Front ach OPEL FRONTERA 1998 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 813 of 6000

5A–3 BRAKE CONTROL SYSTEM

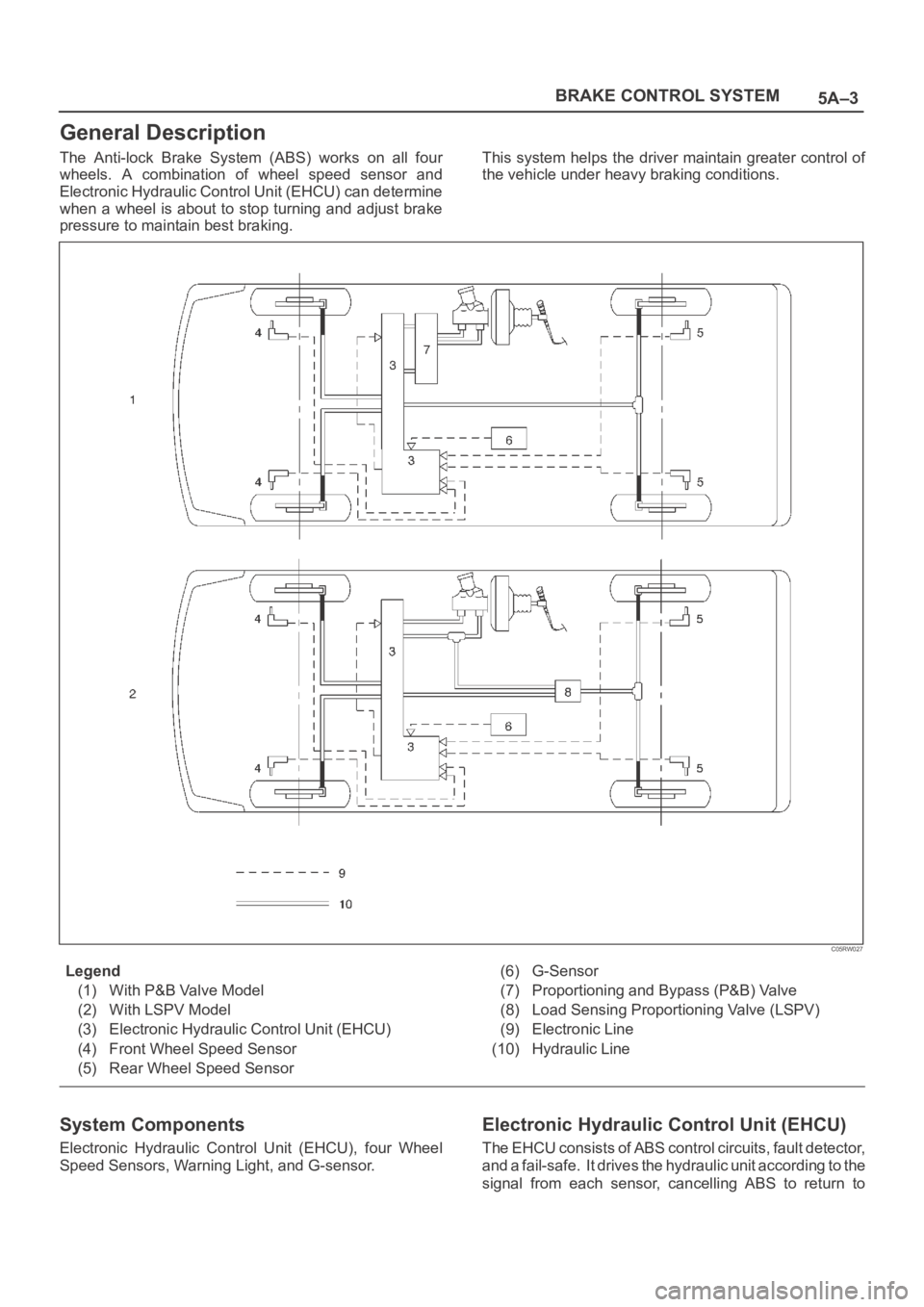

General Description

The Anti-lock Brake System (ABS) works on all four

wheels. A combination of wheel speed sensor and

Electronic Hydraulic Control Unit (EHCU) can determine

when a wheel is about to stop turning and adjust brake

pressure to maintain best braking.This system helps the driver maintain greater control of

the vehicle under heavy braking conditions.

C05RW027

Legend

(1) With P&B Valve Model

(2) With LSPV Model

(3) Electronic Hydraulic Control Unit (EHCU)

(4) Front Wheel Speed Sensor

(5) Rear Wheel Speed Sensor(6) G-Sensor

(7) Proportioning and Bypass (P&B) Valve

(8) Load Sensing Proportioning Valve (LSPV)

(9) Electronic Line

(10) Hydraulic Line

System Components

Electronic Hydraulic Control Unit (EHCU), four Wheel

Speed Sensors, Warning Light, and G-sensor.

Electronic Hydraulic Control Unit (EHCU)

T h e E H C U c o n s i s t s o f A B S c o n t r o l c i r c u i t s , f a u l t d e t e c t o r,

and a fail-safe. It drives the hydraulic unit according to the

signal from each sensor, cancelling ABS to return to

Page 814 of 6000

5A–4

BRAKE CONTROL SYSTEM

normal braking when a malfunction has occurred in the

ABS.

The EHCU has a self-diagnosing function which can

indicate faulty circuits during diagnosis.

The EHCU is mounted on the engine compartment front

right side. It consists of a Motor, Plunger Pump, Solenoid

Valves and Check Valve.

On the outside, the relay box containing a motor relay and

a valve relay is installed.

Solenoid Valves: Reduces or holds the caliper fluid

pressure for each front disc brake or both rear disc brakes

according to the signal sent from the EHCU.

Reservoir: Temporarily holds the brake fluid that returns

from the front and rear disc brake caliper so that pressure

of front disc brake caliper can be reduced smoothly.

Plunger Pump: Feeds the brake fluid held in the reservoir

to the master cylinder.

Motor: Drives the pump according to the signal from

EHCU.

Check Valve: Controls the brake fluid flow.

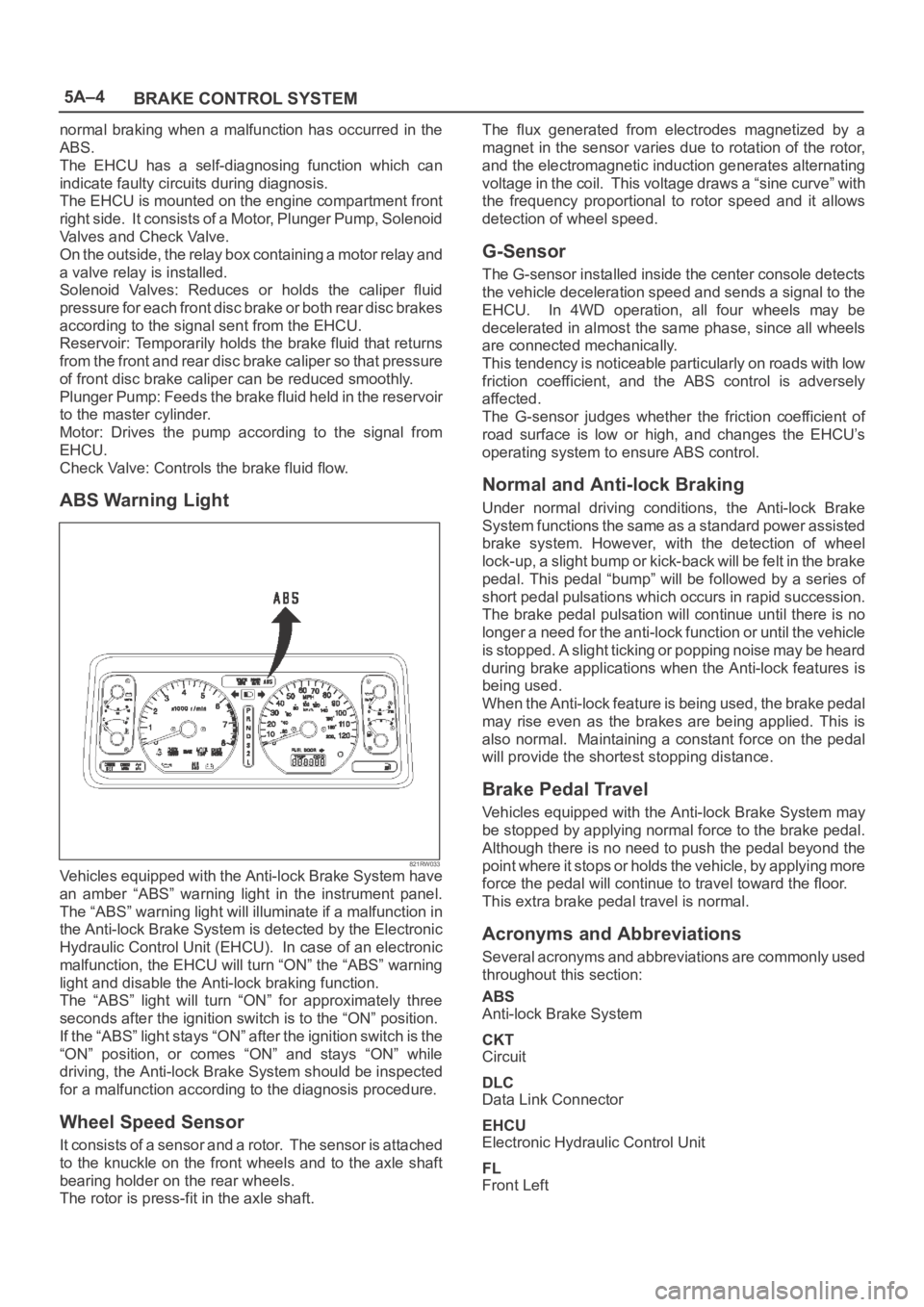

ABS Warning Light

821RW033Vehicles equipped with the Anti-lock Brake System have

an amber “ABS” warning light in the instrument panel.

The “ABS” warning light will illuminate if a malfunction in

the Anti-lock Brake System is detected by the Electronic

Hydraulic Control Unit (EHCU). In case of an electronic

malfunction, the EHCU will turn “ON” the “ABS” warning

light and disable the Anti-lock braking function.

The “ABS” light will turn “ON” for approximately three

seconds after the ignition switch is to the “ON” position.

If the “ABS” light stays “ON” after the ignition switch is the

“ON” position, or comes “ON” and stays “ON” while

driving, the Anti-lock Brake System should be inspected

for a malfunction according to the diagnosis procedure.

Wheel Speed Sensor

It consists of a sensor and a rotor. The sensor is attached

to the knuckle on the front wheels and to the axle shaft

bearing holder on the rear wheels.

The rotor is press-fit in the axle shaft.The flux generated from electrodes magnetized by a

magnet in the sensor varies due to rotation of the rotor,

and the electromagnetic induction generates alternating

voltage in the coil. This voltage draws a “sine curve” with

the frequency proportional to rotor speed and it allows

detection of wheel speed.

G-Sensor

The G-sensor installed inside the center console detects

the vehicle deceleration speed and sends a signal to the

EHCU. In 4WD operation, all four wheels may be

decelerated in almost the same phase, since all wheels

are connected mechanically.

This tendency is noticeable particularly on roads with low

friction coefficient, and the ABS control is adversely

affected.

The G-sensor judges whether the friction coefficient of

road surface is low or high, and changes the EHCU’s

operating system to ensure ABS control.

Normal and Anti-lock Braking

Under normal driving conditions, the Anti-lock Brake

System functions the same as a standard power assisted

brake system. However, with the detection of wheel

lock-up, a slight bump or kick-back will be felt in the brake

pedal. This pedal “bump” will be followed by a series of

short pedal pulsations which occurs in rapid succession.

The brake pedal pulsation will continue until there is no

longer a need for the anti-lock function or until the vehicle

is stopped. A slight ticking or popping noise may be heard

during brake applications when the Anti-lock features is

being used.

When the Anti-lock feature is being used, the brake pedal

may rise even as the brakes are being applied. This is

also normal. Maintaining a constant force on the pedal

will provide the shortest stopping distance.

Brake Pedal Travel

Vehicles equipped with the Anti-lock Brake System may

be stopped by applying normal force to the brake pedal.

Although there is no need to push the pedal beyond the

point where it stops or holds the vehicle, by applying more

force the pedal will continue to travel toward the floor.

This extra brake pedal travel is normal.

Acronyms and Abbreviations

Several acronyms and abbreviations are commonly used

throughout this section:

ABS

Anti-lock Brake System

CKT

Circuit

DLC

Data Link Connector

EHCU

Electronic Hydraulic Control Unit

FL

Front Left

Page 821 of 6000

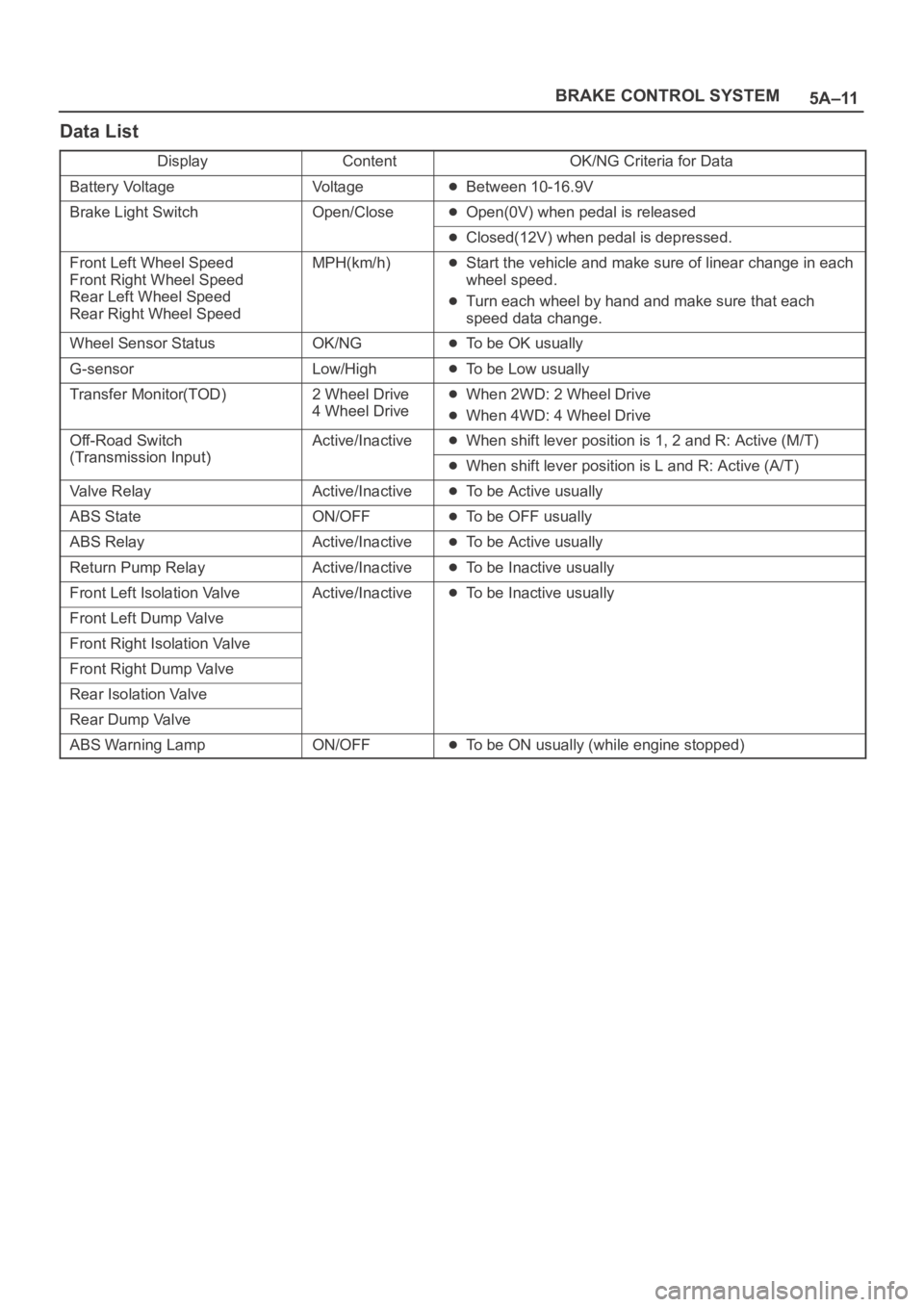

5A–11 BRAKE CONTROL SYSTEM

Data List

DisplayContentOK/NG Criteria for Data

Battery VoltageVo l t a g eBetween 10-16.9V

Brake Light SwitchOpen/CloseOpen(0V) when pedal is released

Closed(12V) when pedal is depressed.

Front Left Wheel Speed

Front Right Wheel Speed

Rear Left Wheel Speed

Rear Right Wheel SpeedMPH(km/h)Start the vehicle and make sure of linear change in each

wheel speed.

Turn each wheel by hand and make sure that each

speed data change.

Wheel Sensor StatusOK/NGTo be OK usually

G-sensorLow/HighTo be Low usually

Transfer Monitor(TOD)2 Wheel Drive

4 Wheel DriveWhen 2WD: 2 Wheel Drive

When 4WD: 4 Wheel Drive

Off-Road Switch

(Transmission Input)

Active/InactiveWhen shift lever position is 1, 2 and R: Active (M/T)

(Transmission Input)When shift lever position is L and R: Active (A/T)

Valve RelayActive/InactiveTo be Active usually

ABS StateON/OFFTo be OFF usually

ABS RelayActive/InactiveTo be Active usually

Return Pump RelayActive/InactiveTo be Inactive usually

Front Left Isolation ValveActive/InactiveTo be Inactive usually

Front Left Dump Valve

Front Right Isolation Valve

Front Right Dump Valve

Rear Isolation Valve

Rear Dump Valve

ABS Warning LampON/OFFTo be ON usually (while engine stopped)

Page 845 of 6000

5A–35 BRAKE CONTROL SYSTEM

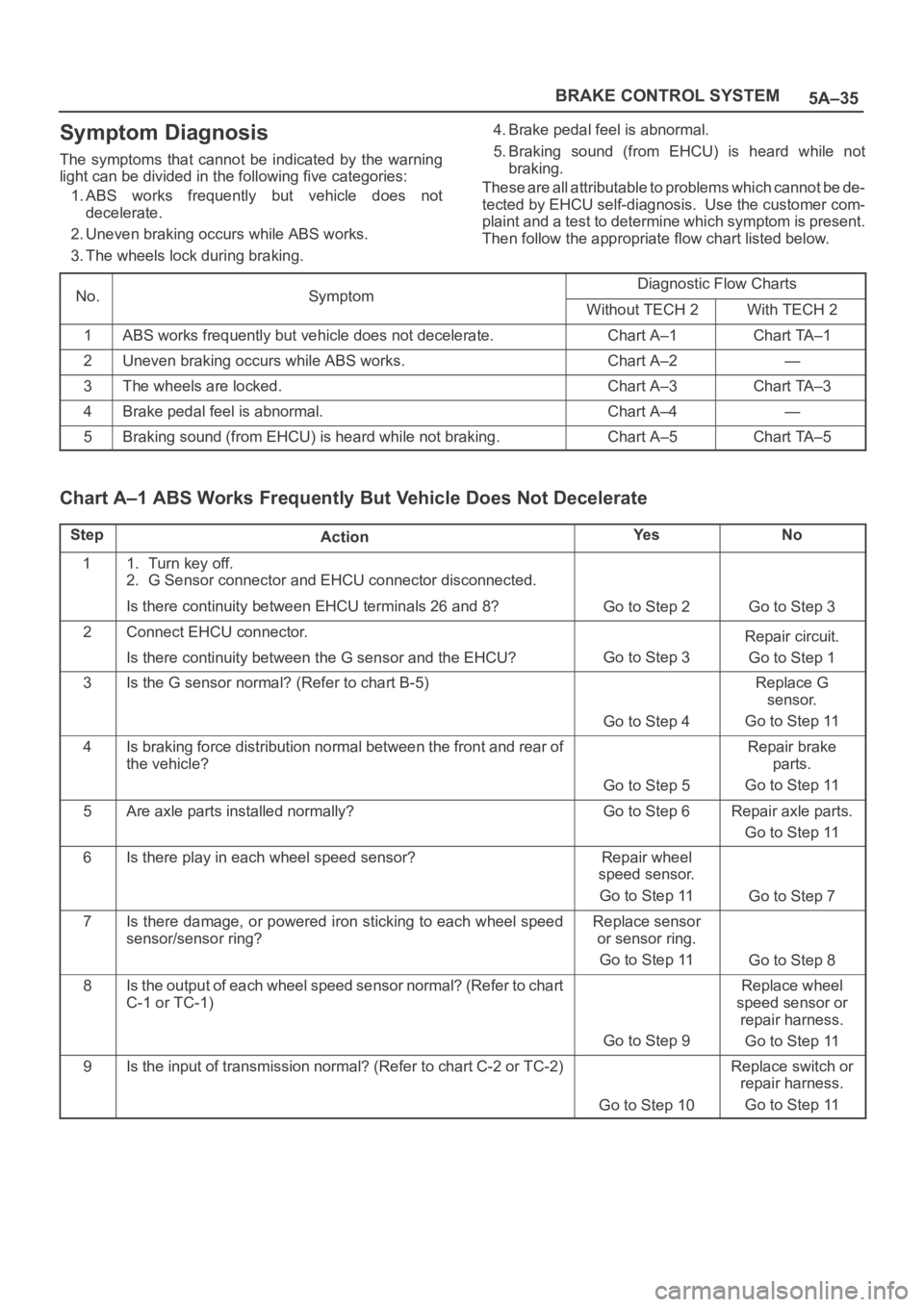

Symptom Diagnosis

The symptoms that cannot be indicated by the warning

light can be divided in the following five categories:

1. ABS works frequently but vehicle does not

decelerate.

2. Uneven braking occurs while ABS works.

3. The wheels lock during braking.4. Brake pedal feel is abnormal.

5. Braking sound (from EHCU) is heard while not

braking.

These are all attributable to problems which cannot be de-

tected by EHCU self-diagnosis. Use the customer com-

plaint and a test to determine which symptom is present.

Then follow the appropriate flow chart listed below.

NoSymptomDiagnostic Flow ChartsNo.Sym tomWithout TECH 2With TECH 2

1ABS works frequently but vehicle does not decelerate.Chart A–1Chart TA–1

2Uneven braking occurs while ABS works.Chart A–2—

3The wheels are locked.Chart A–3Chart TA–3

4Brake pedal feel is abnormal.Chart A–4—

5Braking sound (from EHCU) is heard while not braking. Chart A–5Chart TA–5

Chart A–1 ABS Works Frequently But Vehicle Does Not Decelerate

StepActionYe sNo

11. Turn key off.

2. G Sensor connector and EHCU connector disconnected.

Is there continuity between EHCU terminals 26 and 8?

Go to Step 2Go to Step 3

2Connect EHCU connector.

Is there continuity between the G sensor and the EHCU?

Go to Step 3

Repair circuit.

Go to Step 1

3Is the G sensor normal? (Refer to chart B-5)

Go to Step 4

Replace G

sensor.

Go to Step 11

4Is braking force distribution normal between the front and rear of

the vehicle?

Go to Step 5

Repair brake

parts.

Go to Step 11

5Are axle parts installed normally?Go to Step 6Repair axle parts.

Go to Step 11

6Is there play in each wheel speed sensor?Repair wheel

speed sensor.

Go to Step 11

Go to Step 7

7Is there damage, or powered iron sticking to each wheel speed

sensor/sensor ring?Replace sensor

or sensor ring.

Go to Step 11

Go to Step 8

8Is the output of each wheel speed sensor normal? (Refer to chart

C-1 or TC-1)

Go to Step 9

Replace wheel

speed sensor or

repair harness.

Go to Step 11

9Is the input of transmission normal? (Refer to chart C-2 or TC-2)

Go to Step 10

Replace switch or

repair harness.

Go to Step 11

Page 970 of 6000

6A–14

ENGINE MECHANICAL

Condition CorrectionPossible cause

Trouble in emission control systemHeated Oxygen Sensor circuit openCorrect or replace

Heated Oxygen Sensor defectiveReplace

Signal vacuum hose loosely fitted or

defectiveCorrect or replace

EGR Valve circuit open or shortedCorrect or replace

Exhaust Gas Recirculation Valve

defectiveReplace

ECT Sensor circuit open or shortedCorrect or replace

Canister Purge Valve circuit open or

shortedCorrect or replace

Canister Purge Valve defectiveReplace

ECT Sensor defectiveReplace

Positive Crankcase Ventilation

(PCV) valve and hose cloggedCorrect or replace

Evaporator systemRefer to Section 6E

Trouble in ignition system————Refer to “Engine Lacks Power”

Trouble in cylinder head partsCarbon deposits in combustion

chamberRemove carbon

Carbon deposit on valve, valve seat

and valve guideRemove carbon

Engine Oil Consumption Excessive

ConditionPossible causeCorrection

Oil leakingOil pan drain plug looseRetighten or replace gasket

Crankcase fixing bolts loosenedRetighten

Oil pan setting bolts loosenedRetighten

Oil pan gasket brokenReplace gasket

Front cover retaining bolts loose or

gasket brokenRetighten or replace gasket

Head cover fixing bolts loose or

gasket brokenRetighten or replace gasket

Oil cooler adapter crackedReplace

Oil cooler center bolt looseRetighten

Oil cooler O–ring brokenReplace

Oil cooler piping loose or brokenRetighten or replace

Oil filter adapter crackedReplace

Oil filter attaching bolt loose or rubber

gasket brokenRetighten or replace oil filter

Oil cooler brokenReplace

Crankshaft front or rear oil seal

defectiveReplace oil seal

Oil pressure unit loose or brokenRetighten or replace

Blow–by gas hose brokenReplace hose

Positive Crankcase Ventilation Valve

cloggedClean

Engine/Transmission coupling failedReplace oil seal

Page 987 of 6000

6A–31

ENGINE MECHANICAL

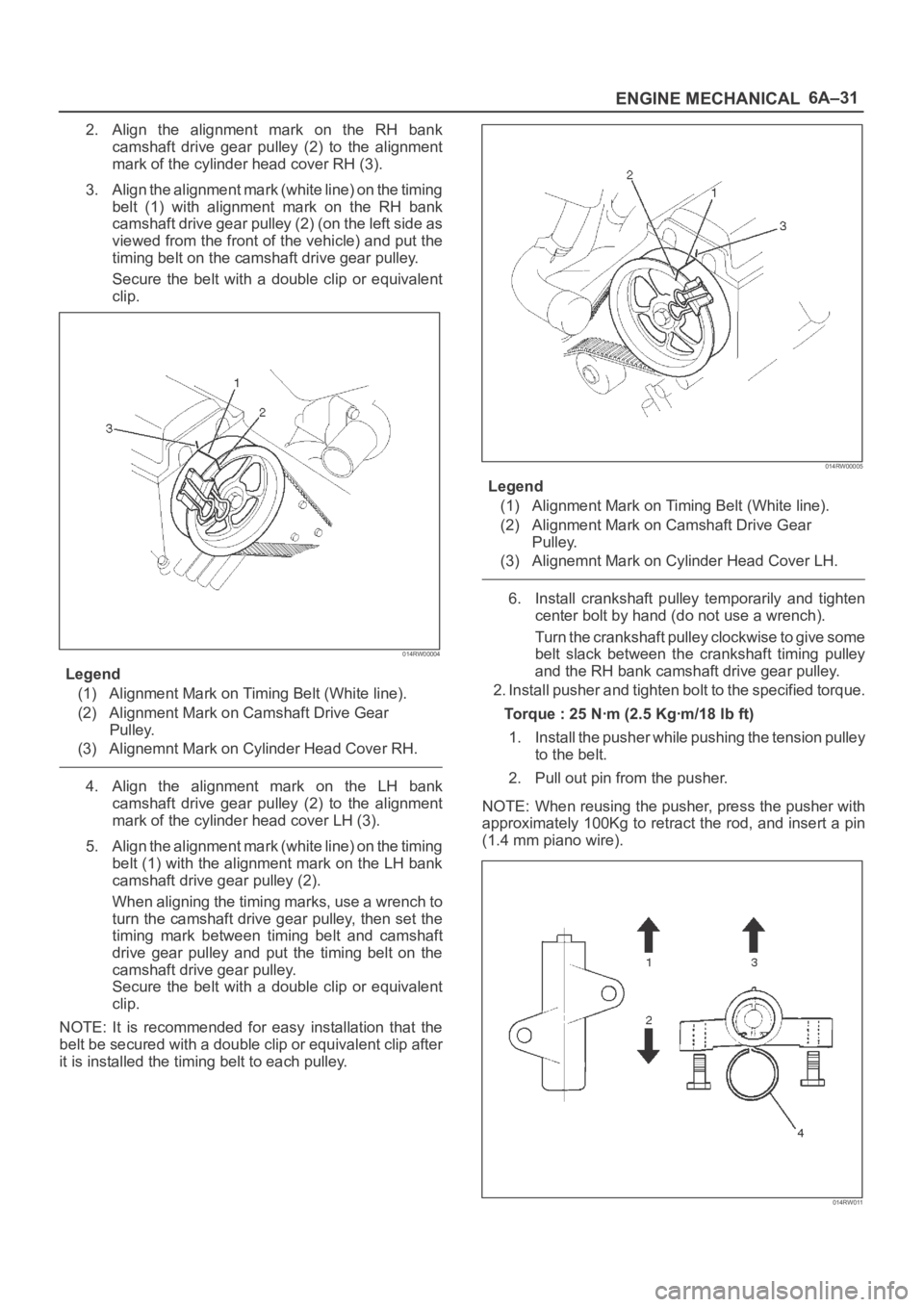

2. Align the alignment mark on the RH bank

camshaft drive gear pulley (2) to the alignment

mark of the cylinder head cover RH (3).

3. Align the alignment mark (white line) on the timing

belt (1) with alignment mark on the RH bank

camshaft drive gear pulley (2) (on the left side as

viewed from the front of the vehicle) and put the

timing belt on the camshaft drive gear pulley.

Secure the belt with a double clip or equivalent

clip.

014RW00004

Legend

(1) Alignment Mark on Timing Belt (White line).

(2) Alignment Mark on Camshaft Drive Gear

Pulley.

(3) Alignemnt Mark on Cylinder Head Cover RH.

4. Align the alignment mark on the LH bank

camshaft drive gear pulley (2) to the alignment

mark of the cylinder head cover LH (3).

5. Align the alignment mark (white line) on the timing

belt (1) with the alignment mark on the LH bank

camshaft drive gear pulley (2).

When aligning the timing marks, use a wrench to

turn the camshaft drive gear pulley, then set the

timing mark between timing belt and camshaft

drive gear pulley and put the timing belt on the

camshaft drive gear pulley.

Secure the belt with a double clip or equivalent

clip.

NOTE: It is recommended for easy installation that the

belt be secured with a double clip or equivalent clip after

it is installed the timing belt to each pulley.

014RW00005

Legend

(1) Alignment Mark on Timing Belt (White line).

(2) Alignment Mark on Camshaft Drive Gear

Pulley.

(3) Alignemnt Mark on Cylinder Head Cover LH.

6. Install crankshaft pulley temporarily and tighten

center bolt by hand (do not use a wrench).

Turn the crankshaft pulley clockwise to give some

belt slack between the crankshaft timing pulley

and the RH bank camshaft drive gear pulley.

2. Install pusher and tighten bolt to the specified torque.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

1. Install the pusher while pushing the tension pulley

to the belt.

2. Pull out pin from the pusher.

NOTE: When reusing the pusher, press the pusher with

approximately 100Kg to retract the rod, and insert a pin

(1.4 mm piano wire).

014RW011

Page 997 of 6000

6A–41

ENGINE MECHANICAL

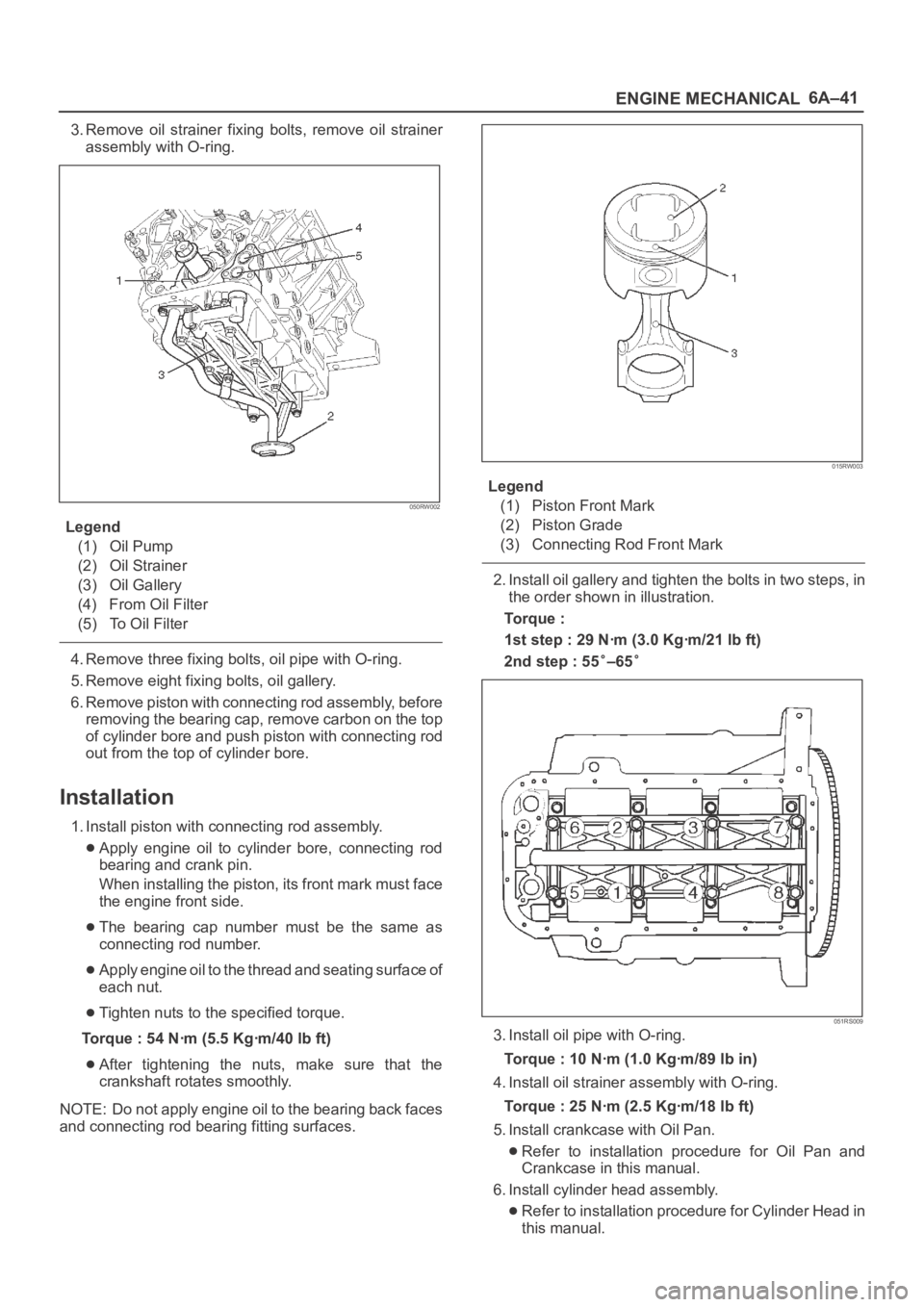

3. Remove oil strainer fixing bolts, remove oil strainer

assembly with O-ring.

050RW002

Legend

(1) Oil Pump

(2) Oil Strainer

(3) Oil Gallery

(4) From Oil Filter

(5) To Oil Filter

4. Remove three fixing bolts, oil pipe with O-ring.

5. Remove eight fixing bolts, oil gallery.

6. Remove piston with connecting rod assembly, before

removing the bearing cap, remove carbon on the top

of cylinder bore and push piston with connecting rod

out from the top of cylinder bore.

Installation

1. Install piston with connecting rod assembly.

Apply engine oil to cylinder bore, connecting rod

bearing and crank pin.

When installing the piston, its front mark must face

the engine front side.

The bearing cap number must be the same as

connecting rod number.

Apply engine oil to the thread and seating surface of

each nut.

Tighten nuts to the specified torque.

Torque : 54 Nꞏm (5.5 Kgꞏm/40 lb ft)

After tightening the nuts, make sure that the

crankshaft rotates smoothly.

NOTE: Do not apply engine oil to the bearing back faces

and connecting rod bearing fitting surfaces.

015RW003

Legend

(1) Piston Front Mark

(2) Piston Grade

(3) Connecting Rod Front Mark

2. Install oil gallery and tighten the bolts in two steps, in

the order shown in illustration.

To r q u e :

1st step : 29 Nꞏm (3.0 Kgꞏm/21 lb ft)

2nd step : 55

–65

051RS009

3. Install oil pipe with O-ring.

Torque : 10 Nꞏm (1.0 Kgꞏm/89 lb in)

4. Install oil strainer assembly with O-ring.

Torque : 25 Nꞏm (2.5 Kgꞏm/18 lb ft)

5. Install crankcase with Oil Pan.

Refer to installation procedure for Oil Pan and

Crankcase in this manual.

6. Install cylinder head assembly.

Refer to installation procedure for Cylinder Head in

this manual.

Page 999 of 6000

6A–43

ENGINE MECHANICAL

6. Remove oil pump assembly.

Refer to removal procedure for Oil Pump in this

manual.

7. Remove cylinder body side bolts.

8. Remove oil gallery.

9. Remove flywheel.

10. Remove rear oil seal retainer.

Refer to removal procedure for Rear Oil Seal in this

manual.

11. Remove connecting rod caps.

12. Remove crankshaft main bearing caps.

13. Remove crankshaft and main bearings.

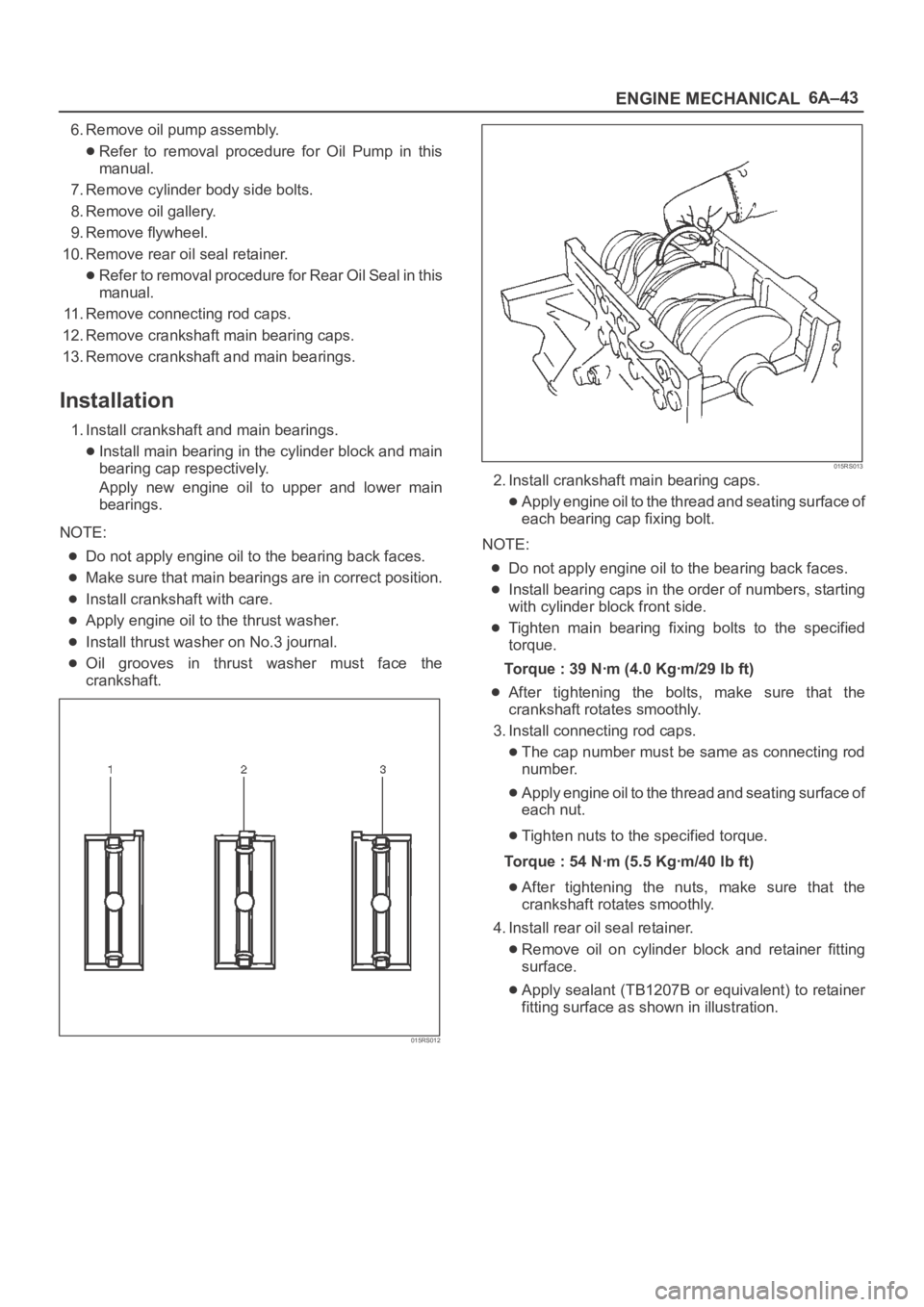

Installation

1. Install crankshaft and main bearings.

Install main bearing in the cylinder block and main

bearing cap respectively.

Apply new engine oil to upper and lower main

bearings.

NOTE:

Do not apply engine oil to the bearing back faces.

Make sure that main bearings are in correct position.

Install crankshaft with care.

Apply engine oil to the thrust washer.

Install thrust washer on No.3 journal.

Oil grooves in thrust washer must face the

crankshaft.

015RS012

015RS013

2. Install crankshaft main bearing caps.

Apply engine oil to the thread and seating surface of

each bearing cap fixing bolt.

NOTE:

Do not apply engine oil to the bearing back faces.

Install bearing caps in the order of numbers, starting

with cylinder block front side.

Tighten main bearing fixing bolts to the specified

torque.

Torque : 39 Nꞏm (4.0 Kgꞏm/29 lb ft)

After tightening the bolts, make sure that the

crankshaft rotates smoothly.

3. Install connecting rod caps.

The cap number must be same as connecting rod

number.

Apply engine oil to the thread and seating surface of

each nut.

Tighten nuts to the specified torque.

Torque : 54 Nꞏm (5.5 Kgꞏm/40 lb ft)

After tightening the nuts, make sure that the

crankshaft rotates smoothly.

4. Install rear oil seal retainer.

Remove oil on cylinder block and retainer fitting

surface.

Apply sealant (TB1207B or equivalent) to retainer

fitting surface as shown in illustration.

Page 1004 of 6000

6A–48

ENGINE MECHANICAL

Engine Assembly

Removal

035RW027

1. Disconnect battery ground and positive cable.

2. Remove battery.

3. Make alignment mark on the engine hood and hinges

before removal in order to return the hood to original

position exactly.

4. Remove engine hood.

5. Drain radiator coolant.

6. Disconnect accelerator cable and automatic cruise

control cable from throttle valve on common

chamber.

7. Disconnect air duct with air cleaner cover.

8. Remove air cleaner assembly.

9. Disconnect canister vacuum hose.

10. Disconnect vacuum booster hose.

11. Disconnect three engine harness connectors.

12. Disconnect harness connector to transmission (left

front side of engine compartment), disconnect shift

on the fly harness connector from front side of front

axle and remove transmission harness bracket from

engine left side.

13. Disconnect ground cable between engine and frame.

14. Disconnect bonding cable connector on the back of

right dash panel.

15. Disconnect bonding cable terminal on the left bank.

16. Disconnect starter harness connector from starter.

17. Disconnect generator harness connector from

generator.

18. Disconnect coolant reserve tank hose from radiator.

19. Remove radiator upper and lower hoses.

20. Remove upper fan shroud.

21. Remove cooling fan assembly four fixing nuts, then

the cooling fan assembly.

22. Move drive belt tensioner to loose side using wrench

then remove drive belt.23. Remove power steering pump fixing bolts, then

power steering pump. Place the power steering pump

along with piping on the body side.

24. Remove air conditioning compressor fixing bolts from

bracket and place the compressor along with piping

on the body side.

25. Remove O

2 sensor harness connectors from exhaust

front pipe.

26. Remove three exhaust pipe fixing nuts from each

bank.

27. Remove two exhaust pipe fixing nuts from each

exhaust pipe, then move exhaust pipe to rear side of

vehicle.

28. Remove flywheel dust covers.

29. Disconnect two heater hoses from engine.

30. Disconnect fuel hoses from right side of transmission.

CAUTION: Plug fuel pipes on engine side and fuel

hoses from fuel tank.

31. Remove transmission assembly. Refer to

Transmission section in this manual.

32. Support the engine by engine hoist.

33. Remove two left side engine mount fixing bolts from

engine mount on chassis side.

34. Remove two right side engine mount fixing bolts from

engine mount on chassis side.

35. Remove engine assembly.

Installation

CAUTION: W h e n a s s e m b l i n g t h e e n g i n e a n d

transmission, confirm that dowels have been

mounted in the specified positions at the engine

side. Take care that dowel positions are different

between the manual transmission and the automatic

transmission.

Page 1005 of 6000

6A–49

ENGINE MECHANICAL

If the engine is assembled in the condition that the

dowels have not been mounted in the specified posi-

tions, the transmission may be damaged the trans-

mission.

012RS009

1. Install engine assembly. Tighten engine mount fixing

bolts to frame to the specified torque.

Torque: 41 Nꞏm (4.2 Kgꞏm/30 lb ft)

2. Reconnect fuel hose to fuel pipe on engine.

3. Install transmission assembly. Refer to Transmission

section in this manual.

4. Reconnect two heater hoses to engine.

5. Install flywheel dust covers.

6. Install exhaust pipe and temporally tighten two (each

bank) rear exhaust flange nuts then tighten three stud

nuts (each bank) between exhaust manifold and

exhaust pipe, finally tighten rear side nuts to the

specified torque.

Torque:

Nuts: 43 Nꞏm (4.4 Kgꞏm/32 lb ft)

Stud nuts: 67 Nꞏm (6.8 Kgꞏm/49 lb ft)

150RW061

Legend

(1) Exhaust Front Pipe RH

(2) O

2 Sensor (for IGM)

150RW062

Legend

(1) Exhaust Front Pipe LH

7. Reconnect O2 sensor connector.

8. Install cooling fan assembly and tighten bolts/nuts to

the specified torque.

Torque : 22 Nꞏm (2.2 Kgꞏm/16 lb ft) for fan pulley

and fan bracket.

Torque : 10 Nꞏm (1.0 Kgꞏm/88.5 lb in) for fan and

clutch assembly.