tow OPEL GT-R 1973 Owner's Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 202 of 625

OPEL 1900 AND MANTA STEERING COLUMN ASSEMBLY 3E.35

II

OPEL 1900 AND MANTA STEERING COLUMN

ASSEMBLY

CONTENTS

SubjectPage No.

DESCRIPTION AND OPERATION:

Description and Operation of Directional Signal

Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description

andOperationofHorn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Description of Steering Column Assembly

. . . . . . . . . . . . . .DIAGNOSIS: (Not Applicable)

MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:

3E-353E-363E-36

Removal and Installation of Steering Column

Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RemovalandInstallationofSteeringWheel. . . . . . . . . . . .Disassembly and Reassembly of Direction Signal

Switch

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly and Reassembly of Steering and

Ignition Lock Cylinder, and Electrical Switch

from Mast Jacket Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

Steering

ColumnSpecifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3E-363E-383E-393E-403E-41

DESCRIPTION AND OPERATIONDESCRIPTION AND OPERATION OF

DIRECTIONAL SIGNAL LEVERhigh to low beam or vice versa. On all

19M) Rallye

cars, when switching from low to high beam posi-

tion, with the fog lamp instrument panel switch ON

The direction signal switch lever is a multi- purpose

lever controlling direction signals, passing signal and

headlight high and low beams. See Figure

3E-2.The dire&M signal lever is provided with a two-

step mechanism for operation of headlight high and

low beams, and passing signal (not in N.J.). With

headlights off, moving the lever repeatedly towards

steering wheel flashes headlights as a passing signal.

With headlights on, moving the lever repeatedly to-

wards steering wheel up to first stop also flashes

passing signal regardless whether or not the direction

signals are switched on. When the lever is moved up

to the second stop, the headlights are changed from

SE.2Figure

3E-2 Directional Signal Lever Position for

Headlamp Operation

Page 214 of 625

GT STEERING COLUMN ASSEMBLY3E- 47

2. Disconnect ignition (white) wire set plug.

3. Remove steering lock retaining screw. See Figure3E-20.Figure 3E-20 Steering Lock Retaining Screw

4. Remove direction signal switch lever.

5. Remove three screws securing signal switch cover

to housing.

6. To remove housing cover, (a) pull cover toward

direction signal switch and move it slightly to the

right. See Figure

3E-21. (b) Turn cover toward the

left and move it further to the right so that the left

retaining screw ear is positioned under the left signal

switch return cam. See Figure

3E-22. (c) Insert direc-

Figure 3E-2 1tion signal switch lever into oblong opening in cover

and push steering lock into housing and remove

cover. See Figure

3E-37.Figure

3E-22Figure 3E.23

7. Remove ignition switch electrical unit. See Figure3B24.

8. Remove wires from connector plug making certain

to note location of each.

9. Tape wire ends together and remove electrical unit

and wire harness.

Installation1. Position electrical unit wire harness through col-

umn and reconnect to connector plug.

Page 230 of 625

WHEELS AND TIRES36-63would require inflation pressures above the maximum allowable, speed must be

limited to 75 miles per hour.

3.Cool tire inflation pressure: After vehicle has been inoperative for 3 hours

or more, or driven less than one mile. Hot tire inflation pressure: After vehicle

has been driven

10 miles or more at 60-70 MPH.

4.Vehicles with luggage racks do not have a vehicle load limit greater than

specified.

5. When towing trailers, the allowable passenger and cargo load must be

reduced by an amount equal to the trailer tongue load on the trailer hitch.

Torque SpecificationWheelNuts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65lb.ft.

IFigure 3G-8 Wheel and Tire - Exploded View

Page 236 of 625

PROPELLER SHAFT AND CENTRAL JOINT4A- 5

1. Check condition of support cushions. If new cush-

ions are installed, torque to 29 lb. ft. See Figure 4A-6.

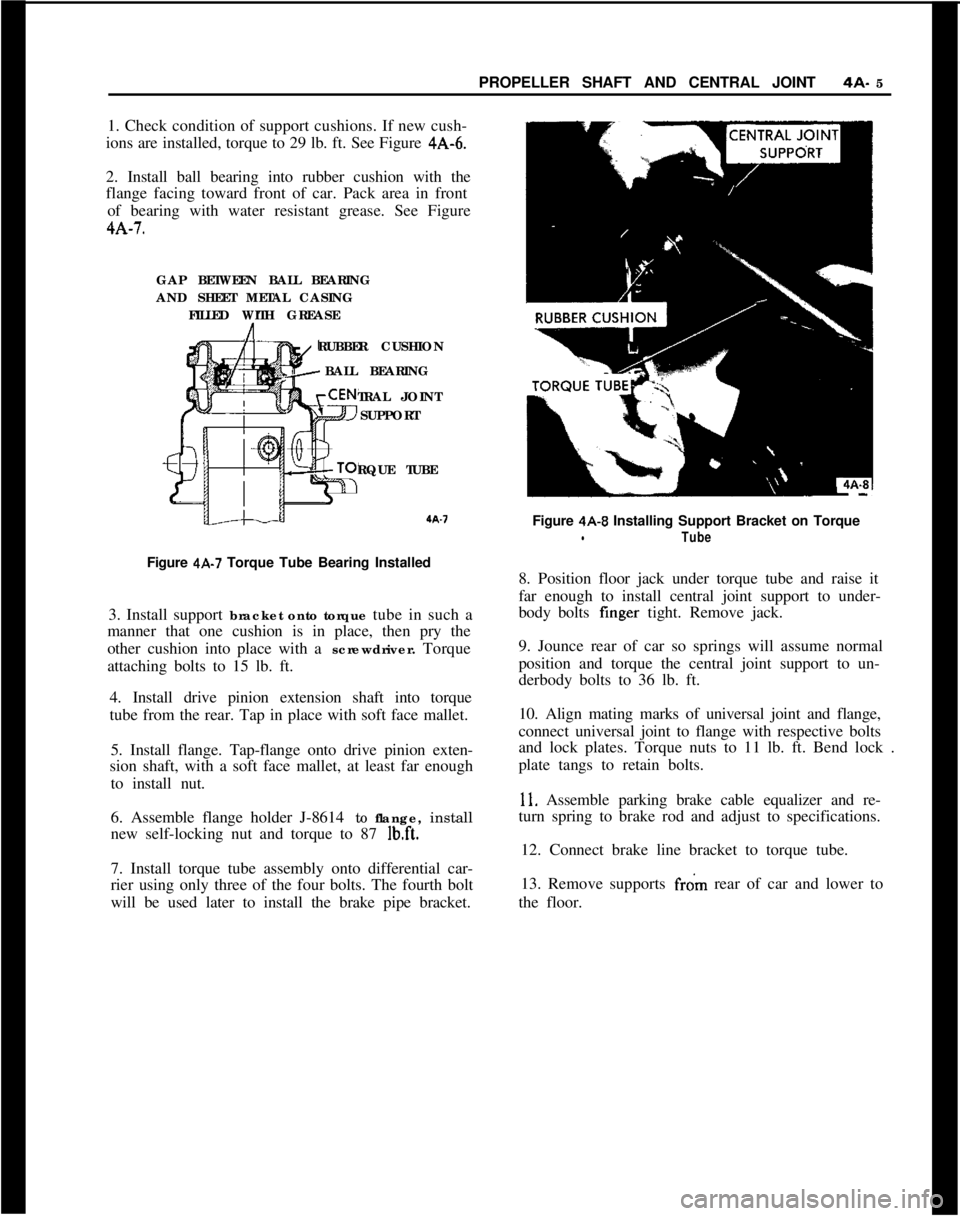

2. Install ball bearing into rubber cushion with the

flange facing toward front of car. Pack area in front

of bearing with water resistant grease. See Figure4A-7.

GAP BETWEEN BALL BEARING

AND SHEET METAL CASING

FILLED WITH GREASE

RUBBER CUSHION

BALL BEARING

TRAL JOINT

SUPPORT

RQUE TUBEa.7

Figure 4A-7 Torque Tube Bearing Installed

3. Install support bracket onto torque tube in such a

manner that one cushion is in place, then pry the

other cushion into place with a screwdriver. Torque

attaching bolts to 15 lb. ft.

4. Install drive pinion extension shaft into torque

tube from the rear. Tap in place with soft face mallet.

5. Install flange. Tap-flange onto drive pinion exten-

sion shaft, with a soft face mallet, at least far enough

to install nut.

6. Assemble flange holder J-8614 to flange, install

new self-locking nut and torque to 87

lb.ft.7. Install torque tube assembly onto differential car-

rier using only three of the four bolts. The fourth bolt

will be used later to install the brake pipe bracket.Figure

4A-8 Installing Support Bracket on TorquelTube8. Position floor jack under torque tube and raise it

far enough to install central joint support to under-

body bolts finger tight. Remove jack.

9. Jounce rear of car so springs will assume normal

position and torque the central joint support to un-

derbody bolts to 36 lb. ft.

10. Align mating marks of universal joint and flange,

connect universal joint to flange with respective bolts

and lock plates. Torque nuts to 11 lb. ft. Bend lock .

plate tangs to retain bolts.

11. Assemble parking brake cable equalizer and re-

turn spring to brake rod and adjust to specifications.

12. Connect brake line bracket to torque tube.

13. Remove supports

f&n rear of car and lower to

the floor.

Page 248 of 625

6. Before installing, shims must be measured to in-

sure that the proper thickness is being used. Install

shims of correct thickness to obtain desired clearance

and reassemble and install pinion shaft lock pin. In-

stall thrust washers with concave side towards differ-

ential case.

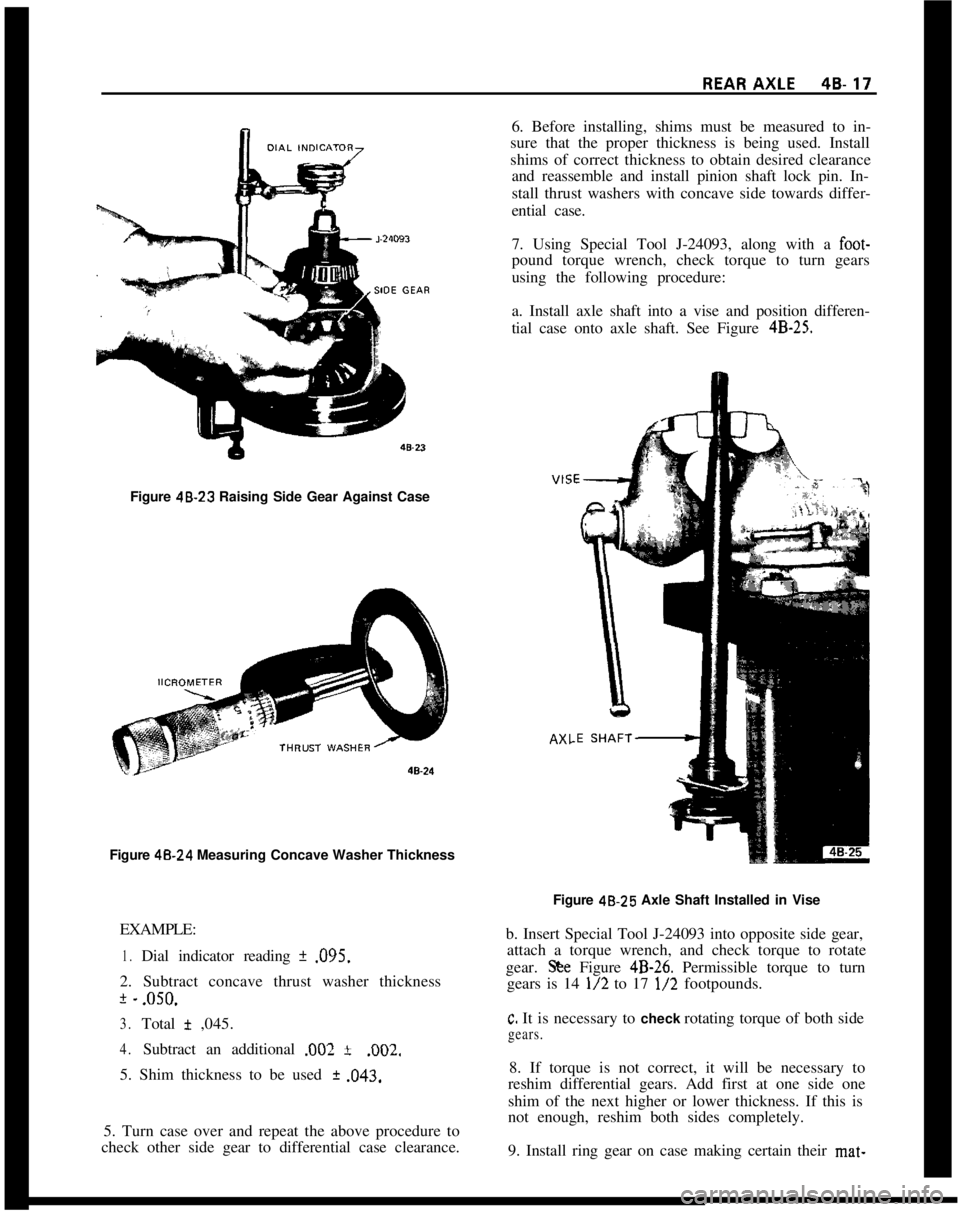

7. Using Special Tool J-24093, along with a foot-pound torque wrench, check torque to turn gears

using the following procedure:

a. Install axle shaft into a vise and position differen-

tial case onto axle shaft. See Figure

4B-25.Figure 48-23 Raising Side Gear Against Case

Figure 48.24 Measuring Concave Washer Thickness

AX,EXAMPLE:

1.Dial indicator reading * .095.

2. Subtract concave thrust washer thickness

+ -.oso.

3.Total + ,045.

4.Subtract an additional .002 *.002.

5. Shim thickness to be used

+ .043.

5. Turn case over and repeat the above procedure to

check other side gear to differential case clearance.Figure 48.25 Axle Shaft Installed in Vise

b. Insert Special Tool J-24093 into opposite side gear,

attach a torque wrench, and check torque to rotate

gear. S& Figure

4B-26. Permissible torque to turn

gears is 14

l/2 to 17 l/2 footpounds.

c. It is necessary to check rotating torque of both side

gears.8. If torque is not correct, it will be necessary to

reshim differential gears. Add first at one side one

shim of the next higher or lower thickness. If this is

not enough, reshim both sides completely.

9. Install ring gear on case making certain their mat-

Page 265 of 625

5A- 61973 OPEL SERVICE MANUAL

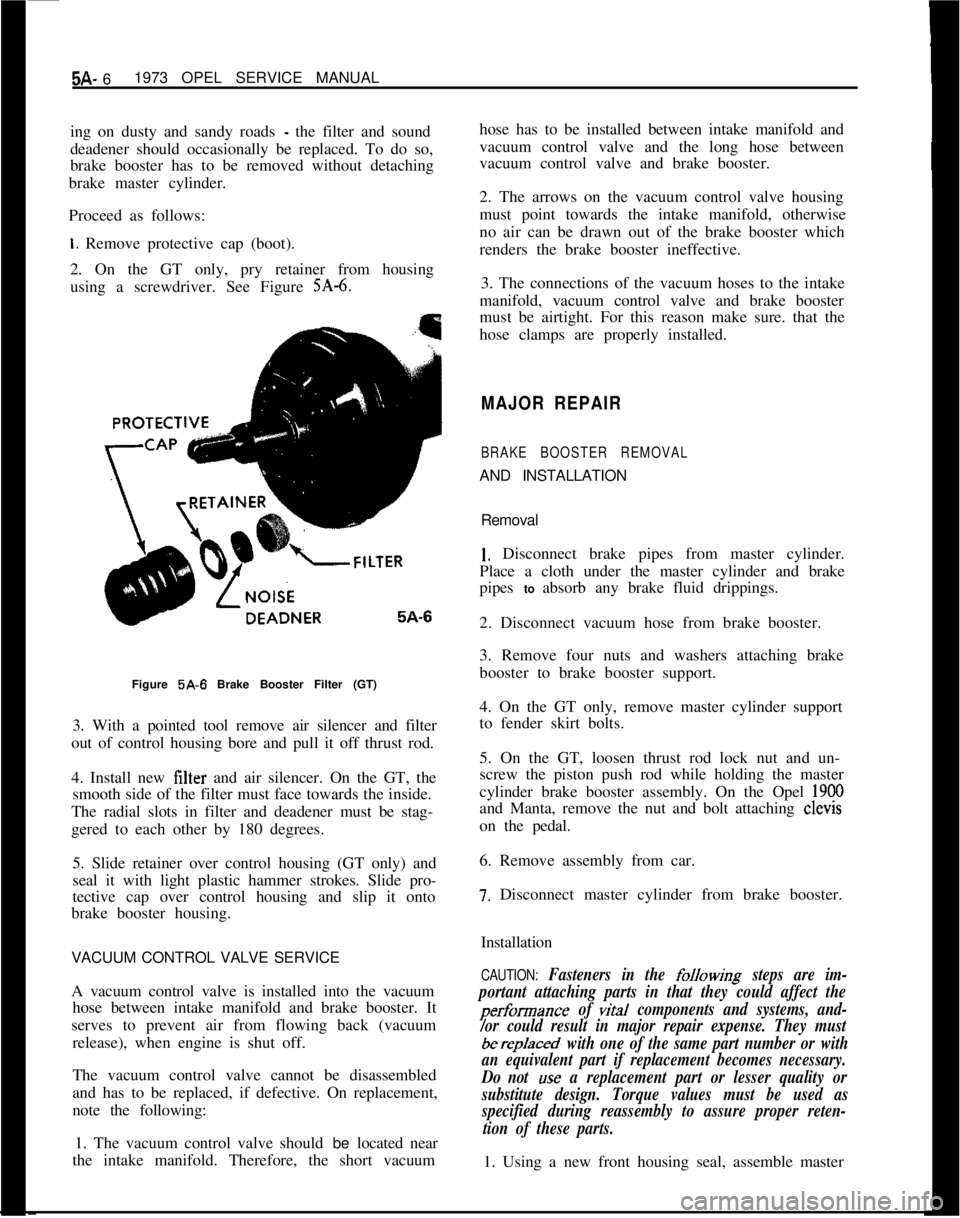

ing on dusty and sandy roads - the filter and sound

deadener should occasionally be replaced. To do so,

brake booster has to be removed without detaching

brake master cylinder.

Proceed as follows:

1. Remove protective cap (boot).

2. On the GT only, pry retainer from housing

using a screwdriver. See Figure

SA-6.Figure 5A-6 Brake Booster Filter (GT)

3. With a pointed tool remove air silencer and filter

out of control housing bore and pull it off thrust rod.

4. Install new filter and air silencer. On the GT, the

smooth side of the filter must face towards the inside.

The radial slots in filter and deadener must be stag-

gered to each other by 180 degrees.

5. Slide retainer over control housing (GT only) and

seal it with light plastic hammer strokes. Slide pro-

tective cap over control housing and slip it onto

brake booster housing.

VACUUM CONTROL VALVE SERVICE

A vacuum control valve is installed into the vacuum

hose between intake manifold and brake booster. It

serves to prevent air from flowing back (vacuum

release), when engine is shut off.

The vacuum control valve cannot be disassembled

and has to be replaced, if defective. On replacement,

note the following:

1. The vacuum control valve should be located near

the intake manifold. Therefore, the short vacuumhose has to be installed between intake manifold and

vacuum control valve and the long hose between

vacuum control valve and brake booster.

2. The arrows on the vacuum control valve housing

must point towards the intake manifold, otherwise

no air can be drawn out of the brake booster which

renders the brake booster ineffective.

3. The connections of the vacuum hoses to the intake

manifold, vacuum control valve and brake booster

must be airtight. For this reason make sure. that the

hose clamps are properly installed.

MAJOR REPAIR

BRAKE BOOSTER REMOVALAND INSTALLATION

Removal

1. Disconnect brake pipes from master cylinder.

Place a cloth under the master cylinder and brake

pipes to absorb any brake fluid drippings.

2. Disconnect vacuum hose from brake booster.

3. Remove four nuts and washers attaching brake

booster to brake booster support.

4. On the GT only, remove master cylinder support

to fender skirt bolts.

5. On the GT, loosen thrust rod lock nut and un-

screw the piston push rod while holding the master

cylinder brake booster assembly. On the Opel

1900and Manta, remove the nut and bolt attaching clevis

on the pedal.

6. Remove assembly from car.

7. Disconnect master cylinder from brake booster.

Installation

CAUTION: Fasteners in the folkwing steps are im-

portant attaching parts in that they could affect the

performance of vital components and systems, and-

/or could result in major repair expense. They must

berep/aced, with one of the same part number or with

an equivalent part if replacement becomes necessary.

Do not

use a replacement part or lesser quality or

substitute design. Torque values must be used as

specified during reassembly to assure proper reten-

tion of these parts.1. Using a new front housing seal, assemble master

Page 270 of 625

DISC BRAKES5B- 11

rLF 5.2. RUBBER FLUID SEALS6.3. HOLLOW PISTONS7.

AL5

3Figure 58.21 Left Front Disc Brake

- Emloded View

the piston circumference by its inherent tension. See

Figure

5B-21. Both pistons are hollow. The open end

of each piston faces the brake disc.

A sheet metal spacer plate with two impressions for

preventing the piston from rotating is installed be-

tween each piston and friction pad and secured by

the friction pad dowel pins. The two friction pads are

positioned on the right and left of the brake disc

recesses in the caliper halves. Each friction pad con-

sists of a backing plate with friction material, which

is abrasive-coated, bonded to it. The friction pad

assemblies are held in position in the brake caliper by

two dowel pins, secured by slit dowel pin retainers,

and by a cross-shaped retaining spring which is pre-

loaded and positioned under the dowel pins, thus

pressing the friction pads and spacer plates firmly

against the pistons. The front brake line leading from

the brake master cylinder attaches to a distribution

tee from which a brake line leads to each front wheel

caliper. The caliper bores are interconnected by fluid

ducts within the caliper halves.

The front wheel disc brakes have self-adjusting pis-

tons. See Figure

5B-22.The adjustment of the pads is effected by the pistons

which push the friction pads ahead towards the

brake disc for a distance equivalent to the amount of

friction pad wear. This means that the greater the

wear the closer the pistons move towards the brake

disc. A running clearance exists between friction

pads and brake disc when the brakes are in “off”

position. This running clearance is provided by the

rubber fluid seals which are positioned in the caliper

half bores and which tightly grip and exert their

pre-load pressure on the pistons. The rubber fluid

seals also prevent the pistons from being pushed into

the caliper half bores more than the distance equiva-

lent to the running clearance. As the friction pads are

adjusted by the pistons, there must be no static pres-

sure in the front brake circuit when the brakes are in“OR position. Non-existence of a static pressure in

the front brake circuit is achieved by eliminating the

check valve in the brake master cylinder on the front

brake circuit. During brake application the pressure

from the brake master cylinder is transferred to the

pistons in the brake caliper. The pistons move ahead

and press the friction pads against both friction

SW-faces of the rotating brake disc. The force exerted on

the brake pedal determines the pressure of the fric-

tion pads against the brake disc. On releasing the

brake pedal, the brake lines of the front brake circuit,

including the caliper half bores, are relieved of

hy-OPERATION

Page 271 of 625

5B- 121973 OPEL SERVICE MANUAL

A = BRAKE ON

THE RUBBER FLUID SEAL TIGHTLY GRIPPING PISTON

IS DEFLECTED IN DIRECTION OF PISTON TRAVELAFRICTION PAD

BRAKE DISCRUBBER FLUID SEALBRAKE

IICALIPER

IPISTON

I

CE BETWEEN RUNNING CLEARAN

FRICTION PAD AND BRAKE DISC

B = BRAKE OFFBTHE PISTON IS RETRACTED BY THE AMOUNT OF

RUBBER FLUID SEAL DEFLECTION. THIS AMOUNT

IS EQUAL TO RUNNING CLEARANCE.SBZZ

Figure 58-22 Rubber Fluid Seal -Automatic Piston Retractiondraulic pressure, and the friction pads and pistonsmove away from the brake disc, leaving a small run-

ning clearance. The brake disc can now rotate freely.

The amount of brake travel is dependent upon the

amount of running clearance. For this reason therunout of the brake disc should be checked, besides

bleeding of the brake system and adjusting the rear

brake shoes, when the pedal free travel is too great.during braking, the rubber seals in the annular

grooves of the brake caliper bores deflect laterally in

the direction of piston movement. See Figure

5B-22,View (A). The seal remains deflected for the duration

of the braking operation. After braking, the caliper

bores are relieved of hydraulic pressure and the rub-

ber seals resume their normal position, thus pulling

or retracting the pistons. The distance traveled by

the pistons is equal to that of the running clearance

between brake disc and friction pads.

The running clearance between brake disc and

fric-tion pads is attained as follows: When the pistons in

the caliper halves are moved towards the brake discThe shifting of the pistons in the direction of the

brake disc due to friction pad wear has no effect on

the running clearance. The running clearance re-mains the same in all piston positions.

DIAGNOSIS

DISC BRAKE TROUBLE DIAGNOSIS

ConditionPulls

Possible Cause

I. Incorrect tire

pressures.Correction1. Inflate evenly on both sides to

the recommended pressures (see

Owner’s Manual).

Page 274 of 625

DISC BRAKES5B- 15

ConditionPossible Cause

2. Binding brake pedal

mechanism.Correction

2. Check and lubricate, ifnecessary.3. Corroded caliper

assembly.3. Clean and lubricate.

MAINTENANCE AND ADJUSTMENTSDISC BRAKE MAINTENANCE

Checking Brake Fluid Level

The brake fluid level in the brake fluid container

must be checked during predelivery inspection, then

every 3,000 miles during inspection and preventive

maintenance servicing.

The brake fluid level must not be higher than the

inscription “MAX” and must be at least up to

“MIN”. Replenish brake fluid, if necessary.

Because of the relatively large brake caliper bore

cross section and the self-adjustment of the disc

brakes, resulting in a greater piston travel to compen-

sate for friction pad wear, the brake fluid level drops

faster than in fluid containers for drum brakes with

their smaller wheel brake cylinders. For this reason

pay special attention to the fluid level in the brake

fluid container.

Drop of brake fluid level can be due to friction pad

wear and may not be due to leakage in the braking

system.On loss of brake fluid due to leakage, the brake sys-

tem must be checked thoroughly.

Friction Pad Adjustment

Friction pad adjustment is not necessary on the front

wheel disc brakes as this is done automatically by the

pistons in the brake calipers.

Lubricating Front Wheel Bearings

When removing one or both brake discs, check lu-

brication of front wheel bearings and the cavity of

the wheel hub and replenish if necessary (see operat-

ion

“Removing and Reinstalling Brake Disc”).

When carrying out other work on disc brakes which

does not necessitate the removal and installation of

the brake disc, lubricating wheel bearings is not

necessary.Checking Disc Brake Friction Pads for Wear

Whenever a disc brake equipped car is in for periodic

service, while the car is raised, the friction pads in

both brake calipers should be checked for wear by

making a simple measurement. Worn or oily friction

pads must be replaced.

Measure friction pad wear as follows:

1. Remove friction pads.

2. Using a one-inch micrometer, measure the thick-

ness of the pad and friction plate. See Figure

5B-23.Figure 58-23 Checking Brake Friction Pad Thickness

3. If any one of the four measurements is less than

-.280, replace all four friction pads. (Partial replace-

ment of friction pads would cause unequal braking.)

Removal and Installation of Friction Pads

1. Raise car and remove front wheels.

2. Drive dowel pins out of brake calipers toward

center of car. See Figure

5B-24. Dowel pins must be

driven inward because they are secured by enlarge

fluted inner ends.

3. Remove friction pads from brake calipers. See

Figure

5B-25.

Page 279 of 625

58.201973 OPEL SERVICE MANUAL

half, and blow out pistons, carefully regulating air

flow. When removing pistons, proceed with extreme

caution and always keep the fingers ofthe hand hold-

ing the brake caliper away from the piston.

Figure 55.33 Removing Caliper Rim Half Piston

Figure 58-34 Removing Caliper Mounting Half Piston

4. Pry rubber fluid seals out of the annular grooves

in the caliper half bores. See Figure

5B-35.5. Check all parts of the brake caliper for wear. If the

caliper half bores are scored or rusted, use a new

complete brake caliper and friction pads. Small, light

rust spots in the caliper half bores or on the pistons

can be removed with fine emery cloth. If pistons are

damaged, even though the caliper half bores are inFigure 58-35 Removing Rubber Fluid Seal From

Caliper Boresgood condition, the piston must be replaced. The

rubber fluid seals and rubber seals with

clapp rings

for the pistons are to be replaced every time repair

work is carried out on the brake caliper.

6. Thoroughly clean all reusable parts

- complete

brake caliper and pistons

- with denatured alcohol

and dry with compressed air. Prior to cleaning, screw

bleeder valve out of caliper.

7. Lightly coat new rubber fluid seals with brake

fluid and insert fluid seals into grooves of brake

caliper bores.

8. Place brake caliper into vise to install pistons.

After installing one piston, change position of brake

caliper in vise to install second piston. The piston to

friction pad spacer plates should be used as a gauge

to locate relieved edge of piston at 20 degrees to

horizontal during piston installation. See Steps

9-IO-

11-12.9. Place caliper mounting half in vise and coat its

bore and piston lightly with brake fluid. Then push

piston, with hollow end towards brake disc, into the

caliper bore. Turn piston so that the relieved edge

faces downwards at an angle of 20 degrees and facing

in brake disc direction. The guide surface in the

caliper half recess at the brake pipe connection side,

will properly align the piston. Push piston into

caliper bore up to the stop.

10. Change position of brake caliper and install sec-

ond piston in the same manner.

11. Install new rubber seals with clamp rings. Make

sure that the rubber seals are properly seated on the