fuse OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 20 of 625

LUBRICATION AND MAINTENANCE OC-11

Throttle Linkage

Check for damaged or missing parts, interference or

binding. Any deficiencies should be corrected with-

out delay.

Headlights

Check for proper aim. Correct as necessary. More

frequent checks should be made if oncoming motor-

ists signal when you are already using your low

beams, or if illumination of the area ‘ahead seems

inadequate.

Underbody

In geographic areas using a heavy concentration of

road salt or other corrosive materials for snow re-

moval or road dust control, flush and inspect the

complete under side of the car at least once each

year, preferably after a winter’s exposure. Particular

attention should be given to cleaning out underbody

members where dirt and other foreign materials may

have collected.

EMISSION CONTROL MAINTENANCE

Thermostatically Controlled Air Cleaner

Inspect installation to make certain that all hoses and

ducts are connected and correctly installed. Also,

check valve for proper operation.

Carburetor Choke

Check choke mechanism for free operation. A bind-

ing condition may have developed from petroleum

gum formation on the choke shaft or from overtight-

ening of air cleaner clamp. Also check electric choke

terminal connections and fuse.

Timing, Dwell and Distributor

Adjust timing and dwell accurately as outlined under

Tune-Up in Group 6 at the first 4 months or 6,ooOmiles of operation, then at 12 month or

12,OQO mile

intervals. Adjustments must be made with test equip-

ment known to be accurate.

Replace distributor points every 12 months or 12,000

miles and carefully clean and inspect the complete

distributor cap to prevent misfiring and deteriora-

tion.

Carburetor and Idle

SpeedTorque carburetor attaching bolts and/or nuts to 12

ft.lbs. to compensate for compression of gasket atiirst 4 months or 6,000 miles of vehicle operation.Adjust idle speed to specifications with known accu-

rate equipment.

Proper functioning of the carburetor is particularly

essential to control of emissions. Correct mixtures

for emission compliance and idle quality have been

preset by Opel. Plastic idle mixture limiters have

been installed on the idle mixture screw, idle air

screw, and throttle stop screw to preclude unauthor-

ized adjustment. The plastic caps on the idle mixture

screw and the idle adjustment screw must be

removed to perform an idle speed adjustment. The

plastic cap on the throttle stop screw is not to be

removed unless some major carburetor repair or re-

placement which affects the throttle stop screw ad-

justment has been necessary.

Carburetor Fuel Inlet Filter

Replace filter at 12 month or

12,OCO mile intervals

or more often if clogged.

Spark Plugs

Replace at

6,ooO mile intervals when operating with

leaded fuels or at 12,000 mile intervals when using

unleaded fuels. Use of leaded fuels results in lead

deposits on spark plugs and can cause misfiring at

mileages less than

12,OilO miles. Where misfiring oc-

curs prior to

6,ooO miles, spark plugs in good condi-

tion can often be cleaned, tested and reinstalled in an

engine with acceptable results.

Spark Plug Wires

Inspect spark plug wires for evidence of checking or

cracking of exterior insulation and tight fit in the

distributor cap and at the spark plugs. Exterior of

wires should be cleaned, any evidence of corrosion

on ends removed and wire replace if deteriorated.

Positive Crankcase Ventilation System

The PCV metered orifice should be cleaned at 12,000

mile intervals under normal use, and at 6,000 mile

intervals when the vehicle is used under the follow-

ing conditions: driving in dusty conditions, extensive

idling, trailer pulling and short trip operation at

freezing temperatures (engine not thoroughly

warmed-up).

Evaporation Control System

Check all fuel and vapor lines and hoses for proper

connections and correct routing as well as condition.

Remove canister and check for cracks or damage.

Replace damaged or deteriorated parts as necessary.

Replace filter in open end of canister at 24month/24,000 mile intervals.

Page 29 of 625

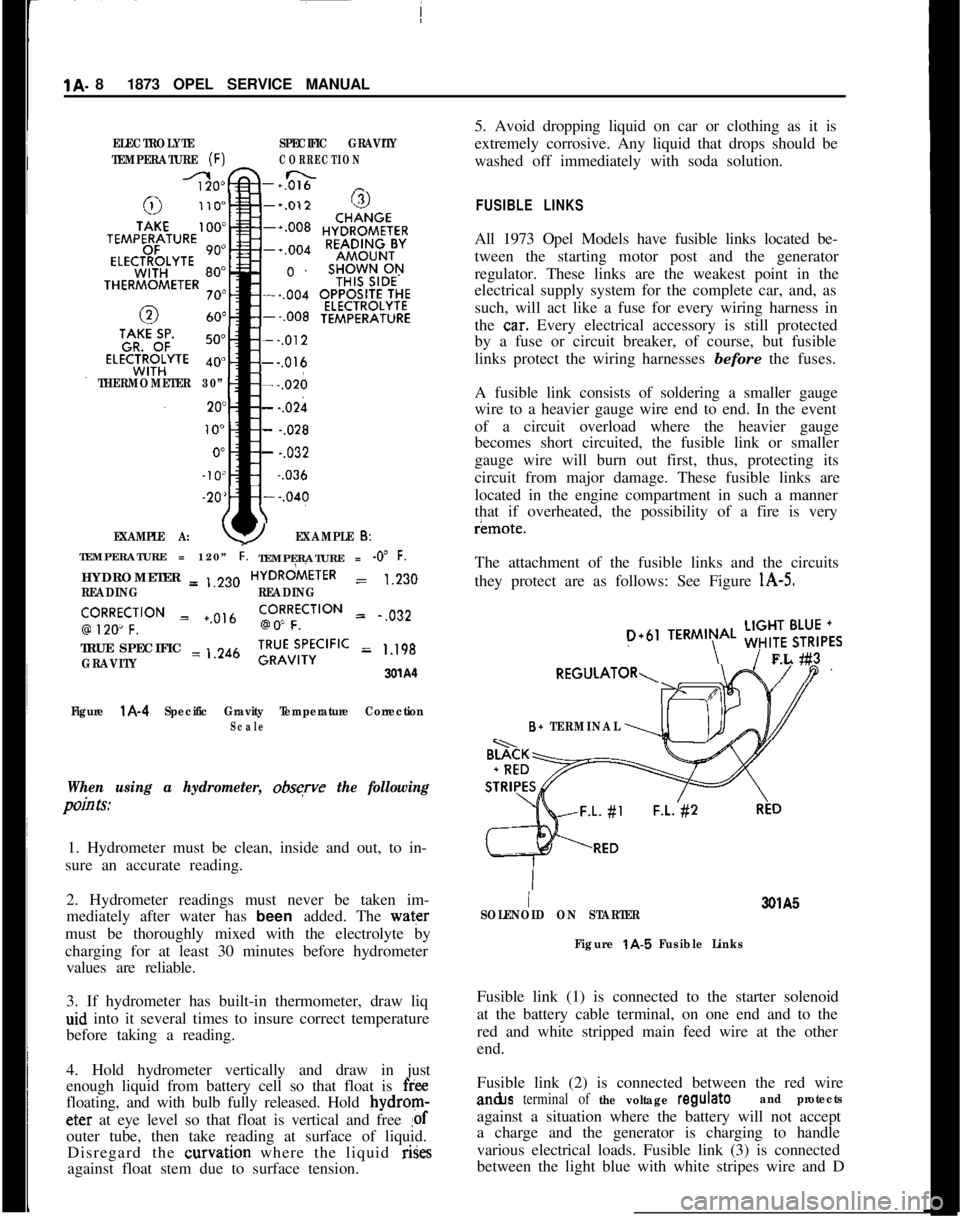

1A. 81873 OPEL SERVICE MANUALELECTROLYTESPECIFIC GRAVITY

TEMPERATURE

(F)CORRECTION

-+0&&n _

THERMOMETER 30”

EXAMPLE A:

--,012---,016---,026

- -.02h

- -.028

- -.032~

-.036

YEXAMPLE 6:TEMPERATURE = 120”

i.TEMPERATURE = -0” F.HYDROMETER = ,,230HYDRdiETER

= 1.230

READINGREADING

‘,9R2Ro~CF;‘“” = +.0,6go!RFfCilON = .,032

TRUE SPECIFIC = ,.246

GRAVITY;RU”v;,‘;CIFIC = 1.198

3xA‘l

Figure

l A-4 Specific Gravity Temperature CorrectionScale

When using a hydrometer, obsqve the following

pain Is:1. Hydrometer must be clean, inside and out, to in-

sure an accurate reading.

2. Hydrometer readings must never be taken im-

mediately after water has been added. The water

must be thoroughly mixed with the electrolyte by

charging for at least 30 minutes before hydrometer

values are reliable.

3. If hydrometer has built-in thermometer, draw liq

aid into it several times to insure correct temperature

before taking a reading.

4. Hold hydrometer vertically and draw in just

enough liquid from battery cell so that float is

freefloating, and with bulb fully released. Hold bydrom-eter at eye level so that float is vertical and free

!ofouter tube, then take reading at surface of liquid.

Disregard the curvation where the liquid rises

against float stem due to surface tension.5. Avoid dropping liquid on car or clothing as it is

extremely corrosive. Any liquid that drops should be

washed off immediately with soda solution.

FUSIBLE LINKSAll 1973 Opel Models have fusible links located be-

tween the starting motor post and the generator

regulator. These links are the weakest point in the

electrical supply system for the complete car, and, as

such, will act like a fuse for every wiring harness in

the

ca.r. Every electrical accessory is still protected

by a fuse or circuit breaker, of course, but fusible

links protect the wiring harnesses before the fuses.

A fusible link consists of soldering a smaller gauge

wire to a heavier gauge wire end to end. In the event

of a circuit overload where the heavier gauge

becomes short circuited, the fusible link or smaller

gauge wire will burn out first, thus, protecting its

circuit from major damage. These fusible links are

located in the engine compartment in such a manner

that if overheated, the possibility of a fire is veryr¬e.

The attachment of the fusible links and the circuits

they protect are as follows: See Figure

l A-5.

D+61TERMIN\AL ;;!$6,,FL #3

B+ TERMINAL

I3QlA5

SOLENOID ON STARTER

Figure

t A-5 Fusible LinksFusible link (1) is connected to the starter solenoid

at the battery cable terminal, on one end and to the

red and white stripped main feed wire at the other

end.

Fusible link (2) is connected between the red wirean&s

terminal of the voltage regulateand protectsagainst a situation where the battery will not accept

a charge and the generator is charging to handle

various electrical loads. Fusible link (3) is connected

between the light blue with white stripes wire and D

Page 58 of 625

WINDSHIELD WIPERSlE- 37WINDSHEILD WIPERS

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Windshield Wiper Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

Windshield Wiper

. . . . . . . . . . . . . . . . . . . , , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:Wiper Transmission

- 1900 and Manta. . . . . . . . . . . . . . . . . . . .W/per Transmission

- GT. . . . . a.* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly of Wiper Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cleaning and Inspection of Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Assembly of Wiper Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

GeneralSpecifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Torque Specifications

. . . . . . . a.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTIOfV AND OPERATION

GENERAL;DESCRlPTlDNThe two-sbeed wiper consists of a round shaped per-

manent magnet type motor and speed reduction gear

box. IOPERATldN

=The wipei motor is controlled through a dash

mounted &itch on all cars. The Rallye and GT, in

addition tb the dash mounted switch, also have a

switch moimted in conjunction with the windshield

washer fodt pump. Depressing the washer pump will

allow the bipers to operate while the pump is de-

pressed. i

DIAGNO;SIS

PRELIMINj9RY INSPECTION

1. Make

c&in of firm wire connections at wiper

motor fuse block and wiper switch.

Page No.

1 E-37

1 E-37E-38

E-38

E-40

E-41

E-4 1E-42

1 E-43

1 E-432. Check to see that the fuse is not blown.

3. Be sure wiper motor is not loose on fire wall.

4. With the yellow wire disconnected from terminal

No. 53 on the

wi@er motor, turn the ignition switch

and wiper switch to the on position and check volt-

age available to the wiper motor. There should be 12

volts available at the durple wire with a properly

charged battery.

Checking Wiper Operation1. Turn ignition switch on and engage wiper switch

to see if wiper motor will operate.

2. If wiper action is slow or inoperative, turn swit-

ches off and detach wiper control

inn from crank

arm.3. Operate wiper manually checking for excessive

bind in linkage. Correct if necessary.

Page 75 of 625

lG- 54 1973 OPEL SERVICE’ MANtiAL/SIGNAL SYSTEMSCdNTENTS

9Subject

DESCRIPTION AND OPERAT!ON:

Directional Signal Lever

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .HazardWarning

Flasher. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .BrakeSystemWarningLight

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

SignalSystem,.......................

i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUS,TMENTS:

MAJOR REPAIR:

Directional Signal Switch

:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HornRemoval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Removing Horn Contact

. . . . :.............................................

SPECIFICATIONS:

FuseChart. . . . . . I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page No.

1 G-54

1 G-54

1 G-55

lG-55 _1 G-55

1 G-55

16-551 G-55

1 G-56

DESCRIPTION AND OPERATION

DIRECTIONAL SIGNAL LEVERThe direction signal switch lever is a multi- purpose

lever controlling direction signals, passing signal,

and high and low beams. See Figure

lG-1.301Gl

Figure lG-1 Directional Signal Position for Headlamp

OperationThe direction signal lever is provided with a

two-step mechanism for operation of headlight high and

low beams, and passing signal (not in New Jersey).

With headlights off, moving the lever repeatedly to-

wards steering wheel flashes headlights as a passing

signal. With headlights on, moving the lever repeat-

edly towards steering wheel up to first stop also

flashes passing signal regardless whether or not the

direcl:ion signals are switched on. When the lever is

moved up to the second stop, the headlights are

changed from high to low beam

dr vice versa. On all

Rallye cars, when switching from low to high beam

position, with the fog lamp instrument panel switch

“ON” and ignition switch in “RUN” position, the

fog lights are automatically

switChed off. Direction

signals work in the normal manner; pushing the lever

up for right turn signal and pulling the lever down

for left turn signal.

The horn button is located in the center part of the

steering wheel. The horn is actuated by pushing

down on the ends of both spokes on Opel 1900 andManta’s or on the center horn button on the Rallye.

The button is provided with a spring-loaded plunger.See Figure

lG-2.

Page 77 of 625

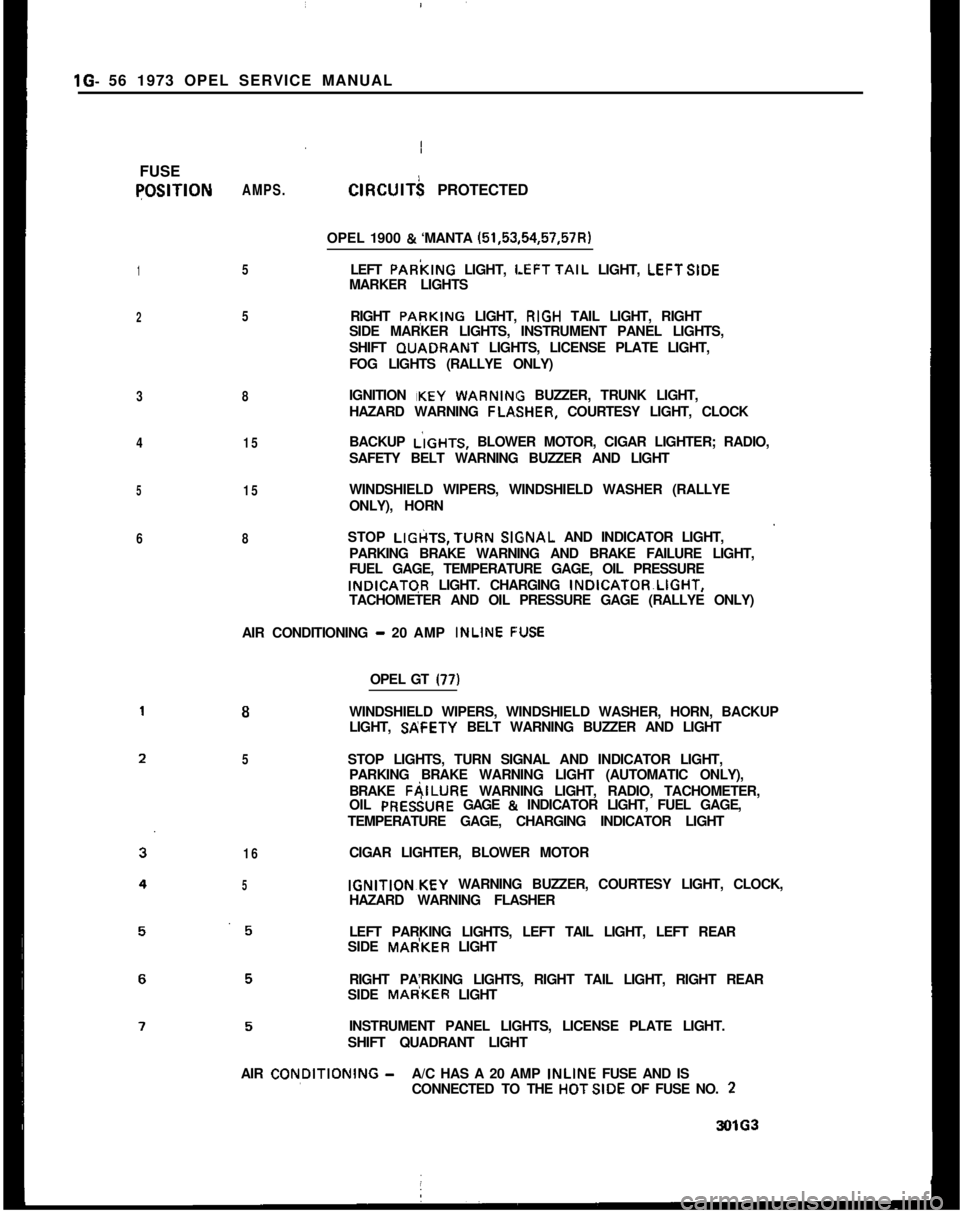

:lG- 56 1973 OPEL SERVICE MANUAL

I

FUSEqOSlTlON

1

2

3

4

5

6AMPS.

5

5

8

15

15

8ClRClJlT$ PROTECTED

OPEL 1900

& ‘MANTA (51,53,54,57,57R)

LEFT PARkING LIGHT,

LEFTTAIL LIGHT, LEFTSIDE

MARKER LIGHTS

RIGHT PApKING LIGHT, RIGH TAIL LIGHT, RIGHT

SIDE MARKER LIGHTS, INSTRUMENT PANEL LIGHTS,

SHIFT GUADRANT LIGHTS, LICENSE PLATE LIGHT,

FOG LIGHTS (RALLYE ONLY)

IGNITION IKEY

WARNIN BUZZER, TRUNK LIGHT,

HAZARD WARNING FLA,SHER, COURTESY LIGHT, CLOCK

BACKUP L’IGHTS, BLOWER MOTOR, CIGAR LIGHTER; RADIO,

SAFETY BELT WARNING BUZZER AND LIGHT

WINDSHIELD WIPERS, WINDSHIELD WASHER (RALLYE

ONLY), HORN

STOP LIGtiTS,TURN

SlGsNAL AND INDICATOR LIGHT,

PARKING BRAKE WARNING AND BRAKE FAILURE LIGHT,

FUEL GAGE, TEMPERATURE GAGE, OIL PRESSUREINDICATGR LIGHT. CHARGING INDICATOR~LIGHT,

TACHOMETER AND OIL PRESSURE GAGE (RALLYE ONLY)

AIR CONDITIONING

- 20 AMP INLINE F:USE

8

5

16

5OPEL GT

(77)WINDSHIELD WIPERS, WINDSHIELD WASHER, HORN, BACKUP

LIGHT, SP;FETY BELT WARNING BUZZER AND LIGHT

STOP LIGHTS, TURN SIGNAL AND INDICATOR LIGHT,

PARKING BRAKE WARNING LIGHT (AUTOMATIC ONLY),

BRAKE FAILURE WARNING LIGHT, RADIO, TACHOMETER,

OIL PRESiURE GAGE

& INDICATOR LIGHT, FUEL GAGE,

TEMPERATURE GAGE, CHARGING INDICATOR LIGHT

CIGAR LIGHTER, BLOWER MOTORIGNITION~KEY WARNING BUZZER, COURTESY LIGHT, CLOCK,

HAZARD WARNING FLASHER

LEFT PARKING LIGHTS, LEFT TAIL LIGHT, LEFT REAR

SIDE MAdKER LIGHT

RIGHT PA’RKING LIGHTS, RIGHT TAIL LIGHT, RIGHT REAR

SIDE MAdKER LIGHT

INSTRUMENT PANEL LIGHTS, LICENSE PLATE LIGHT.

SHIFT QUADRANT LIGHT

AIR CON,DlTlONlNG

-A/C HAS A 20 AMP INLINE FUSE AND IS

CONNECTED TO THE HOTSIDE OF FUSE NO. 23OlG3

Page 86 of 625

GAUGES

CONTENTS

Subject

DESCRIPTION AND OPERATION:

DIAGNOSIS:

Temperature and Fuel Gauge

System-Opel1900-Manta. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FuelGauge-GT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS:

MAJOR REPAIR:

Opel 1900

- Manta

Voltage Stabilizer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Speedometer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Electric

ClockorTachometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Temperature Indicator or Fuel Gauge

. . . . . . . . . . . . . . . . . . . .Rallye

Gauges. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Temperature

SendingUnit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Oil Pressure Sending Unit

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .GT

Speedometer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tachometer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Temperature Indicator and Fuel Gauge Dash, Unit

Electric

Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Ammeter

andOilPressureGauge. . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

DIAGNOSISITEM(ERATURE

& FUEL GAUGE - SYSTEM

DIAGNOSIS (OPEL 1900, MANTA)

/

ConditionPossible Cause

I

Page No.

1l-65

1l-67

1l-67

1l-68

1l-68

1l-69

1l-69

1l-69

1l-70

1l-70

1l-70

1l-70

1l-71

1l-71

Correction

Temperature and gas gaugeinopetative1. Blown fuse1. Replace fuse. If new fuse

blows, repair short.

2. Defective voltage

stabilizer1. Install 40 ohm resistors

between ground

& connectors

(disconnect from units)

of temperature sending imit

and gas gauge tank unit. If

both dash units do not move

to full scale (tolerance

-one pointer width of either

side of full scale reading)

and the distance of movement

on the scale is the same,,

replace the voltage stabdner.

Page 513 of 625

9A-4 1973 OPEL SERVICE MANUAL

Figure 9A-4 Heater Control

Blower Switch - This switch actuates blower motor

to low or high blower speed.

HEATER SYSTEM OPERATION

To operate heater proceed as follows:

1. Position air inlet, heater-defroster control as

desired.

White arrow head pointing down--air out of heater

outlets. White arrow head pointing up--air out of

defroster outlets.

Between lower and upper position--air to both heater

and defroster outlets.

2. Position temperature control as desired to increase

or decrease temperature of air flow.

3. Position blower switch as desired to operate

blower at low or high speed.

Dlid3NDSlS

HEATER SYSTEM TROUBLE DIAGNOSIS

TROUBLE

Temperature of heated air at outlets too low.

CAUSE AND CORRECTION

Check radiator cap for proper sealing action-- re-

place if necessary.

Check for adequate coolant supply. If level is down,

correct cause of coolant loss and refill radiator.

Inspect hose for kinks--relieve kink or replace hoses.

Check thermostat operation by measuring tempera-

ture of coolant at radiator. Temperature should be

within 5 degrees F. of thermostat rated value (189

degrees F.).

Check that air doors and water temperature control

valye are operating properly.

Check for plugged heater core--backflush heater core

as necessary.

TROUBLE

Inadequate defrosting action.

CAUSE AND COiiRECTlON

Examine heater-defroster door for proper operat-

ions--adjust bowden cable as required so that door is

fully closed in FULL DEFROST position.

Check that air hoses connecting to defroster outlets

are secure.

Check for air leaks around edges of heater air dis-

tributor housing--seal leaks as necessary with body

sealer. Check for body air leaks and seal as necessary

with body sealer.

TROUBLE

Blower inoperative.

CAUSE AND CORRECTION

Check blower fuse--replace if necessary, fuse position

3 - amperage 8.

Check wiring for open circuit--correct as required. Inspect for defective component (i.e., blower switch

or blower motor)--replace or repair as necessary.

MAINTENANCE AND ADJUSTMENTS

CONTROL CABLE ADJUSTMENT

Adjustment of control cables is accomplished by po-

sitioning of the jacket or sheath of the control cable

as held by the clamps on the control assembly and

heater case.

To adjust control cables, loosen clamps and move

cable sheath in or out as required to obtain full travel

of lever or of door or both.

Page 521 of 625

9A-i2 1973 OPEL SERVICE MANUAL

Check that air doors and water temperature control

valve are operating properly.

Check for plugged heater core-backflush heater core

as necessary.TROUBLEInadequate defrosting action.

CAUSE AND CORRECTIONExamine heater-defroster door for proper operation.

Adjust bowden cable so that door is fully closed in

FULL DEFROST position.

Check that air hoses connecting to defroster outlets

are secure.

Check for air leaks around edges of heater air dis-

tributor housing. Seal leaks, as necessary, with bodysea@. Check for body air leaks and seal, as neces-

sary, with body sealer.

TROUBLEBlower inoperative.

CAUSE AND CORRECTIONCheck blower fuse. Replace, if necessary, fuse posi-

tion 4

- amperage 15.

Check wiring for open circuit. Correct, as required.

Inspect for defective component, (i.e., blower switch

or blower motor)

- replace or repair as necessary.

MAINTENANCE AND ADJUSTMENTS

CONTROL CABLE ADJUSTMENTAdjustment of control cables is accomplished by po-

sitioning of the jacket or sheath of the control cable,

as held by the clamps on the control assembly and

heater case or by loosening screws and slidingbowden wire to obtain desired door or water valve

position.

MAJOR REPAIR

REMOVING AND INSTALLING HEATER HOUSING

Removal1. Unscrew hood lock together with ground wire(ground wire only on vehicles with radio interference

suppression). See Figure 9A-33.

Figure 9A-33 Hood Lock Attachments

2. Unscrew heater housing cover.

3. Pull hose of windshield washer system off jet and

take jet out of housing cover.

4. Unscrew bowden control wire from heater valve.

5. Unscrew heater housing from dash panel and pull

it off carefully. See Figure 9A-34.

Figure 9A-34 Heater Housing Attachments

6. Remove water hoses from heater core and pull

heater core out of heater housing. See Figure

9A-35.

Page 527 of 625

98.18 1973 OPEL SERVICE MANUAL

DESCRIPTION AND OPERATION

FUNDAMENTAL PRINCIPLES OF REFRIGERATION

We all know what air conditioning does for us, but

very few understand how or why it works. An air

conditioner is functionally very similar to a refrigera-

tor, so let’s take a look at refrigeration. A refrigerator

is a simple mechanism which, surprisingly enough,

works quite a bit like a tea-kettle boiling on a stove.

That may sound far-fetched, but there is more

similarity between the two than most of us would

suspect. In fact, a modern refrigerator can make ice-

cubes and keep food cool and fresh only because a

liquid called the refrigerant boils inside the freezer.

Of codrse everyone knows a boiling tea-kettle is

“hot” and a refrigerator is “cold”. However, this is

where most of us are apt to get confused. We usually

think of “cold” as a definite, positive condition. Ac-

tually though, there is no such thing as “cold”. The

only way we can define it is in a rather negative sort

of way by saying “cold” is simply the lack of heat

just as darkness is the lack of light. We can:t make

things cold directly. All we can do is remove some

of the heat they contain and they will become cold

as a result. And that is the main job of any ice-box

or refrigerator. Both are simply devices for removing

heat.

All substances contain some heat. Theoretically, the

lowest temperature that any substance could obtain

is 459 degrees Fahrenheit below Zero. This may be

called “Cold”, and anything warmer than this con-

tains heat. Since man has never succeeded in getting

all the heat out of an object, we must think about the

transfer of heat from one object to another when

talking about controlling temperatures.

Figure

96-1 Transfer of Heat

Transfer of HeatThe only thing that will attract heat is a colder ob-ject.

:Like water, which always flows down-hill, heat

always flows down a temperature scale

- from a

warm level down to a colder one. When we hold our

hands out toward the fireplace, heat flows from the

hot fire out to our cold hands (Fig.

9B-1). When we

make a snowball, heat always flows from our warm

hands to the colder snow. In an ice-box, the ice al-

ways is colder than the stored food, so heat naturally

is drawn out of the warm food by the colder ice.

Measurement of HeatEveryone thinks he knows how heat is measured.

Thermometers are used in most: homes. Whenever

we speak of temperature from now on, we will mean

Fahrenheit. They can tell how hot a substance is, but

they can’t tell us everything about heat.

Figure

98-2 Applied Temperature Alone is Not the

Sole Measurement of Heat

When we put a tea-kettle on a stove, we expect it to

get hotter and hotter until it finally boils. All during

the process, we can tell exactly how hot the water is

by means of a thermometer (Fig.

9B-2). However,

our thermometer will show us that the flame is just

as hot when we first put the tea-kettle on the stove

as it is when the water finally boils. Why doesn’t the

water boil immediately then? Also, why does it take

longer to boil a quart of water than a cupful? Obvi-

ously temperature isn’t the only measurement of

heat.

Even though heat is intangible, it can be measured by

quantity as well as intensity. It is recognized that

thermometers indicate only the intensity of heat. The

unit for measuring quantity of heat is specified as

that amount necessary to make 1 pound of water 1

degree warmer (Fig.

9B-3). We call this quantity of

heat a British Thermal Unit. Often it is abbreviated

to Btu.

Perhaps we can get a better idea of these two charac-

Page 532 of 625

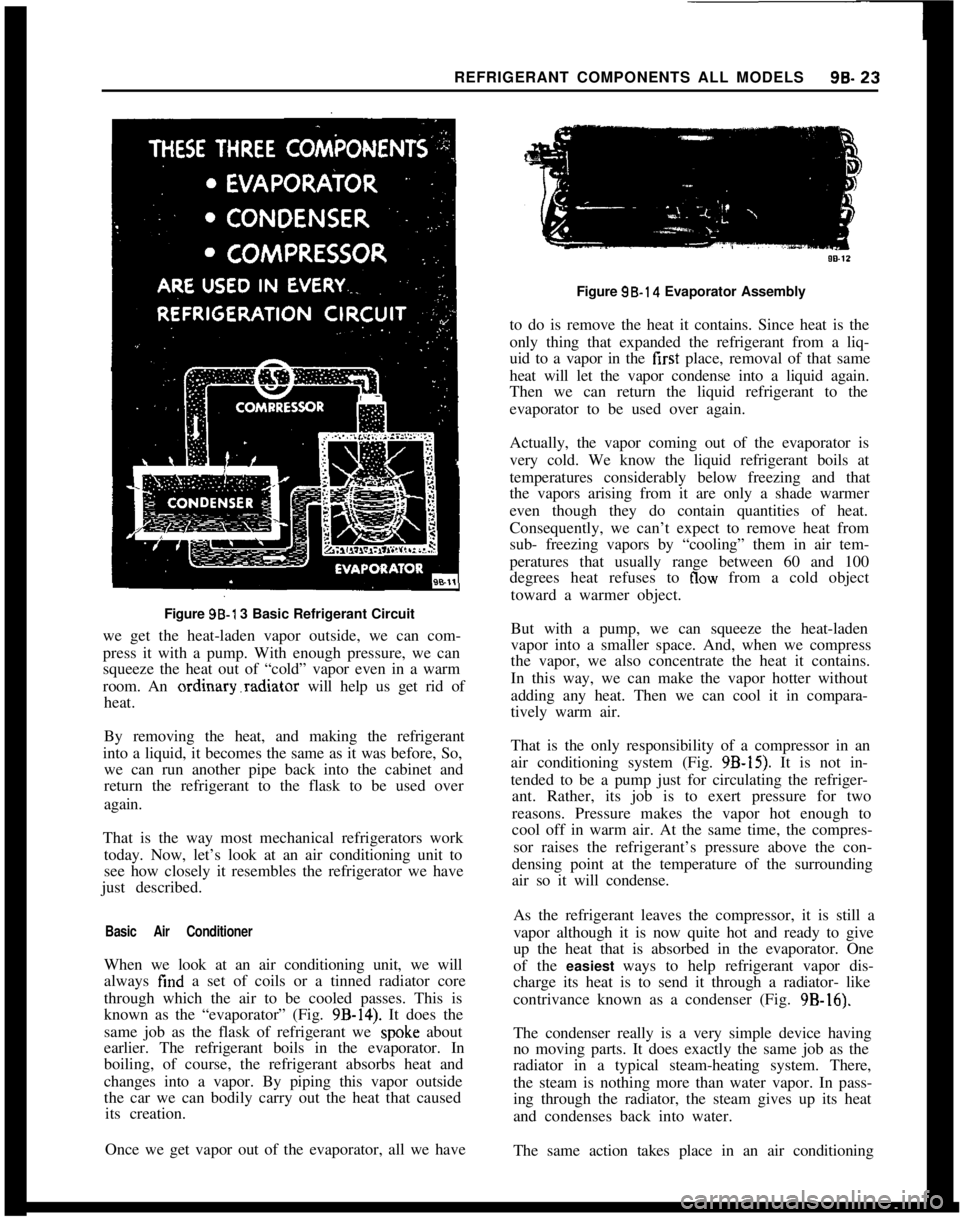

REFRIGERANT COMPONENTS ALL MODELS96.23Figure 96-l 3 Basic Refrigerant Circuit

we get the heat-laden vapor outside, we can com-

press it with a pump. With enough pressure, we can

squeeze the heat out of “cold” vapor even in a warm

room. An ordinary.radiator will help us get rid of

heat.

By removing the heat, and making the refrigerant

into a liquid, it becomes the same as it was before, So,

we can run another pipe back into the cabinet and

return the refrigerant to the flask to be used over

again.

That is the way most mechanical refrigerators work

today. Now, let’s look at an air conditioning unit to

see how closely it resembles the refrigerator we have

just described.

Basic Air ConditionerWhen we look at an air conditioning unit, we will

always find a set of coils or a tinned radiator core

through which the air to be cooled passes. This is

known as the “evaporator” (Fig.

9B-14). It does the

same job as the flask of refrigerant we

spok.e about

earlier. The refrigerant boils in the evaporator. In

boiling, of course, the refrigerant absorbs heat and

changes into a vapor. By piping this vapor outside

the car we can bodily carry out the heat that caused

its creation.

Once we get vapor out of the evaporator, all we haveFigure 98.14 Evaporator Assembly

to do is remove the heat it contains. Since heat is the

only thing that expanded the refrigerant from a liq-

uid to a vapor in the first place, removal of that same

heat will let the vapor condense into a liquid again.

Then we can return the liquid refrigerant to the

evaporator to be used over again.

Actually, the vapor coming out of the evaporator is

very cold. We know the liquid refrigerant boils at

temperatures considerably below freezing and that

the vapors arising from it are only a shade warmer

even though they do contain quantities of heat.

Consequently, we can’t expect to remove heat from

sub- freezing vapors by “cooling” them in air tem-

peratures that usually range between 60 and 100

degrees heat refuses to

flow from a cold object

toward a warmer object.

But with a pump, we can squeeze the heat-laden

vapor into a smaller space. And, when we compress

the vapor, we also concentrate the heat it contains.

In this way, we can make the vapor hotter without

adding any heat. Then we can cool it in compara-

tively warm air.

That is the only responsibility of a compressor in an

air conditioning system (Fig.

9B-15). It is not in-

tended to be a pump just for circulating the refriger-

ant. Rather, its job is to exert pressure for two

reasons. Pressure makes the vapor hot enough to

cool off in warm air. At the same time, the compres-

sor raises the refrigerant’s pressure above the con-

densing point at the temperature of the surrounding

air so it will condense.

As the refrigerant leaves the compressor, it is still a

vapor although it is now quite hot and ready to give

up the heat that is absorbed in the evaporator. One

of the easiest ways to help refrigerant vapor dis-

charge its heat is to send it through a radiator- like

contrivance known as a condenser (Fig. 9B-16).

The condenser really is a very simple device having

no moving parts. It does exactly the same job as the

radiator in a typical steam-heating system. There,

the steam is nothing more than water vapor. In pass-

ing through the radiator, the steam gives up its heat

and condenses back into water.

The same action takes place in an air conditioning