OPEL FRONTERA 1998 Workshop Manual

Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 661 of 6000

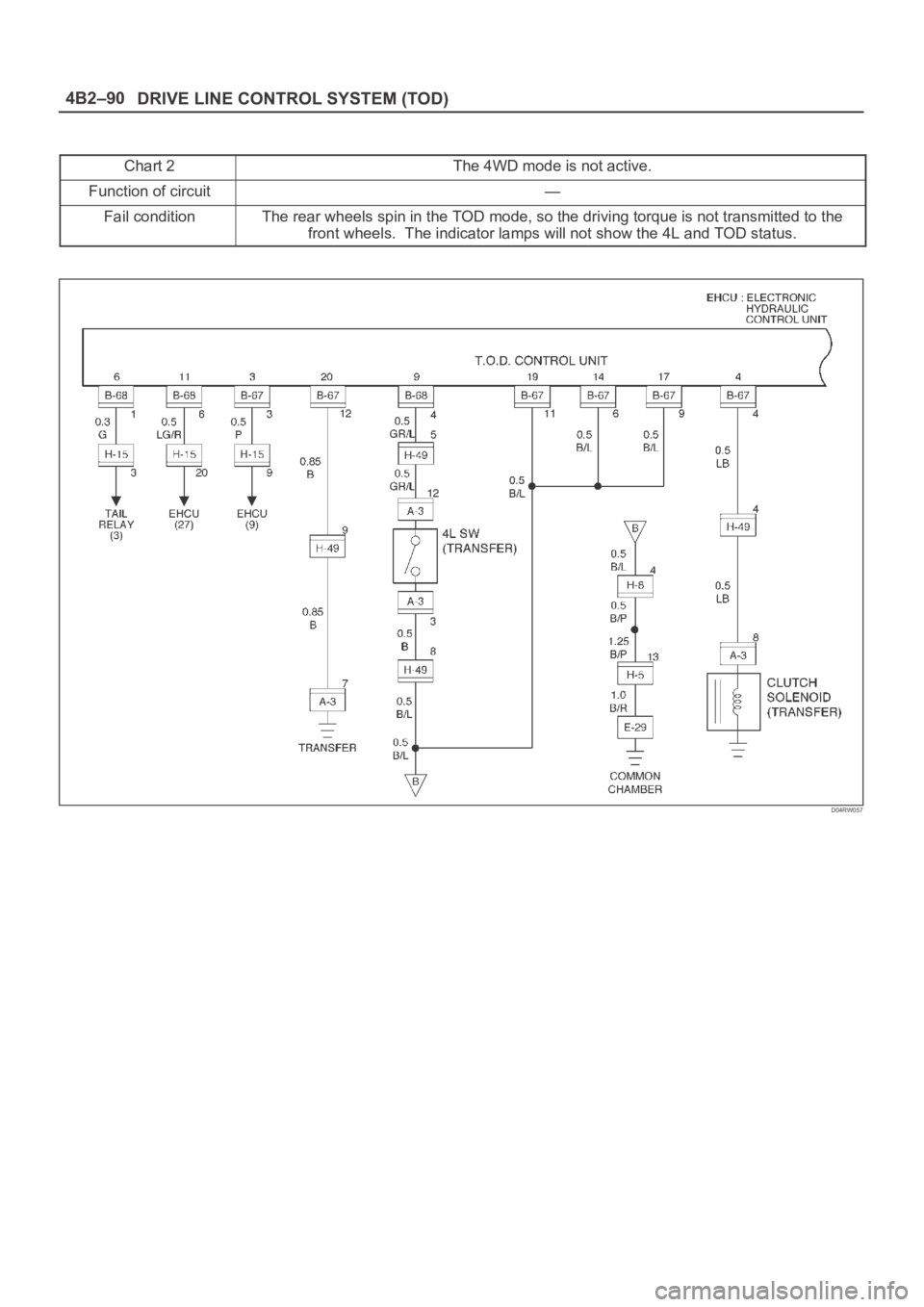

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–90

Chart 2The 4WD mode is not active.

Function of circuit—

Fail conditionThe rear wheels spin in the TOD mode, so the driving torque is not transmitted to the

front wheels. The indicator lamps will not show the 4L and TOD status.

D04RW057

Page 662 of 6000

4B2–91 DRIVE LINE CONTROL SYSTEM (TOD)

StepActionYe sNo

1Is the trouble code 31 or 26 recorded?Examine the

trouble based on

“Diagnosis from

Trouble Codes”.

Go to Step 7

Go to Step 2

2Is any of the trouble codes 28, 32 and 33 recorded?Examine the

trouble based on

“Diagnosis from

Trouble Codes”.

Go to Step 7

Go to Step 3

3When the transfer lever is in the specified position, do the TOD

indicator lamps show the correct status?

Go to Step 4

Examine the

trouble based on

“Trouble

Diagnosis

Depending on

The Status of

TOD Indicator”.

Go to Step 7

4Shift the transfer lever to the 4L position, fully turn the steering to

the left (or right) end, and start the creep run. Does the tight

corner braking occur?

Go to Step 5

Repair the

transfer

assembly.

Go to Step 7

51. Shift the transfer lever to the high (TOD) position.

2. Turn on the starter switch.

Does the voltage between terminals 4 and 20 indicate at least

0.1V while the throttle is completely open?

Go to Step 6

The ECU has

failed. Replace

the ECU.

Go to Step 7

6Does the voltage between terminals 4 and 20 indicate at least 3V

while the throttle is completely closed?The TOD clutch

is worn. Repair

the transfer

assembly.

Go to Step 7

The ECU has

failed. Replace

the ECU.

Go to Step 7

7Check that all the parts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow”.

Return to Step 7

Page 663 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–92

Chart 3The shift on the fly system generates gear noises.

(The fuel economy is bad in the 2H mode.)

Function of circuit—

Fail conditionWhen the vehicle is run in the 2H mode, the shift on the fly system generates gear

noises or the front wheel gears are engaged to generate a shock.

D04RW055

Page 664 of 6000

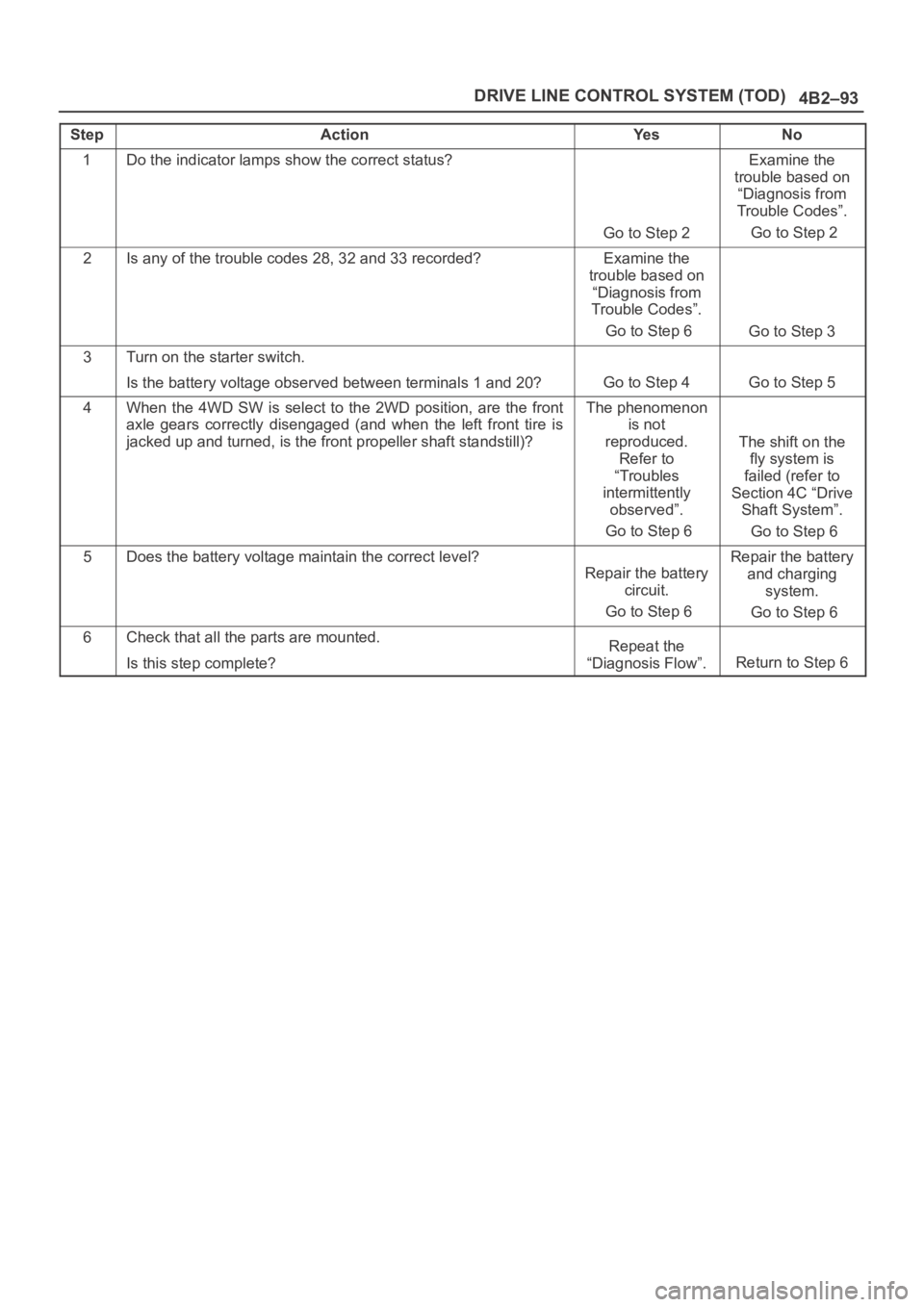

4B2–93 DRIVE LINE CONTROL SYSTEM (TOD)

StepActionYe sNo

1Do the indicator lamps show the correct status?

Go to Step 2

Examine the

trouble based on

“Diagnosis from

Trouble Codes”.

Go to Step 2

2Is any of the trouble codes 28, 32 and 33 recorded?Examine the

trouble based on

“Diagnosis from

Trouble Codes”.

Go to Step 6

Go to Step 3

3Turn on the starter switch.

Is the battery voltage observed between terminals 1 and 20?

Go to Step 4Go to Step 5

4When the 4WD SW is select to the 2WD position, are the front

axle gears correctly disengaged (and when the left front tire is

jacked up and turned, is the front propeller shaft standstill)?The phenomenon

is not

reproduced.

Refer to

“Troubles

intermittently

observed”.

Go to Step 6

The shift on the

fly system is

failed (refer to

Section 4C “Drive

Shaft System”.

Go to Step 6

5Does the battery voltage maintain the correct level?

Repair the battery

circuit.

Go to Step 6

Repair the battery

and charging

system.

Go to Step 6

6Check that all the parts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow”.

Return to Step 6

Page 665 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–94

Chart 4The braking distance gets long even when the ABS is active.

Function of circuit—

Fail conditionEnough deceleration is not obtained and the braking distance gets long even when the

ABS is active in the 2H mode.

D04RW055

Page 666 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–95

Step Action Yes No

1 Are the brake and ABS systems healthy?

Go to Step 2Repair the

brake and ABS.

Go to Step 4

2 Turn on the starter switch.

Is the battery voltage observed between terminals 1 and 20?

Go to Step 3Repair the

battery system.

Go to Step 4

3 1. Select the 4WD SW to the 2WD position.

2. The voltage between terminals 3 and 19 range between 7.5

and 16V (0.24 seconds make a cycle)

Does the voltage within the range specified?Examine the

trouble based

on “Diagnosis

from Trouble

Codes".

Go to Step 4The ECU has

failed. Replace

the ECU.

Go to Step 4

4 Check that all the par ts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow". Return to Step 4

Page 667 of 6000

4C–1 DRIVE SHAFT SYSTEM

DRIVELINE/AXLE

DRIVE SHAFT SYSTEM

CONTENTS

Service Precaution 4C–2. . . . . . . . . . . . . . . . . . . . . .

General Description 4C–2. . . . . . . . . . . . . . . . . . . . .

Diagnosis 4C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Shaft 4C–4. . . . . . . . . . . . . . . . . . . . . . . . .

Rear Axle Shaft and Associated Parts 4C–4. . . .

Removal 4C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–5. . . . . . . . . . . . . . . . . .

Oil Seal Replacement 4C–6. . . . . . . . . . . . . . . . . .

Installation 4C–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Special Tools 4C–8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Hub and Disc (with Shift on the Fly) 4C–9. .

Disassembled View 4C–9. . . . . . . . . . . . . . . . . . . .

Disassembly 4C–9. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–10. . . . . . . . . . . . . . . . . .

Reassembly 4C–11. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Hub and Disc with Manual Locking Hub 4C–14

Disassembled View 4C–14. . . . . . . . . . . . . . . . . . . .

Disassembly 4C–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–16. . . . . . . . . . . . . . . . . .

Reassembly 4C–16. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–20. . . . . . . . . . . . .

Special Tools 4C–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Drive Shaft Joint 4C–22. . . . . . . . . . . . . . . . . . .

Front Drive Shaft Joints Replacement 4C–22. . . .

Front Axle Drive Shaft 4C–23. . . . . . . . . . . . . . . . . . .

Front Axle Drive Shaft and Associated

Parts 4C–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–25. . . . . . . . . . . . . . . . . .

Bushing Replacement 4C–25. . . . . . . . . . . . . . . . . . Reassembly 4C–26. . . . . . . . . . . . . . . . . . . . . . . . . .

Shift On The Fly System 4C–28. . . . . . . . . . . . . . . . .

Shift On The Fly System and Associated

Parts 4C–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–28. . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 4C–30. . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–35. . . . . . . . . . .

Special Tools 4C–36. . . . . . . . . . . . . . . . . . . . . . . . . .

Front Propeller Shaft 4C–37. . . . . . . . . . . . . . . . . . . . .

General Description 4C–37. . . . . . . . . . . . . . . . . . . . .

Front Propeller Shaft and Associated Parts 4C–38

Removal 4C–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4C–39. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly (Except TOD 4

4) 4C–40. . . . . . . . .

Universal Joint Disassembly 4C–41. . . . . . . . . . . .

Inspection and Repair 4C–42. . . . . . . . . . . . . . . . . .

Universal Joint Reassembly 4C–45. . . . . . . . . . . . .

Reassembly (Except TOD 4

4) 4C–46. . . . . . . . . .

Main Data and Specifications 4C–47. . . . . . . . . . .

Rear Propeller Shaft 4C–48. . . . . . . . . . . . . . . . . . . . .

General Description 4C–48. . . . . . . . . . . . . . . . . . . . .

Rear Propeller Shaft and Associated Parts 4C–48

Removal 4C–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 4C–49. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 4C–50. . . . . . . . . . . . . . . . . . . . . . . . . .

Universal Joint Disassembly 4C–51. . . . . . . . . . . .

Inspection and Repair 4C–52. . . . . . . . . . . . . . . . . .

Universal Joint Reassembly 4C–53. . . . . . . . . . . . .

Reassembly 4C–54. . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specifications 4C–55. . . . . . . . . . .

Page 668 of 6000

4C–2

DRIVE SHAFT SYSTEM

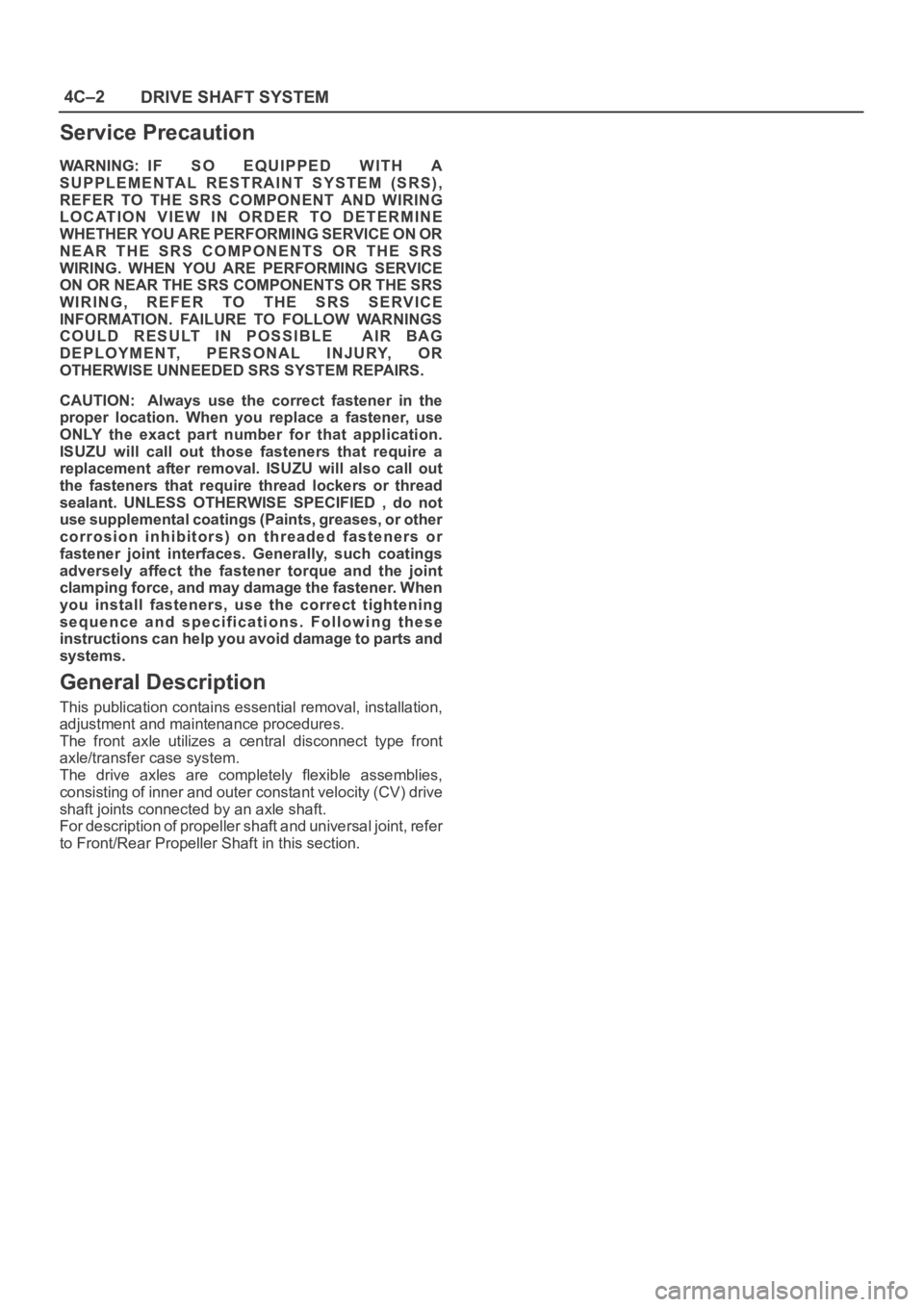

Service Precaution

WARNING: IF SO EQUIPPED WITH A

SUPPLEMENTAL RESTRAINT SYSTEM (SRS),

REFER TO THE SRS COMPONENT AND WIRING

LOCATION VIEW IN ORDER TO DETERMINE

WHETHER YOU ARE PERFORMING SERVICE ON OR

NEAR THE SRS COMPONENTS OR THE SRS

WIRING. WHEN YOU ARE PERFORMING SERVICE

ON OR NEAR THE SRS COMPONENTS OR THE SRS

WIRING, REFER TO THE SRS SERVICE

INFORMATION. FAILURE TO FOLLOW WARNINGS

COULD RESULT IN POSSIBLE AIR BAG

DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED , do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

General Description

This publication contains essential removal, installation,

adjustment and maintenance procedures.

The front axle utilizes a central disconnect type front

axle/transfer case system.

The drive axles are completely flexible assemblies,

consisting of inner and outer constant velocity (CV) drive

shaft joints connected by an axle shaft.

For description of propeller shaft and universal joint, refer

to Front/Rear Propeller Shaft in this section.

Page 669 of 6000

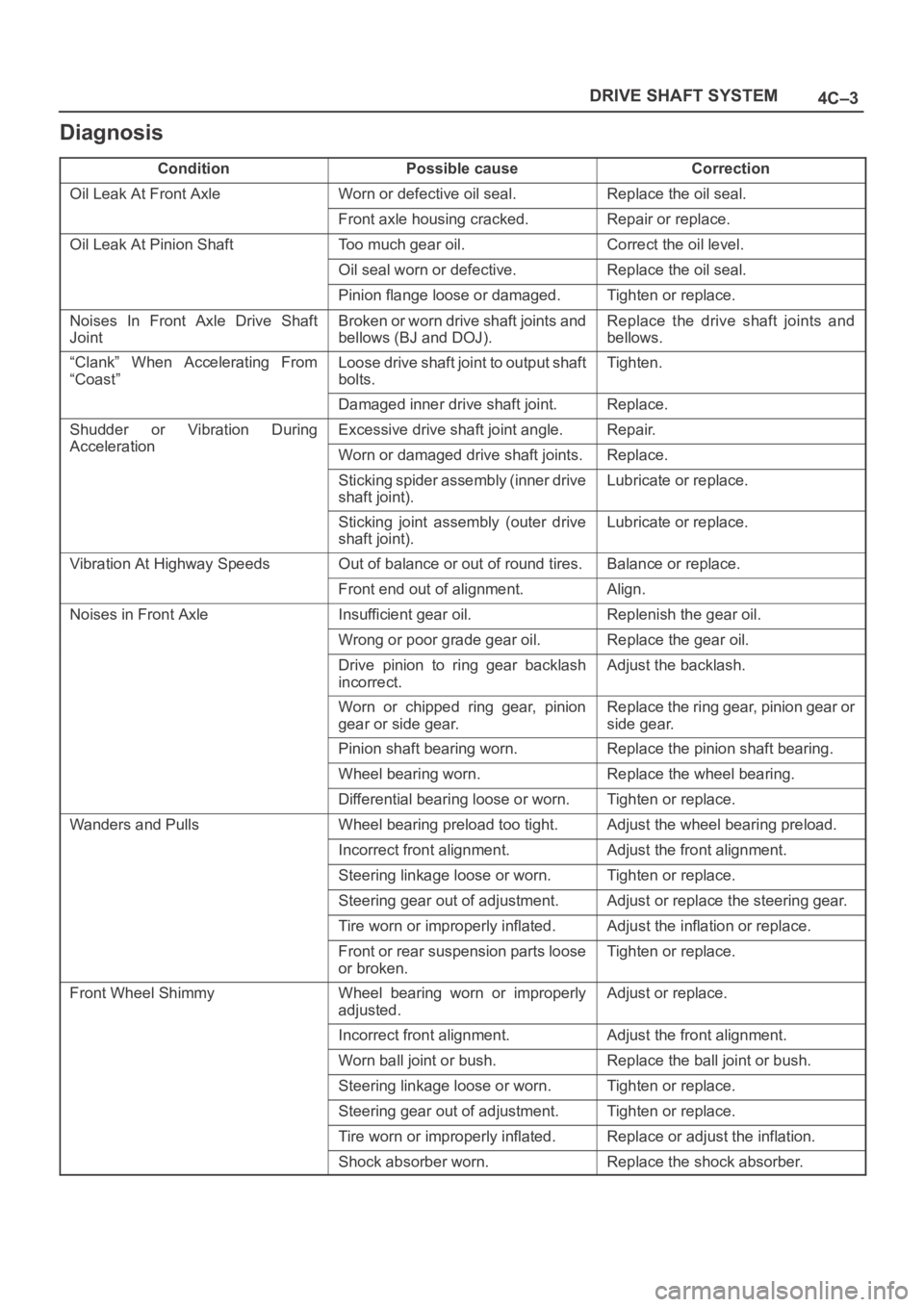

4C–3 DRIVE SHAFT SYSTEM

Diagnosis

ConditionPossible causeCorrection

Oil Leak At Front AxleWorn or defective oil seal.Replace the oil seal.

Front axle housing cracked.Repair or replace.

Oil Leak At Pinion ShaftToo much gear oil.Correct the oil level.

Oil seal worn or defective.Replace the oil seal.

Pinion flange loose or damaged.Tighten or replace.

Noises In Front Axle Drive Shaft

JointBroken or worn drive shaft joints and

bellows (BJ and DOJ).Replace the drive shaft joints and

bellows.

“Clank” When Accelerating From

“Coast”Loose drive shaft joint to output shaft

bolts.Tighten.

Damaged inner drive shaft joint.Replace.

Shudder or Vibration During

Acceleration

Excessive drive shaft joint angle.Repair.

AccelerationWorn or damaged drive shaft joints.Replace.

Sticking spider assembly (inner drive

shaft joint).Lubricate or replace.

Sticking joint assembly (outer drive

shaft joint).Lubricate or replace.

Vibration At Highway SpeedsOut of balance or out of round tires.Balance or replace.

Front end out of alignment.Align.

Noises in Front AxleInsufficient gear oil.Replenish the gear oil.

Wrong or poor grade gear oil.Replace the gear oil.

Drive pinion to ring gear backlash

incorrect.Adjust the backlash.

Worn or chipped ring gear, pinion

gear or side gear.Replace the ring gear, pinion gear or

side gear.

Pinion shaft bearing worn.Replace the pinion shaft bearing.

Wheel bearing worn.Replace the wheel bearing.

Differential bearing loose or worn.Tighten or replace.

Wanders and PullsWheel bearing preload too tight.Adjust the wheel bearing preload.

Incorrect front alignment.Adjust the front alignment.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Adjust or replace the steering gear.

Tire worn or improperly inflated.Adjust the inflation or replace.

Front or rear suspension parts loose

or broken.Tighten or replace.

Front Wheel ShimmyWheel bearing worn or improperly

adjusted.Adjust or replace.

Incorrect front alignment.Adjust the front alignment.

Worn ball joint or bush.Replace the ball joint or bush.

Steering linkage loose or worn.Tighten or replace.

Steering gear out of adjustment.Tighten or replace.

Tire worn or improperly inflated.Replace or adjust the inflation.

Shock absorber worn.Replace the shock absorber.

Page 670 of 6000

4C–4

DRIVE SHAFT SYSTEM

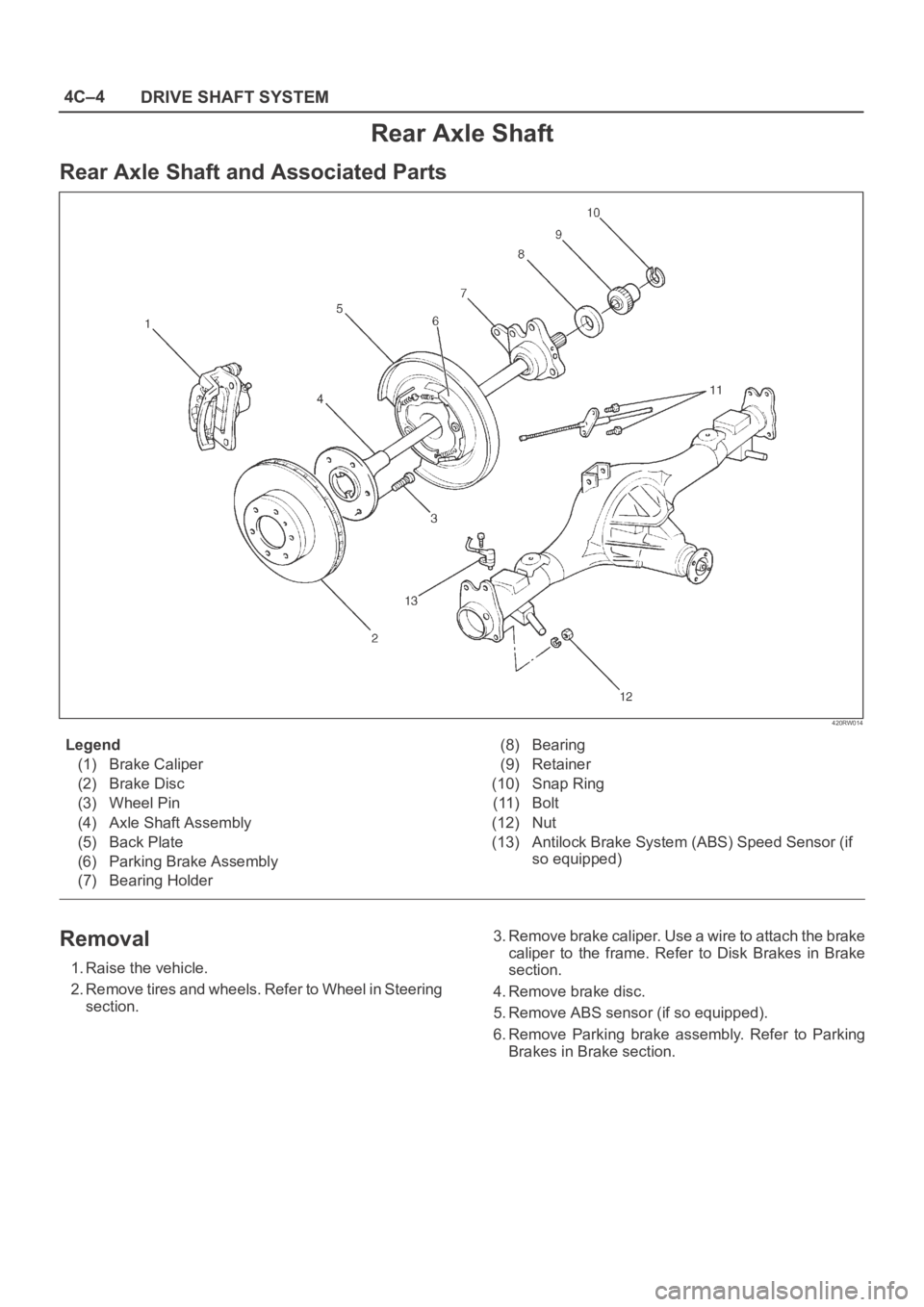

Rear Axle Shaft

Rear Axle Shaft and Associated Parts

420RW014

Legend

(1) Brake Caliper

(2) Brake Disc

(3) Wheel Pin

(4) Axle Shaft Assembly

(5) Back Plate

(6) Parking Brake Assembly

(7) Bearing Holder(8) Bearing

(9) Retainer

(10) Snap Ring

(11) Bolt

(12) Nut

(13) Antilock Brake System (ABS) Speed Sensor (if

so equipped)

Removal

1. Raise the vehicle.

2. Remove tires and wheels. Refer to Wheel in Steering

section.3. Remove brake caliper. Use a wire to attach the brake

caliper to the frame. Refer to Disk Brakes in Brake

section.

4. Remove brake disc.

5. Remove ABS sensor (if so equipped).

6. Remove Parking brake assembly. Refer to Parking

Brakes in Brake section.