Front ach OPEL FRONTERA 1998 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1998, Model line: FRONTERA, Model: OPEL FRONTERA 1998Pages: 6000, PDF Size: 97 MB

Page 1299 of 6000

6E–182

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0205 Injector 5 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When

the driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by the 58X

crankshaft position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0205 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0205 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0205 is the result of a

hard failure or an intermittent condition.

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 5 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.

Page 1302 of 6000

6E–185 ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0206 Injector 6 Control Circuit

D06RW034

Circuit Description

The powertrain control module (PCM) has six individual

injector driver circuits. Each controls an injector. When

the driver circuit is grounded by the PCM, the injector is

activated. The PCM monitors the current in each driver

circuit. The voltage on each driver is monitored to detect

a fault. If the voltage is not what the PCM expects to

m o n i t o r o n t h e c i r c u i t , a D T C i s s e t . T h i s D T C i s a l s o s e t i f

an injector driver is shorted to voltage or if there is an open

circuit.

Conditions for Setting the DTC

The battery voltage is more than 9 volts.

The engine is turning, determined by 58X crankshaft

position input signal.

The injector voltage does not equal the ignition voltage

when the injector is commanded “OFF” or the injector

voltage does not equal 0 volts when the injector is

commanded “ON.”

The above conditions are met for 15 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0206 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Diagnostic Aids

An injector driver circuit that is open or shorted to voltage

will cause a DTC P0206 to set. It will also cause a misfire

due to an inoperative injector. A misfire DTC will also be

set indicating which cylinder is inoperative.

Long term and short term fuel trims that are excessively

high or low are a good indication that an injector is faulty.

Use Fuel Injector Coil Test Procedure to check for faulty

injectors.

Test Description

The number(s) below refer to the step number(s) on the

Diagnostic Chart.

3. This step determines if DTC P0206 is the result of a

hard failure or an intermittent condition.

5. A special injector test connector is provided so that

the injectors can be electrically tested without

removal of the manifold. On the Trooper, the

special 7-way gray connector is located at the front

of the charcoal canister. The test connector can be

identified by the blue connector lock which is

tethered to the wiring harness. If the light for

cylinder 6 is “ON” steady before cranking the engine

as well as while cranking the engine, then the

injector driver circuit is shorted to ground.

Page 1351 of 6000

6E–234

ENGINE DRIVEABILITY AND EMISSIONS

Diagnostic Trouble Code (DTC) P0502 VSS Circuit Low Input

D06RW019

Circuit Description

The vehicle speed sensor has a magnet rotated by the

transmission output shaft. Attached to the sensor is a hall

effect circuit the interacts with the magnetic field treated

by the rotating magnet. A 12-volt operating supply for the

speed sensor hall circuit is supplied from the meter fuse.

The VSS pulses to ground the 9-volt signal sent from the

powertrain control module (PCM) on the reference circuit.

The PCM interprets vehicle speed by the number of

pulses to ground per second on the reference circuit.

Conditions for Setting the DTC

Engine is running.

Engine coolant temperature is above 60C (140F).

Engine speed is between 1800 RPM and 2500 RPM.

Throttle angle is between 10% and 40%.

Engine load is greater than 50 kPa.

MAP sensor indicates greater than 50 kPa manifold

pressure.

PCM detects no VSS signal for 12.5 seconds over a

period of 25 seconds.

Action Taken When the DTC Sets

The PCM will illuminate the malfunction indicator lamp

(MIL) the first time the fault is detected.

The PCM will store conditions which were present

when the DTC was set as Freeze Frame and in the

Failure Records data.

Conditions for Clearing the MIL/DTC

DTC P0502 can be cleared by using the Tech 2 “Clear

Info” function or by disconnecting the PCM battery

feed.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

10. To avoid backprobing the VSS and possibly

damaging a seal or terminal, the VSS output can be

tested at the point where the transmission harness

connects to the engine harness. Power and ground

are applied by jumpers to the VSS through the

connectors which are located just in front of the air

cleaner assembly. The VSS signal is monitored

with a DVM as the rear driveshaft turns. The

wheels can be turned to rotate the driveshaft, or in

2-wheels-drive vehicles the driveshaft can be turned

directly.

12. The speedometer-to-PCM VSS signal wire is

spliced to a wire leading to the cruise control

module. If a short to ground or voltage is indicated

between the PCM and speedometer, it could be on

the cruise control circuit if the vehicle is equipped

with cruise control.

Page 1353 of 6000

6E–236

ENGINE DRIVEABILITY AND EMISSIONS

DTC P0502 – VSS Circuit Low Input

StepNo Ye s Va l u e ( s ) Action

101. Ignition “OFF.”

2. Disconnect the MAF sensor and remove the air

cleaner assembly and filter element to gain access

to the 16-way black connector located immediately

to the rear of the left front headlamp. The connector

attaches the VSS wires from the transmission

harness to the left-side engine harness.

3. Disconnect the black 16-way connector.

4. Select a terminal adapter from kit J 35616 that can

be used with a jumper to supply B+ to the blue wire

with a yellow tracer (transmission side of the

connector).

5. Use another terminal adapter to attach a voltmeter

to the light-green wire with a w h i l e t r a c e r ( n e x t t o t h e

wire in the previous step.)

6. Disconnect the blue connector next to the black

16-way connector, and locate the black/red tracer

wire at one corner of the blue connector. The

black/red wire is the VSS ground. Use a terminal

adapter to attach a jumper to ground to the

black/red VSS ground wire at the transmission side

of the blue connector.

7. Raise the rear wheels off the ground with

transmission in neutral.

Does the DVM toggle back and forth between 0.6 V and

10 V as the wheels (and driveshaft) are rotated?

—Go to Step 11Go to Step 12

11Replace the VSS.

Is the action complete?

—Verify repair—

12Check for an open or short between the PCM and the

speedometer.

Was a problem found?

—Verify repairGo to Step 13

13Replace the PCM.

IMPORTANT:The replacement PCM must be

programmed. Refer to

UBS 98model year Immobilizer

Workshop Manual.

Is the action complete?—Verify repair—

Page 1417 of 6000

6E–300

ENGINE DRIVEABILITY AND EMISSIONS

4. Disconnect the red, white, and blue electrical

connectors at the PCM.

5. Remove the two screws in the front of the PCM.

6. Remove the one screw at the left rear of the PCM.

7. Pull the PCM straight out from the dashboard.

TS23757

Installation Procedure

1. Insert the PCM into the dashboard.

Line up the holes in front for the mounting screws.

2. Install the PCM with two screws in the front and one

screw at the left rear.

3. Plug the red, white, and blue connectors into the

appropriate sockets.

TS23757

EEPROM

General Description

The Electronically Erasable Programmable Read Only

Memory (EEPROM) is a permanent memory that is

physically soldered within the PCM. The EEPROM

contains program and calibration information that the

PCM needs to control powertrain operation.

EEPROM Programming

1. Step-up – Ensure that the following conditions have

been met:

The battery is fully charged.

The ignition is “ON.”

The Vehicle Interface Module cable connection at

the DLC is secure.

2. Program the PCM using the latest software matching

the vehicle. Refer to up-to-date Techline equipment

user’s instructions.

3. If the PCM fails to program, Refer to

UBS 98 model

year Immobilizer Workshop Manual.

Functional Check

1. Perform the On-Board Diagnostic System Check.

2. Start the engine and run for one minute.

3. Scan for DTCs using the Tech 2.

Power Steering Pressure (PSP)

Switch

General Description

The Power Steering Pressure (PSP) switch closes when

the hydraulic pressure reaches 3920

690 kPa (570

100 psi). This causes the PCM to actuate the idle air

control valve in order to prevent the additional load from

slowing down the engine. The switch opens when the

hydraulic pressure drops to 2970

560 kPa (430 80

psi).

Removal Procedure

1. Disconnect the PSP switch pigtail from the wiring

harness.

The pigtail is permanently attached to the switch.

Do not attempt to remove the wires from the

sensor.

Have a container ready to catch the power steering

fluid that leaks out of the line when the switch is

removed.

Page 1486 of 6000

6G–7 ENGINE LUBRICATION

Oil Pan and Crankcase

Removal

1. Disconnect battery ground cable.

2. Drain engine oil.

3. Lift vehicle by supporting the frame.

4. Remove front wheels.

5. Remove oil level dipstick from level gauge tube.

6. Remove stone guard.

7. Remove radiator under fan shroud.

8. Remove suspension cross member fixing bolts, 2 pcs

each per side and remove suspension cross member.

9. Remove pitman arm and relay lever assembly, using

the 5–8840–2005–0 remover, remove pitman arm

from the steering unit and remove four fixing bolts for

relay lever assembly.

10. Remove axle housing assembly four fixing bolts from

housing isolator side and mounting bolts from wheel

side. At this time support the axle with a garage jack

and remove axle housing assembly.

11. Remove oil pan fixing bolts.

12. Remove oil pan, using 5–8840–2153–0 sealer cutter,

remove oil pan.

013RS003

13. Remove crankcase fixing bolts.

14. Remove crankcase, using 5–8840–2153–0 sealer

cutter, remove crankcase.

NOTE: Do not deform or damage the flange of oil pan and

crankcase.

Replace the oil pan and/or crankcase if deformed or dam-

aged.

013RS003

Installation

1. Install crankcase.

1. Remove residual sealant, lubricant and moisture

from mounting surface, then dry thoroughly.

2. Properly apply a 4.5 mm (0.7 in) wide bead of

sealant (TB-1207C or equivalent) to mounting

surface of crankcase.

Sealant beat must be continuous.

The crankcase must be installed within 5

minutes after sealant application before the

sealant hardens.

013RW010

Page 1737 of 6000

6A – 4 ENGINE MECHANICAL

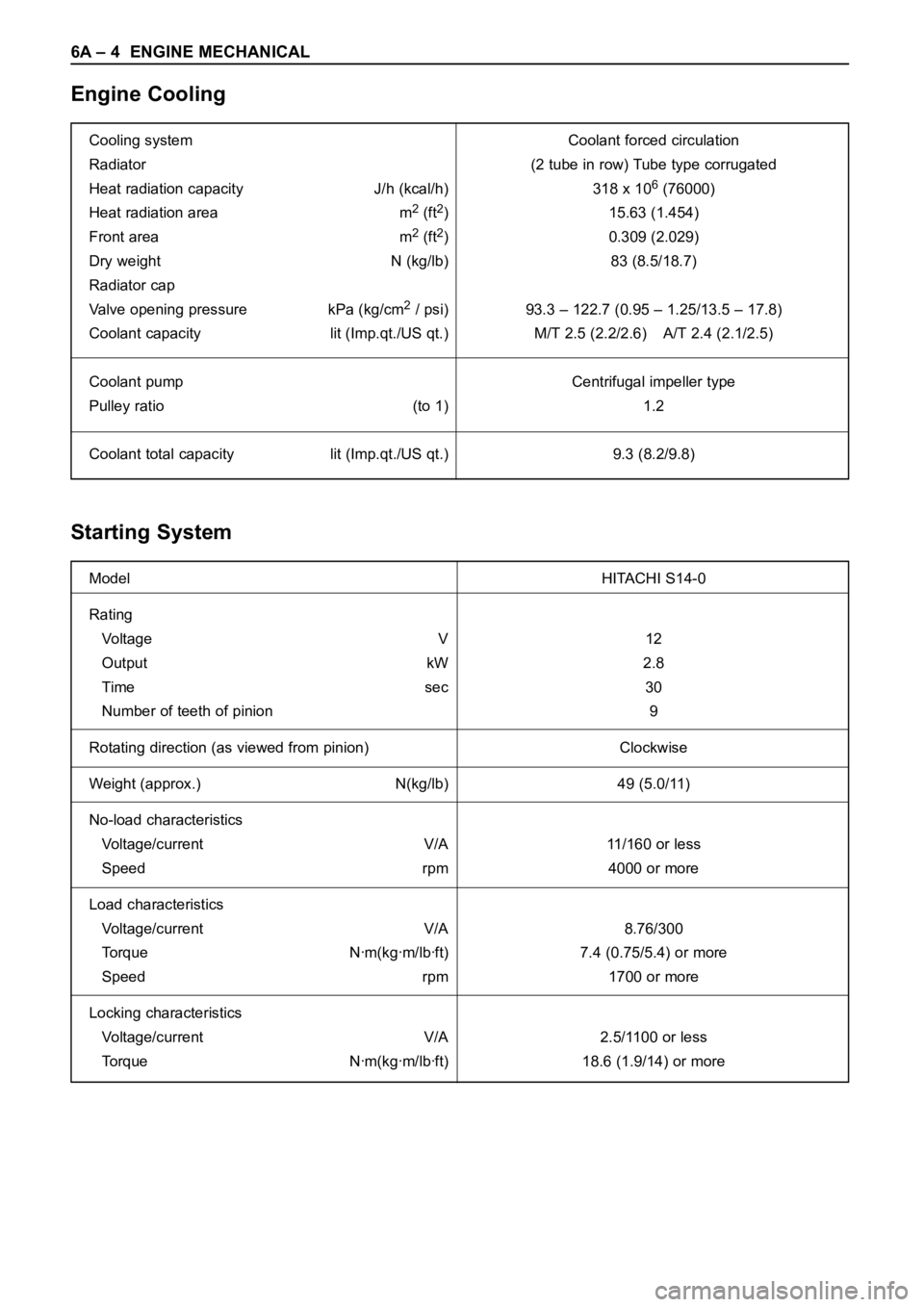

Engine Cooling

Starting System

Cooling system Coolant forced circulation

Radiator (2 tube in row) Tube type corrugated

Heat radiation capacity J/h (kcal/h) 318 x 10

6(76000)

Heat radiation area m

2(ft2) 15.63 (1.454)

Front area m

2(ft2) 0.309 (2.029)

Dry weight N (kg/lb) 83 (8.5/18.7)

Radiator cap

Valve opening pressure kPa (kg/cm

2/ psi) 93.3 – 122.7 (0.95 – 1.25/13.5 – 17.8)

Coolant capacity lit (Imp.qt./US qt.) M/T 2.5 (2.2/2.6) A/T 2.4 (2.1/2.5)

Coolant pump Centrifugal impeller type

Pulley ratio (to 1) 1.2

Coolant total capacity lit (Imp.qt./US qt.) 9.3 (8.2/9.8)

Model HITACHI S14-0

Rating

Vo l t a ge V 1 2

Output kW 2.8

Time sec 30

Number of teeth of pinion 9

Rotating direction (as viewed from pinion) Clockwise

Weight (approx.) N(kg/lb) 49 (5.0/11)

No-load characteristics

Voltage/current V/A 11/160 or less

Speed rpm 4000 or more

Load characteristics

Voltage/current V/A 8.76/300

Torque Nꞏm(kgꞏm/lbꞏft) 7.4 (0.75/5.4) or more

Speed rpm 1700 or more

Locking characteristics

Voltage/current V/A 2.5/1100 or less

Torque Nꞏm(kgꞏm/lbꞏft) 18.6 (1.9/14) or more

Page 1778 of 6000

ENGINE MECHANICAL 6A – 45

Cylinder head gasket and piston projection mm

CAUTION:

The projection of each piston should be 0.333

mm or more and less than 0.483 mm.

Maximum difference in projection between

pistons should be less than 0.1 mm.

If the piston projection is without standard,

reassemble the engine all over again.

3. Install cylinder head assembly, tighten bolts by

angular tightening method.

To r q u e :

1st step; 49 Nꞏm (4.9 kgꞏm/35.4 lb ft)

2nd step; 60°

3rd step; 60°

CAUTION: The cylinder head bolts cannot be

reused.

4. Install camshaft carrier assembly.

Refer to “Camshaft” in this manual.

5. Install oil rail and injector assembly.

Refer to “Oil rail and injector” in this manual.

6. Install injector harness to connect harness

connector.

Note: Apply liquid gasket (TB 1207B or equivalent) to

the rubber seal of the camshaft end, injector harness

gasket area and No. 1 camshaft bracket. Refer to the

Cylinder head cover.

7. Install cylinder head cover.

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft)

8. Install glow plug to tighten specified torque.

Torque: 15 Nꞏm (1.5 kgꞏm/11 lb ft) and connectglow plug harness.

9. Install intake manifold.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

10. Install fuel return pipe.

11. Install fuel pipe in between fuel pump and intake

manifold.

12. Install water pipe in between cylinder head and

water pump.

Tighten flange bolt to the specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

13. Install front plate.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

14. Install camshaft pulley, tighten with angular

tightening method.

1st step 40 Nꞏm (4.0 kgꞏm/29 lb ft)

2nd step 60°

NOTE: Apply engine oil to camshaft pulley bolt.

15. Align timing mark oil pump pulley and camshaft

pulley to front plate then put the timing belt and

tighten tensioner bolt.

Torque: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft) for M8

50 Nꞏm (5.1 kgꞏm/37 lb ft)

16. Install CMP sensor bracket.

17. Install timing belt cover.

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft)

18. Fill with about 300 cc of engine oil from the high

pressure oil pipe installing port of oil rail using an oil

filler.

If assembled without filling the oil rail with oil, the

time for engine start will be longer.

19. Immediately install high pressure oil pipe to tighten

with specified torque.

Torque: 80 Nꞏm (8 kgꞏm/57.9 lb ft)

20. Install cylinder head noise insulator cover.

Torque: 9 Nꞏm (0.9 kgꞏm/6.5 lb ft)

Grade A Grade B Grade C

011RW042

Grade Piston projectionGasket

thickness

A more 0.333 to less 0.383 1.35

B more 0.383 to less 0.433 1.40

C more 0.433 to less 0.483 1.45

Page 1791 of 6000

6A – 58 ENGINE MECHANICAL

14. Camshaft pulley

1) Align TDC mark with crankshaft pulley and gear

case cover.

2) Set camshaft stopper on the end of intake and

exhaust camshaft.

Camshaft Stopper: 5-8840-2592-0

3) Install key to camshaft and install camshaft

pulley.

4) Apply engine oil to camshaft pulley fixing bolt

and tighten bolt with angular tightening method.

First step: 40 Nꞏm (4.0 kgꞏm / 29 lb ft)

Second step: 60° to 90°

15. Timing belt

1) Install tensioner and tighten the bolt temporarily.

2) Align timing mark with camshaft pulley timing

mark and timing gear case timing mark.

3) Set No.1 cylinder TDC position.4) Install the timing belt in the following order

camshaft pulley, oil pump pulley, tensioner.

NOTE:

1) It is recommended for easy installation that the belt

be secured with a double clip after it is installed to

each pulley.

2) The “ISUZU” mark should be read from the front of

the engine when installing the timing belt.

5) Install the belt tensioner.

6) Conform not phase difference each pulley.

7) Tension the timing belt with two turns of the

crankshaft.

8) Tighten the tensioner bolt in order A to B to the

specified torque.

Torque: Bolt A 5 Nꞏm (0.5 kgꞏm/3.6 lb ft)

Bolt B 2 Nꞏm (0.2 kgꞏm/1.4 lb ft)

Legend

(1) Align Mark

(2) Camshaft Pulley

(3) Timing Belt

(4) Oil Pump Pulley

(5) Bolt B

(6) Tensioner Assy

(7) Tensioner Bolt A

(8) Tensioner Spring

16. CMP sensor bracket

1) Install CMP sensor bracket and tighten bolt to

the specified torque.

Torque: 20 Nꞏm (2.0 kgꞏm / 14.5 lb ft)

17. Timing belt cover

1) Install timing belt cover and tighten bolt to the

specified torque.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

2) Tighten CMP sensor to the specified torque.

Torque: 9 Nꞏm (0.9 kgꞏm / 6.5 lb ft)

012RW036

012RW099

1

2

3

8

67

4 5

F06RW055

Page 1813 of 6000

6A – 80 ENGINE MECHANICAL

3. Piston and Connecting Rod Assembly

1) Apply engine oil to the cylinder bores, the

connecting rod bearings and the crankshaft pins

and each piston ring and piston.

2) Align the front mark (2) of piston and front mark

(3) of connecting rod then assemble them.

3) The N mark of the piston ring is faced toward the

top, check to see that the piston ring end gap is

correctly positioned.

Legend

(1) 1st piston ring end gap

(2) 2nd piston ring end gap

(3) Oil ring end gap4) Insert the piston/connecting rod assemblies into

each cylinder with the piston ring compressor.

The front marks must be facing the front of the

engine.

Piston Ring Compressor: 5-8840-9018-0

5) Match the numbered caps with the numbers on

the connecting rods. Align the punched marks

on the connecting rods and caps.

6) Apply engine oil to the threads and seating faces

of the nuts.

7) Tighten the cap nuts in 2 steps, using angular

tightening method as shown in the following

specifications.

1st step: 29 Nꞏm (3.0 kgꞏm/22 lb ft)

2nd step: 45°– 60°

After tightening the cap nuts, check to see that

the crankshaft rotates smoothly

4. Piston Cooling Oil Pipe

If the piston cooling oil pipe is forcibly assembled,

the end of the oil jet may bend. It could make it

impossible to supply oil to the piston cooling holes,

which will sometimes cause piston seizure.

Sufficient care should be taken to pipe assembly

work.

1) Tighten the bolt and oil jet plug to the specified

torque.

Torque:

M6: 8 Nꞏm (0.8 kgꞏm/6 lb ft)

M8: 20 Nꞏm (2.0 kgꞏm/14.5 lb ft)

Oiling Jet Plug: 30 Nꞏm (3.1 kgꞏm/22 lb ft)

5. Crank case

1) Refer to “Crank case” in this manual.

6. Apply liquid gasket (TB-1207C or equivalent) to

retainer then install it to rear end of cylinder block

within 5 minutes.

7. Crankshaft Rear Oil Seal

1) Tighten the adapter to the crankshaft rear and

section with 2 bolts.

2) Insert the oil seal into the peripheral section of

the adapter.

3) Insert the sleeve into the adapter and tighten it

with a bolt (M12 x 1.75L = 70) until the adapter

hits the sleeve.

4) Remove the adapter and the sleeve.

5) Check the dimension of the oil seal setting from

rear end of crankshaft.

Standard Dimension = 12.5 ± 0.3 mm

Oil Seal Installer: 5-8840-2359-0

2

3

1

015RW051

3

1

2

015RW083