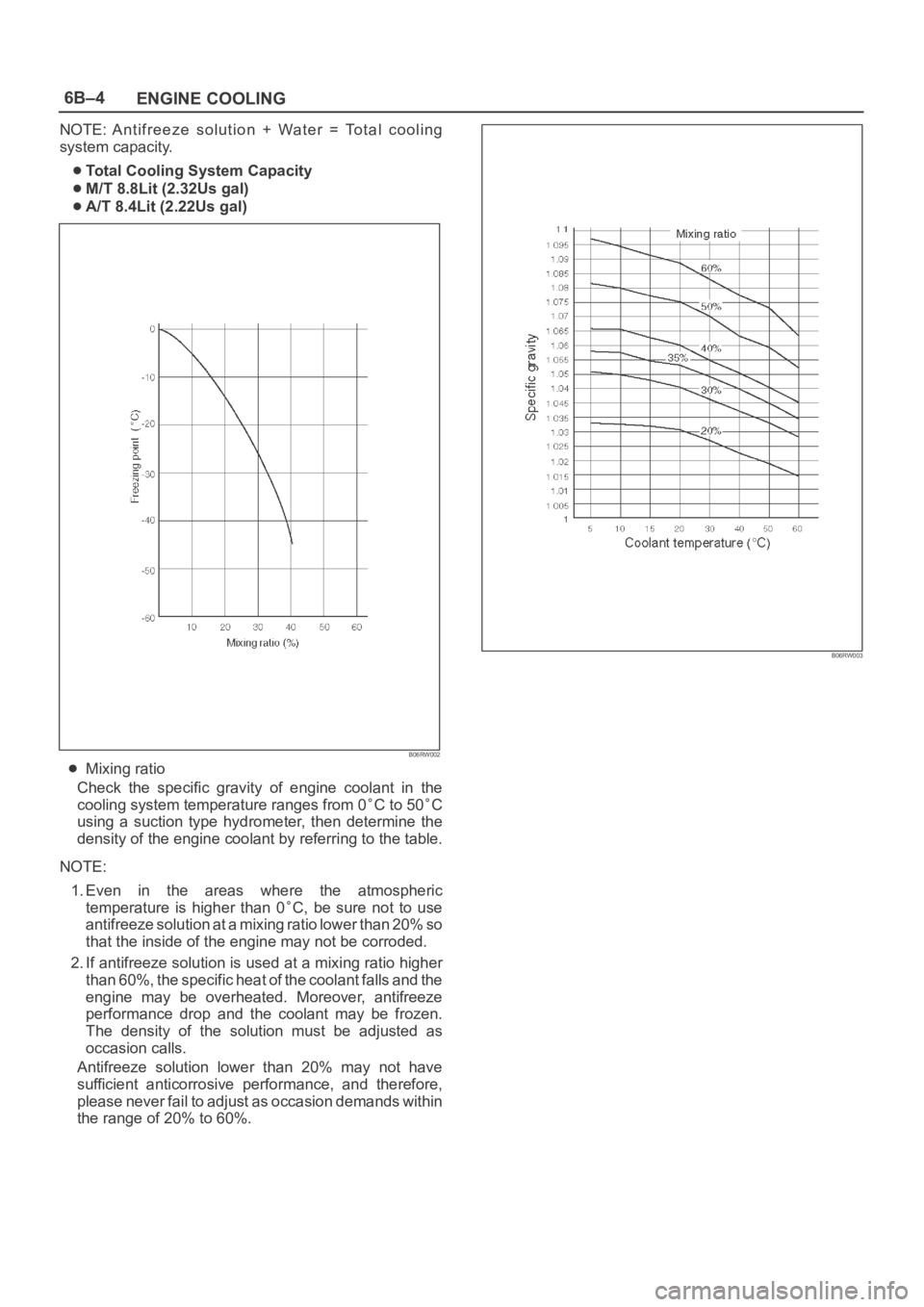

NOTE: Antifreeze solution + Water = Total cooling

system capacity.

Total Cooling System Capacity

M/T 8.8Lit (2.32Us gal)

A/T 8.4Lit (2.22Us gal)

B06RW002

Mixing ratio

Check the specific gravity of engine coolant in the

cooling system temperature ranges from 0

C to 50C

using a suction type hydrometer, then determine the

density of the engine coolant by referring to the table.

NOTE:

1. Even in the areas where the atmospheric

temperature is higher than 0

C, be sure not to use

antifreeze solution at a mixing ratio lower than 20% so

that the inside of the engine may not be corroded.

2. If antifreeze solution is used at a mixing ratio higher

than 60%, the specific heat of the coolant falls and the

engine may be overheated. Moreover, antifreeze

performance drop and the coolant may be frozen.

The density of the solution must be adjusted as

occasion calls.

Antifreeze solution lower than 20% may not have

sufficient anticorrosive performance, and therefore,

please never fail to adjust as occasion demands within

the range of 20% to 60%.

B06RW003

Page 4599 of 6000

6B–6

ENGINE COOLING

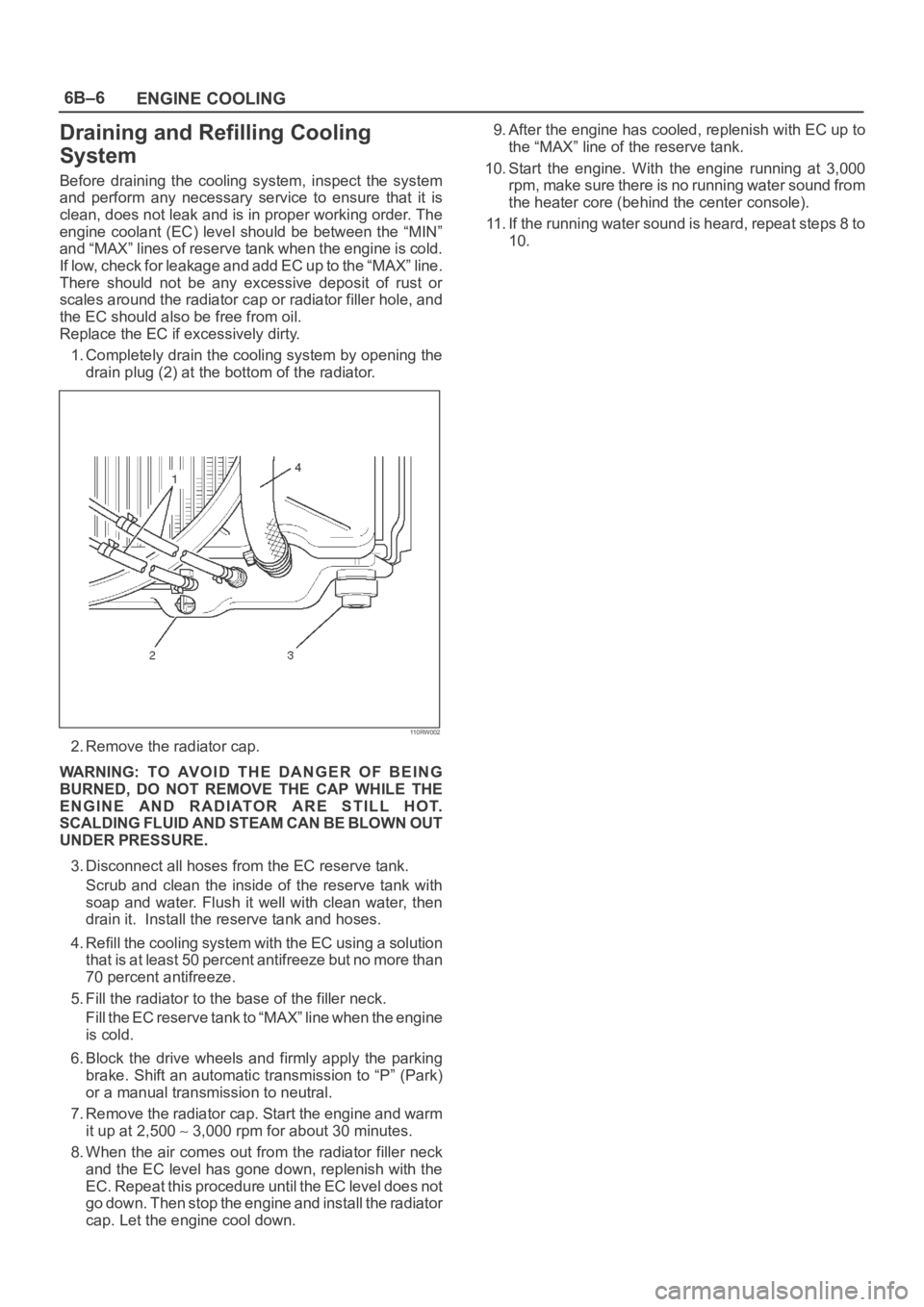

Draining and Refilling Cooling

System

Before draining the cooling system, inspect the system

and perform any necessary service to ensure that it is

clean, does not leak and is in proper working order. The

engine coolant (EC) level should be between the “MIN”

and “MAX” lines of reserve tank when the engine is cold.

If low, check for leakage and add EC up to the “MAX” line.

There should not be any excessive deposit of rust or

scales around the radiator cap or radiator filler hole, and

the EC should also be free from oil.

Replace the EC if excessively dirty.

1. Completely drain the cooling system by opening the

drain plug (2) at the bottom of the radiator.

110RW002

2. Remove the radiator cap.

WARNING: TO AVOID THE DANGER OF BEING

BURNED, DO NOT REMOVE THE CAP WHILE THE

ENGINE AND RADIATOR ARE STILL HOT.

SCALDING FLUID AND STEAM CAN BE BLOWN OUT

UNDER PRESSURE.

3. Disconnect all hoses from the EC reserve tank.

Scrub and clean the inside of the reserve tank with

soap and water. Flush it well with clean water, then

drain it. Install the reserve tank and hoses.

4. Refill the cooling system with the EC using a solution

that is at least 50 percent antifreeze but no more than

70 percent antifreeze.

5. Fill the radiator to the base of the filler neck.

Fill the EC reserve tank to “MAX” line when the engine

is cold.

6. Block the drive wheels and firmly apply the parking

brake. Shift an automatic transmission to “P” (Park)

or a manual transmission to neutral.

7. Remove the radiator cap. Start the engine and warm

it up at 2,500

3,000 rpm for about 30 minutes.

8. When the air comes out from the radiator filler neck

and the EC level has gone down, replenish with the

EC. Repeat this procedure until the EC level does not

go down. Then stop the engine and install the radiator

cap. Let the engine cool down.9. After the engine has cooled, replenish with EC up to

the “MAX” line of the reserve tank.

10. Start the engine. With the engine running at 3,000

rpm, make sure there is no running water sound from

the heater core (behind the center console).

11. If the running water sound is heard, repeat steps 8 to

10.

Page 4601 of 6000

6B–8

ENGINE COOLING

3. Idle pulley

Install idle pulley and tighten bolt to the specified

torque.

Torque: 52 Nꞏm (5.3 Kgꞏm/38 lb ft)4. Timing beltInstall timing belt. Refer to timing belt installation

step in “Timing Belt” in this manual.

5. Connect radiator inlet hose and replenish EC.

6. Connect battery ground cable.

Thermostat

Thermostat and Associated Parts

031RW001

Legend

(1) Thermostat Housing

(2) Thermostat

(3) Outlet Pipe

Removal

1. Disconnect battery ground cable.

2. Drain engine coolant from the radiator and engine.

3. Disconnect radiator hose from the inlet pipe.

4. Remove thermostat housing.

5. Remove thermostat(2).

Inspection

Suspend the thermostat in a water–filled container using

thin wire. Place a thermometer next to the thermostat.

Do not directly heat the thermostat.

Gradually increase the water temperature. Stir the water

so that the entire water is same temperature.

031RS003Confirm the temperature when the valve first begins to

open.

Valve opening temperature 74.5C

78.5C

(166.1

F 173.3F)

Confirm the temperature when the valve is fully opened.

Valve full open temperature and lift More than

8.5mm (0.33 in) at 90

C (194F)

Make necessary repair and parts replacement if extreme

wear or damage is found during inspection.

Installation

1. Install thermostat into the outlet pipe(4) making sure

that the air hole is in the up position.

2. Install thermostat housing and tighten bolts to the

specified torque.

Torque: 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

3. Installation rubber hose.

4. Replenish engine coolant (EC).

5. Start engine and check for EC leakage.

Page 4603 of 6000

6B–10

ENGINE COOLING

6. Disconnect the reserve tank hose(4) from radiator.

7. Remove bracket(5).

110RW004

8. Lift up and remove the radiator assembly with hose,

taking care not to damage the radiator core with a fan

blade.

9. Remove rubber cushions on both sides at the bottom.

Inspection

Radiator Cap

Measure the valve opening pressure of the pressurizing

valve with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside

the standard range.

Valve opening pressure kPa (psi) 88.3

117.7

(12.8

17.1)

Cap tester: 5–8840–0277–0

Adapter: 5–8840–2603–0

Check the condition of the vacuum valve in the center of

the valve seat side of the cap. If considerable rust or dirt is

found, or if the valve seat cannot be moved by hand, clean

or replace the cap.Valve opening vacuum kPa (psi) 1.96

4.91

(0.28

0.71)

110RS006

Radiator Core

1. A bent fin may result in reduced ventilation and

overheating may occur. All bent fins must be

straightened. Pay close attention to the base of the fin

when it is being straightened.

2. Remove all dust, bugs and other foreign material.

Flushing the Radiator

Thoroughly wash the inside of the radiator and the engine

coolant passages with cold water and mild detergent.

Remove all signs of scale and rust.

Cooling System Leakage Check

Use a radiator cap tester to force air into the radiator

through the filler neck at the specified pressure of 196 kPa

(28.5 psi) with a cap tester:

Leakage from the radiator

Leakage from the coolant pump

Leakage from the water hoses

Check the rubber hoses for swelling.