check oil OPEL GT-R 1973 Repair Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 471 of 625

7C-1101973 OPEL SERVICE MANUALHSEAL

REVERSE CLUTCH

Figure

7C-151Figure 7C-153Figure

7C-15230. Install new oil seals on reverse clutch piston. See

Figure

7C-153.31. Install reverse clutch piston onto rear face of oil

pump using liberal amount of transmission fluid. See

Figure

7C-154.32. Inspect reverse clutch piston springs. Evidence of

extreme heat or burning in the area of the clutch may

have caused the springs to take a heat set and would

justify replacement of the springs.

33. Install the twenty-four reverse clutch piston re-

turn springs.Figure

7C-15434. Install retaining seat.

35. Compress return springs using second and re-

verse clutch piston spring compressor tool J-2590-12

with adapter J-21420-1. Care should be taken not to

damage retainer should retainer catch in snap ring

groove. See Figure 7C-155.

36. Install snap ring using snap ring pliers such as

J-8059. See Figure 7C-155. Do not air check reverse

clutch as the clutch is not complete and damage to

the return spring retaining seat may occur.

Page 472 of 625

AUTOMATIC TRANSMISSION 7C-111

OIL PUMP /’ASSEMBLY

ASPklNG

I(ETAINERSNAP RING

PLIERS

h7C146

Figure 7C.15537. Turn oil pump and reverse clutch assembly so

that oil pump face is facing up.

38. Install oil pump gears using the location mark

made before disassembly.

39. Check the end clearance of both gears to the oil

pump face. Clearance should be between

.0005 to

.0035. See Figure 7C-156.Disassembly, Inspection and Reassembly of Second

Clutch

1. Remove ring gear retaining ring from second

clutch drum. See Figure X-157.

GEAR

Figure

7C-1572. Remove ring gear. See Figure

7C-158.

SECOND CLUTCH DRUM

:-157Figure

7C-15641. Replace the oil pump assembly if the end clear-

ance is not within specifications.Figure 76.158

3. Remove second clutch spacer plate retaining ring.

4. Remove second clutch spacer plate. See Figure7c- 159.

Page 477 of 625

7C.1161973 OPEL SERVICE MANUALDRUM

THIRD CLUTCH

PISTON

70174Figure 7C-174

damaged, replace piston. Install new lip seal on pis-

ton. See Figure

7C-175.

CHECKTHI

Figure 7C-175

12. Install new oil lip seal on input shaft inside of

third clutch drum. See Figure

7C-176.13. Inspect steel thrust washer on front face of third

clutch drum. Replace if scored or damaged. See Fig-

ure 7c-177.

14. Install third clutch piston into third clutch drum

using a

.020 music wire crimped into a piece of cop-

per tubing and a liberal amount of transmission fluidFigure 7C-176

Figure 7C-177

so that lip seal is not damaged upon installation. See

Figure

7C-178.15. Install the 12 third clutch piston return springs

onto piston.

16. Install retaining seat.

17. Using compressor tool J-23075 on retaining seat,

compress piston return springs. Care must be taken

so that retaining seat does not catch in snap ring

groove and damage retainer.

18. Install snap ring using snap ring pliers such as J-

8059.

Page 485 of 625

7C.1241973 OPEL SERVICE MANUAL

14. Remove the downshift timing valve plug retain-

ing pin and remove downshift timing valve plug.

Remove the low speed downshift timing valve and

spring.

15. Remove the manual low and r&erse control

valve retaining pin. Remove the spring and the

manual low control valve and the reverse control

valve.

16. Remove the l-2 accumulator valve retaining pin

and remove the l-2 accumulator valve plug, l-2 ac-

cumulator valve and spring.

17. A clean work area which is free of dirt and dust

should be used to inspect, clean and install the valves

in the valve body. Handle valve components with

clean hands and tools. Since most valve failures are

caused initially by dirt or other foreign matter pre-

venting a valve from functioning properly, a

thorough cleaning of all the components with a

cleaning solvent is essential. Do not use paraffin toclean out the valve body passages and valve bore.

Compressed air may be used to blow out the pas-

sages.18. Inspect each valve for free movement in its re-

spective bore in

t.he valve body. If necessary, use

crocus cloth to remove small burrs on a valve. Do

not remove the sharp edges of the valves as these

edges perform a cleaning action within the bore.

19. Inspect the valve springs for distortion or col-

lapsed coils. Replace the entire valve body assembly

if any parts are damaged.

20. Inspect the transfer plate for dents or distortion.

Replace transfer plate if necessary.

21. Reassemble the valves, springs, plugs and retain-

ing pins in their proper location and order into the

valve body using a liberal amount of transmission

fluid. See the spring data chart which includes the

spring identification sizes in the event springs have

been disarranged.

LocationApplication

PumpPressureRegulator Valve....................................................

PumpPrimingValve

...........................................................

.............Valve Body1.2ShiftValve......................................................................

Valve Body2-3ShiftValve......................................................................

Valve BodyDetentPressureRegulatorValve......................................

Valve BodyHigh-Speed Timing Valve....................................................

Valve BodyLow-Speed

TimingValve....................................................

Valve BodyReverse and Low Control Valve

........................................

CSSDetentValve..........................................................................

Valve Body1-2 Accumulator Valve........................................................

Valve Body3-2Control

Valve..................................................................

Gov. BodySecondary

Governor Valve................................................

Valve BodyAccumulator Piston

..............................................................

CaseServo Return..........................................................................SHVOServoCushion

........................................................................

Clutch PackClutchReturn(All)................................................................ SPRING IDENTIFICATION CHART

FreeOuter

HeightDiameter

2.756

,7601.043

,3202.467

,7201.769

,7001.625,474

1.349

,4061.380,406

1.343

,4062.569

,6751.072

,5201.853

.4061.317

,4061.9171.224

2.2401.850

1.0391.267

1.050

,42422. Install spring and accumulator piston in valve

body.

23. Compress accumulator piston with C-clamp and

install retaining ring.

24. Install new valve body gasket.2. Inspect and clean oil passages with cleaning sol-

vent and air.

3. Check for good retention of band anchor pins.

25. Bolt the transfer plate and gasket to the valve

body. Torque to 6-8 lbs. ft.

Disassembly, Inspection and Reassembly of Case

1. Inspect case for damage. See Figure

7C-202.4. Inspect all threaded holes for thread damage.

5. Inspect detent valve and modulator valve bores for

scratches or scoring.

6. Inspect case bushing inside of case at rear. If

da-maged, remove bushing with remover and installer

tool J-23 130-3 and driver handle J-8092. See Figure

7C-203.

Page 486 of 625

AUTOMATIC TRANSMISSION 7C-1251. CASE VENT4.3RD CLUTCH7.SUCTION

2. CONVERTER OUT5MODULATOR8.LINE/3.2ND CLUTCH

6. BOOST9.REVERSEFigure 7C-202 Case Front View Oil Passage

Identification

7.

!nspect reaction sun gear drum bushing sleeve

inside case at rear for scoring. If necessary, replace

sleeve before installing rear case bushing.

8. Remove sleeve by grinding. Care must be used in

order that aluminum case is not damaged when

grinding sleeve.

9. Install new sleeve using installer tool J-23130-7

and driver handle J-8092.

10. Install new case bushing using remover and in-

staller tool J-23130-3 and driver handle J-8092.

Bushing should be installed flush with case at rear.

See Figure

7C-203.Figure 7C-2031. Drain Converter. If clutch disc material or

foreign matter has been found while draining con-

verter,

replace entire converter assembly as it can not be

cleaned properly.

2. Air check converter for leaks using converter

checking tool J-21369. Install tool and tighten. Ap-

ply 80 psi air pressure to tool. See Figure

7C-204.Figure 7C-204

3. Submerge in water and check for leaks.

4. Check converter hub surfaces for scoring or wear.

Installation of Selector Lever and Shaft1. Install new selector lever shaft oil seal in case.

Insert selector lever shaft through case from outside.

Care should be exercised so that oil seal is not da-

maged. See Figure

7C-206.2. Insert spring pin in case to secure selector lever

shaft.3. Guide selector lever over shaft and secure with

lock nut.

4. Insert parking

paw1 actuator rod from front of the

case and through hole in case at rear. See Figure 7C-

207.5. Install parking

paw1 actuator rod retaining ring.

Installation of Low Band1. Turn transmission case so that front of case is

upward.

Page 490 of 625

AUTOMATIC TRANSMISSION 7C-129

4. Install reverse clutch cushion plate (wave washer)2. Insert guide pin into oil pump for alignment of

into case.converter housing and lower housing onto pump.Determining Selective Washer Size

1. Place gauging tool J-23085 on case flange andagainst input shaft. See Figure

7C-215.3. Install new oil seal washers on converter housing

to oil pump bolts, and loosely install bolts into con-

verter housing.

4. Use convkrter housing to oil pump aligning tool J-23082 to align converter housing to pump. See Fig-

ure

7C-216. Tool should bottom on oil pump gear.

Figure 7C-2 152. Loosen thumb screw on tool to allow inner shaft

to drop on second clutch drum hub.

3. Tighten thumb screw and remove tool J-23085.

4. Place selective washer removed from transmission

against inner shaft of tool J-23085. Selective washer

should be flush with top face of shaft. If not flush,

select next larger or smaller washer until correct size

is obtained. The washer selected should be exactly

flush or slightly below inner shaft for correct end

play in transmission. Selective washer removed from

transmission may be oil soaked and discolored.

CObX

ID

Yellow

Blue

Red

BVSNIl

GPX3”

Black

Thickness,070.,074,076.,080

.08 l-.085,086.,090,091.,095

,097.,101

Installation of Converter Housing, Oil Pump and

Reverse Clutch Assembly1. Turn case so that bottom of transmission is facing

upward.

1. Install oil pump wear plate onto oil pump.2. Slide governor hub along output shaft and seat

Figure 7C-2 165. Tighten the five bolts. Torque to

13-17 Ibs. ft. and

remove aligning tool l-23082.

6. Install new converter housing to case rubber oil

seal.7. Install new pump flange gasket.

8. Place selective washer, previously determined,

onto the oil pump shaft and retain with petroleum

jelly (unmedicated).

9. Install two guide pins in case and lower converter

housing and oil pump into case. See Figure

7C-217.10. Bolt converter housing to case using new oil seal

washers on all seven bolts. Torque to 13-17 lbs. ft.

I I. Check for correct assembly by turning input shaft

by hand.

Installation of Governor Assembly

Page 495 of 625

7C-1341973 OPEL SERVICE MANUAL

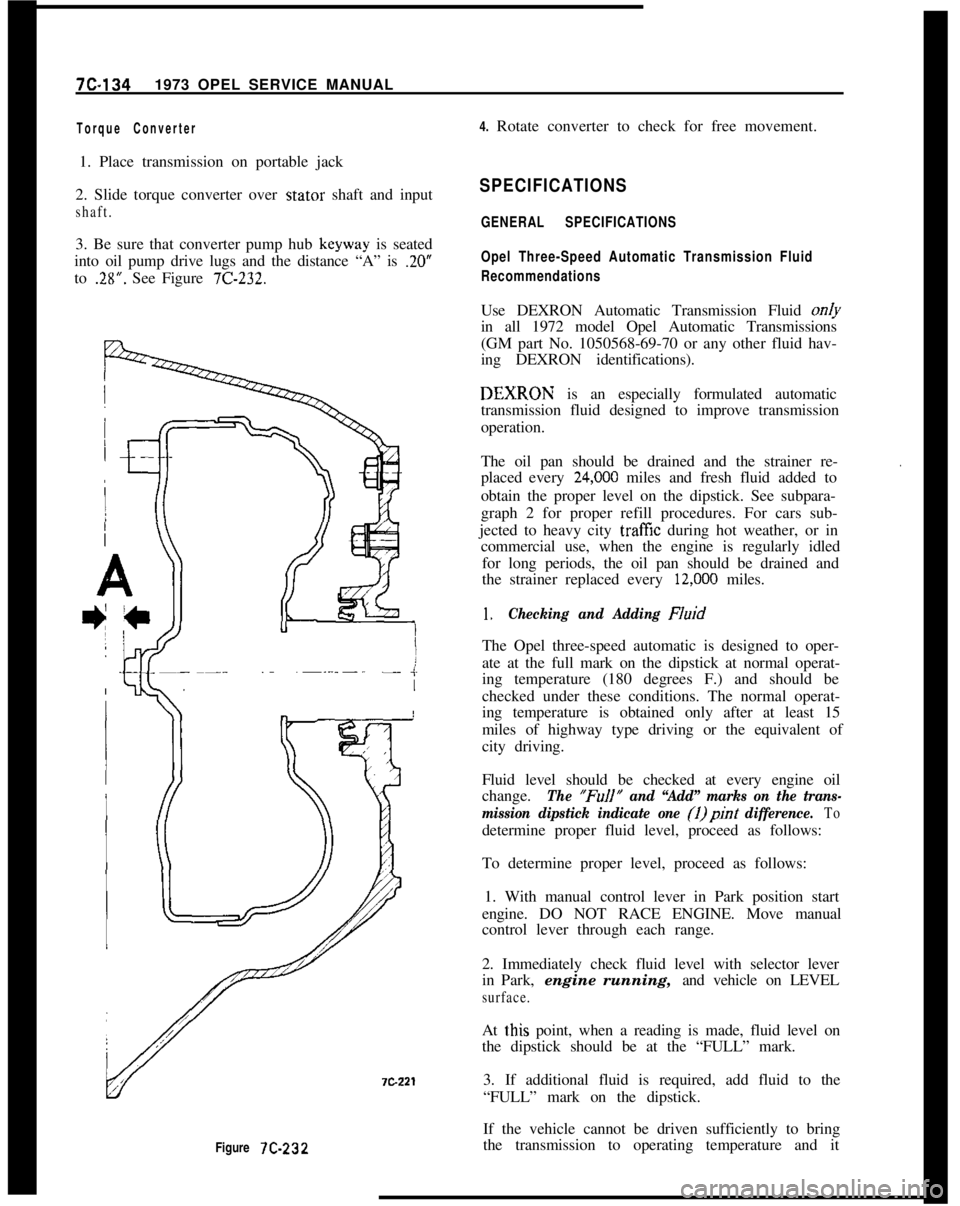

Figure 7C-232

Torque Converter4. Rotate converter to check for free movement.

1. Place transmission on portable jack

2. Slide torque converter over stator shaft and input

shaft.3. Be sure that converter pump hub keyway is seated

into oil pump drive lugs and the distance “A” is

.20”to

.28”. See Figure 7C-232.

SPECIFICATIONS

GENERAL SPECIFICATIONS

Opel Three-Speed Automatic Transmission Fluid

RecommendationsUse DEXRON Automatic Transmission Fluid on/y

in all 1972 model Opel Automatic Transmissions

(GM part No. 1050568-69-70 or any other fluid hav-

ing DEXRON identifications).DEXIRON is an especially formulated automatic

transmission fluid designed to improve transmission

operation.

The oil pan should be drained and the strainer re-

placed every

24,ooO miles and fresh fluid added to

obtain the proper level on the dipstick. See subpara-

graph 2 for proper refill procedures. For cars sub-

jected to heavy city

traff%z during hot weather, or in

commercial use, when the engine is regularly idled

for long periods, the oil pan should be drained and

the strainer replaced every

12,ooO miles.

.

1.Checking and Adding FluidThe Opel three-speed automatic is designed to oper-

ate at the full mark on the dipstick at normal operat-

ing temperature (180 degrees F.) and should be

checked under these conditions. The normal operat-

ing temperature is obtained only after at least 15

miles of highway type driving or the equivalent of

city driving.

Fluid level should be checked at every engine oil

change.

The “FuIl” and “Add” marks on the trans-

mission dipstick indicate one (1)pint

difference. Todetermine proper fluid level, proceed as follows:

To determine proper level, proceed as follows:

1. With manual control lever in Park position start

engine. DO NOT RACE ENGINE. Move manual

control lever through each range.

2. Immediately check fluid level with selector lever

in Park, engine running, and vehicle on LEVEL

surface.At

t,his point, when a reading is made, fluid level on

the dipstick should be at the “FULL” mark.

3. If additional fluid is required, add fluid to the

“FULL” mark on the dipstick.

If the vehicle cannot be driven sufficiently to bring

the transmission to operating temperature and it

Page 496 of 625

AUTOMATIC TRANSMISSION 7C-135

becomes necessary to check the fluid level, the trans-

mission may be checked at room temperature (70

degrees F.) as follows:

1. With manual control lever in Park position start

engine. DO NOT RACE ENGINE. Move manual

control lever through each range.

2. lmmediately check fluid level with selector lever

in Park, engine running, and vehicle on LEVEL sur-

face.At this point, when a reading is made, fluid level on

the dipstick should be I/4” below the “ADD” mark.

3. If additional fluid is required add fluid to bring

level to

l/4” below the “ADD” mark on the dip-

stick.If transmission fluid level is correctly established at

70 degrees F. it will appear at the “FULL” mark on

the dipstick when the transmission reaches normal

operating temperature (180 degrees F.) The fluid

level is set

l/4” below the “ADD” mark on the

dipstick to allow for expansion of the fluid which

occurs as transmission temperatures rise to normal

operating temperature of 180 degrees F.

Do not overfill, as foaming and loss of fluid through

the vent pipe might occur as fluid heats up. If fluid

is too low especially when cold, complete loss

of’drive may result which can cause transmission fail-

ure.

2.Draining oilpan and rep/a&g strainer assembly.

(a) Raise car on hoist or p/ace OnJxk stands, and

provide container to collect draining fluid.

(b) Remove oil pan and gasket. Discard gasket.

(c) Drain fluid from oil pan. Clean pan with solvent

and dry thoroughly with clean compressed air.

(d) Remove strainer assembly, strainer gasket and

discard.

(e) Install new oil strainer gasket. Install new strainer

assembly.

(f) Install new gasket on oil pan and install pan.

Tighten attaching bolts to 7-10 lb. ft.

(g) Lower car and add approximately three (3) pints

of transmission fluid through filler tube.

(h) With manual control lever in Park position, start

engine. DO NOT RACE ENGINE. Move manual

control lever through each range.

(i) Immediately check fluid level with selector leverin Park, engine running, and vehicle on LEVEL

sur-

face.(i) Add additional fluid to bring level to

l/4” below

the “ADD” mark on the dipstick. Do not overfill.

3.Adding Fluid to Fill Dry Transmission and Con-

verter Assembly

The fluid capacity of the Opel Three Speed Auto-

matic transmission and converter assembly is ap-

proximately IO-l/2 pints, but correct level is

determined by the mark on the dipstick rather than

by amount added. In cases of transmission overhaul,

when a complete fill is required, including a new

converter proceed as follows:

(a) Add approximately 10-l/2 pints of transmission

fluid through tiller tube.

The converter should be replaced on any major fail-

ure, such as a clutch or gearset, and an excessive

amount of foreign material is indicated in the pan. If

installation of a new converter is not required add

approximately five (5) pints of transmission fluid.

(b) With manual control lever in Park position start

engine and run at 1000 RPM. DO NOT RACE EN-

GINE. Move manual control lever through each

range.

(c) Immediately check fluid level with selector lever

in Park, engine running, and vehicle on LEVEL

sur-

face.(d) Add additional fluid to bring level to

l/4” below

the “ADD” mark on the dipstick. Do not overfill.

Opel Three Speed Automatic Transmission Towing

Instructions

If an Opel equipped with an automatic transmission

must be towed, the following precautions must be

observed:

The car may be towed safely on its rear wheels with

the shift lever in neutral position at speeds of 35 miles

per hour or less under most conditions.

However, the drive shaft must be disconnected or the

car towed on its front wheels if:

a. Tow speeds in excess of 35 mph are necessary.

b. Car must be towed for extended distances (over 50

miles).

c. Transmission is not operating properly.

If car is towed on its front wheels, the steering wheel

Page 497 of 625

7C-1361973 OPEL SERVICE MANUALshould be secured to keep the front wheels in a

straight-ahead position.sand,. mud, or snow, move the selector lever from

“D” to “R” in a repeat pattern while simultaneously

applying moderate pressure to the accelerator. DoRocking Carnot race engine. Avoid spinning wheels when trying

If it becomes necessary to rock the car to free it fromto free the car.

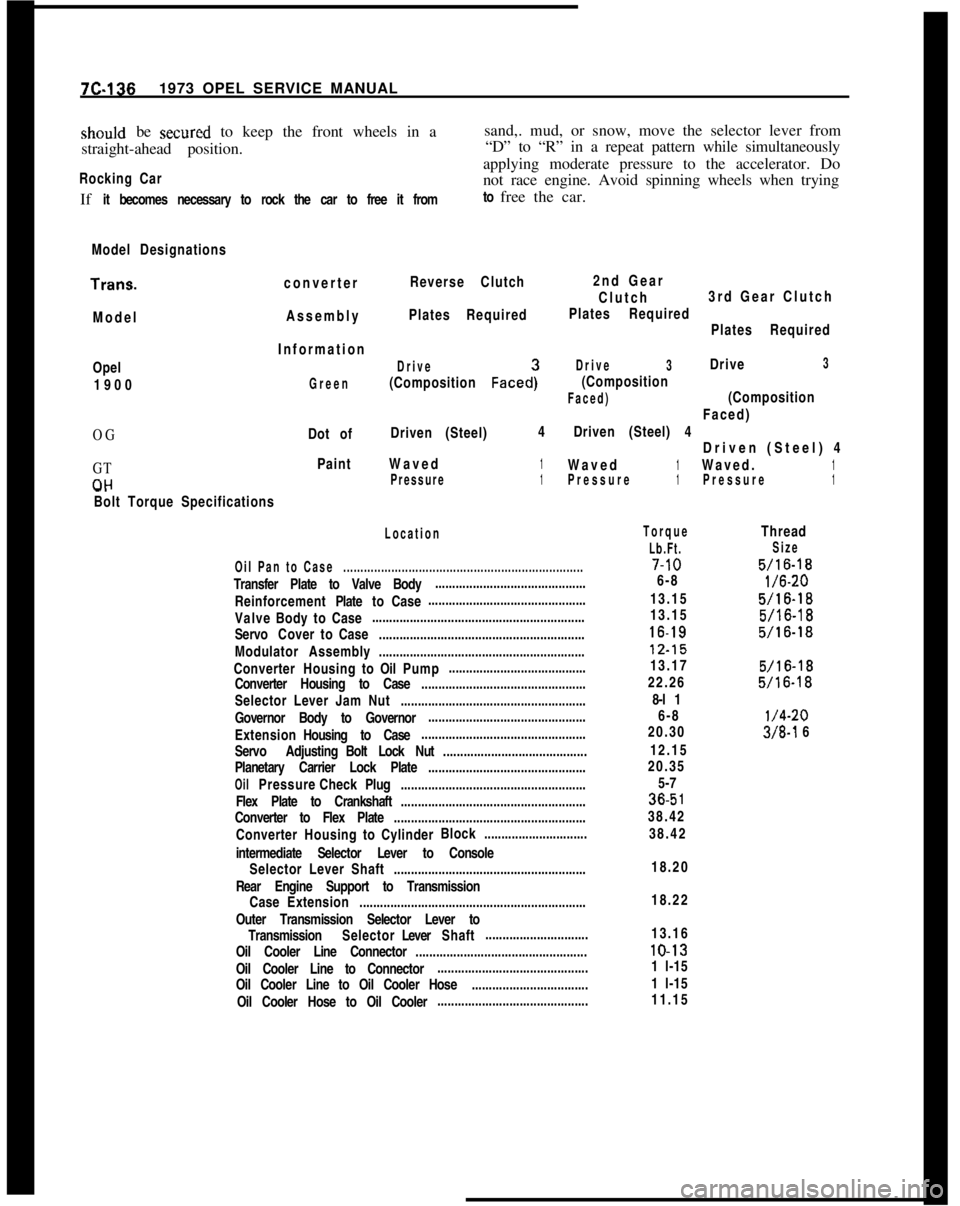

Model DesignationsTrans.

converterReverse Clutch

ModelAssemblyPlates Required2nd Gear

Clutch3rd Gear Clutch

Plates Required

Plates RequiredOpel

1900

OG

GT

CIHInformation

Drive

(Composition Faced:

Drive3Drive3

Green

(Composition

Faced)(CompositionFaced)

Dot ofDriven (Steel)4Driven (Steel) 4

Driven (Steel) 4

PaintWaved1Waved1Waved.1Pressure1Pressure1Pressure1-.

Bolt Torque Specifications

Location

Oil Pan to Case......................................................................Transfer Plate to Valve Body............................................

ReinforcementPlatetoCase..............................................

ValveBodytoCase..............................................................

ServoCovertoCase............................................................

Modulator Assembly............................................................

ConverterHousingtoOilPump........................................

Converter Housing to Case................................................

Selector Lever Jam Nut......................................................

Governor Body to Governor..............................................

ExtensionHousing to Case................................................

Servo AdjustingBolt Lock Nut..........................................

Planetary Carrier Lock Plate..............................................

OilPressureCheckPlug......................................................

Flex Plate to Crankshaft......................................................

Converter to Flex Plate........................................................

ConverterHousingtoCylinderBlock..............................

intermediate Selector Lever to Console

Selector Lever Shaft........................................................

Rear Engine Support to Transmission

CaseExtension..................................................................

Outer Transmission Selector Lever to

TransmissionSelectorLeverShaft..............................

Oil Cooler Line Connector..................................................

Oil Cooler Line to Connector............................................

Oil Cooler Line to Oil Cooler Hose..................................

Oil Cooler Hose to Oil Cooler............................................

Torque

Lb.Ft.7-10

6-8

13.15

13.1516-1812.15

13.17

22.26

8-l 1

6-8

20.30

12.15

20.35

5-736.5

138.42

38.42

Thread

Size

5/16-18

l/6-20

5/16-18

5/16-18

5/16-18

5/16-18

5/16-18

l/4-20

3/8-l 6

18.20

18.22

13.1610-13

1 l-15

1 l-15

11.15

Page 529 of 625

98-20 1973 OPEL SERVICE MANUAL

If we were to put a thermometer in the cold drain

water, we would see the temperature gradually creep

upwards. That is to be expected because heat is flow-

ing into the cold water making it warmer. Before

long the water would be as warm as the stored foods.

Then the water could no longer attract heat because

heat will not flow from one warm object to another

equally warm object. Since we no longer can draw

heat out of the foods we no longer are cooling them.

Now, let’s see what happens when we put ice instead

of cold water into the ice-box. This time, we’ll set the

thermometer on top of the ice (Fig. 9B-5). When wefirst look at the thermometer, it reads 32 degrees. A

couple of hours later, we open the ice compartment

door. The ice block is smaller because some of the ice

has already melted away

- but the thermometer still

reads 32 degrees. Again, still later, even more of the

ice has melted, yet the termometer continues to read

32 degrees. So long as any ice remains, no matter

how much of it has melted away, the temperature of

the ice stays right at 32 degrees.

All this time the ice has been soaking up heat, yet it

never gets any warmer no matter how much heat it

draws from the stored food. On the other hand, the

cold drain water got progressively warmer as it

soaked up heat. Why is it the addition of heat will

make water warmer yet won’t raise the temperature

of ice above the 32 degrees mark? If we till one

drinking glass with ice and another with cold water,

and put both glasses in the same room where they

could absorb equal amounts of heat from the room

air, we will find it takes much, much longer for the

ice to melt and reach room temperature than it did

for the water in the other glass to reach the same

temperature. Obviously, most of the heat was being

used to melt the ice. But it was the heat that appar-

ently disappeared or went into hiding because if

couldn’t be located with a thermometer. To best de-

scribe this disappearing heat, scientists turned to

Latin for the right word. They chose the word “la-

tent” which means hidden.

Latent Heat

So latent heat is nothing more nor less than hidden

heat which can’t be found with a thermometer.

What happens to the latent heat? Where does it

disappear to? At first it was thought it was in the

water that melted from the ice. But that wasn’t ex-

actly the right answer because, upon checking water

temperature as it melts from ice, it will be found that

it is only a shade warmer than the ice itself. It is not

nearly warm enough to account for all the heat the

ice had absorbed. The only possible answer is that

the latent heat had been used up to change the ice

from a solid into a liquid.

Many substances can be either a solid, or a liquid, ora gas. It just depends on the temperature whether

water for example was a liquid, or a solid (ice), or gas

(steam) (Fig.

9B-6).Figure 99-6 Temperature Determines State of Water

If we put some water in a tea-kettle, set it over a tire

and watch the thermometer as the water gets hotter

and hotter, the mercury will keep rising until the

water starts to boil. Then the mercury seems to stick

at the 212 degrees mark. If we put more wood on the

fire, despite all the increased heat, the mercury will

not budge above the 212 degree mark (Fig.

9B-7).Figure 98.7 Boiling Water Never Exceeds 2 12

DegreesEven though many housewives won’t believe it, no

matter how large or hot you make the flame, you

can’t make water hotter than 2 12 degrees. As a liquid

changes into a gas, it absorbs abnormally great

amounts of heat without getting any hotter. Here is

another instance where heat disappears.

Now we have two different kinds of latent heat,

which are quite alike. To keep their identities sepa-

rate, the first one is called latent heat of fusion. Since

fusion means the same as melting, it is a good de-

scriptive name. The other kind is called latent heat

of vaporization because‘ that means the same as

evaporation.

It may seem as though we have drifted into a story