Front ach OPEL FRONTERA 1998 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 274 of 6000

HD6 TYPE COMPRESSOR

Metric Thread Size Information

Compressor to mounting bracket bolts (Front)

M10

1.5 – 6H

Compressor to mounting bracket bolts (Rear)

M8

1.25 – 6H

Suction-discharge port screw

M10

1.5 – 6HCompressor shaft

M9

1.25 – 6H

Internal hub-clutch drive assembly

M22

1.5 – 6H

COMPRESSOR CLUTCH PLATE AND HUB

ASSEMBLY

Removal

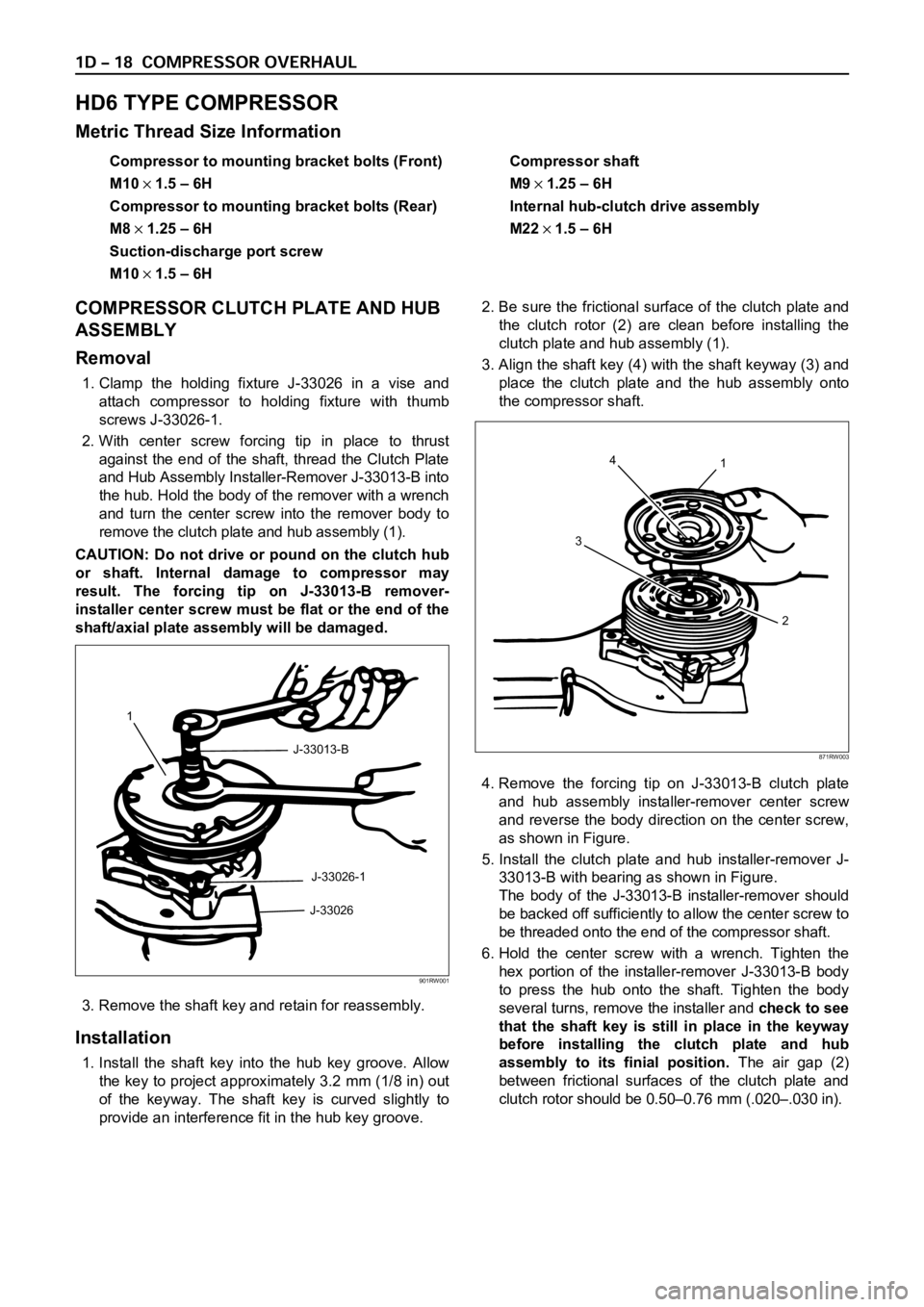

1. Clamp the holding fixture J-33026 in a vise and

attach compressor to holding fixture with thumb

screws J-33026-1.

2. With center screw forcing tip in place to thrust

against the end of the shaft, thread the Clutch Plate

and Hub Assembly Installer-Remover J-33013-B into

the hub. Hold the body of the remover with a wrench

and turn the center screw into the remover body to

remove the clutch plate and hub assembly (1).

CAUTION: Do not drive or pound on the clutch hub

or shaft. Internal damage to compressor may

result. The forcing tip on J-33013-B remover-

installer center screw must be flat or the end of the

shaft/axial plate assembly will be damaged.

3. Remove the shaft key and retain for reassembly.

Installation

1. Install the shaft key into the hub key groove. Allow

the key to project approximately 3.2 mm (1/8 in) out

of the keyway. The shaft key is curved slightly to

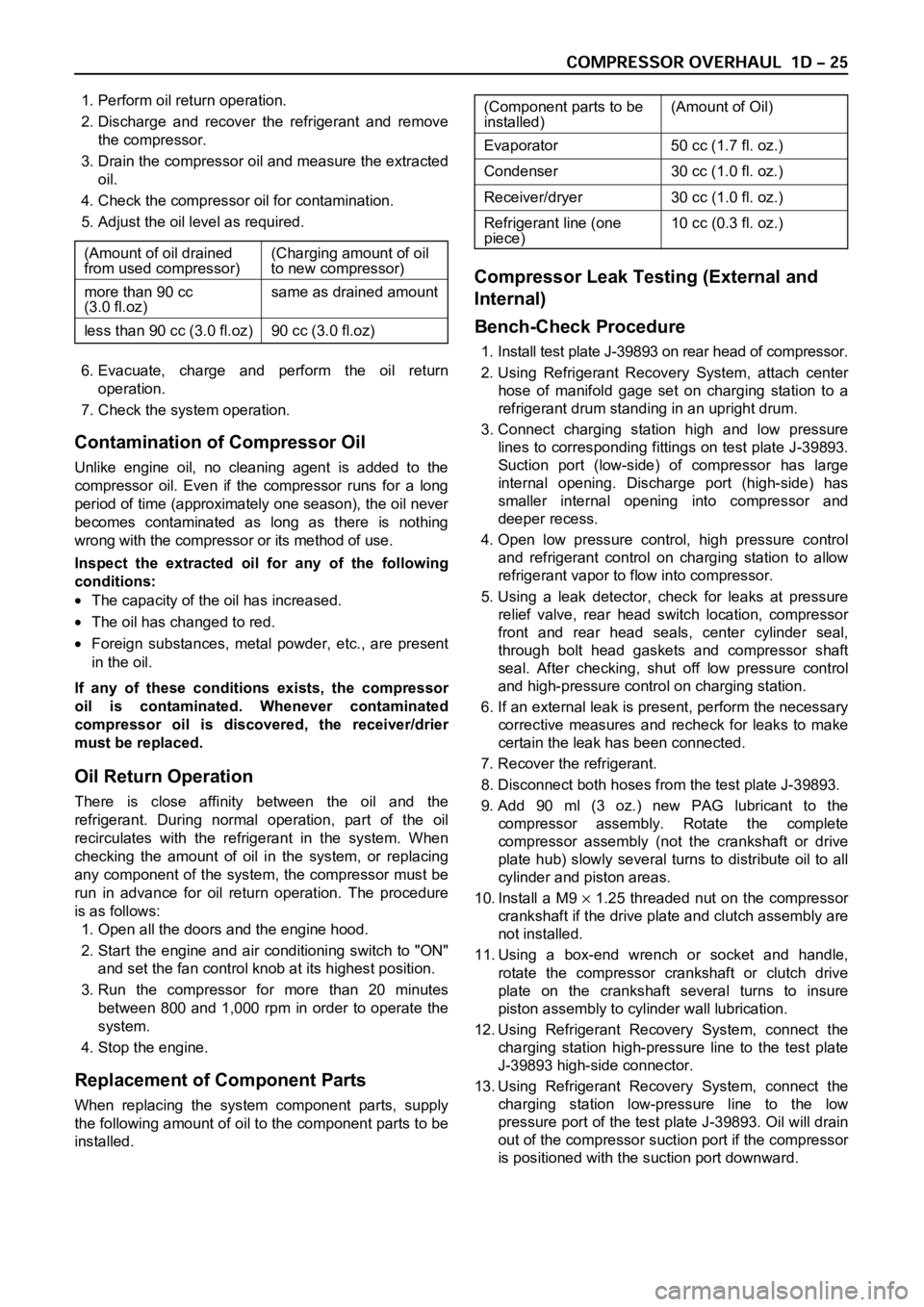

provide an interference fit in the hub key groove.2. Be sure the frictional surface of the clutch plate and

the clutch rotor (2) are clean before installing the

clutch plate and hub assembly (1).

3. Align the shaft key (4) with the shaft keyway (3) and

place the clutch plate and the hub assembly onto

the compressor shaft.

4. Remove the forcing tip on J-33013-B clutch plate

and hub assembly installer-remover center screw

and reverse the body direction on the center screw,

as shown in Figure.

5. Install the clutch plate and hub installer-remover J-

33013-B with bearing as shown in Figure.

The body of the J-33013-B installer-remover should

be backed off sufficiently to allow the center screw to

be threaded onto the end of the compressor shaft.

6. Hold the center screw with a wrench. Tighten the

hex portion of the installer-remover J-33013-B body

to press the hub onto the shaft. Tighten the body

several turns, remove the installer and check to see

that the shaft key is still in place in the keyway

before installing the clutch plate and hub

assembly to its finial position.The air gap (2)

between frictional surfaces of the clutch plate and

clutch rotor should be 0.50–0.76 mm (.020–.030 in).

1

J-33013-B

J-33026-1

J-33026

901RW001

4

31

2

871RW003

Page 281 of 6000

1. Perform oil return operation.

2. Discharge and recover the refrigerant and remove

the compressor.

3. Drain the compressor oil and measure the extracted

oil.

4. Check the compressor oil for contamination.

5. Adjust the oil level as required.

6. Evacuate, charge and perform the oil return

operation.

7. Check the system operation.

Contamination of Compressor Oil

Unlike engine oil, no cleaning agent is added to the

compressor oil. Even if the compressor runs for a long

period of time (approximately one season), the oil never

becomes contaminated as long as there is nothing

wrong with the compressor or its method of use.

Inspect the extracted oil for any of the following

conditions:

The capacity of the oil has increased.

The oil has changed to red.

Foreign substances, metal powder, etc., are present

in the oil.

If any of these conditions exists, the compressor

oil is contaminated. Whenever contaminated

compressor oil is discovered, the receiver/drier

must be replaced.

Oil Return Operation

There is close affinity between the oil and the

refrigerant. During normal operation, part of the oil

recirculates with the refrigerant in the system. When

checking the amount of oil in the system, or replacing

any component of the system, the compressor must be

run in advance for oil return operation. The procedure

is as follows:

1. Open all the doors and the engine hood.

2. Start the engine and air conditioning switch to "ON"

and set the fan control knob at its highest position.

3. Run the compressor for more than 20 minutes

between 800 and 1,000 rpm in order to operate the

system.

4. Stop the engine.

Replacement of Component Parts

When replacing the system component parts, supply

the following amount of oil to the component parts to be

installed.

Compressor Leak Testing (External and

Internal)

Bench-Check Procedure

1. Install test plate J-39893 on rear head of compressor.

2. Using Refrigerant Recovery System, attach center

hose of manifold gage set on charging station to a

refrigerant drum standing in an upright drum.

3. Connect charging station high and low pressure

lines to corresponding fittings on test plate J-39893.

Suction port (low-side) of compressor has large

internal opening. Discharge port (high-side) has

smaller internal opening into compressor and

deeper recess.

4. Open low pressure control, high pressure control

and refrigerant control on charging station to allow

refrigerant vapor to flow into compressor.

5. Using a leak detector, check for leaks at pressure

relief valve, rear head switch location, compressor

front and rear head seals, center cylinder seal,

through bolt head gaskets and compressor shaft

seal. After checking, shut off low pressure control

and high-pressure control on charging station.

6. If an external leak is present, perform the necessary

corrective measures and recheck for leaks to make

certain the leak has been connected.

7. Recover the refrigerant.

8. Disconnect both hoses from the test plate J-39893.

9. Add 90 ml (3 oz.) new PAG lubricant to the

compressor assembly. Rotate the complete

compressor assembly (not the crankshaft or drive

plate hub) slowly several turns to distribute oil to all

cylinder and piston areas.

10. Install a M9

1.25 threaded nut on the compressor

crankshaft if the drive plate and clutch assembly are

not installed.

11. Using a box-end wrench or socket and handle,

rotate the compressor crankshaft or clutch drive

plate on the crankshaft several turns to insure

piston assembly to cylinder wall lubrication.

12. Using Refrigerant Recovery System, connect the

charging station high-pressure line to the test plate

J-39893 high-side connector.

13. Using Refrigerant Recovery System, connect the

charging station low-pressure line to the low

pressure port of the test plate J-39893. Oil will drain

out of the compressor suction port if the compressor

is positioned with the suction port downward. (Component parts to be (Amount of Oil)

installed)

Evaporator 50 cc (1.7 fl. oz.)

Condenser 30 cc (1.0 fl. oz.)

Receiver/dryer 30 cc (1.0 fl. oz.)

Refrigerant line (one 10 cc (0.3 fl. oz.)

piece)

(Amount of oil drained (Charging amount of oil

from used compressor) to new compressor)

more than 90 cc same as drained amount

(3.0 fl.oz)

less than 90 cc (3.0 fl.oz) 90 cc (3.0 fl.oz)

Page 451 of 6000

DIFFERENTIAL (FRONT) 4A1–14

7. Record the pinion depth code on the head of the

drive pinion.

The number indicates a necessary change in the

pinion mounting distance. A plus number indi-

cates the need for a greater mounting distance

(which can be achieved by decreasing the shim

thickness). A minus number indicates the need

for a smaller mounting distance (which can be

achieved by increasing the shim thickness). If ex-

amination reveals pinion depth code “0”, the pin-

ion is “nominal”.

425RS023

Page 454 of 6000

4A1–17 DIFFERENTIAL (FRONT)

NOTE: When staking, be sure to turn the nut to insure

that there is no change in bearing preload. Make sure of

preload again as instructed in 3).

415RW019

Legend

(1) 1.3mm or less

12. Install adjust shim.

1. Attach the side bearing to the differential

assembly without shims. Support the opposite

side using a pilot to prevent bearing damage.

425RS029

Legend

(1) Drive handle:5–8840–0007–0

(2) Installer:9–8522–1164–0

(3) Pilot:9–8521–1743–0

2. Insert the differential cage assembly with bearing

outer races into the side bearing bores of the

carrier.

425RS030

3. Using two sets of feeler gauges, insert a feeler

stock of sufficient thickness between each

bearing outer race and the carrier to remove all

end play. Make certain the feeler stock is pushed

to the bottom of the bearing bores.

Mount the dial indicator 5–8840–0126–0 on the

carrier so that the indicator stem is at right angles

to a tooth on the ring gear.

425RW049

Page 455 of 6000

DIFFERENTIAL (FRONT) 4A1–18

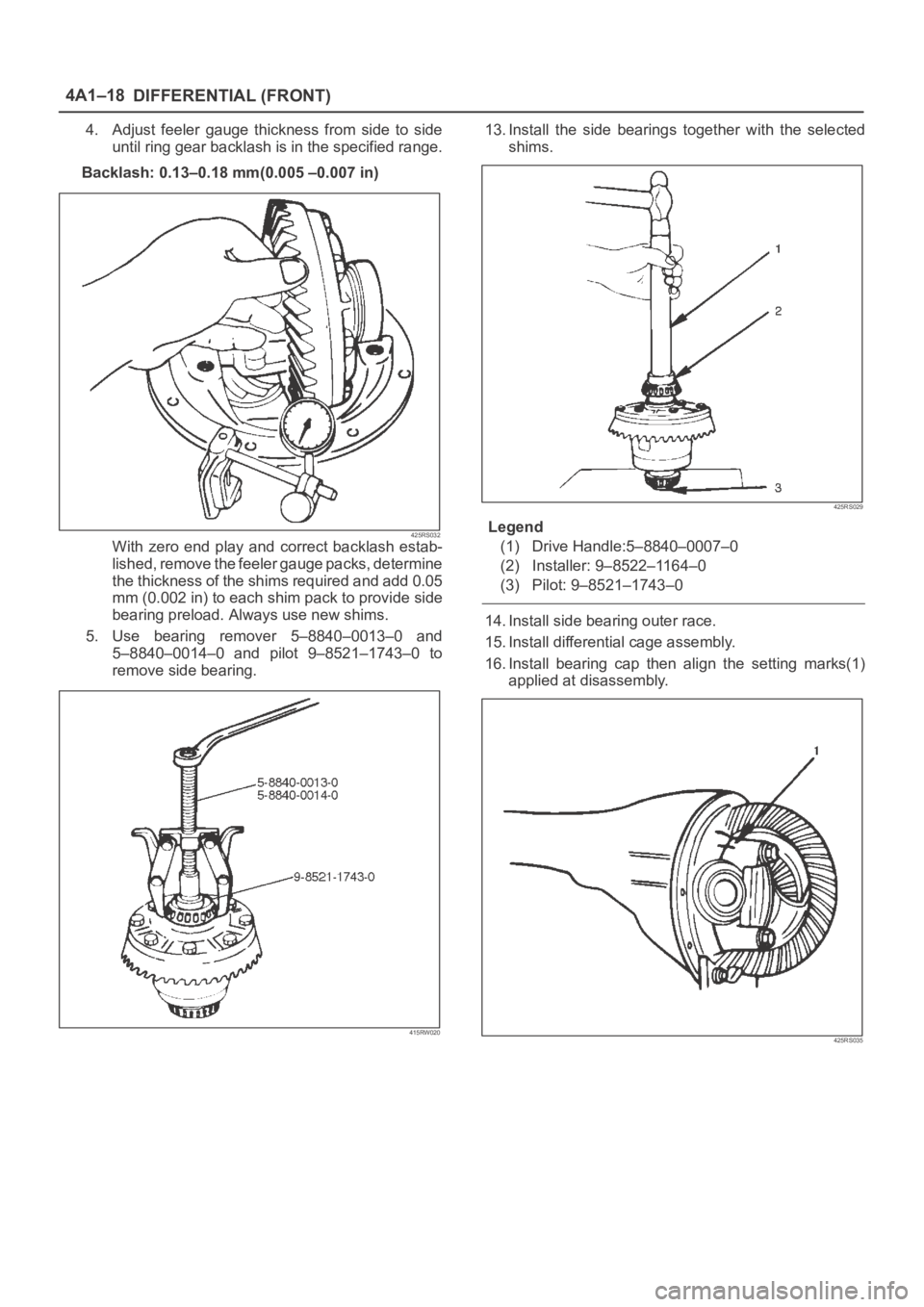

4. Adjust feeler gauge thickness from side to side

until ring gear backlash is in the specified range.

Backlash: 0.13–0.18 mm(0.005 –0.007 in)

425RS032With zero end play and correct backlash estab-

lished, remove the feeler gauge packs, determine

the thickness of the shims required and add 0.05

mm (0.002 in) to each shim pack to provide side

bearing preload. Always use new shims.

5. Use bearing remover 5–8840–0013–0 and

5–8840–0014–0 and pilot 9–8521–1743–0 to

remove side bearing.

415RW020

13. Install the side bearings together with the selected

shims.

425RS029

Legend

(1) Drive Handle:5–8840–0007–0

(2) Installer: 9–8522–1164–0

(3) Pilot: 9–8521–1743–0

14. Install side bearing outer race.

15. Install differential cage assembly.

16. Install bearing cap then align the setting marks(1)

applied at disassembly.

425RS035

Page 457 of 6000

DIFFERENTIAL (FRONT) 4A1–20

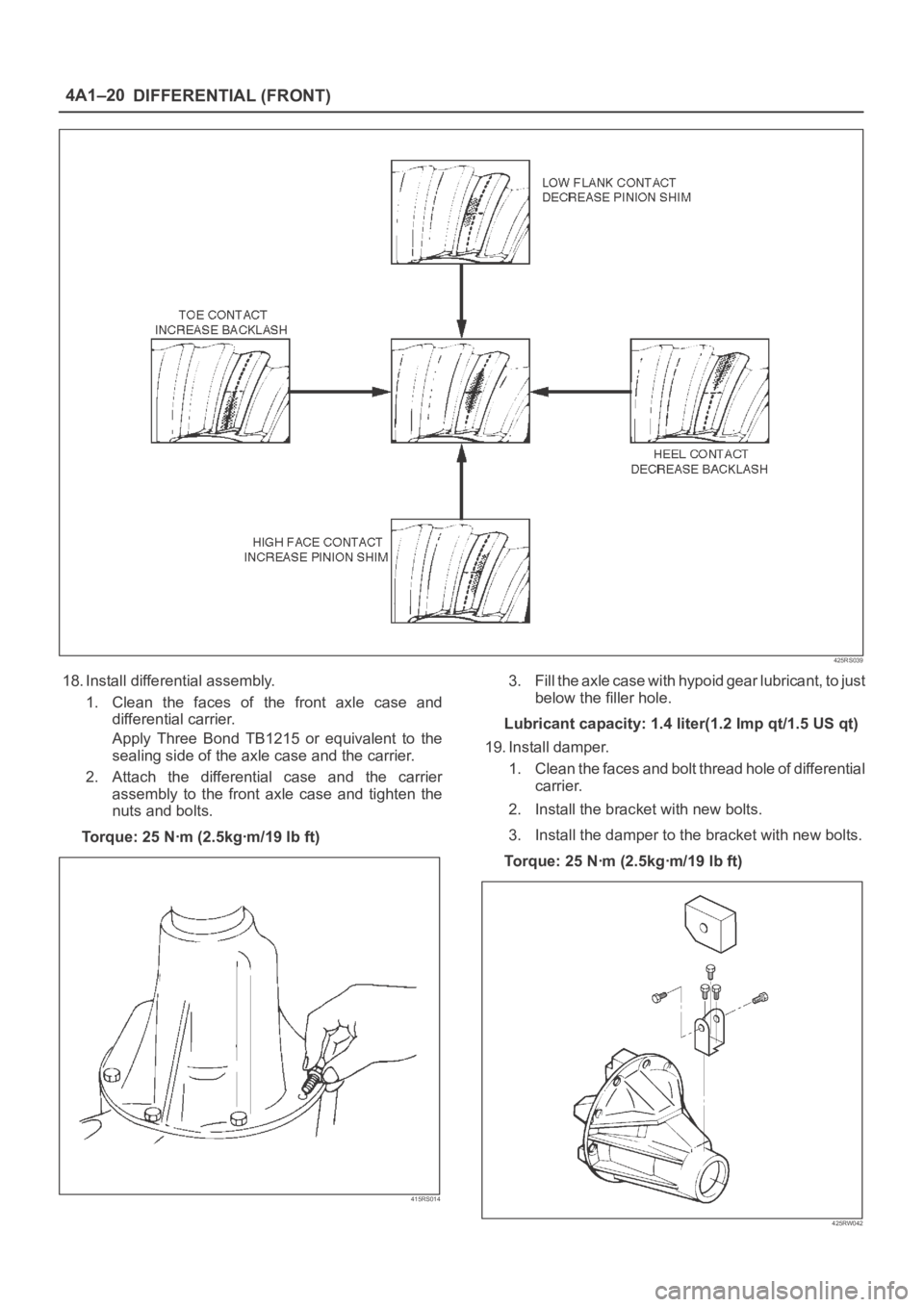

425RS039

18. Install differential assembly.

1. Clean the faces of the front axle case and

differential carrier.

Apply Three Bond TB1215 or equivalent to the

sealing side of the axle case and the carrier.

2. Attach the differential case and the carrier

assembly to the front axle case and tighten the

nuts and bolts.

To r q u e : 2 5 N ꞏm ( 2 . 5 k g ꞏm / 1 9 l b f t )

415RS014

3. Fill the axle case with hypoid gear lubricant, to just

below the filler hole.

Lubricant capacity: 1.4 liter(1.2 Imp qt/1.5 US qt)

19. Install damper.

1. Clean the faces and bolt thread hole of differential

carrier.

2. Install the bracket with new bolts.

3. Install the damper to the bracket with new bolts.

Torque: 25 Nꞏm (2.5kgꞏm/19 lb ft)

425RW042

Page 649 of 6000

DRIVE LINE CONTROL SYSTEM (TOD) 4B2–78

StepNo Ye s Action

15When the transfer lever is shifted to the high position and 4WD

switch shifted to 4WD position, is 0V observed on each VSV?

Go to Step 16

Repair the circuit

or replace the

VSV.

Go to Step 19

16When the transfer lever is shifted to the 4L position, is 0V

observed on each VSV?

Go to Step 17

Repair the circuit

or replace the

VSV.

Go to Step 19

17Is the vacuum pressure supplied to the VSV?

Go to Step 18

Repair the

vacuum system.

Go to Step 19

18Can the single AXLE switch enable and disable the continuity?

Repair the shift

on the fly system

(refer to Section

4C “Front Axle”.

Go to Step 19

Replace the

AXLE switch

(refer to Section

4C “Drive Shaft

System” of

Chassis Repair

Manual).

Go to Step 19

19Check that all the parts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow”.

Return to Step 19

Page 652 of 6000

4B2–81 DRIVE LINE CONTROL SYSTEM (TOD)

StepNo Ye s Action

16When the transfer lever is shifted to the 4L position, is 0V

observed on each VSV?

Go to Step 17

Repair the circuit

or replace the

VSV.

Go to Step 19

17Is the vacuum pressure supplied to the VSV?

Go to Step 18

Repair the

vacuum system.

Go to Step 19

18Can the single AXLE switch enable and disable the continuity?

Repair the shift

on the fly system

Refer to Section

4C “Front Axle”.

Go to Step 19

Replace the

AXLE switch

Refer to Section

4C “Drive Shaft

System”.

Go to Step 19

19Check that all the parts are mounted.

Is this step complete?Repeat the

“Diagnosis Flow”.

Return to Step 19

Page 678 of 6000

4C–12

DRIVE SHAFT SYSTEM

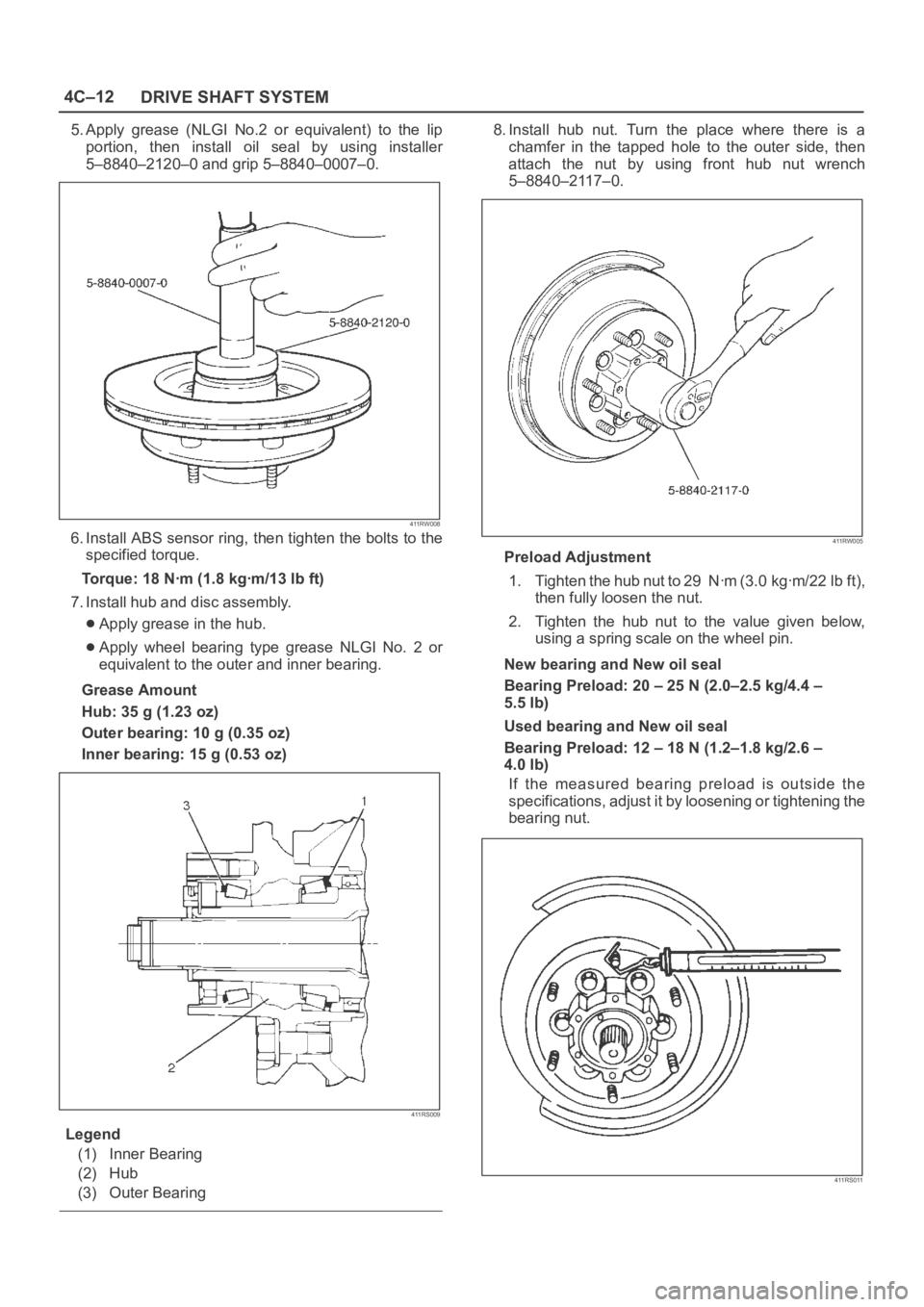

5. Apply grease (NLGI No.2 or equivalent) to the lip

portion, then install oil seal by using installer

5–8840–2120–0 and grip 5–8840–0007–0.

411RW008

6. Install ABS sensor ring, then tighten the bolts to the

specified torque.

Torque: 18 Nꞏm (1.8 kgꞏm/13 lb ft)

7. Install hub and disc assembly.

Apply grease in the hub.

Apply wheel bearing type grease NLGI No. 2 or

equivalent to the outer and inner bearing.

Grease Amount

Hub: 35 g (1.23 oz)

Outer bearing: 10 g (0.35 oz)

Inner bearing: 15 g (0.53 oz)

411RS009

Legend

(1) Inner Bearing

(2) Hub

(3) Outer Bearing

8. Install hub nut. Turn the place where there is a

chamfer in the tapped hole to the outer side, then

attach the nut by using front hub nut wrench

5–8840–2117–0.

411RW005

Preload Adjustment

1. Tighten the hub nut to 29 Nꞏm (3.0 kgꞏm/22 lb ft),

then fully loosen the nut.

2. Tighten the hub nut to the value given below,

using a spring scale on the wheel pin.

New bearing and New oil seal

Bearing Preload: 20 – 25 N (2.0–2.5 kg/4.4 –

5.5 lb)

Used bearing and New oil seal

Bearing Preload: 12 – 18 N (1.2–1.8 kg/2.6 –

4.0 lb)

If the measured bearing preload is outside the

specifications, adjust it by loosening or tightening the

bearing nut.

411RS011

Page 703 of 6000

4C–37 DRIVE SHAFT SYSTEM

Front Propeller Shaft

General Description

Since the propeller shaft is balanced carefully, welding or

any other modifications are not permitted.Alignment marks should be applied to each propeller

shaft before removal.

401RW002