Front ach OPEL FRONTERA 1998 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 705 of 6000

4C–39 DRIVE SHAFT SYSTEM

401RW053

401RW052

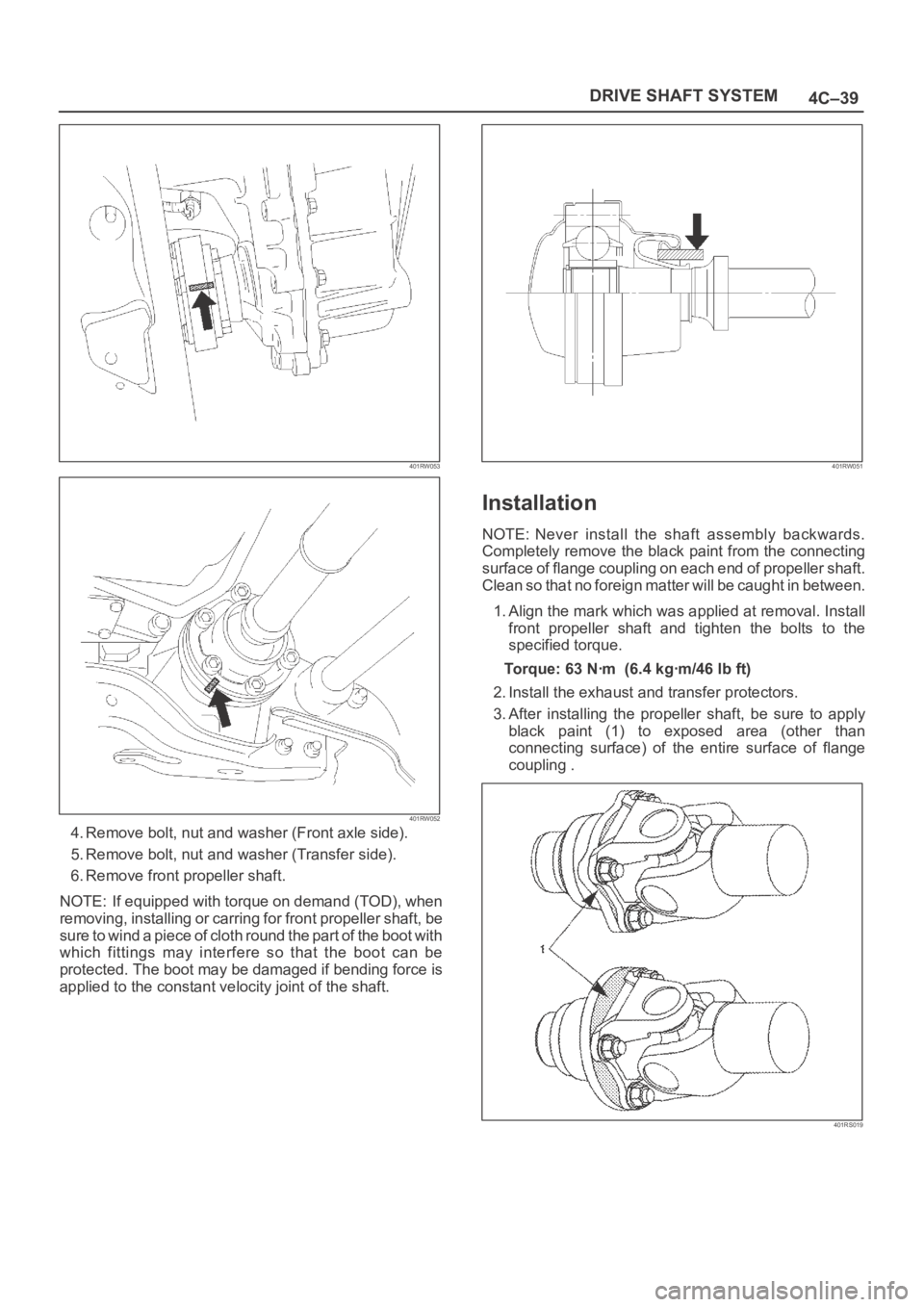

4. Remove bolt, nut and washer (Front axle side).

5. Remove bolt, nut and washer (Transfer side).

6. Remove front propeller shaft.

NOTE: If equipped with torque on demand (TOD), when

removing, installing or carring for front propeller shaft, be

sure to wind a piece of cloth round the part of the boot with

which fittings may interfere so that the boot can be

protected. The boot may be damaged if bending force is

applied to the constant velocity joint of the shaft.

401RW051

Installation

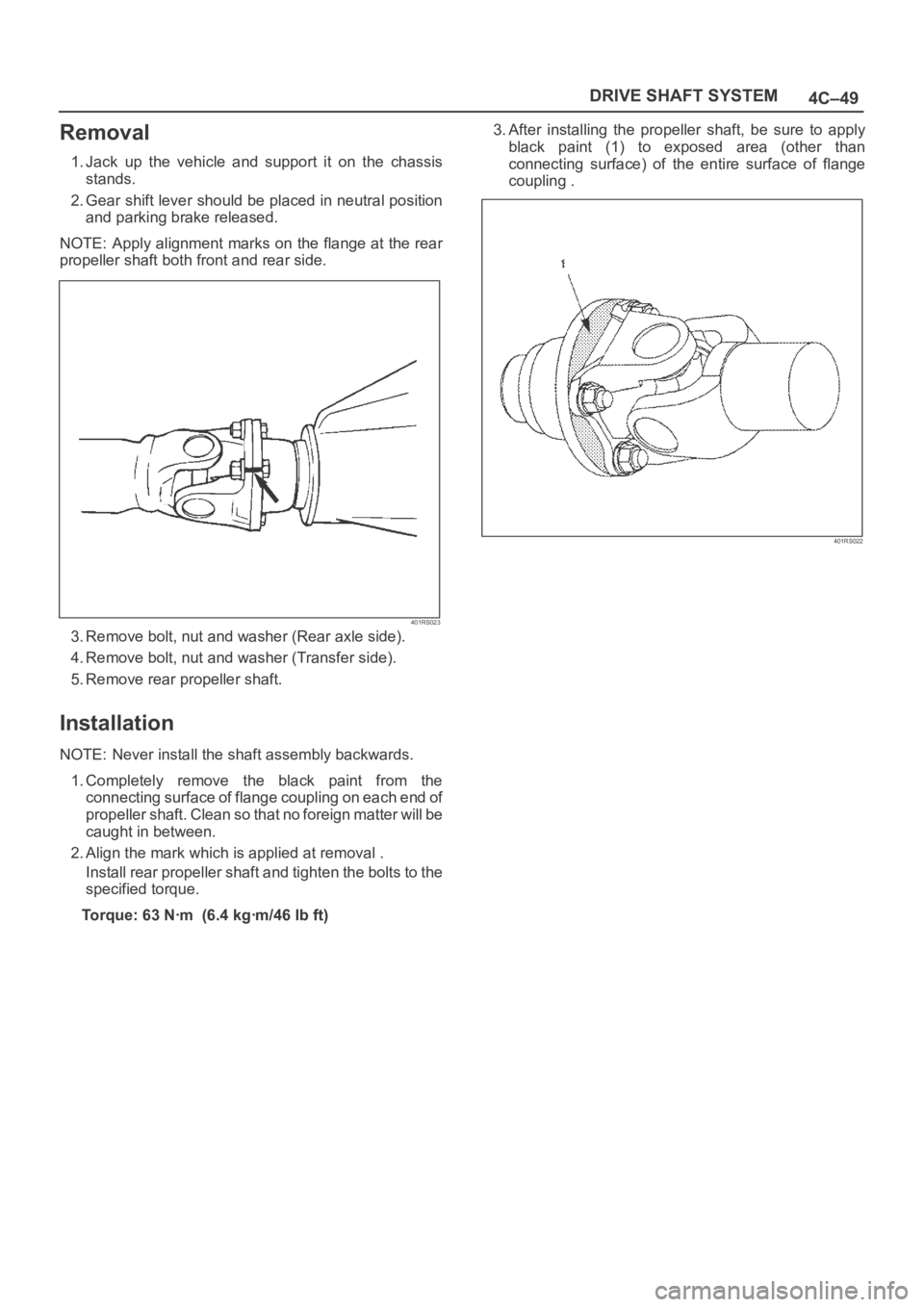

NOTE: Never install the shaft assembly backwards.

Completely remove the black paint from the connecting

surface of flange coupling on each end of propeller shaft.

Clean so that no foreign matter will be caught in between.

1. Align the mark which was applied at removal. Install

front propeller shaft and tighten the bolts to the

specified torque.

Torque:63Nꞏm (6.4kgꞏm/46lbft)

2. Install the exhaust and transfer protectors.

3. After installing the propeller shaft, be sure to apply

black paint (1) to exposed area (other than

connecting surface) of the entire surface of flange

coupling .

401RS019

Page 710 of 6000

4C–44

DRIVE SHAFT SYSTEM

401RW047

Front Axle Flange Run-out

1. Set a dial gage at right angle near the outer

circumference of the flange face and check the

run-out of the flange face.

Limit: 0.15 mm (0.006 in)

401RW046

2. Set a dial gage at right angle near the inner

circumference and check the run-out of the flange.

Limit: 0.15 mm (0.006 in)

401RW045

3. If vibration is felt during the 4H AUTO drive, disconnct

the propeller shaft at the front axle. Reinstall the

propeller shaft at 60

, 120, 180, 240, and 300

and conduct test drive in each position and check if

there is vibration.

401RW044

Page 715 of 6000

4C–49 DRIVE SHAFT SYSTEM

Removal

1. Jack up the vehicle and support it on the chassis

stands.

2. Gear shift lever should be placed in neutral position

and parking brake released.

NOTE: Apply alignment marks on the flange at the rear

propeller shaft both front and rear side.

401RS023

3. Remove bolt, nut and washer (Rear axle side).

4. Remove bolt, nut and washer (Transfer side).

5. Remove rear propeller shaft.

Installation

NOTE: Never install the shaft assembly backwards.

1. Completely remove the black paint from the

connecting surface of flange coupling on each end of

propeller shaft. Clean so that no foreign matter will be

caught in between.

2. Align the mark which is applied at removal .

Install rear propeller shaft and tighten the bolts to the

specified torque.

Torque: 63 Nꞏm (6.4 kgꞏm/46 lb ft)3. After installing the propeller shaft, be sure to apply

black paint (1) to exposed area (other than

connecting surface) of the entire surface of flange

coupling .

401RS022

Page 735 of 6000

4D1–14

TRANSFER CASE (STANDARD TYPE)

6. Join the rod grooves of 2WD–4WD actuator

assembly (12) and shift rod (11).

220RW030

Legend

(11) Shift Rod: 2WD–4WD (Position: 4WD)

(12) 2WD–4WD Actuator Assembly (Mode: 2WD)

(13) Rear Cover Assembly

7. Push the 2WD–4WD actuator assembly (12) with

2WD–4WD shift rod (11) till the shift rod (11) reaches

the 2WD position.

220RW031

Legend

(14) Position: 2WD

(15) Mode: 2WD

8. Tighten the 2WD–4WD actuator bolts to the specified

torque.

Torque: 19 Nꞏm (1.9kgꞏm/14 lb ft)

9. Install the actuator heat protector.

10. Connect the actuator breather hose to the actuator.11. Install the control box assembly.

Torque: 19 Nꞏm (1.9kgꞏm/14 lb ft)

12. Connect the breather hoses to the control box.

13. Install the rear companion flange and front

companion flange, using the companion flange holder

5–8840–0133–0 (J–8614–11) to tighten the flange

nuts to the transfer case.

262RW067

14. Tighten the new transfer flange nuts to the specified

torque.

To r q u e

Rear companion flange: 167 Nꞏm (17.0kgꞏm/123

lb ft)

Front companion flange: 137 Nꞏm (14.0kgꞏm/101

lb ft)

15. Use the punch 5–8840–2293–0 (J–39209) to stake

the rear companion flange nut at two spots.

266RW027

Page 754 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–33

NOTE: Do not reuse the stopper plate. (Shift On The Fly

model)

24. Disassemble the 2WD–4WD clutch hub and sleeve

assembly.

Springs (1) (Shift On The Fly model)

Inserts (2) (Shift On The Fly model)

Clutch Hub (3)

Sleeve (4)

226RW133

25. Use a bench press and the ball bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (4) from front output shaft (5).

262RW071

26. Remove bearing snap ring (29) from transfer case.

27. Remove the counter gear assembly (28) from the

transfer case (1).

28. Use a pair of snap ring pliers to remove the snap ring

(20).29. Use a bench press and the bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (21).

30. Use a pair of snap ring pliers to remove the snap ring

(27).

31. Use a bench press and the bearing remover

5–8840–0015–0 (J–22912–01) to remove the ball

bearing (26).

226RW191

32. Remove the spacer (25).

33. Remove the belleville spring (24).

34. Remove the sub–gear (anti–lash plate) (23) from the

counter gear (22).

Inspection and Repair

1. Make the necessary repair or parts replacement if

wear, damage or any other abnormal conditions are

found during inspection.

2. Wash all parts thoroughly in clean solvent. Be sure all

old lubricant, metallic particles, dirt, or foreign

material are removed from the surfaces of every part.

Apply compressed air to each oil feed port and

channel in each case half to remove any obstructions

or cleaning solvent residue.

Gears

1. Inspect all the gear teeth for signs of excessive wear

or damage and check all the gear splines for burrs,

nicks, wear or damage. Remove the minor nicks or

scratches on an oil stone. Replace any part exhibiting

excessive wear or damage.

Front Output Gear Inside Diameter

1. Use an inside dial indicator to measure the gear inside

diameter.

Page 759 of 6000

4D1–38

TRANSFER CASE (STANDARD TYPE)

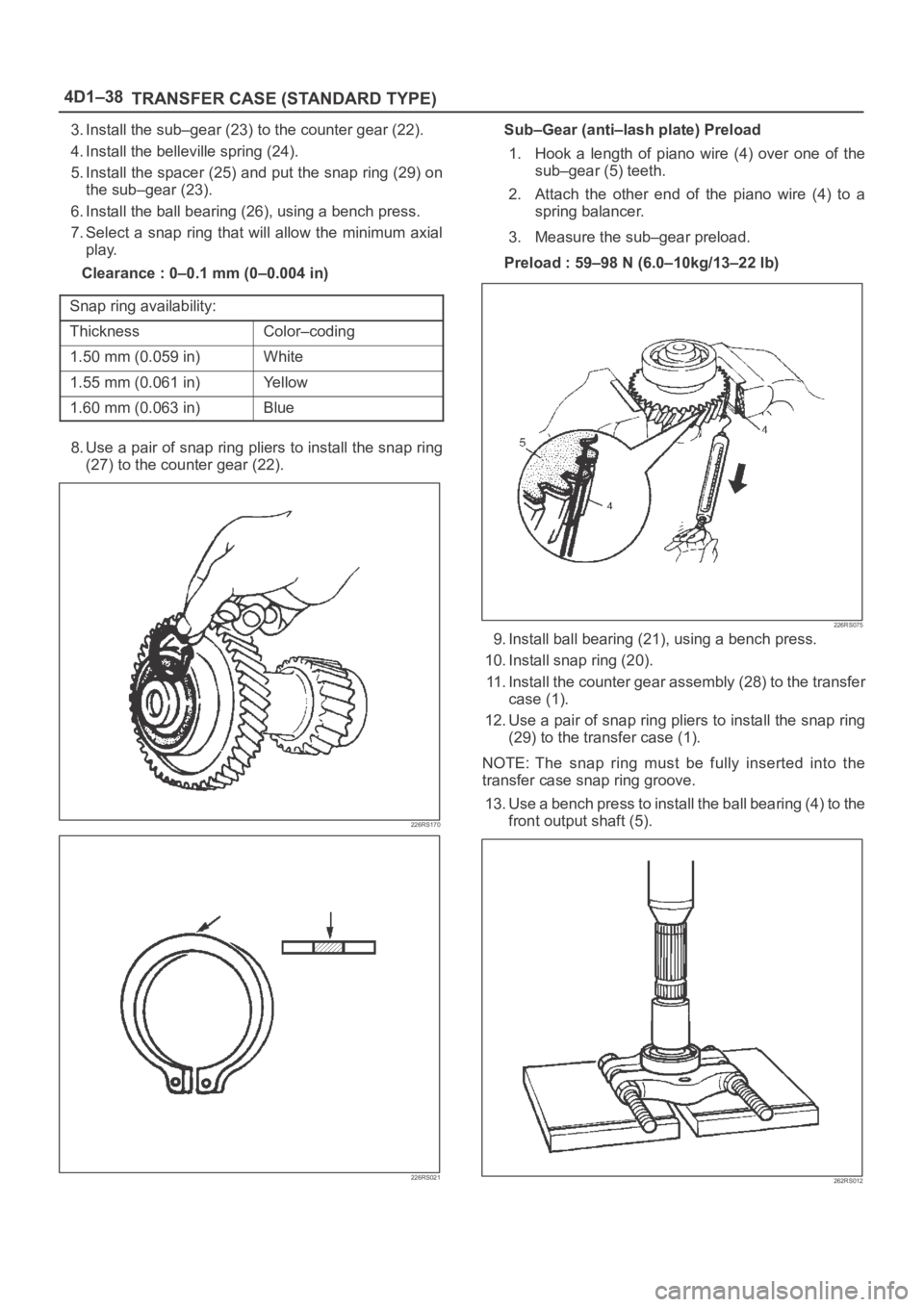

3. Install the sub–gear (23) to the counter gear (22).

4. Install the belleville spring (24).

5. Install the spacer (25) and put the snap ring (29) on

the sub–gear (23).

6. Install the ball bearing (26), using a bench press.

7. Select a snap ring that will allow the minimum axial

play.

Clearance : 0–0.1 mm (0–0.004 in)

Snap ring availability:

ThicknessColor–coding

1.50 mm (0.059 in)White

1.55 mm (0.061 in)Yellow

1.60 mm (0.063 in)Blue

8. Use a pair of snap ring pliers to install the snap ring

(27) to the counter gear (22).

226RS170

226RS021

Sub–Gear (anti–lash plate) Preload

1. Hook a length of piano wire (4) over one of the

sub–gear (5) teeth.

2. Attach the other end of the piano wire (4) to a

spring balancer.

3. Measure the sub–gear preload.

Preload : 59–98 N (6.0–10kg/13–22 lb)

226RS075

9. Install ball bearing (21), using a bench press.

10. Install snap ring (20).

11. Install the counter gear assembly (28) to the transfer

case (1).

12. Use a pair of snap ring pliers to install the snap ring

(29) to the transfer case (1).

NOTE: The snap ring must be fully inserted into the

transfer case snap ring groove.

13. Use a bench press to install the ball bearing (4) to the

front output shaft (5).

262RS012

Page 760 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–39

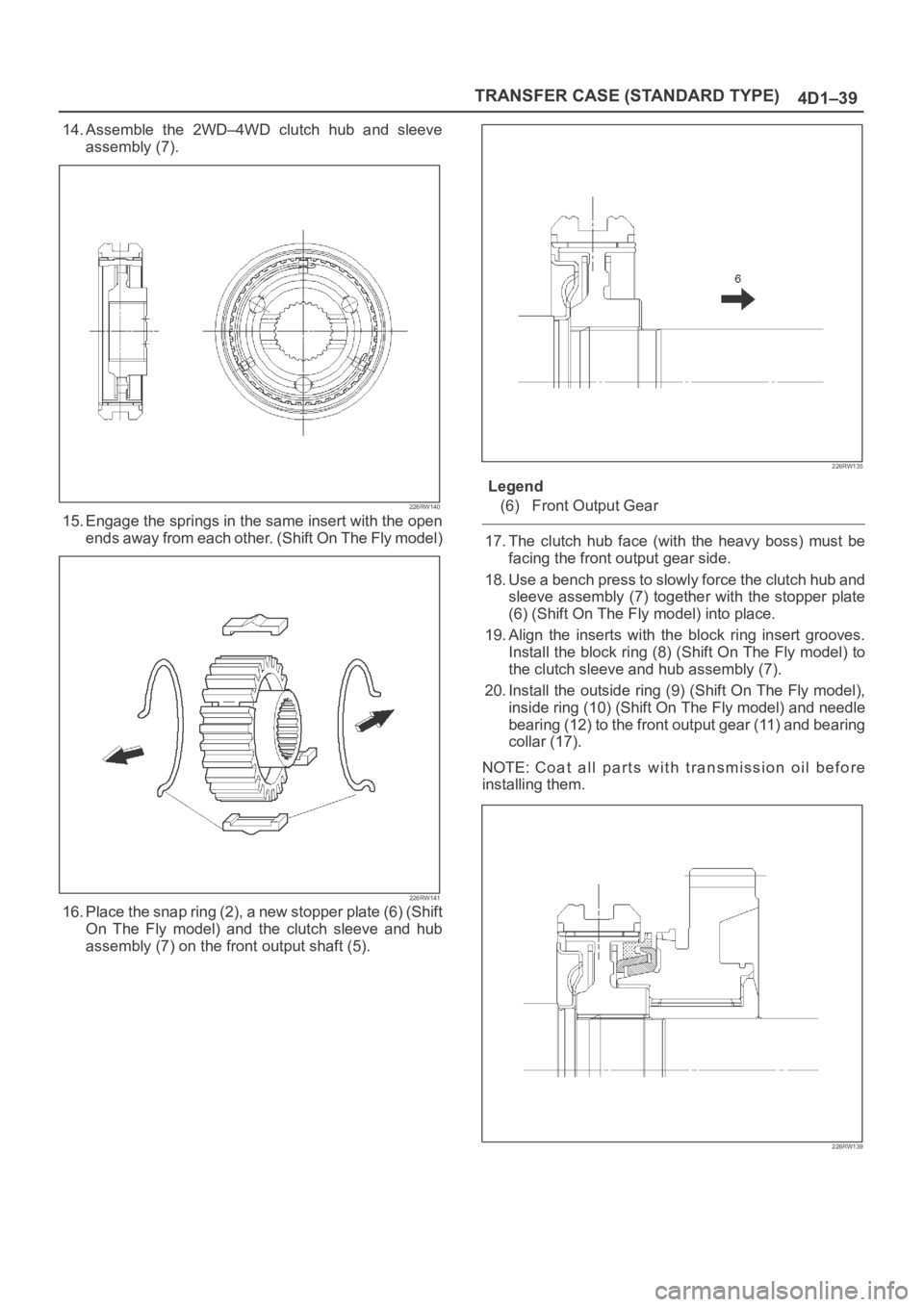

14. Assemble the 2WD–4WD clutch hub and sleeve

assembly (7).

226RW140

15. Engage the springs in the same insert with the open

ends away from each other. (Shift On The Fly model)

226RW141

16. Place the snap ring (2), a new stopper plate (6) (Shift

On The Fly model) and the clutch sleeve and hub

assembly (7) on the front output shaft (5).

226RW135

Legend

(6) Front Output Gear

17. The clutch hub face (with the heavy boss) must be

facing the front output gear side.

18. Use a bench press to slowly force the clutch hub and

sleeve assembly (7) together with the stopper plate

(6) (Shift On The Fly model) into place.

19. Align the inserts with the block ring insert grooves.

Install the block ring (8) (Shift On The Fly model) to

the clutch sleeve and hub assembly (7).

20. Install the outside ring (9) (Shift On The Fly model),

inside ring (10) (Shift On The Fly model) and needle

bearing (12) to the front output gear (11) and bearing

collar (17).

NOTE: Coat all parts with transmission oil before

installing them.

226RW139

Page 762 of 6000

TRANSFER CASE (STANDARD TYPE)

4D1–41

27. Use a pair of snap ring pliers to install the snap ring

(19) to the output shaft (5).

Sub gear (anti lash plate) preload (M/T)

1. Hook a length of piano wire (4) over one of the

sub–gear (5) teeth.

2. Attach the other end of the piano wire to (4) a

spring balancer.

3. Measure the sub–gear preload.

Preload: 59–98 N (6.0–10.0kg/13–22 lb)

(M/T)

226RS075

28. Install front output gear assembly (3) to the transfer

case (1).

29. Use a pair of snap ring pliers to install the snap ring (2)

to the transfer case (1).

NOTE: The snap ring must be fully inserted into the

transfer case snap ring groove.

30. Use a bench press to install the ball bearing (32) to the

input shaft (31).

265RS003

31. Install the plate (34), ball (35), and bearing collar (36)

and place the snap ring (33).

32. Install the needle bearing (37) and input gear (38).

33. The clutch hub face (with the heavy boss) must be

facing the transfer input gear side (7).

226RW136

34. Install the high–low clutch hub and sleeve (39), using

a bench press.

35. Install the input shaft assembly (30) to the transfer

case (1).

36. Install the snap ring (33) to the transfer case (1).

NOTE: The snap ring must be fully inserted into the

transfer case snap ring groove.

37. Install the front companion flange temporarily and use

the flange holder 5–8840–0133–0 (J–8614–11) and

lock nut wrench 5–8840–2156–0 (J–37219) to install

the lock nut (40).

Torque: 137 Nꞏm (14.0kgꞏm/101 lb ft)

226RW190

38. Use the punch to stake the lock nut (40) at one spot.

Page 782 of 6000

4D2–15 TRANSFER CASE (TOD)

4. Apply a thin coat of grease to the seal ring of each

front and rear speed sensor, and mount the sensors

carefully.

5. Tighten the bolts to the specified torque.

Torque : 5 Nꞏm (0.5 kgꞏm/43 lb in)

NOTE: Pay attention not to mount the front (or rear)

sensor to the rear (or front) sensor position.

6. Install the ball bearing (1) for the front output shaft as

flat as shown in the figure.

261RW008

7. Mount the coil assembly and tighten the nuts to the

specified torque.

Torque : 10 Nꞏm (1.0 kgꞏm/87 lb in)

8. Connect the terminal in the central connector.

NOTE: Be careful not to damage other terminals.

9. Install speed gear and tone wheel.

10. Mount the ball bearing (2) as flat as shown in the

figure.

261RW009–1

11. Using snap ring pliers, install the snap ring to the

transfer cover assembly.NOTE: Securely install the snap ring to the groove of the

transfer cover assembly.

Page 802 of 6000

4D2–35 TRANSFER CASE (TOD)

2. Mount the front output shaft to the transfer case.

266RW012

3. Install the shifter lever shaft.

4. Install the snap ring.

5. Install the reduction lever assembly to the shifter lever

shaft and fix the assembly with the snap ring.

261RW021

6. Install the cam to the cam pilot block.

7. Attach the washer to the cam pilot block and fix the

washer with the snap ring.

261RW029

8. Mount the reduction fork to the lock-up shaft.

9. Install the spring pin to the reduction fork and lock-up

roll.

261RW020