lights OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 19 of 625

CC-10 1973 OPEL SERVICE MANUAL

wiper blades. Check amount and direction of fluid

sprayed by washers during use.,

E. Defrosters - Check performance by moving con-

trols to “DEF” and noting

am$nmt of air directed

against the windshield.

I

F. Wheel Alignment and

Balabce - In addition to

abnormal tire wear, the need fbr wheel alignment

service may be indicated by a pull to the right or

!eftwhen driving on a straight and level road. The need

for wheel balancing is usually

iddicated by a vibra-

tion of the steering wheel or

se;+ tihile driving at

normal highway speeds.I

IG. Brakes

- Be alert to illumiriation of the brake

warning light or changes in braking action,

SUCK as

repeated pulling to one side, unusual sounds when

braking or increased brake pedal travel. Any of thesecould indicate the need for

brakk system inspection

and/or service.

H. Parking Brake and Transmission “PARK”

Mechanism

- Check parking brake holding ability by

parking on a fairly steep hill and restraining the vehi-

cle with the parking brake only.

eon cars with auto-

matic transmissions, check the holding ability of the

“PARK” mechanism by releasing all brakes after

the transmission selector lever hak been placed in the“P” position.

I. Glass

- Check for broken, scrritched, dirty or da-

maged glass on vehicle that

coulld obscure vision’or

become an injury hazard.

J. Lights and Buzzers

- Check all instrument panel

illuminating and warning lights,’ seat belt reminder

light and buzzer, ignition key

b&er, interior lights,

license plate lights, side marker! lights, headlamps,

parking lamps, tail lamps, brake lights, turn signals,

backup lamps, and hazard warding flashers. Have

someone observe operation of

&ach exterior light

while you activate the controls: The operation of

instrument panel warning lights is covered in the

“Starting and Operating“ section of your

Own&%

Manual.K. Transmission Shift Indicator

‘- Check to be sure

automatic transmission shift

indiCator accurately i”-

dicates the shift position selected.

I

CAUTION: Before making thk check below,I

be sure to have a clear dist&e ahead and:

behind the car, set the parking brake and

firmly apply the foot brake.

Do not depress

accelerator pedal. Be prepared to

turn off ’

ignition switch

immediat+y if engine

should start.L. Starter Safety Switch (Automatic Transmissibn

Cars)

- Check starter safety switch by placing the

transmission in each of the driving gears while

at-tempting to start the engine. The starter should oper-ate only in the Park (“P”) or Neutral (“N”)

positions.

M. Horn

- Blow the horn occasionally to be sure thatit works. (Ignition switch must be in the “ON” posi-

tion.)

N. Seat Back Latches

- Check to see that seat back

latches are holding by pulling forward on the top of

each folding seat back.

0. Rearview Mirrors and Sun Visors

- Check that

friction joints are properly adjusted so mirrors and

sun visors stay in the selected position.

P. Door Latches

- Check for positive closing, latch-

ing and locking.

Q. Hood Latches - Check to make sure hood closesfirmly by pressing on the hood at the latching point

after each closing. Check also for broken, damaged

or missing parts which might prevent secure latch-

ing.R. Fluid Leaks

- Check for fuel, water, oil or other

fluid leaks by observing the ground beneath the vehi-cle after it has been parked for a while. If gasoline

fumes or fluid are noticed at any time, the cause

should be determined and corrected without delay

because of the possibility of fire.

S. Exhaust System

- Be alert to any change in the

sound of the exhaust system or a smell of fumes

which may indicate a leak.

Head Restraints

- Check that no head restraint

components are missing, damaged or loose. (Does

not apply to GT Models).

Disc BrakesCheck brake pads and condition of rotors while

wheels are removed during tire rotation. (Note belowregarding more frequent checks also applies to disc

brakes.)

Parking and Drum BrakesCheck drum

brake linings and other internal brake

components at each wheel (drums, wheel cylinders,

etc.). Parking brake adjustment also should be

checked whenever drum brake linings are checked.

NOTE: More frequent checks should be

made if driving conditions a.nd habits result

in frequent brake application. When brakes

require relining, it is recommended thatyou use those genuine General Motors

parts specified for your car,and Delco fluid

as required.

Page 20 of 625

LUBRICATION AND MAINTENANCE OC-11

Throttle Linkage

Check for damaged or missing parts, interference or

binding. Any deficiencies should be corrected with-

out delay.

Headlights

Check for proper aim. Correct as necessary. More

frequent checks should be made if oncoming motor-

ists signal when you are already using your low

beams, or if illumination of the area ‘ahead seems

inadequate.

Underbody

In geographic areas using a heavy concentration of

road salt or other corrosive materials for snow re-

moval or road dust control, flush and inspect the

complete under side of the car at least once each

year, preferably after a winter’s exposure. Particular

attention should be given to cleaning out underbody

members where dirt and other foreign materials may

have collected.

EMISSION CONTROL MAINTENANCE

Thermostatically Controlled Air Cleaner

Inspect installation to make certain that all hoses and

ducts are connected and correctly installed. Also,

check valve for proper operation.

Carburetor Choke

Check choke mechanism for free operation. A bind-

ing condition may have developed from petroleum

gum formation on the choke shaft or from overtight-

ening of air cleaner clamp. Also check electric choke

terminal connections and fuse.

Timing, Dwell and Distributor

Adjust timing and dwell accurately as outlined under

Tune-Up in Group 6 at the first 4 months or 6,ooOmiles of operation, then at 12 month or

12,OQO mile

intervals. Adjustments must be made with test equip-

ment known to be accurate.

Replace distributor points every 12 months or 12,000

miles and carefully clean and inspect the complete

distributor cap to prevent misfiring and deteriora-

tion.

Carburetor and Idle

SpeedTorque carburetor attaching bolts and/or nuts to 12

ft.lbs. to compensate for compression of gasket atiirst 4 months or 6,000 miles of vehicle operation.Adjust idle speed to specifications with known accu-

rate equipment.

Proper functioning of the carburetor is particularly

essential to control of emissions. Correct mixtures

for emission compliance and idle quality have been

preset by Opel. Plastic idle mixture limiters have

been installed on the idle mixture screw, idle air

screw, and throttle stop screw to preclude unauthor-

ized adjustment. The plastic caps on the idle mixture

screw and the idle adjustment screw must be

removed to perform an idle speed adjustment. The

plastic cap on the throttle stop screw is not to be

removed unless some major carburetor repair or re-

placement which affects the throttle stop screw ad-

justment has been necessary.

Carburetor Fuel Inlet Filter

Replace filter at 12 month or

12,OCO mile intervals

or more often if clogged.

Spark Plugs

Replace at

6,ooO mile intervals when operating with

leaded fuels or at 12,000 mile intervals when using

unleaded fuels. Use of leaded fuels results in lead

deposits on spark plugs and can cause misfiring at

mileages less than

12,OilO miles. Where misfiring oc-

curs prior to

6,ooO miles, spark plugs in good condi-

tion can often be cleaned, tested and reinstalled in an

engine with acceptable results.

Spark Plug Wires

Inspect spark plug wires for evidence of checking or

cracking of exterior insulation and tight fit in the

distributor cap and at the spark plugs. Exterior of

wires should be cleaned, any evidence of corrosion

on ends removed and wire replace if deteriorated.

Positive Crankcase Ventilation System

The PCV metered orifice should be cleaned at 12,000

mile intervals under normal use, and at 6,000 mile

intervals when the vehicle is used under the follow-

ing conditions: driving in dusty conditions, extensive

idling, trailer pulling and short trip operation at

freezing temperatures (engine not thoroughly

warmed-up).

Evaporation Control System

Check all fuel and vapor lines and hoses for proper

connections and correct routing as well as condition.

Remove canister and check for cracks or damage.

Replace damaged or deteriorated parts as necessary.

Replace filter in open end of canister at 24month/24,000 mile intervals.

Page 25 of 625

1A. 4 1973 OPEL SERVICE MANUAL

gravity corrected to 80 degrees F.’ shows more than

a thirty point

(.030) drop from the initial tilling with

electrolyte, or if one or more cells’gas violently after

addition of electrolyte, the batteiy should be fulty

charged before use.

3. For best performance in cold weather (32 degrees

F. or less), or if the battery and the electrolyte are not

at 60 degrees F., or above at time of activation, warm

the battery by boost charging.

TROUBLE DIAGNOSIS

BATTERY AND CABLES. TRDUBLE DIAGNOSIS

Quick Check of Battery and Cables

Whenever electrical trouble developes, it is desirable

to make a quick check of the battery and cables to

make certain that this source of current is in good

condition, securely connected, and is functioning

properly. This check will also give a good check on

the cranking system.

1. Turn on the lights. They should’burn steadily and

with normal brilliance.

2. With lights burnings, operate the cranking motor.

Either have the headlights shining on a wall so their

brilliance can be noted, or have someone watching

the headlights.

3. When cranking motor solenoid switch is

closeh,one of the following conditions will occur; (1) Lights

will stay bright or will dim slightly if temperature is

cold, and engine will be cranked at normal speed; (P

Lights will

gb out; (3) Lights will dim considerably;

(4) Lights will stay bright but no cranking action will

take place. The first named condition indicates that

nothing is wrong with the battery, cables, and crank-

ing system. The other conditions indicate trouble

aSfollows:

4. If fightsgo

out as cranking motor solenoid switch

is closed, it indicates a poor connection in the circuit

between battery and cranking motor. Check battery

cables and clean and tighten loose or corroded termi-

nals.

5. If

lights dim considerably as cranking motor

solenoid switch is closed, it indicates that the battery

is run down, or there is a condition in cranking

mb-tor or engine which causes an excessive current drain

on the battery. A low battery will be indicated by ,a

clattering noise in cranking motor solenoid because

the battery cannot sustain the voltage required to

hold solenoid plunger “in” after switch contacts

close and the “pull in” winding is shorted out.

Test battery with a 421 Battery Test. If battery is

found to be in good condition check cranking motor.

6.Iflights stay bright but no cranking action occurswhen cranking motor solenoid switch is closed, it

indicates an open circuit in cranking motor, switch,

or control circuit.

Testing Resistance of Cables and Terminal

Connections

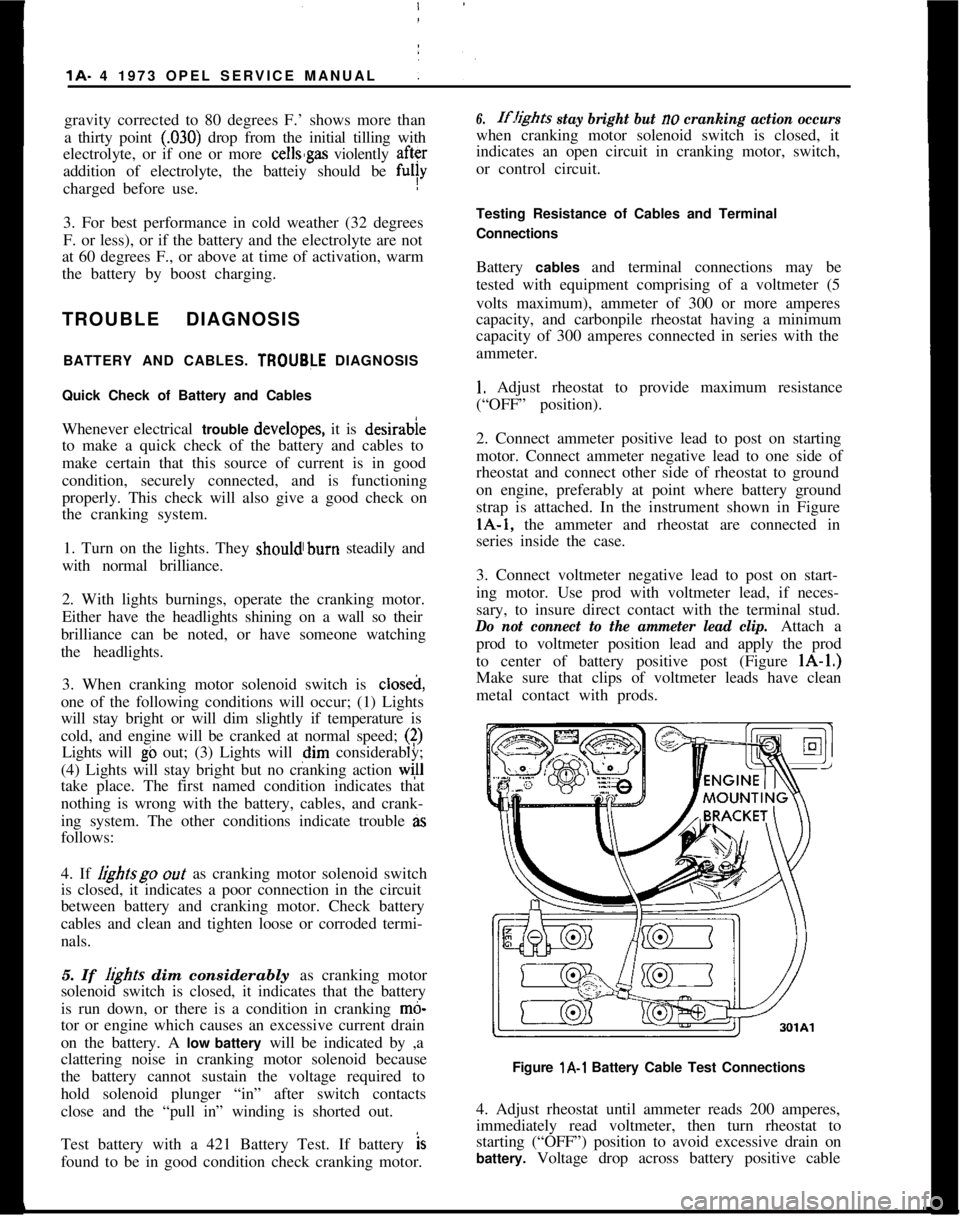

Battery cables and terminal connections may be

tested with equipment comprising of a voltmeter (5

volts maximum), ammeter of 300 or more amperes

capacity, and carbonpile rheostat having a minimum

capacity of 300 amperes connected in series with the

ammeter.

I. Adjust rheostat to provide maximum resistance

(“OFF” position).

2. Connect ammeter positive lead to post on starting

motor. Connect ammeter negative lead to one side of

rheostat and connect other side of rheostat to ground

on engine, preferably at point where battery ground

strap is attached. In the instrument shown in FigurelA-1, the ammeter and rheostat are connected in

series inside the case.

3. Connect voltmeter negative lead to post on start-

ing motor. Use prod with voltmeter lead, if neces-

sary, to insure direct contact with the terminal stud.

Do not connect to the ammeter lead clip.Attach a

prod to voltmeter position lead and apply the prod

to center of battery positive post (Figure lA-1.)

Make sure that clips of voltmeter leads have clean

metal contact with prods.

Figure l A-l Battery Cable Test Connections

4. Adjust rheostat until ammeter reads 200 amperes,

immediately read voltmeter, then turn rheostat to

starting (“OFF”) position to avoid excessive drain on

battery. Voltage drop across battery positive cable

Page 26 of 625

BATTERY AND CABLES - ALL MODELSlA- 5

and terminal connections should not exceed 2/10

volt.

5. Connedt voltmeter positive lead to ground on en-

gine.

At&h prod to voltmeter negative lead and

apply prod to center of battery negative post. Volt-

age drop across the battery ground cable and termi-

nal conne$tions should not exceed 2/10 volt at

200amps.

6. A reading in excess of 2/10 volt when testing

either battery cable indicates excessive resistance in

cable or cpnnections. Clean and tighten cable or con-

nections. Clean and tighten cable terminals

(sub-para. c, below) and recheck for voltage drop. If volt-

age drop Still exceeds 2/10 volt, replace cable with a

genuine Buick-Opel cable to insure ample capacity.

Undercharge Failure of BatteryThe most frequent trouble experienced with storage

batteries is failure to maintain a state of charge suffi-

cient to crank the engine and also furnish current to

the ignitibn system, lights and accessories. Failure to

maintain a proper state of charge may be due to one

or more of the following conditions:

1.

Opertiting Conditions. When determining cause

of premature failure of a battery, consideration must

be given /to the conditions under which the car is

operated.,

In very low temperatures the capacity of a storage

battery

ii considerably reduced and the energy re-

quired f& cranking the. engine is considerably in-

creased. :

Frequent starting, particularly in cold weather,

ac-compani

place in the limited running time. This condition is

aggravated by night driving when lights are turned

on, or by operation of an air conditioner in heavy

traffic.

When thk car is operated under these conditions,adjusting,the voltage regulator to the high limit may

allow enough increase to keep the battery at a safe

state of charge. If the high limit setting does not

maintain a safe state of charge, an occasional booster

charge should be given to the battery.

2. Low charging Rate. In case of premature battery

failure, tbe charging rate of alternator should always

be checked and adjusted if below specifications.

3.

Zntemd Condition The internal condition of the

battery niay be such that it cannot hold a chargesatisfactoiily. Check electrolyte level and test the

battery using the 421 Battery Test.

Overcharge Failure of BatteryA common cause of battery failure is overcharging,

that is, continued input of excessive charging current

after the battery has reached a fully charged condi-

tion.

One evidence that battery is being overcharged is the

need for frequent addition of water to the battery in

order to maintain the electrolyte level above the tops

of the battery separators, since overcharging causes

rapid water loss. When this becomes evident, the

charging rate of alternator should be immediately

checked, as well as the voltage regulator, and ad-

justed to avoid internal damage to battery.

ADJUSTMENTS AND MINOR SERVICEPERIODIC BATTERY INSPECTION AND SERVICE

The battery requires very little attention, but peri-

odic inspection is essential to secure the maximum

efficiency and life. The following services are essen-

tial to maintain the battery at maximum efficiency.

WARNING: Never expose battery to open flame or

electric spark

- battery action generates hydrogen gas

which is flammable and explosive. Do not allow bat-

tery fluid to contact skin, eyes, fabrics or painted

surfaces

- fluidis a sulfuric acid solution which could

cause serious personal injury or property damage.

Wear eye protection when working with battery.

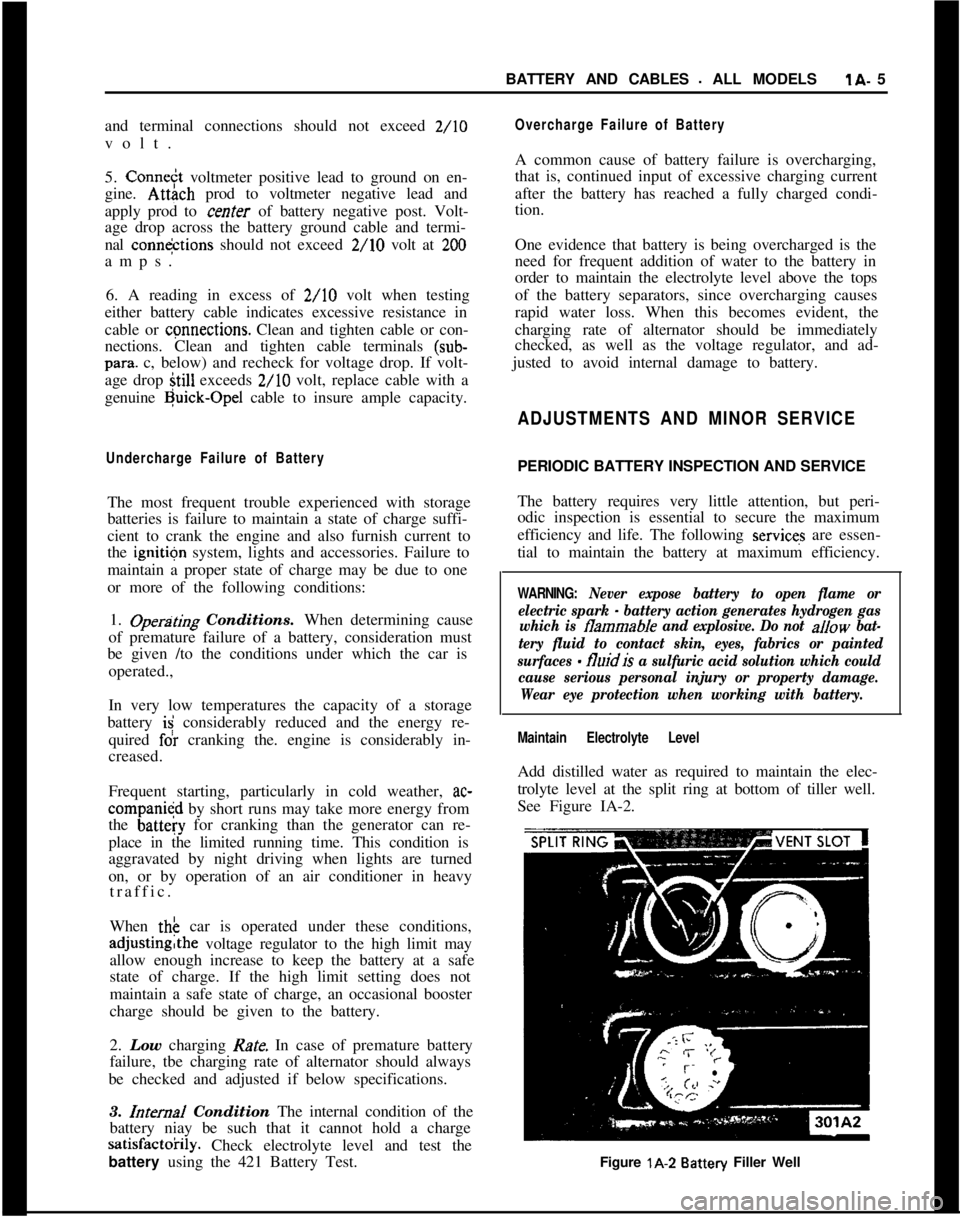

Maintain Electrolyte LevelAdd distilled water as required to maintain the elec-

trolyte level at the split ring at bottom of tiller well.

See Figure IA-2.

Figure lA-2

Battery Filler Well

Page 33 of 625

19- 12 1973 OPEL SERVICE MANUAL :ConditionPosiible CauseCorrection4. Voltage drop.1. Check wiring and wiring

connections.

5. Overrun&g clutch slips.1. Replace overrunning clutch.

The cranking motor keeps

on rotating after ignition

switch is off.1. Ignition

{witch does not

cut off or solenoid switch

sticks.

1, Immediately disconnect cranking

motor cable from battery. Inspect

and/or replace or repair ignition and

solenoid switches as required.

The drive pinion does notdemesh after engine has

been cranked.1. Drive pinion or ring gear

1. Clean components as specified.

teeth clogged or flattened.Replace as required.

Return spring slack or broken.MAlNTEilANCE AND ADJUSTMENT

/

STARTING SYSTEM CHECKS

Voltage Loss ChecksWhen the starter cranks too slowly, check the bat-

tery state of charge and all electrical connections

between the battery and starter.

1. Turn on headlights and

opera’te starter. If head-

lights dim considerably when starter is engaged, the

battery may be discharged or be defective. Check the

battery.

2. If the headlights stay bright but the starter d&s

not turn over, the starter cables may be faulty or the

starter defective.

(a) Test battery voltage while cranking engine

1(9volts minimum).

(b) Check voltage from starter tkrminal of solenoid

to starter frame while cranking engine.

3. The difference in readings taken in Operations 2a

and 2b above represents the

volt& drop through the

cables and solenoid switch. Voltdge drop should

Gotexceed

.5 volt.

4. Locate excessive resistance as follows:

(a) Turn voltmeter to scale above 12 volts and con-

nect voltmeter leads

across connection or switch: to

be checked.

(b) With starter switch closed, turn voltmeter switch

to lowest scale and take reading as quickly as possi-

ble, then turn switch back to higher scale and stop

cranking engine.(c) Voltmeter must not read more than

.2 volt across

any

c:onnection. If voltmeter reads more than .2 volt,

the

d~efect must be corrected.

Starter Current Draw - Lock Test1. Make sure battery is fully charged and in good

condition.

2. Connect a volt ampere starter tester according to

manufacturer’s instructions.

3. Pull parking brake on securely, shift transmission

into 4th (direct) gear and actuate starter. (Starter will

not

t,urn engine because engine is locked through

transmission.)

4. While starter is actuated, read voltage and current.

Refer to Specification Chart.

(a) Voltage low

_ poor battery or a voltage loss in the

starter circuit.

(b) Current high

- short circuit in starter. Overhaul

starter.

(c) Current low

- commutator dirty, brushes worn,

solenoid switch contacts defective or open circuit in

starter. Overhaul starter.

Starter Current Draw. On Car1. Bring engine to normal operating temperature.

2. Stop engine and disconnect coil wire from dis-

tributor.

3. Ground coil wire to prevent excessive coil voltage

build up.

Page 66 of 625

LIGHTING SYSTEMSlF-45LIGHTING SYSTEMS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

LightingSystems................................................................

DIAGNOSIS:MAINTENANCT AND ADJUSTMENTS:

Headlamp Aiming..............................................................

MAJOR REPAIR:

Opel 1900

- Manta

HeadlightSwitch............................................................

Fog Lamp or Heated Rear Window Switch

..........

SealBeam........................................................................

Tail Lamps........................................................................

LicensePlateLamp........................................................

FrontSideMarker..........................................................

Rear Side Marker..........................................................

Courtesy Light................................................................

DoorJamSwitch............................................................

GT

Front Turn Signal..........................................................

SealBeam........................................................................

Tail Lamps........................................................................

Side Marker......................................................................

LicensePlateLamp........................................................

Backup Lamp

..................................................................

InteriorLight....................................................................

Headlamp Switch..........................................................

DoorJamSwitch............................................................

SPECIFICATIONS:

Page No.

1 F-45

1 F-46

1 F-46

1 F-47

1 F-47

1 F-40

1 F-49

1 F-49

1 F-50

1 F-50

1 F-50lF-51lF-51lF-51

1 F-52

1 F-52

1 F-53

1 F-53

1 F-53

1 F-53

DESCRIPTION AND OPERATION

DESCRIPTION OF LIGHTING SYSTEMThe

three-baition light switch on Opel 1900 and

Manta corjtrols the headlights, taillights, parking

lights, side marker lights, instrument panel lights,

and the lic&se plate light.

When the

Qght switch knob is pulled out to the first

stop, the .pxking lights, side marker lights, the Ii-

cerise plate light, and the instrument panel lights will

light.

Pulling the knob out all the way turns the headlights

on.The instrument panel lights come on when the head-

light switch is pulled out to the first stop or pulled

out ‘all the way. The instrument panel lights are

turned off by turning the switch knob counterclock-

wise past the first detent.

Page 67 of 625

1F. 46 1973 OPEL SERVICE MANUAL

’

/

Headlight High-Low Beam Control and Passing:

SignalI

When the headlights have been switched on, high

and low beam selection is made by raising the direc-

tional signal lever toward steering wheel. Each

ti&the lever is raised, beam position, will change.

When the headlights are not on, a flashing headlight

signal may be given by raising and lotiering the di-

rectional signal lever. With the headlights on and

inlow beam position, raising and lowering the direc-

tional signal lever will also cause the headlights to

flash.

Fog Light SwitchAll Rallye models are equipped with two white f?g

lights mounted below the front bumper.

The fog light toggle switch is located on the

insty-ment cluster to the left of the temperature and

fuelgauge cluster.

/

The fog lights can be turned off at any time by the

toggle switch, but can only be tyrned on when: :

1. The ignition switch on or the

?gine running.!

2. The fog light toggle switch lower half is pushed

in.3. The parking lights and/or low beam headlights

are

OKThe fog lights are automatically turned off if the

ignition switch is on and the headlights are switched

to high beam position.

Courtesy LightThe courtesy light illuminates the interior of the Car

when any door is opened. The courtesy light can also

be turned on with all doors closed by tilting the l&s.

GT Headlamp MechanismThe concealed headlamps are moved mechanically.

Pushing actuating lever on left side of console opens

headlamps and pulling lever closes headlamps. Two

(2) meshing gear segments convert the movement, of

the lever to a rotation of 180 degrees. The pivots of

the headlamps lie below the centerline so that with

headlamps in closed position, the headlamp housing

is flush with front sheet metal. Refer to Group 110,

Section “F”, for service procedures on the GT head-

lamp mechanism.

A white indicator lamp in the instrument panel lights

if the headlamps are not completely opened lorclosed The switches of the headlamp electrical sys-

tem are located behind the left headlamp operating,

mechanism.

MAINTENANCE AND ADJUSTMENTSHEADLAMP AIMING

The headlamps must be properly aimed in order to

obtain maximum road illumination and safety that

has been built into the headlighting equipment. With

the Guide T-3 type sealed beam units, proper aiming

is even more important because the increased range

and power of this lamp make even slight variations

from recommended aiming hazardous to approach-

ing motorists. The headlamps must be checked for

proper aim whenever a sealed beam unit is replaced

and after an adjustment or repairs of the front end

sheet metal assembly.

Regardless of method used for checking headlamp

aim, car must be at normal weight, that is, with gas,

oil, water, and spare tire. Tires must be uniformly

inflated to specified pressure. If car will regularly

carry an unusual load in rear compartment, or a

trailer, these loads should be on car when headlamps

are checked. Some States have special requirements

for headlamp aiming adjustment, and these require-

ments should be known and observed.

Horizontal and vertical aiming of each seal beam

unit is provided by two adjusting screws which move

the mounting ring in the body against the tension of

the coil spring. There is no adjustment for focus,

since the sealed beam unit is set for proper focus

during manufacturing assembly.

MAJOR REPAIRHEADLIGHT SWITCH

- OPEL 1900. MANTA

Removal1. Remove instrument cluster cover panel. See Sec-

tion H.

2. Compress retaining springs and pull switch out.

See Figure 1 F-

1.3. Pull multiple socket off switch.

Installation

1: Plug multiple socket in switch and push switch in

panel until clips lock in place.

2. Replace instrument cover and secure with two (2)

screws.

Page 68 of 625

LIGHTING SYSTEMSlF-472. Install switch in panel.

3. Replace instrument cluster cover.

EXTERIOR LIGHTSModels 51-53-54

Headlamp Sealed Beam Unit Removal1. Remove two screws on headlight ring.

2. Remove four screws holding headlight retainer to

body. See Figure lF-3.

Figure 1 F-l Removing Headlight Switch

I

3.

Rep& two (2) plugs over screws and replace

heater control knobs.

FOG LIGHT OR HEATED REAR GLASS SWITCHRemoval I

1. Removd instrument cluster cover. See Section H.

I

2. Press

ddwn retaining clip and pull switch out. See

Figure lF-2.

Figure 1 F-3 - Removing Headlight Retainer

- Models

51-53-54

3. Disconnect wiring connectors,

4. Remove headlight from inside engine compart-

ment.

Figure 1Fi2 - Removal of Fog Light or Heated Rear

Glass Switch

3. Removelwires from switch.

Installation/

1. Connect;wire to switch,

Installation1. Plug in wiring connector on sealed beam and re-

place four (4) headlight retaining screws.

2. Replace headlight ring.

Models 57-57R

Removal

I. Disconnect wiring connector.

2. Remove four screws holding headlight retainer

from inside engine compartment.

Page 70 of 625

LIGHTING SYSTEMSlF-492. Take

Le:s off housing. See Figure lF-7.

3. Remove housing.1

Installation;I

1. Install

le$ in housing.

2. Replace

+.Model 54

;,

1, Remove Ilamp lens from outside.

/

2. Remove kear quarter trim pad.

/

3. Remove

ifour screws from inside car. See FigurelF- 8.

Figure 1 F-8

I- Removing Tail Light Housing - Model 54

I

4. Disconnkct wiring connector.

I

1. Connect iwiring to lamp

2. Install hbusing using four (4)

scre%s.3. Replace

p quarter trim pad

4. Replace

Lens,Models

57-$RI

Removal1. Unscrew!lens from housing.2.

III luggage compartment, unscrew three (3) hous-

ing attaching nuts. See Figure lF-9.

Figure lF-9 Tail Light Housing Attaching Nuts

-Models 57.57R

3. Disconnect wire connector.

Installation1. Plug in wiring harness.

2. Replace housing with three (3) attaching nuts.

3. Replace lens.

Rear License Plate Lamp Assembly Removal1. Remove two screws holding housing to bumper.

2. Pull lamp assembly down.

3. To replace bulb, take out two

screws holding lens

in place.

Installation1. Replace bulb and lens to housing.

2. Replace lamp assembly to bumper with two (2)

screws.

SIDE MARKER LIGHTS

Front Removal1. Remove outer lens.

2. Remove two sheet metal screws for housing at-

tachment.

3. Disconnect wire connectors.

Page 71 of 625

1 F- 50 1973 OPEL SERVlCE,MANUAL

Installation

1. Connect wiring harness.

2. Replace housing with two (2) screws.

3. Rep&e lens.

Rear RemovalRemove two screws from support bracket aed

remove housing and lens. See Figure lF-10.

,&y...2&L&-i -:,..; 3O’F’OFigure 1 F-10

- Removing Rear Side Marker Lampx

kallationInstall housing and lens with two (2) attach&gSCFSVS.

INTERIOR LIGHTS

Courtesy Light Removal1. Pry courtesy light out of roof frame, as shown in

Figure 1 F-

11.

t2. Pull wires off flat plugs. See Figure lF-12.

Figure lF-12 -Courtesy Light Wire Connections

Installation1. Connect wires to flat plugs, a) red wire, b)

greywire, and c) brown wire.

2. Push light back into roof frame.

Door Jam Switch Removal1. Remove door jam switch

attach’ing screws.

2. Remove switch and disconnect wire.

Installation1. Connect wire to switch.

Figure lF-1 1

- Removing Courtesy LightFigure 1 F-l 3 Removing Parking Light Lens