turn signal OPEL GT-R 1973 User Guide

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 99 of 625

I i--

LI

.

lJ- 78 1873 OPEL SERVICE~MANUAL’

Figure lJ-5 Turn

Signal and Hazard Flasher - GT

Page 197 of 625

3D- 301973 OPEL SERVICE MANUALFigure 3D-8 - Removing Clamp Bolt3. Remove cotter pin located on left and right tie rod

end and unscrew nut.

4. Using Tool J-21687, press tie rod ends out of

steering arms.

5. Disconnect steering gear housing from front sus-

pension cross member and remove steering gear

together with tie rods.

Installation . GTCAUTION: Fasteners are important attaching parts in

that they could affect the performance of vital com-

ponents and systems, and/or could result in major

repair expense. They must be replaced

with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not

use a re-

placement part of lesser quality or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

1. Position steering gear on front suspension cross

member and torque attaching bolts to 18

lb.ft.2. Position tie rod ball studs in steering arms; install

nuts and torque to 29 lb.ft. Lock in position with new

cotter pins.

3. Fully turn steering wheel so that flat or cutout

surface on lower portion of steering shaft is parallel

to flexible coupling bolt hole.

4. Install the lower end of steering shaft to the flexi-

ble coupling and adjust dimension between steering

wheel hub and direction signal switch housing cover

to

l/8 and 3/32 inch. Maintain adjustment by tight-

ening flexible coupling bolt and nut to 15 lb.ft. Lock

the bolt and nut in position with lock-plate tabs.5. Reinstall stop bolt into steering column.

6. Full turn steering wheel both right and left. If any

resistance is noticeable, it will be necessary to remove

the sleering column and correct the cause.

D. Installation (Opel 1900. Manta)CAUTION: Fasteners are important attachingparts in

that they could affect the performance of vital com-

ponents and systems, and/or could result in

maJbrrepair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a re-

placement part oflesser

quaky or substitute design.

Torque values must be used as specified during reas-

sembly to assure proper retention of these parts.

1. Prior to installation, set steering gear to high

point. The steering wheel spokes point downwards in

an oblique angle. The elongated cutout of the lower

steering mast must coincide with the clamp bolt hole

of the pinion flange.

2. Position steering gear on front suspension cross

member and torque attaching bolts to 29 lb.ft.

3. Position tie rod studs in steering arms. Install nuts

and torque to 29

Ib.ft. Lock in position with new

cotter pin.

4. Install the lower end of the steering shaft to flexi-

ble coupling and torque clamp bolt to 22

lb.ft.5. Attach guard plate to both side members and

lower deflector panel.

DISASSEMBLY AND ASSEMBLY OF

STEERING GEAR ASSEMBLY WITH TIE RODS

Disassembly - GT1. Carefully clamp gear assembly in soft jaw vise and

slip clamps and rubber bellows off gear housing to

expose area where ball joint screws into rack.

2. Bend up round edges of lockplates from tie rod

ball studs and disconnect tie rod ball studs from rack.

See Figure

3D-9). It is important that rack be held

secure with open end wrench to prevent damage to

rack teeth.

3. Loosen adjusting screw lock nut; remove adjusting

screw from steering gear housing, and take out thrust

spring and sintered bronze shell. See Figure

3D-11.4. Rotate gear assembly in vise so that pinion shaft

portion of assembly is held by vise, and remove pin-

ion nut, flat washer, and special washer.

Page 203 of 625

3E- 361973 OPEL SERVICE MANUAL

and ignition switch in RUN position, the fog lights

are automatically switched off. Direction signals

work in the normal manner; pushing the lever up for

right turn signal and pulling the lever down for left

turn signal.

DESCRIPTION AND OPERATION OF HORN

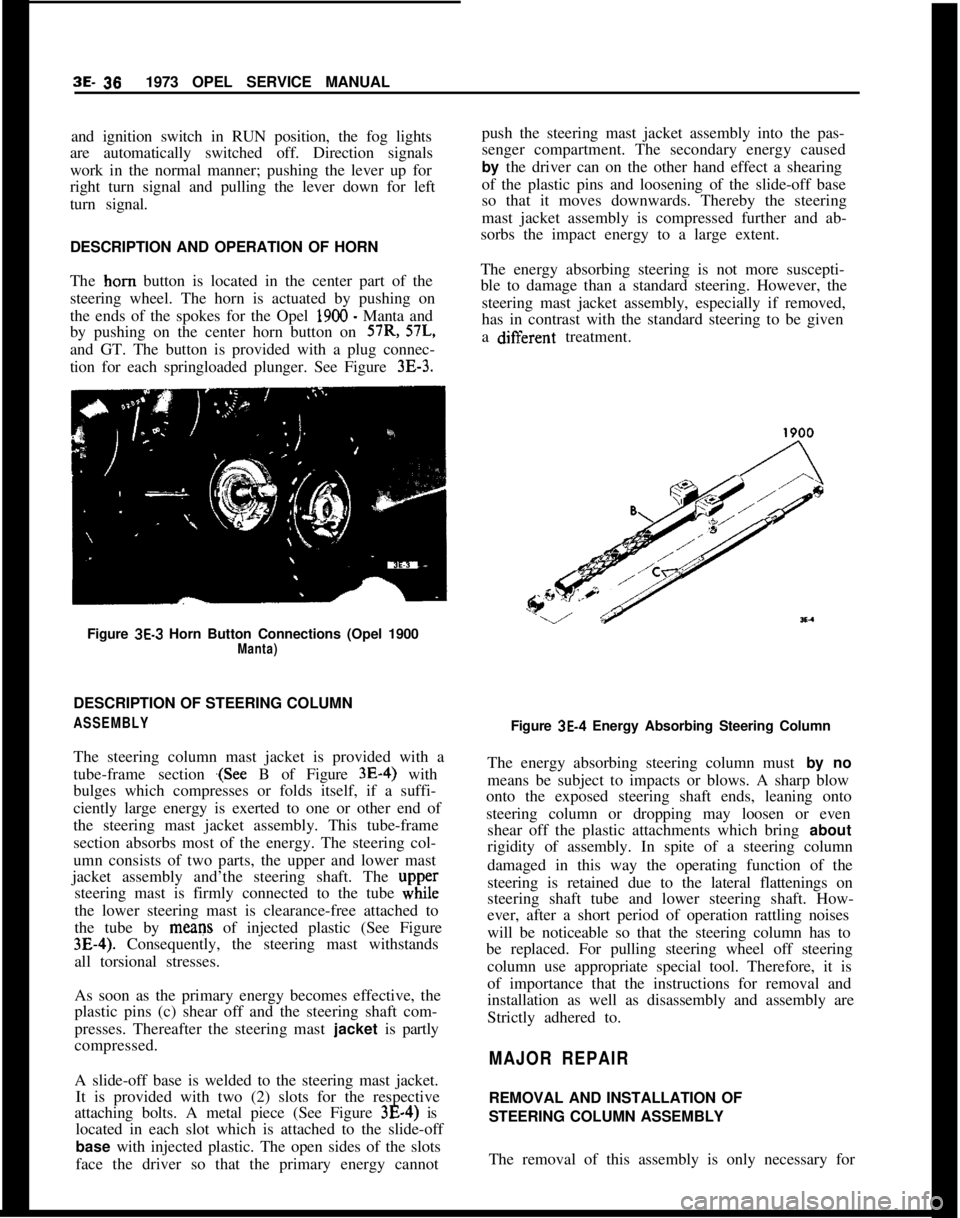

The horn button is located in the center part of the

steering wheel. The horn is actuated by pushing on

the ends of the spokes for the Opel 1900 - Manta and

by pushing on the center horn button on 57R, 57L,

and GT. The button is provided with a plug connec-

tion for each springloaded plunger. See Figure

3E-3.Figure

3E-3 Horn Button Connections (Opel 1900Manta)DESCRIPTION OF STEERING COLUMN

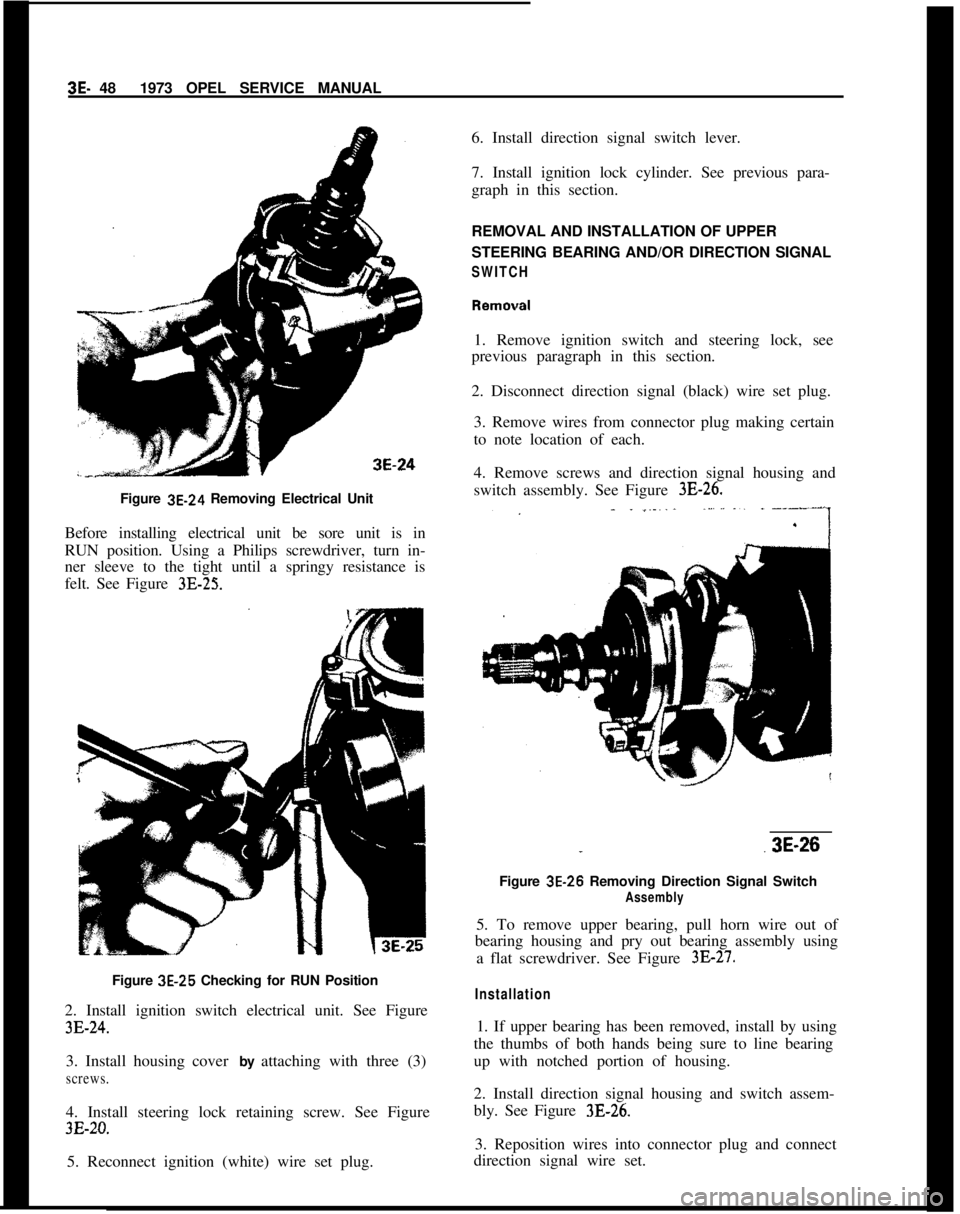

ASSEMBLYThe steering column mast jacket is provided with a

tube-frame section

.(See B of Figure 3E-4) with

bulges which compresses or folds itself, if a suffi-

ciently large energy is exerted to one or other end of

the steering mast jacket assembly. This tube-frame

section absorbs most of the energy. The steering col-

umn consists of two parts, the upper and lower mast

jacket assembly and’the steering shaft. The

upp,ersteering mast is firmly connected to the tube while

the lower steering mast is clearance-free attached to

the tube by means of injected plastic (See Figure

3E-4). Consequently, the steering mast withstands

all torsional stresses.

As soon as the primary energy becomes effective, the

plastic pins (c) shear off and the steering shaft com-

presses. Thereafter the steering mast jacket is partly

compressed.

A slide-off base is welded to the steering mast jacket.

It is provided with two (2) slots for the respective

attaching bolts. A metal piece (See Figure 3E-4) is

located in each slot which is attached to the slide-off

base with injected plastic. The open sides of the slots

face the driver so that the primary energy cannotpush the steering mast jacket assembly into the pas-

senger compartment. The secondary energy caused

by the driver can on the other hand effect a shearing

of the plastic pins and loosening of the slide-off base

so that it moves downwards. Thereby the steering

mast jacket assembly is compressed further and ab-

sorbs the impact energy to a large extent.

The energy absorbing steering is not more suscepti-

ble to damage than a standard steering. However, the

steering mast jacket assembly, especially if removed,

has in contrast with the standard steering to be given

a difierent treatment.

Figure

3E-4 Energy Absorbing Steering Column

The energy absorbing steering column must by no

means be subject to impacts or blows. A sharp blow

onto the exposed steering shaft ends, leaning onto

steering column or dropping may loosen or even

shear off the plastic attachments which bring about

rigidity of assembly. In spite of a steering column

damaged in this way the operating function of the

steering is retained due to the lateral flattenings on

steering shaft tube and lower steering shaft. How-

ever, after a short period of operation rattling noises

will be noticeable so that the steering column has to

be replaced. For pulling steering wheel off steering

column use appropriate special tool. Therefore, it is

of importance that the instructions for removal and

installation as well as disassembly and assembly are

Strictly adhered to.

MAJOR REPAIRREMOVAL AND INSTALLATION OF

STEERING COLUMN ASSEMBLY

The removal of this assembly is only necessary for

Page 205 of 625

3E- 38 ,1973 OPEL SERVICE MANUAL

ponents and systems, and/or could result in major

repair expense. They must be replaced with one or

the same part number or with

an equivalent part if

replacement becomes necessary. Do not use a

re-

placement part of lesser quality or substitute design.

Torque

values must be used as specified during reas-

sembly to assure proper retention of these parts.On installation, make sure steering wheel spokes

point downwards and steering gear is in high point.

1. Carefully insert steering mast into universal joint

flange.

2. Loosely attach slide-off base attaching nuts at un-

derside of instrument panel.

3. Attach steering mast jacket at front of dash, using

a notched hex nut.

4. Torque nuts at slide-off base to II

lb.ft.5. Tighten screw at steering mast clamp to 22

lb.ft.6. Reconnect wires to directional signal switch and

ignition switch.

7. Reconnect battery.

REMOVAL AND INSTALLATION OF

STEERING WHEELThis procedure may be performed with the steering

column assembly either removed or installed in the

car.

Removal

1. Disconnect battery.

2. Pry off horn cap and remove wires from cap. See

Figure

3E-3.3. Bend lockplate tabs down and take off steering

shaft nut and lockplate.

4. Install steering wheel remover J-21686 as shown

in Figure

3E-9 and pull off steering wheel.

Installation1. Before installing steering wheel, lubricate return

pin and sliding area on directional signal switch re-

turn cams and horn contact ring.

2. Make sure that clamp bolt in steering shaft flange

is on top.

3. Make sure notch on steering shaft face is in hori-

zontal position.Figure

3E-9 Removing Steering Wheel

4. With the steering wheel centered, place the steer-

ing wheel onto the steering shaft.

5. Install steering wheel lockplate and nut. Torque to

11

lb.ft.

CAUTION:

This steering wheeI to steering shaft fas-

tener is an important attaching part in that it could

affect the

performance of vital components and sys-

tems, and/or could result in major repair expense. It

must be repked

with one of the same part number

or with an equivalent part if replacement becomes

necessary. Do not use a replacement part of lesser

quality or substitute design. Torque

values must be

used as specified during reassembly to assure proper

retention of this part.6. Bend lockplate tabs up, connect horn cap wires

and replace cable and cap.

7. Reconnect battery.

REMOVAL AND REPLACEMENT OF HORN

CONTACT RING

1. Remove steering wheel.

2. Cut off defective contact ring at wire.

3. Strip wire approximately

l/8”.4. Install new part and solder connection with resin

core solder.

5. Lubricate contact ring with lubriplate, or equiva-

lent.

6. Reinstall steering wheel.

Page 207 of 625

3E- 40 1973 OPEL SERVICE MANUAL

on steering and ignition lock bracket using a new

tear-off bolt (hexagon head tears

ofD.

3. Disconnect slide-off base, install upper half of sig-

nal switch housing cover, and loosely reattach

slide-

off base.

4. Attach steering mast jacket at front of dash panel.

See Figure

3E-7.

5. Torque slide-off base attaching nuts to 11 lb.ft.

6. Install lower half of signal switch housing cover

and connect signal switch, as well as steering ignition

lock wire set.

7. Install steering wheel and torque nut to 11

Ib.ft.

Always use new lock plate.

DISASSEMBLY AND REASSEMBLY OF STEERING

AND IGNITION LOCK CYLINDER AND ELECTRICAL SWITCH FROM MAST JACKET

ASSEMBLY

Disassembly. GT

Disconnect the battery before proceeding.

1. Remove steering wheel.

2. Turn ignition switch to ON position.

3. Insert a suitable rod into stop pin hole on side of

steering and ignition lock (See Figure

3E-13) and

take out steering and ignition lock cylinder. 4. Remove two screws securing electrical switch to

steering and ignition lock housing and take out

switch.

Disassembly (Opel 1900 . Manta)

1. Rezmove steering wheel.

2. Unscrew split signal switch housing cover and

remove lower half. See Figure

3E-10.

3. Remove lock cylinder by pushing in lock spring of

the cylinder using a piece of wire. Cylinder must be

in the

” 1” position. See Figure 3E-14.

Figure 3E-14 Removing Lock Cylinder

Reassembly

1. On the GT reassemble electrical switch into steer-

ing and ignition

lock housing and rotate switch until:

(1) cam in lock housing recess fits into slotted hole

in rear of electrical switch, and (2) projection on

electrical switch fits into recess on lock housing.

2. On the Opel 1900

- Manta, insert lock cylinder in

the

P l* position into housing. Install lower half of

signal switch housing.

3. Reinstall steering wheel.

Figure 3E-13 Removing Ignition Lock Cylinder

Page 212 of 625

GT STEERING COLUMN ASSEMBLY3E- 45

loose must never be done. The only recommendation

for freeing frozen steering wheels is to use a penetrat-

ing lubricant.Installation1. Before installing steering wheel, lubricate return

pin and slide area on direction signal switch return

cams and horn ring contact.

2. With steering wheel properly aligned to shaft, in-

stall lockplate and nut. Torque nut to 15

Ib.ft.

CAUTION:

This steering wheel to steering shafi fas-

tener is an important attac&ng part in that it could

affect the performance of vital components and sys-

tems, and/or could result in major repair expense. It

must be

rep/aced with one of the same part number

or with an equivalent part, if replacement becomes

necessary. Do not use a replacement part of lesser

quality or substitute design. Torque values must be

used as specified during reassembly to assure proper

retention of this part.3. Bend up lockplate tab and install horn cap.

4. Reconnect battery.

REMOVAL AND INSTALLATION OF IGNITION

LOCK CYLINDER

RemovalThis procedure may be performed with the steering

column assembly either removed or installed in the

car.1. Remove steering wheel, as outlined previously in

this Group.

2. Position lock cylinder to run position.

3. Using suitable piece of wire, push in lock cylinder

retaining pin and remove lock cylinder. See Figure3E- 18.

Installation1. Insert lock cylinder into lock cylinder housing.

2. Install steering wheel, as outlined previously in

this section.

REMOVAL AND INSTALLATION OF STEERING

COLUMN ASSEMBLY

Removal1. Position steering so that front wheels are straight

ahead.Figure

3E-18 Removing Lock Cylinder

2. Loosen steering shaft upper universal joint lower

clamp bolt. See Figure

3E-19.3. Drill off heads of both tear bolts by first drilling

an 3/16 inch pilot hole and then inserting a

l/4 inch

bolt extractor to remove lockbolt.

4. Disconnect ignition (white) and direction signal

(black) wire set plugs.

5. Support steering column assembly and remove

both hex. head bolts.

6. Pull steering column assembly off center steering

shaft. Do not apply any force as plastic injections in

center steering shaft may be loosened and shaft

would then require replacement.

Installation

CAUTION:

Fasteners are important attachingparts in

that they

cooId affect the performance of vital com-

ponents and systems, and/or could result in major

repair expense. They must be replaced with one of

the same part number or with an equivalent part if

replacement becomes necessary. Do not use a re-

placement part of lesser quality or

substitute design.

Torque values must be used as specified during

reas-

sembIy to assure proper retention of these parts.1. Install steering column assembly onto steering

shaft and torque steering shaft upper universal joint

lower clamp bolt to 14

lb.ft.2. Install hex head bolts and torque to 14

lb.ft.

NOTE:

Be sure to install ground wire.

Page 214 of 625

GT STEERING COLUMN ASSEMBLY3E- 47

2. Disconnect ignition (white) wire set plug.

3. Remove steering lock retaining screw. See Figure3E-20.Figure 3E-20 Steering Lock Retaining Screw

4. Remove direction signal switch lever.

5. Remove three screws securing signal switch cover

to housing.

6. To remove housing cover, (a) pull cover toward

direction signal switch and move it slightly to the

right. See Figure

3E-21. (b) Turn cover toward the

left and move it further to the right so that the left

retaining screw ear is positioned under the left signal

switch return cam. See Figure

3E-22. (c) Insert direc-

Figure 3E-2 1tion signal switch lever into oblong opening in cover

and push steering lock into housing and remove

cover. See Figure

3E-37.Figure

3E-22Figure 3E.23

7. Remove ignition switch electrical unit. See Figure3B24.

8. Remove wires from connector plug making certain

to note location of each.

9. Tape wire ends together and remove electrical unit

and wire harness.

Installation1. Position electrical unit wire harness through col-

umn and reconnect to connector plug.

Page 215 of 625

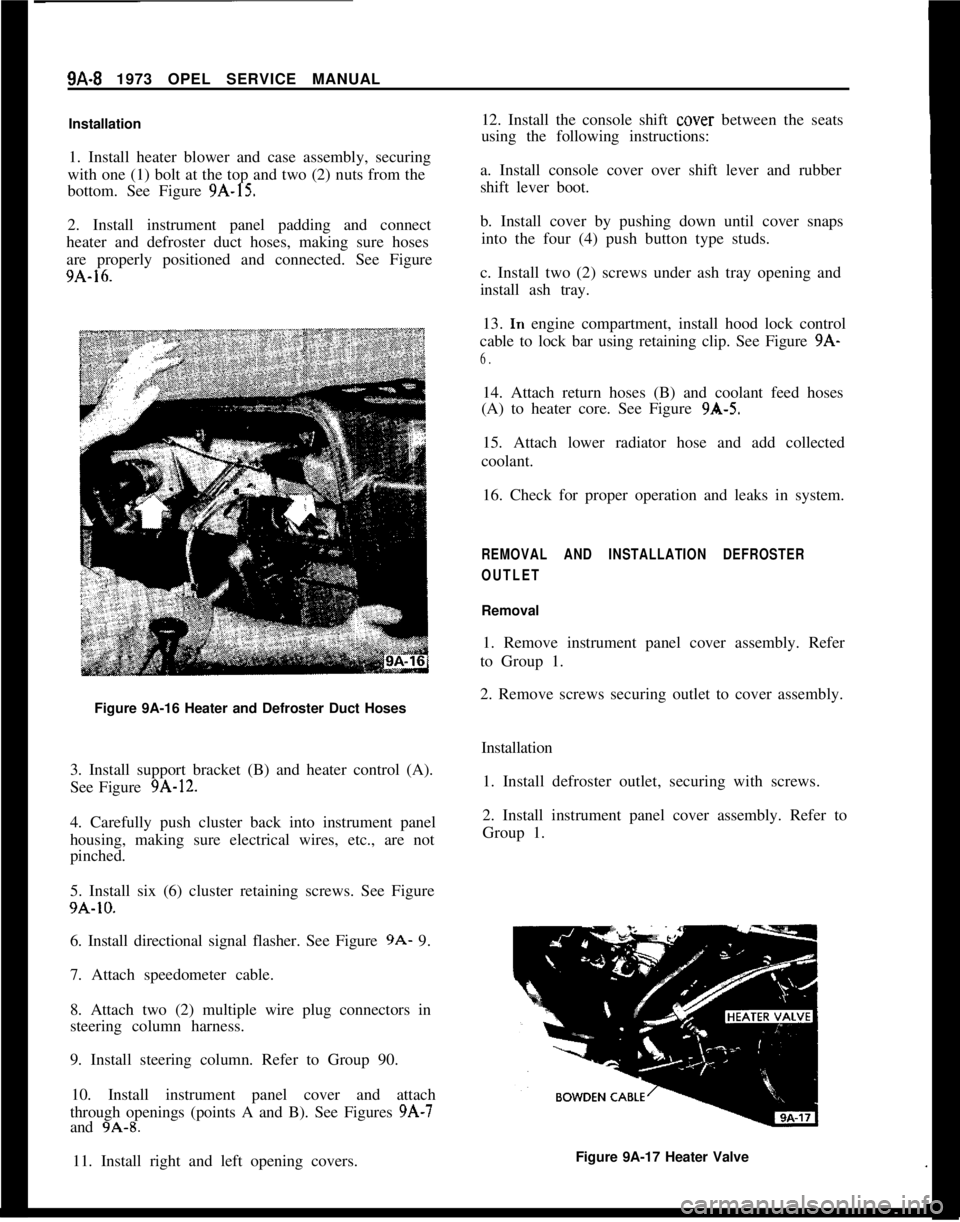

3E- 481973 OPEL SERVICE MANUAL

Figure 3E-24 Removing Electrical Unit

Before installing electrical unit be sore unit is in

RUN position. Using a Philips screwdriver, turn in-

ner sleeve to the tight until a springy resistance is

felt. See Figure 3E-25.Figure 3E-25 Checking for RUN Position

2. Install ignition switch electrical unit. See Figure

3E-24.3. Install housing cover by attaching with three (3)

screws.4. Install steering lock retaining screw. See Figure

3E-20.5. Reconnect ignition (white) wire set plug.6. Install direction signal switch lever.

7. Install ignition lock cylinder. See previous para-

graph in this section.

REMOVAL AND INSTALLATION OF UPPER

STEERING BEARING AND/OR DIRECTION SIGNAL

SWITCH1. Remove ignition switch and steering lock, see

previous paragraph in this section.

2. Disconnect direction signal (black) wire set plug.

3. Remove wires from connector plug making certain

to note location of each.

4. Remove screws and direction signal housing and

switch assembly. See Figure

3E-26.

..3E-26

Figure 3E-26 Removing Direction Signal Switch

Assembly5. To remove upper bearing, pull horn wire out of

bearing housing and pry out bearing assembly using

a flat screwdriver. See Figure

3E-27.

Installation1. If upper bearing has been removed, install by using

the thumbs of both hands being sure to line bearing

up with notched portion of housing.

2. Install direction signal housing and switch assem-

bly. See Figure 3B26.

3. Reposition wires into connector plug and connect

direction signal wire set.

Page 517 of 625

9A-8 1973 OPEL SERVICE MANUAL

Installation

1. Install heater blower and case assembly, securing

with one (1) bolt at the top and two (2) nuts from the

bottom. See Figure

9A-15.

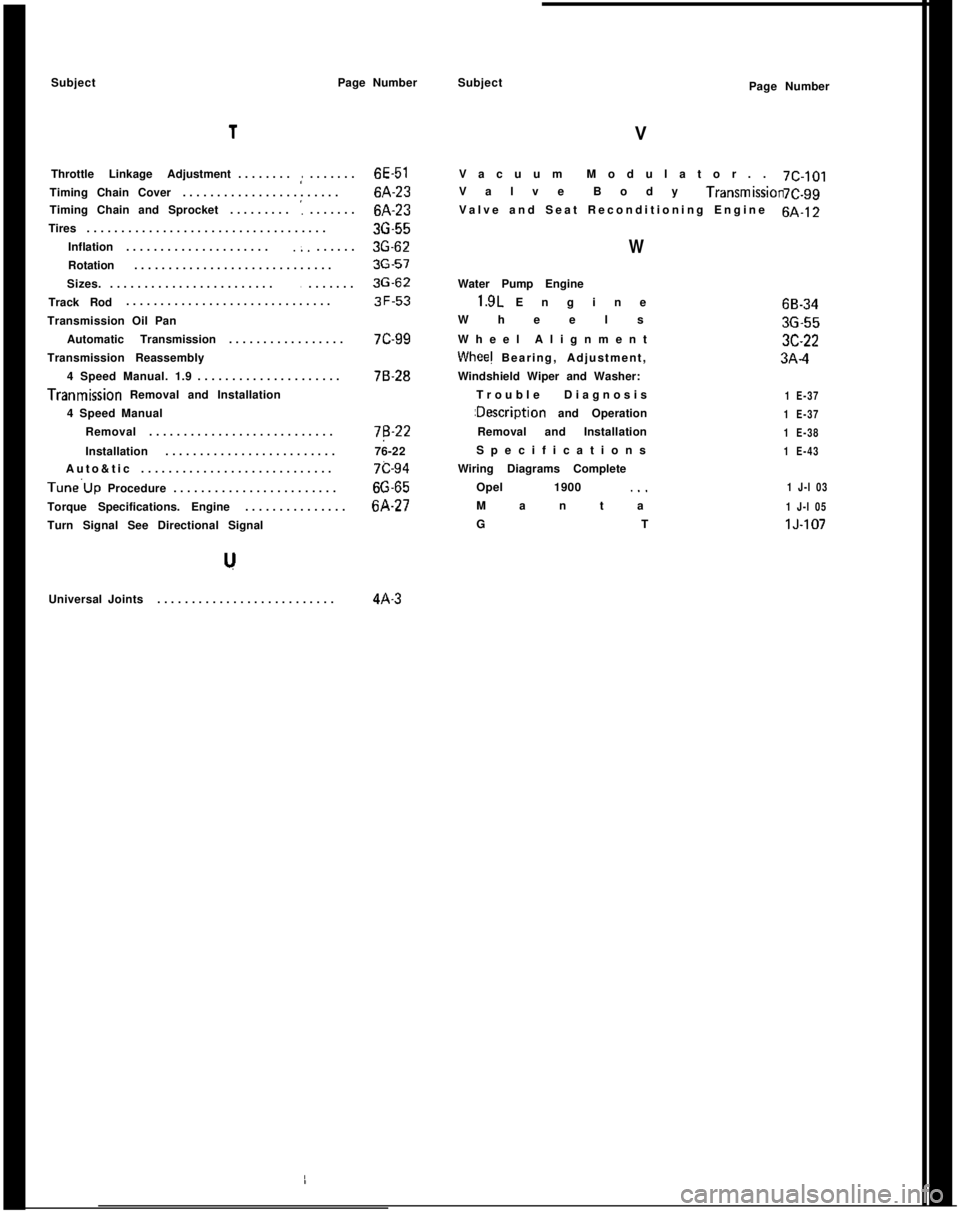

2. Install instrument panel padding and connect

heater and defroster duct hoses, making sure hoses

are properly positioned and connected. See Figure

9A-16.

Figure 9A-16 Heater and Defroster Duct Hoses

3. Install support bracket (B) and heater control (A).

See Figure

9A-12.

4. Carefully push cluster back into instrument panel

housing, making sure electrical wires, etc., are not

pinched.

5. Install six (6) cluster retaining screws. See Figure

9A-10.

6. Install directional signal flasher. See Figure

9A- 9.

7. Attach speedometer cable.

8. Attach two (2) multiple wire plug connectors in

steering column harness.

9. Install steering column. Refer to Group 90.

10. Install instrument panel cover and attach

through openings (points A and B). See Figures

9A-7

and 9A-8.

11. Install right and left opening covers. 12. Install the console shift

cover

between the seats

using the following instructions:

a. Install console cover over shift lever and rubber

shift lever boot.

b. Install cover by pushing down until cover snaps into the four (4) push button type studs.

c. Install two (2) screws under ash tray opening and

install ash tray. 13.

In engine compartment, install hood lock control

cable to lock bar using retaining clip. See Figure

9A-

6.

14. Attach return hoses (B) and coolant feed hoses

(A) to heater core. See Figure

9A-5.

15. Attach lower radiator hose and add collected

coolant.

16. Check for proper operation and leaks in system.

REMOVAL AND INSTALLATION DEFROSTER

OUTLET

Removal

1. Remove instrument panel cover assembly. Refer

to Group 1.

2. Remove screws securing outlet to cover assembly.

Installation1. Install defroster outlet, securing with screws.

2. Install instrument panel cover assembly. Refer to

Group 1.

Figure 9A-17 Heater Valve

Page 624 of 625

SubjectPage Number1

Throttle Linkage Adjustment........,:.......6E-51

Timing Chain Cover.......................6A-23

Timing Chain and Sprocket.........

':.......6A-23

Tires...................................36-55

Inflation.....................

.;.......3G-62

Rotation.............................36-57

Sizes.........................

........3G-62

Track Rod..............................3F-53

Transmission Oil Pan

Automatic Transmission.................7C-99

Transmission Reassembly

4 Speed Manual. 1.9.....................76-28Tranmission Removal and Installation

4 Speed Manual

Removal...........................7B-22

Installation.........................76-22

Auto&tic............................7c-94Tune’Up Procedure........................66-65

Torque Specifications. Engine...............6A-27

Turn Signal See Directional Signal

Universal Joints..........................4A-3Subject

VPage Number

Vacuum Modulator..7C-101

Valve Body Transmlssmn7C.99

Valve and Seat Reconditioning Engine6A-12

WWater Pump Engine1.9L Engine

Wheels

Wheel Alignment

Whee! Bearing, Adjustment,

Windshield Wiper and Washer:

Trouble Diagnosis:Description and Operation

Removal and Installation

Specifications

Wiring Diagrams Complete

Opel 1900 ._.

Manta

GT

1 E-37

1 E-37

1 E-38

1 E-43

1 J-l 03

1 J-l 05lJ-10768-3436-553C-223A-4