dead battery OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 30 of 625

BATTERY AND CABLES - ALL MODELSlA- 9

plus 61 terminal of the voltage regulator and protects

the circuit to the generator telltale light.

BATTERY RECHARGING

There are two separate methods of recharging batter-

ies which giffer basically in the rate of charge. In the

slow-charge method, the battery is supplied a rela-

tively small amount of current for an extended

period of time. In the quick-charge method, the bat-

tery is supplied with a high current for a short period

of time.

Slow-Charging

Slow charking is the best and only method of com-

pletely ch+rging a battery. The slow-charge method,

properly applied, may be safely used under all possi-

ble conditions of the battery, provided electrolyte is at proper

wl in all cells. The battery may be fully

charged by this method, unless the battery is not

capable of taking a full charge. The normal slow

charging rate for the

12.volt battery is 5 amperes.

Full ch&e of battery is indicated when all cell spe-

cific gravities do not increase when checked at three

intervals

of one hour and all cells are gassing freely.

Due to the low rate during slow charging, plenty of

time must ,be allowed. Charge periods of 24 hours or

more are often required.

Quick-Charging

Since time!is often of most importance to the battery

owner, quick-charging must sometimes be used to

partially charge the battery so that the engine will

start and the owner can be on his way.

Charge at:50 amperes for 20 minutes (50 times 20

equals

100Q ampere minutes). If charger will not give

this rate, charge for an equal number of ampere mi-

nutes at the best rate available. Too high a current

during quick-charging will damage battery plates.

A battery cannot be brought up to a fully charged

condition

by the quick-charge method. The battery

can be substantially recharged or boosted, but in

order to bring the battery to a fully charged condi-

tion, the charging cycle must be finished by charging

at a low

oi normal rate. Some quick-chargers have

a

provisioA for finishing the charging cycle at a low

rate so

tha’t the battery can be brought up to a fully

charged condition.

Used

with:care, and employing all safeguards prov-

ided by the manufacturer, a quick-charger will not

damage a battery

which is in good condition.

BATTERY REMOVAL AND INSTALLATION

Removal

1. Disconnect battery cables (remove negative cable

first to prevent possible shorting).

2. Remove battery hold down

l&acket.

3. Remove battery.

Installation

‘1. Place battery back in hold down position.

2. Tighten hold down bracket bolts.

3. Connect battery cables (connect positive cable first

to prevent possible shorting).

FUSIBLE LINK REMOVAL AND INSTALLATION

Replace a burned out fusible link as follows:

1. Disconnect battery.

2. Disconnect connector eye on end of fusible link.

3. Cut off other end of burned out link, along with

solder joint.

4. Strip insulation from end of new fusible link and

from end of wiring harness so that each will slide into

soldering sleeve.

5. Crimp new link in soldering sleeve and solder

carefully.

6. Cover new connection tightly with electrical tape.

I. Install new link connector eye on other end of

fusible link.

A burned out fusible link connected to the starter

solenoid would be indicated by:

1. All electrical accessories dead.

2. Starter dead - will not even click. Even with a

nearly dead battery, the starter solenoid will

gener-

ally engage; therefore, no click means no solenoid

action, possibly due to a burned out fusible link.

SPECIFICATIONS

BATTERY SPECIFICATIONS

Delco-General 12 volt-44 amp hour storage battery

is installed as original equipment. Replace with a

Delco Energizer

Y55.

Page 40 of 625

IIIGNITION SYSTEMlC- 19

11. (Startx position.) The ignition key must be

released as soon as engine starts. The switch then

returns aujomatically to the on position.

IGNITION

GOILThe ignition coil consists of a laminated non- mag-

netic iron

(core enclosed by two coils; the primary

winding and the secondary winding.

The prim+y circuit consists of the power source

(battery), the ignition switch, the ignition coil pri-

mary winding, the distributor breaker points with

ignition condenser connected in parallel, and all con-

necting

lo& tension wiring.

The secondary circuit consists of the ignition coil

secondary ‘winding, the spark plugs, all connecting

high tens@ wiring, the distributor cap and the

ro-tor.

When the’ ignition switch is turned on and the

breaker pdints are closed, current flows through the

ignition

c&l primary winding and produces a mag-

netic field wound the coil windings.

When the breaker points are separated by the revolv-

ing distributor cam, the magnetic field collapses and

induces a high voltage surge in the secondary wind-

ing,

produ;cing a spark between the spark plug elec-

trodes. ,

The ignitidn condenser which is connected in paral-

lel with the breaker points, prevents arcing between

the

separa’ted breaker contacts, and current flow

after~ the breaker points have been separated, thus

causing a kery rapid collapse of the magnetic field

around th$ Ignition coil.

/

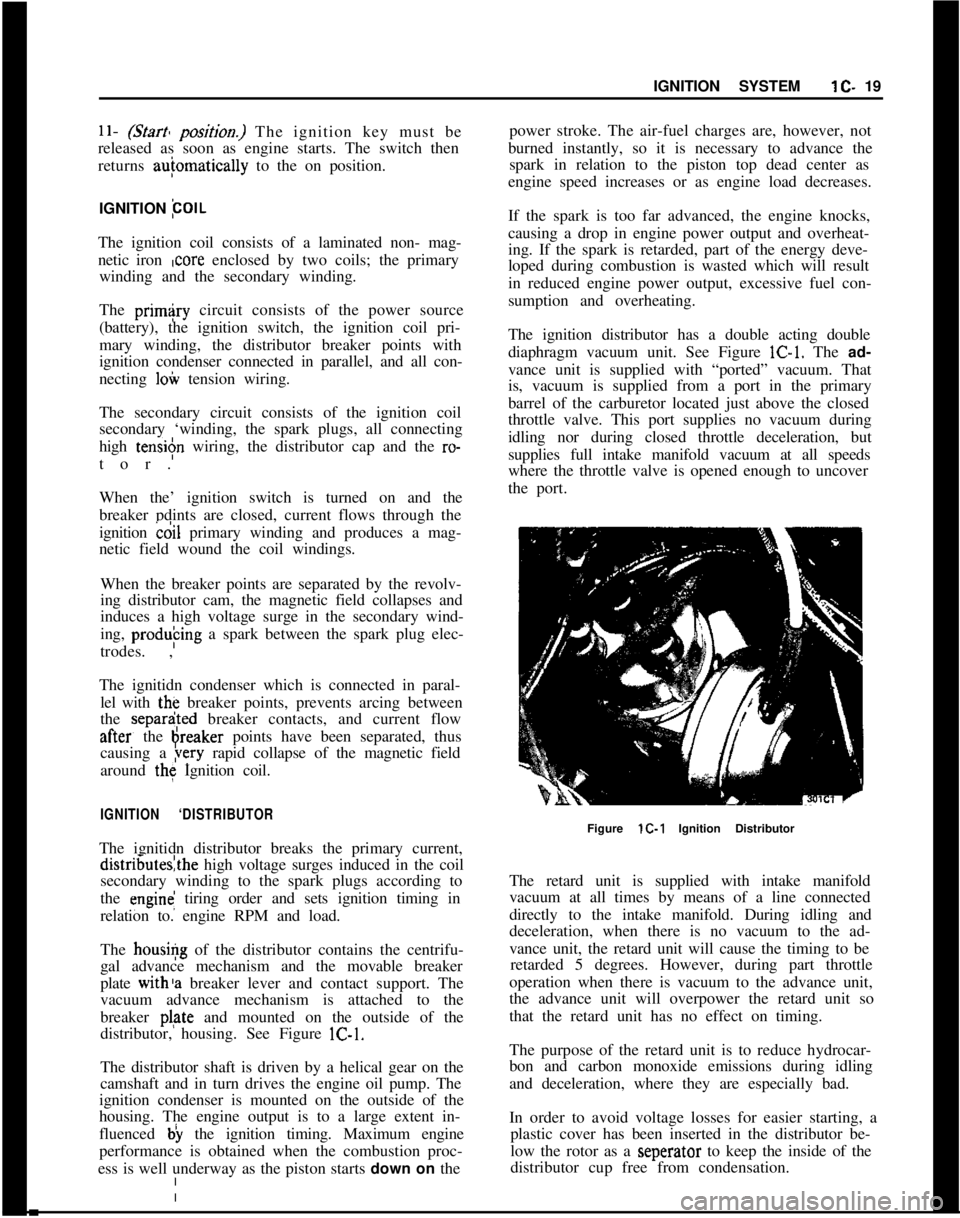

IGNITION ‘DISTRIBUTORThe ignitidn distributor breaks the primary current,distributeslthe high voltage surges induced in the coil

secondary winding to the spark plugs according to

the engin< tiring order and sets ignition timing in

relation to. engine RPM and load.

The housi+g of the distributor contains the centrifu-

gal advance mechanism and the movable breaker

plate with’s breaker lever and contact support. The

vacuum advance mechanism is attached to the

breaker plate and mounted on the outside of the

distributor, housing. See Figure lC-1.

The distributor shaft is driven by a helical gear on the

camshaft and in turn drives the engine oil pump. The

ignition condenser is mounted on the outside of the

housing. The engine output is to a large extent in-

fluenced b) the ignition timing. Maximum engine

performance is obtained when the combustion proc-

ess is well underway as the piston starts down on thepower stroke. The air-fuel charges are, however, not

burned instantly, so it is necessary to advance the

spark in relation to the piston top dead center as

engine speed increases or as engine load decreases.

If the spark is too far advanced, the engine knocks,

causing a drop in engine power output and overheat-

ing. If the spark is retarded, part of the energy deve-

loped during combustion is wasted which will result

in reduced engine power output, excessive fuel con-

sumption and overheating.

The ignition distributor has a double acting double

diaphragm vacuum unit. See Figure lC-1. The ad-

vance unit is supplied with “ported” vacuum. That

is, vacuum is supplied from a port in the primary

barrel of the carburetor located just above the closed

throttle valve. This port supplies no vacuum during

idling nor during closed throttle deceleration, but

supplies full intake manifold vacuum at all speeds

where the throttle valve is opened enough to uncover

the port.

Figure lC-1 Ignition Distributor

The retard unit is supplied with intake manifold

vacuum at all times by means of a line connected

directly to the intake manifold. During idling and

deceleration, when there is no vacuum to the ad-

vance unit, the retard unit will cause the timing to be

retarded 5 degrees. However, during part throttle

operation when there is vacuum to the advance unit,

the advance unit will overpower the retard unit so

that the retard unit has no effect on timing.

The purpose of the retard unit is to reduce hydrocar-

bon and carbon monoxide emissions during idling

and deceleration, where they are especially bad.

In order to avoid voltage losses for easier starting, a

plastic cover has been inserted in the distributor be-

low the rotor as a seperator to keep the inside of the

distributor cup free from condensation.

Page 332 of 625

FUEL SYSTEM6C- 41

covered with sound deadening compound. See Fig-

ure

6C-10.7. Remove fuel tank vent hose and tiller hose. See

Figure 6C- 11.

8. Remove fuel tank attaching bolts and gauge wire

and remove tank.

Installation

1. Install tank and tighten attaching bolts.

2. Replace gauge wire. Install vent hose, making cer-

tain it is not kinked and seal vent hose hole in floor.

3. Install spare tire support attaching brackets, sup-

port panel, hold-down, and brackets.

4. Install spare tire and jack.

5. Install fuel line and rubber cap.

6. Connect battery.FUEL LINES. FUEL GAUGE TANK UNITS

All fuel lines are plastic and have an outside diameter

of

,240 inches. Unlike metal lines, plastic lines are

not flared.

When replacing a plastic line, place the line in hot

water to make it flexible. Using the old line as a

pattern, form the new line. Let the line cool com-

pletely, then route it in the same location as the old

line. To prevent chafing against the underbody, nine

(9) rubber grommets are placed at points on the line

between the fuel tank and the fuel pump. When re-

placing fuel gauge tank units, coat gasket on both

sides and first threads of attaching screws with seal-

ing compound.

CLEANING FUEL TANK

1. Remove fuel tank.

2. Empty fuel tank through filler neck.

3. Remove fuel gauge tank unit, together with suc-

tion tube and screen. Clean screen and blow out from

cover side. Flush fuel tank.

SPECIFICATIONSFuel Tank Capacity (Gallons)

Opel 1900 and Manta

....................................................................................................11.9GT

....................................................................................................................................13.2FuelGaugeType

........................................................................................................Electrical

Fuel Pump Type

......................................................................................................Mechanical

Fuel Pump Drive

..................................................................................Eccentric on Camshaft

Fuel Pump Pressure at 1950 (RPM)................................................................3.1 to 3.7 P.S.I.FuelFilter

............................................................................................................In-LineFilter