light OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 555 of 625

98-46 1973 OPEL SERVICE MANUAL

shut off vacuum pump. Open refrigerant control

valve and allow some refrigerant to enter system.

Locate and repair all leaks.

7. After evacuating for 15 minutes, add l/2 lb. of

refrigerant to system. Purge this

l/2 lb. and reevacu-

ate for 15 minutes. This second evacuation is to be

certain that as much contamination is removed from

the system as possible.

8. Only after evacuating as above, system is ready

for charging. Note reading on sight glass of charging

cylinder. If it does not contain a sufficient amount

for a full charge, till to proper level.

9. Close low pressure valve on charging station.

Fully open station refrigerant control valve and al-

low all liquid refrigerant to enter system. When full

charge of refrigerant has entered system, turn off

refrigerant control valve and close both hand shut-

off valves.

10. If full charge of refrigerant will not enter system,

close high pressure control and refrigerant control

valves. Start engine and run at low idle with com-

pressor operating. Crack refrigerant control valve

and low pressure control on station. Watch low side

gauge and keep gauge below 50 psi by regulating

refrigerant control valve. Closing valve will lower

pressure. This is to prevent liquid refrigerant from

reaching the compressor while the compressor is op-

erating. When required charge has entered system,

close refrigerant control valve and close low pressure

control.

11. System is now charged and should be perform-

ance- tested before removing gauges.

Adding Refrigerant

The following procedure should be used in adding

small amounts of refrigerant that may have been lost

by leaks or while opening system for servicing the

compressor. Before adding refrigerent to replace that

lost by leaks, check for evidence of oil loss and add

oil if necessary.

This procedure will only apply if the air inlet temper-

ature is above 70 degrees F. at the condenser.

1. Remove caps from compressor gauge fittings.

Attach gauge set to gauge fittings, making sure

adapter (J- 5420) is between low pressure gauge hose

and suction gauge fitting, and J-9459 is between high

pressure gauge hose and discharge gauge fitting.

2. Start engine, turn air conditioning temperature

control knob to full cold position, blower switch to

Max Hi. Operate for ten

(IO) minutes at 2000 RPM

to stabilize system.

3. Observe the refrigerant through the sight glasscover of receiver-dehydrator with the system operat-

ing,

IO see if there are any bubbles evident.

a. If no bubbles are evident, then bleed system slowly

through the discharge valve until bubbles appear in

the receiver-dehydrator. Add 1 lb. of refrigerant as

explained under “Charging the

ISystem”.b. If bubbles are visible in the receiver-dehydrator

with the temperature control krlob in the full cold

position and the blower at MAX speed, it indicates

a partial or complete plug in a line, a shortage of

refrigerant, or both. Correct condition. Add refriger-

ant

u~ntil the sight glass clears, then add another 1 lb.

of refrigerant.

4. Attach flexible hose from center fitting of gauge

set loosely to refrigerant drum or on disposable can

valvxs. Open high and low pressure valves on the

gauge set slightly to purge pressure gauge lines of air.

Tighten fitting of refrigerant drum or can when satis-

fied ihat all air has been removed from gauge lines.

Close (clockwise) both hand shut-off valves or gauge

set.5. Partially charge system.

REFRIGERANT DRUM METHOD:

A. Place pail containing hot water that does not have

a temperature exceeding 125 degrees F. on scales,

place refrigerant drum in pa” containing water, note

weig,ht and only open low pressure valve on gauge

set.B. Start engine, turn temperature control knob to full

cold position and place blower switch in Max Hi.

Operate engine for 10 minutes at 2000 RPM to sta-

bilize system.

C. With compressor operating, slowly open valve on

refrigerant drum and allow refrigerant to flow into

system (through manifold gauge set) until liquid in-

dicator clears up and immediately shut off valve ai

gauge set or on refrigerant drum. Check weight of

refrigerant drum and pail of water. Then slowly open

valve on gauge set (or refrigerant drum) and add one

more lb. of refrigerant. Note total amount of refriger-

ant added.

DISPOSABLE CAN METHOD:

A. Make sure the outlet valve on the J-6271 valve is

fully clockwise and attach the J-6271 to a 1 lb. can

of refrigerant by backing off the valve from the top

of the retainer, slipping the valve onto the can and

turning the valve into the retainer until tight. DO

NOT accidentally open outlet valve during this oper-

ation, as turning the valve into the retainer punctures

the top of the can to make it ready for charging.

.

Page 563 of 625

96-54 1973 OPEL SERVICE MANUAL

valve. The filter screen at the inlet port may be re-

placed. Remove screen by threading a lo-32 NF

screw into old filter screen. With a washer and a nut

on the screw arranged to work as a puller screw, hold

the body of the screw and turn the nut. Insert the

new filter screen into the inlet port and lightly tap

screen only enough to seat.

1. Install expansion valve using new o-rings during

installation. Lubricate o-rings prior to installation

using No. 525 viscosity oil.

2. Install evaporator assembly and case attaching

screws. See Figure 9B-70.3. Install blower motor assembly into case and se-

cure with attaching screws. See Figure

9B-69.4. Install finger guard shields and fan housing case.

See Figure

9B-69.5. Install resistor assembly and electrical connector.

Install blower motor connector. See Figure

9B-69.6. Install assembly into car carefully guiding

evaporator pipes up through cowl opening. See Fig-

ure

9B-71.Figure 93-7 1 Inlet and Outlet Pipes and O-Rings

-Opel 1900 Manta

7. Install two (2) upper attaching evaporator at-

taching nuts. See Figures 9B-66 and

9B-67.8. Install two (2) attaching case mounting bracket

to instrument panel screws. See Figure

9B-67.9. Connect two (2) drain hoses underneath evapora-

tor.10. Install evaporator inlet and outlet pipes retainer

and rubber grommet. See Figure

9B-65.11. Connect vacuum cut-off switch and electrical

wiring, making sure the delay restrictor and checkvalve hoses are installed correctly. See Figures

9B-63and 64.

.gB-72 Delay Restrictor and Check Valve Hose.Assembly

12. Install refrigerant hoses and pipes using new

o-rings on line fittings and evacuate system. Refer to

EVACUATING SYSTEM.

13. While system is being evacuated, install in-line

fuse and left side of distributor duct. See Figure 9B-

61.14. Install glove box.

15. Install negative battery cable and charge system.

Refer to CHARGING SYSTEM.

REMOVAL AND INSTALLATION OF CONDENSER

ASSEMBLY -OPEL 1900. MANTA

Removal

1. Remove negative battery cable from battery.

2. Remove air cleaner.

3. Discharge system. Refer to DISCHARGING

SYSTEM.

4. While system is discharging, remove lower radia-

tor hose from radiator and drain coolant into a suita-

ble container.

5. Remove fan shroud.

6. On vehicles with automatic transmission, un-

screw oil lines from connectors on lower radiator

tank and plug lines. It is essential that no dirt enters

the oil lines. When unscrewing oil lines, hold connec-

tors on lower radiator tank with pliers to avoid leak-

ages. Ensure that no dirt enters oil cooler.

7. Remove upper radiator hose from radiator.

8. Remove lower attaching nut and slide radiator

upward and out of engine compartment.

9. Remove inlet and outlet hoses from condenser

Page 565 of 625

98-56 1973 OPEL SERVICE MANUAL

oil cooler lines to lower radiator tank. It is essential

that no dirt enters the oil lines. When tightening oil

lines hold connectors on lower radiator tank with

pliers to avoid leakages. Ensure that no dirt enters oil

cooler. Torque to 11-15 Ibs. ft.

7. Install fan shroud.

8. Install upper radiator hose.

9. Install lower radiator hose and add collected coo-

lant.

All Opel

1900’s and Manta’s are provided with a

radiator initial fill of an anti-freeze solution contain-

ing corrosion inhibitor. The anti-freeze has either a

glycol or glycerin base and protects the engine

against freezing, down to minus 22 degrees F. (minus

30 degrees C.). Before the start of the cold season,

coolant must be checked with a hydrometer and if

necessary, brought to the necessary specific gravity

by adding anti-freeze. Anti-freeze added, must have

a glycol or glycerin base. As the specific gravities of

all anti-freeze solutions having a glycol or glycerin

base are practically the same, the hydrometer can be

used for all these types. Because of the tolerances of

the hydrometer, or slight differences in specific

gravity, variations of plus or minus 5 degrees can be

expected. Coolant must be checked at a temperature

of plus 68 degrees F. (plus 20 degrees C.).

IO. Install negative battery cable and air cleaner.

11. Charge system. Refer to CHARGING SYS-

TEM.

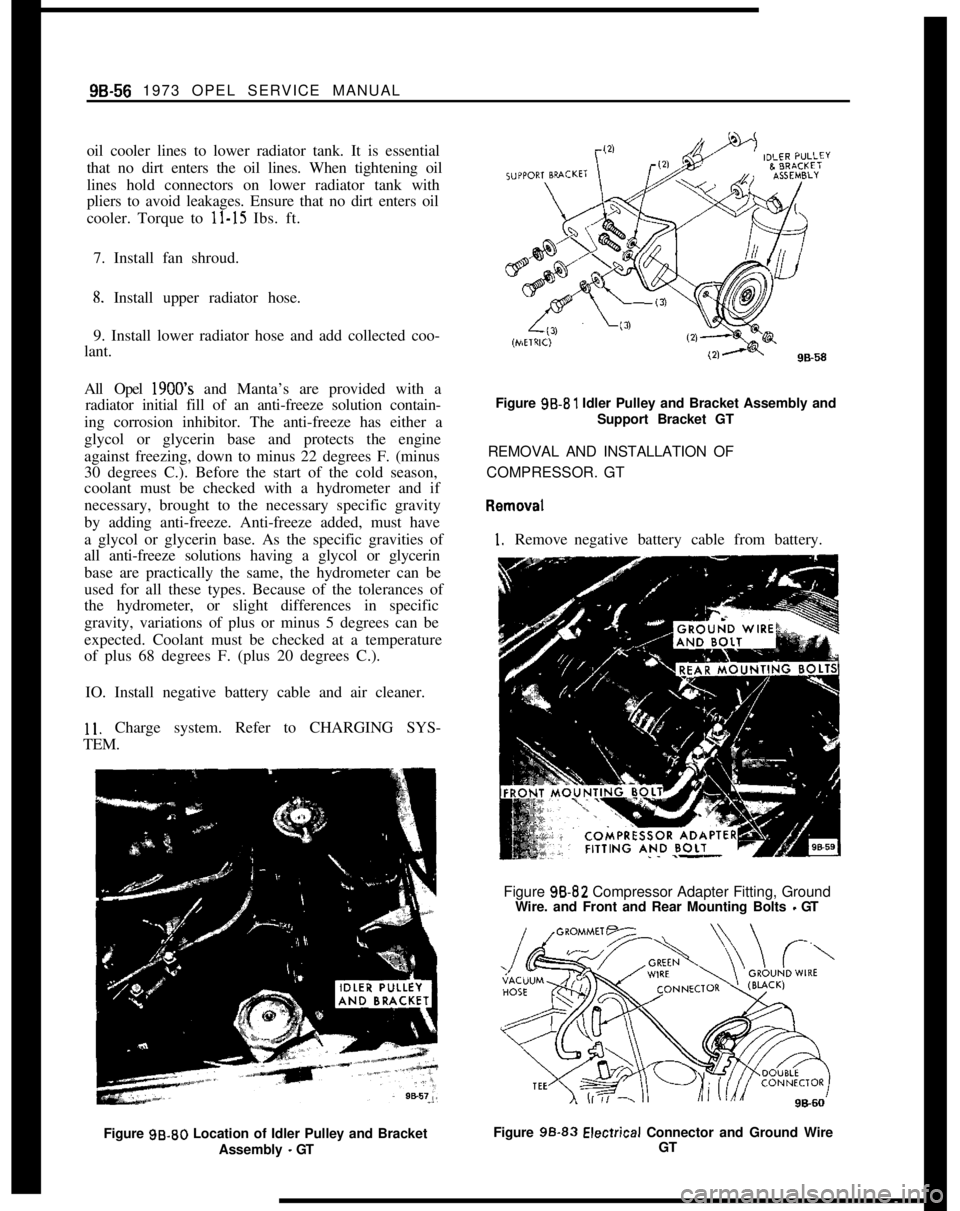

Figure 99.80 Location of Idler Pulley and Bracket

Assembly

- GTFigure 99.81 Idler Pulley and Bracket Assembly and

Support Bracket GT

REMOVAL AND INSTALLATION OF

COMPRESSOR. GT

I. Removenegative battery cable from battery.

Figure 98-82 Compressor Adapter Fitting, Ground

Wire. and Front and Rear Mounting Bolts

- GT

Figure 99.83

Elecirical Connector and Ground Wire

GT

Page 570 of 625

REFRIGERANT COMPONENTS ALL MODELS96.61

CAPILLARY T”BEFigure 98.95 Evaporator and Expansion Valve

Assembly GT

valve from refrigerant lines, and tape closed open

ends of lines and inlet and outlet ports of expansion

valve.

Installation5. Install resistor assembly.

6. Install evaporator assembly into car and install

mounting bracket. See Figure

9B-96.Figure 98.96 Evaporator and Blower Assembly

- GT

If expansion valve or refrigerant lines have been ex-

posed to

,the atmosphere for any amount of time and

moisture may have entered the valve or the system,

flush the system and install new receiver-dehydrator

or valve as necessary.7. Untape the refrigerant lines and the inlet and

outlet pipes from the evaporator and install using

new o-rings on line fittings.

Due to the possible adjustment difficulties involved

if the expansion valve is disassembled, disaisembly of

the valve is not recommended. The valve may be

cleaned by submerging it in a bath of trichlorethy-

lene, alcohol, or similar solvent. Dry by blowing iil-tered compressed air through the outlet port of the

valve. The filter screen at the inlet port may be re-

placed. Remove screen by threading a lo-32 NF

screw intp old filter screen. With a washer and a nut

on the screw arranged to work as a puller screw, hold

the body of the screw and turn the nut. Insert the

new filter screen into the inlet port and lightly tap

screen only enough to seat.

1. Install expansion valve using new o-rings during

installation. Lubricate o-rings prior to installation

using No. 525 viscosity oil.

2. Install evaporator assembly and case attaching

screws.

3. Install blower motor assembly into case and se-

cure with attaching screws.

4. Install finger guard shields and fan housing case.Figure 98-97 Refrigerant Hoses and Hose Clamps

Under Car

- GT

Page 582 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 73

F

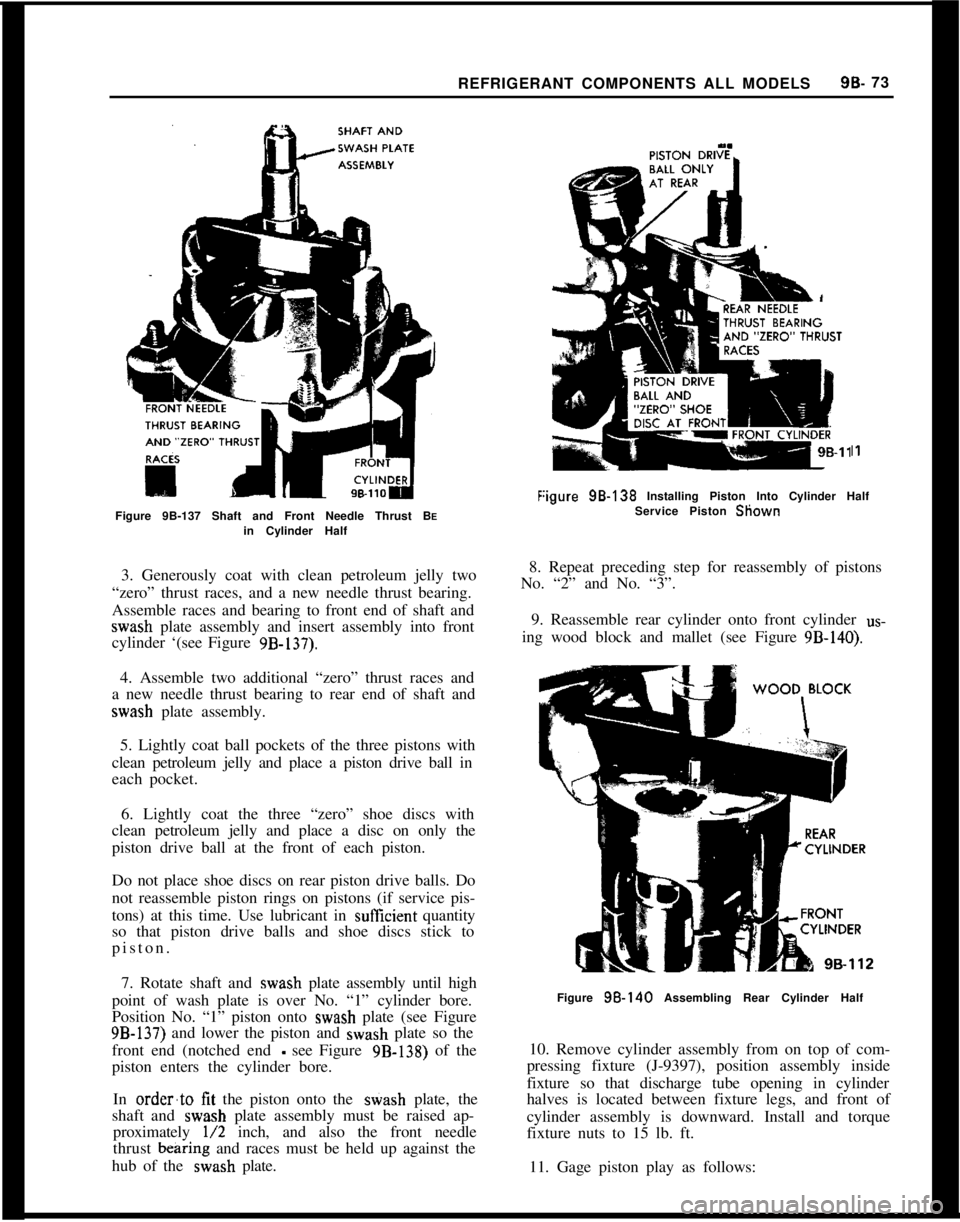

Figure 9B-137 Shaft and Front Needle Thrust BEin Cylinder Half

I1

:igure 98.138 Installing Piston Into Cylinder Half

Service Piston Sliown

3. Generously coat with clean petroleum jelly two

“zero” thrust races, and a new needle thrust bearing.

Assemble races and bearing to front end of shaft and

wash plate assembly and insert assembly into front

cylinder ‘(see Figure

9B-137).

8. Repeat preceding step for reassembly of pistons

No. “2” and No. “3”.

9. Reassemble rear cylinder onto front cylinder

us-

ing wood block and mallet (see Figure 9B-140).

4. Assemble two additional “zero” thrust races and

a new needle thrust bearing to rear end of shaft and

wash plate assembly.

5. Lightly coat ball pockets of the three pistons with

clean petroleum jelly and place a piston drive ball in

each pocket.

6. Lightly coat the three “zero” shoe discs with

clean petroleum jelly and place a disc on only the

piston drive ball at the front of each piston.

Do not place shoe discs on rear piston drive balls. Do

not reassemble piston rings on pistons (if service pis-

tons) at this time. Use lubricant in

sufEcient quantity

so that piston drive balls and shoe discs stick to

piston.

7. Rotate shaft and

wash plate assembly until high

point of wash plate is over No. “1” cylinder bore.

Position No. “1” piston onto

wash plate (see Figure

9B-137) and lower the piston and wash plate so the

front end (notched end

- see Figure 9B-138) of the

piston enters the cylinder bore.

In

order’to tit the piston onto the stiash plate, the

shaft and

wash plate assembly must be raised ap-

proximately

l/2 inch, and also the front needle

thrust

bearing and races must be held up against the

hub of the

wash plate.

Figure 98.140 Assembling Rear Cylinder Half

10. Remove cylinder assembly from on top of com-

pressing fixture (J-9397), position assembly inside

fixture so that discharge tube opening in cylinder

halves is located between fixture legs, and front of

cylinder assembly is downward. Install and torque

fixture nuts to 15 lb. ft.

11. Gage piston play as follows:

Page 585 of 625

9B-76 1973 OPEL SERVICE MANUAL

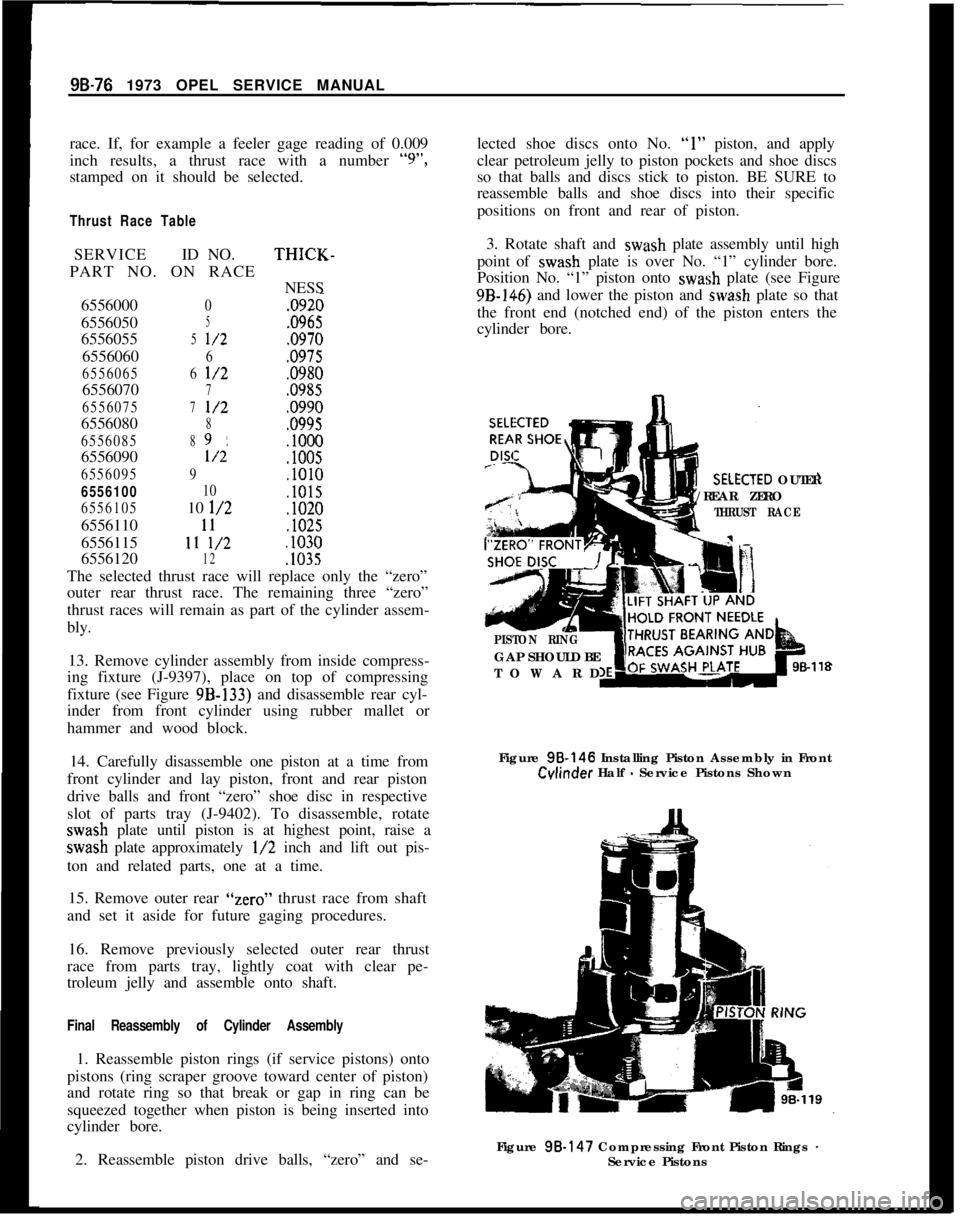

race. If, for example a feeler gage reading of 0.009

inch results, a thrust race with a number “9”,

stamped on it should be selected.Thrust Race TableSERVICEID NO.THICK-

PART NO. ON RACE

NESS

6556000

0.0920

6556050

5.09656556055

5l/2.09706556060

6.0975

65560656

l/2.09806556070

7.0985

6556075

7l/2.09906556080

8.0995

6556085

8l/2.lOOO6556090

T/2,100s

65560959.lOlO

655610010,101s

655610510 l/2.10206556110

.10256556115

11111/2.10306556120

12.1035The selected thrust race will replace only the “zero”

outer rear thrust race. The remaining three “zero”

thrust races will remain as part of the cylinder assem-

bly.

13. Remove cylinder assembly from inside compress-

ing fixture (J-9397), place on top of compressing

fixture (see Figure 9B-133) and disassemble rear cyl-

inder from front cylinder using rubber mallet or

hammer and wood block.

14. Carefully disassemble one piston at a time from

front cylinder and lay piston, front and rear piston

drive balls and front “zero” shoe disc in respective

slot of parts tray (J-9402). To disassemble, rotatewash plate until piston is at highest point, raise awash plate approximately

l/2 inch and lift out pis-

ton and related parts, one at a time.

15. Remove outer rear ‘?ero” thrust race from shaft

and set it aside for future gaging procedures.

16. Remove previously selected outer rear thrust

race from parts tray, lightly coat with clear pe-

troleum jelly and assemble onto shaft.

Final Reassembly of Cylinder Assembly1. Reassemble piston rings (if service pistons) onto

pistons (ring scraper groove toward center of piston)

and rotate ring so that break or gap in ring can be

squeezed together when piston is being inserted into

cylinder bore.

2. Reassemble piston drive balls, “zero” and se-lected shoe discs onto No. “1” piston, and apply

clear petroleum jelly to piston pockets and shoe discs

so that balls and discs stick to piston. BE SURE to

reassemble balls and shoe discs into their specific

positions on front and rear of piston.

3. Rotate shaft and wash plate assembly until high

point of wash plate is over No. “1” cylinder bore.

Position No. “1” piston onto wash plate (see Figure9B-146) and lower the piston and wash plate so that

the front end (notched end) of the piston enters the

cylinder bore.XTED OUTER

/REAR ZERO

THRUST RACE

PISTON RINGGAP SHOULD BE

TOWARD

98-118Figure 98.146 Installing Piston Assembly in Front

Cvlinder Half - Service Pistons Shown

Figure 98.147 Compressing Front Piston Rings

-Service Pistons

Page 586 of 625

REFRIGERANT COMPONENTS ALL MODELS99.77

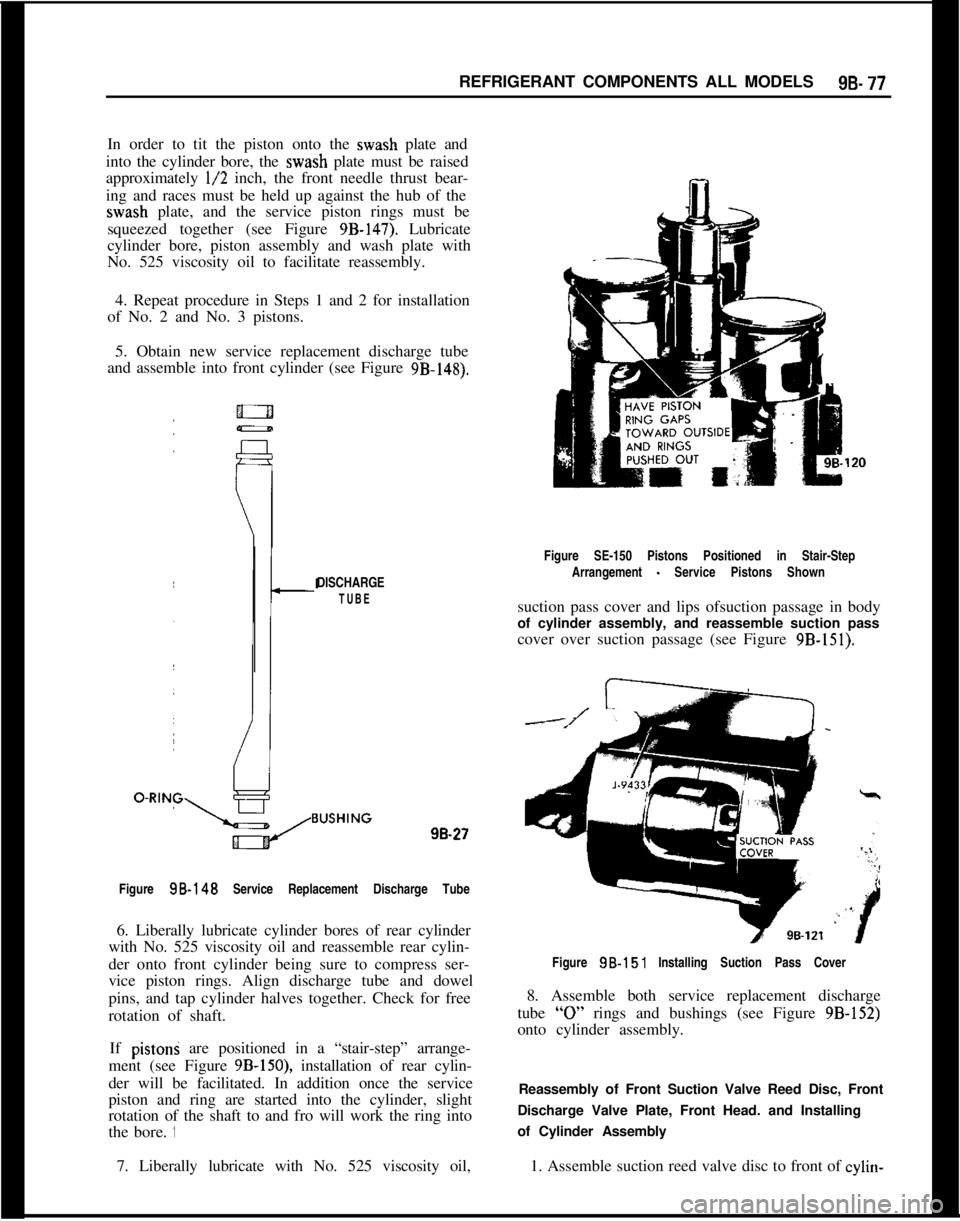

In order to tit the piston onto the wash plate and

into the cylinder bore, the wash plate must be raised

approximately l/2 inch, the front needle thrust bear-

ing and races must be held up against the hub of thewash plate, and the service piston rings must be

squeezed together (see Figure

9B-147). Lubricate

cylinder bore, piston assembly and wash plate with

No. 525 viscosity oil to facilitate reassembly.

4. Repeat procedure in Steps 1 and 2 for installation

of No. 2 and No. 3 pistons.

5. Obtain new service replacement discharge tube

and assemble into front cylinder (see Figure

9B-148).Figure SE-150 Pistons Positioned in Stair-Step

DISCHARGE

TUBEArrangement

- Service Pistons Shown

suction pass cover and lips ofsuction passage in body

of cylinder assembly, and reassemble suction pass

cover over suction passage (see Figure

9B-151).98.27

Figure

SB-148 Service Replacement Discharge Tube

6. Liberally lubricate cylinder bores of rear cylinder

with No. 525 viscosity oil and reassemble rear cylin-

der onto front cylinder being sure to compress ser-

vice piston rings. Align discharge tube and dowel

pins, and tap cylinder halves together. Check for free

rotation of shaft.

If pistoni are positioned in a “stair-step” arrange-

ment (see Figure

9B-150), installation of rear cylin-

der will be facilitated. In addition once the service

piston and ring are started into the cylinder, slight

rotation of the shaft to and fro will work the ring into

the bore. ‘IFigure

98.151 Installing Suction Pass Cover

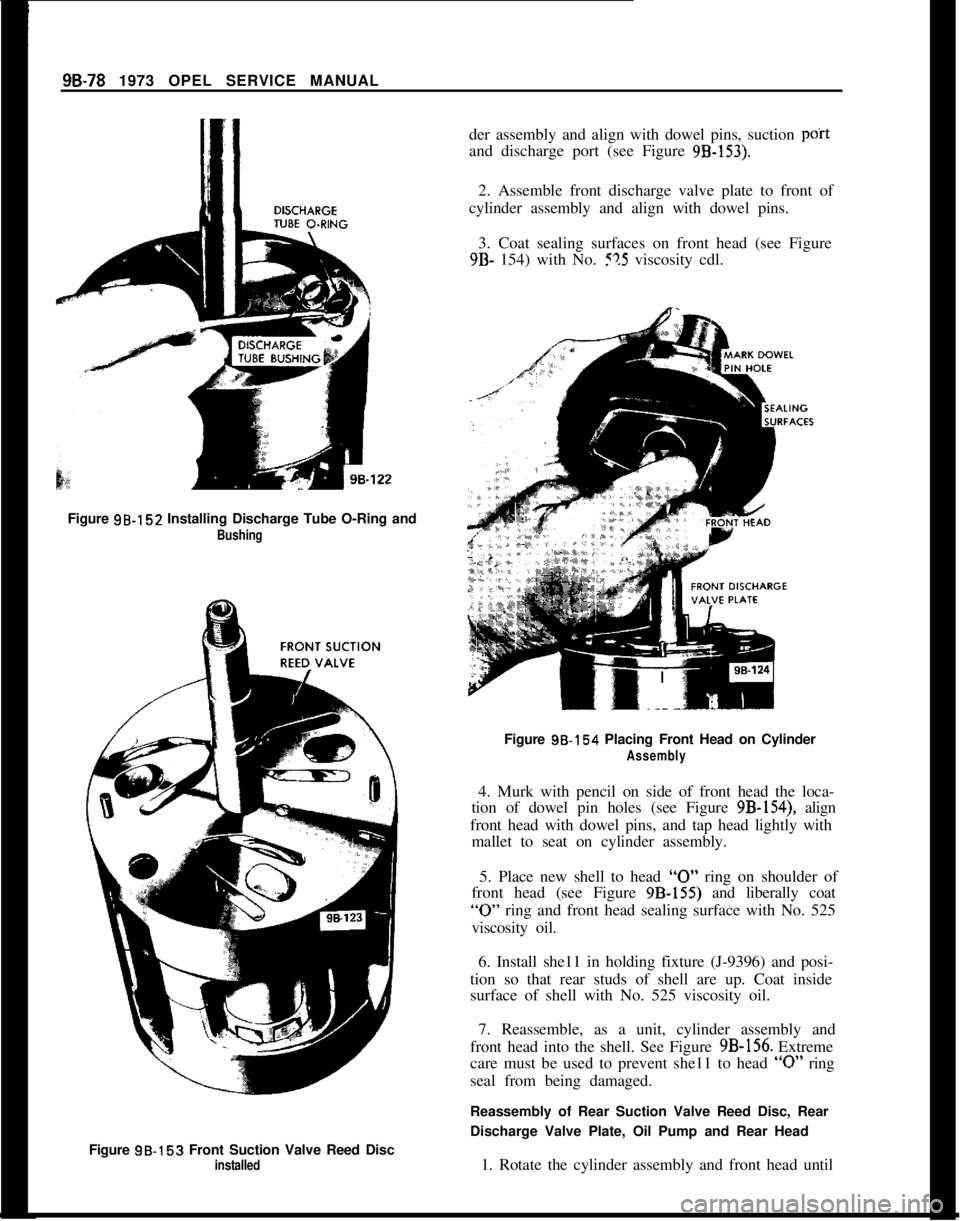

8. Assemble both service replacement discharge

tube

“0” rings and bushings (see Figure 9B-152)

onto cylinder assembly.

Reassembly of Front Suction Valve Reed Disc, Front

Discharge Valve Plate, Front Head. and Installing

of Cylinder Assembly

7. Liberally lubricate with No. 525 viscosity oil,1. Assemble suction reed valve disc to front of cylin-

Page 587 of 625

98-78 1973 OPEL SERVICE MANUAL

der assembly and align with dowel pins, suction poitand discharge port (see Figure

9B-153).2. Assemble front discharge valve plate to front of

cylinder assembly and align with dowel pins.

3. Coat sealing surfaces on front head (see Figure9B- 154) with No. !?5 viscosity cdl.

Figure 98.152 Installing Discharge Tube O-Ring and

BushingFigure 98.154 Placing Front Head on Cylinder

Assembly4. Murk with pencil on side of front head the loca-

tion of dowel pin holes (see Figure 9B-154), align

front head with dowel pins, and tap head lightly with

mallet to seat on cylinder assembly.

5. Place new shell to head

“0” ring on shoulder of

front head (see Figure 9B-155) and liberally coat

“0” ring and front head sealing surface with No. 525

viscosity oil.

6. Install she11 in holding fixture (J-9396) and posi-

tion so that rear studs of shell are up. Coat inside

surface of shell with No. 525 viscosity oil.

Figure 9B-153 Front Suction Valve Reed Disc

installed7. Reassemble, as a unit, cylinder assembly and

front head into the shell. See Figure 9B-156. Extreme

care must be used to prevent she11 to head

“0” ring

seal from being damaged.

Reassembly of Rear Suction Valve Reed Disc, Rear

Discharge Valve Plate, Oil Pump and Rear Head

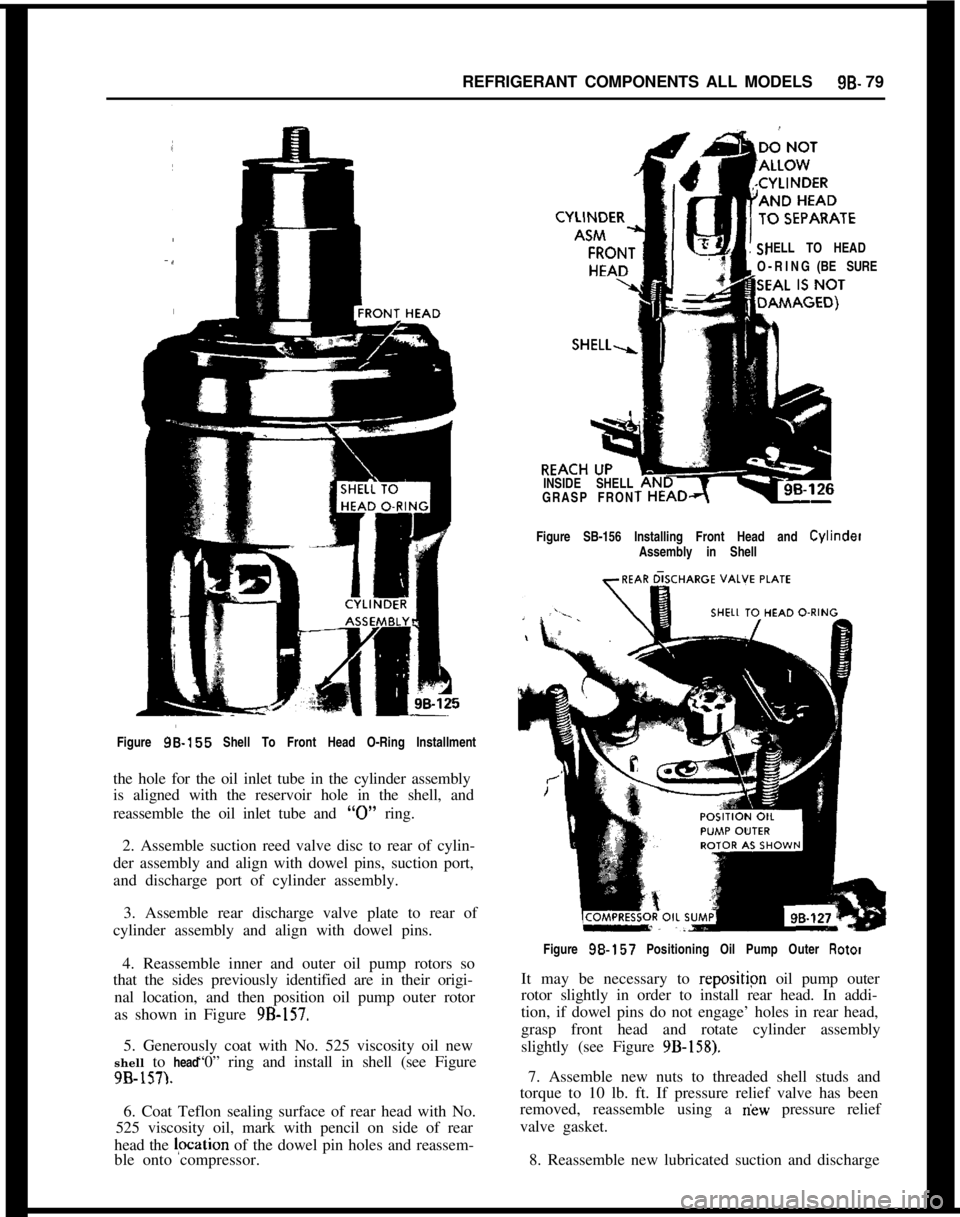

1. Rotate the cylinder assembly and front head until

Page 588 of 625

REFRIGERANT COMPONENTS ALL MODELS9B- 79

HELL TO HEAD

O-RING(BE SURE

INSIDE SHELL

GRASP FRON

Figure SB-156 Installing Front Head and Cylinder

Assembly in Shell

Figure

96-155 Shell To Front Head O-Ring Installment

the hole for the oil inlet tube in the cylinder assembly

is aligned with the reservoir hole in the shell, and

reassemble the oil inlet tube and

“0” ring.

2. Assemble suction reed valve disc to rear of cylin-

der assembly and align with dowel pins, suction port,

and discharge port of cylinder assembly.

3. Assemble rear discharge valve plate to rear of

cylinder assembly and align with dowel pins.

4. Reassemble inner and outer oil pump rotors so

that the sides previously identified are in their origi-

nal location, and then position oil pump outer rotor

as shown in Figure

9B-157.5. Generously coat with No. 525 viscosity oil new

“0” ring and install in shell (see Figure shell to head

9B-157).6. Coat Teflon sealing surface of rear head with No.

525 viscosity oil, mark with pencil on side of rear

head the lpcation of the dowel pin holes and reassem-

ble onto compressor.Figure

98.157 Positioning Oil Pump Outer Rotor

It may be necessary to repositipn oil pump outer

rotor slightly in order to install rear head. In addi-

tion, if dowel pins do not engage’ holes in rear head,

grasp front head and rotate cylinder assembly

slightly (see Figure

9B-158).7. Assemble new nuts to threaded shell studs and

torque to 10 lb. ft. If pressure relief valve has been

removed, reassemble using a

riew pressure relief

valve gasket.

8. Reassemble new lubricated suction and discharge

Page 604 of 625

98.96 1973 OPEL SERVICE MANUALr DARK BLUE

LIGHT BLUE STRIPE

CUTOUT111111DARK GREEN DARK GREEN

,,

I

,\,\

BATTERYl LJ

\flu- +tL-2+- -7- -RESISTOR

A

EXlSilNG‘IWIRE

I

I

IFUSE BLOCK*,*,- I./SWITCH

r

ti‘WIREfIfI

1- IAAI

i$+.-lAC~,‘XESW WIRE

I I

TTEVAPO.RATOREVAPO.RATOR

BLACK WITH RED STRIPE BLACK WITH RED

Sl96-143

Figure 9B-188 Wiring Schematic‘RIPE96-143

Figure 9B-188 Wiring Schematic

SPECIFICATIONS

Blower Motor Type

......................................................................................................12 VDC

Blower Fan Type

..................................................................................................Squirrel Cage