windshield wipers OPEL GT-R 1973 Service Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 18 of 625

LUBRICATION AND MAINTENANCE OC-9

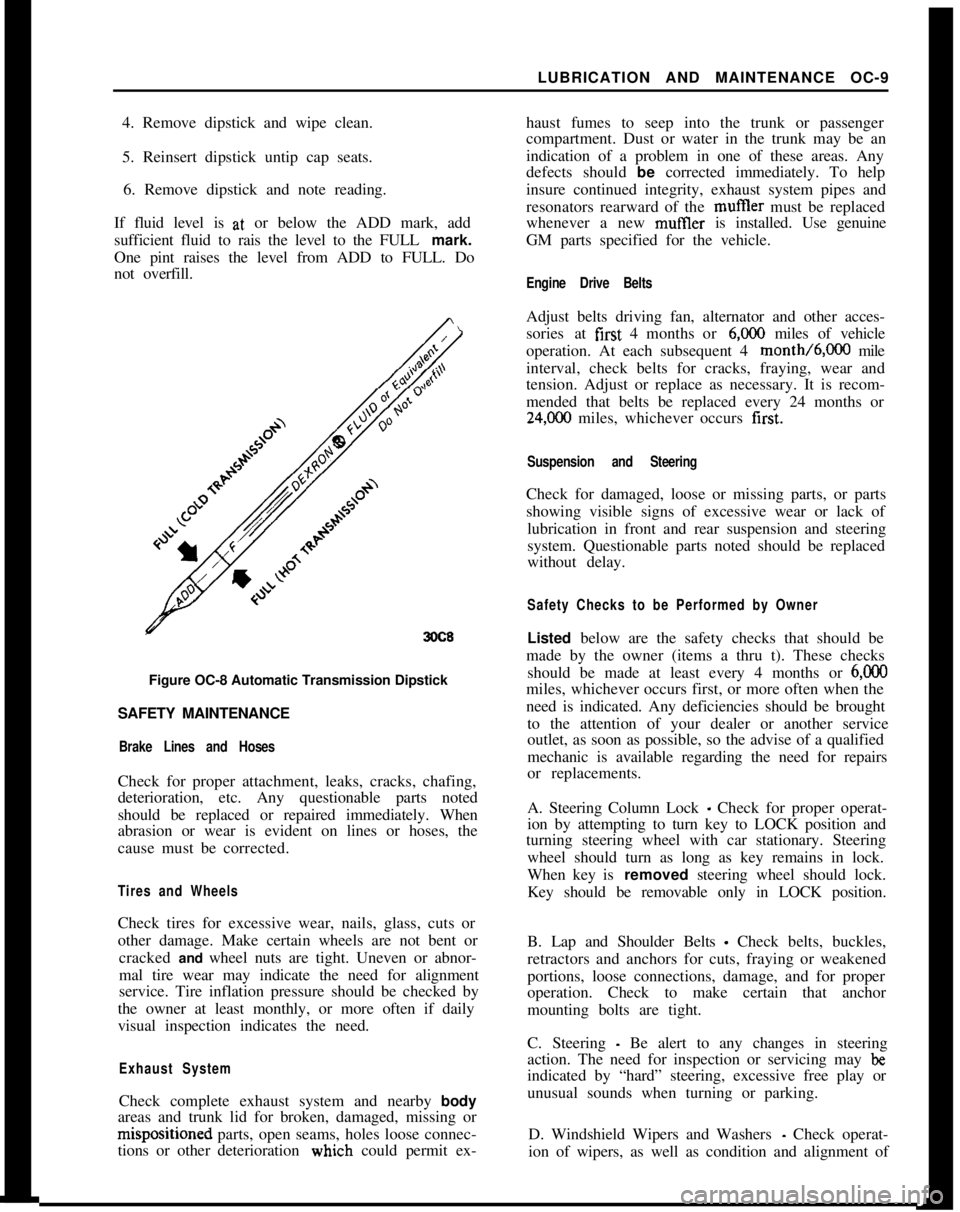

4. Remove dipstick and wipe clean.

5. Reinsert dipstick untip cap seats.

6. Remove dipstick and note reading.

If fluid level is at, or below the ADD mark, add

sufficient fluid to rais the level to the FULL mark.

One pint raises the level from ADD to FULL. Do

not overfill.

3OC8Figure OC-8 Automatic Transmission Dipstick

SAFETY MAINTENANCE

Brake Lines and HosesCheck for proper attachment, leaks, cracks, chafing,

deterioration, etc. Any questionable parts noted

should be replaced or repaired immediately. When

abrasion or wear is evident on lines or hoses, the

cause must be corrected.

Tires and WheelsCheck tires for excessive wear, nails, glass, cuts or

other damage. Make certain wheels are not bent or

cracked and wheel nuts are tight. Uneven or abnor-

mal tire wear may indicate the need for alignment

service. Tire inflation pressure should be checked by

the owner at least monthly, or more often if daily

visual inspection indicates the need.

Exhaust SystemCheck complete exhaust system and nearby body

areas and trunk lid for broken, damaged, missing orm&positioned parts, open seams, holes loose connec-

tions or other deterioration wiuch could permit ex-haust fumes to seep into the trunk or passenger

compartment. Dust or water in the trunk may be an

indication of a problem in one of these areas. Any

defects should be corrected immediately. To help

insure continued integrity, exhaust system pipes and

resonators rearward of the muftler must be replaced

whenever a new mufIler is installed. Use genuine

GM parts specified for the vehicle.

Engine Drive BeltsAdjust belts driving fan, alternator and other acces-

sories at first 4 months or

6,ooO miles of vehicle

operation. At each subsequent 4 month/6,000 mile

interval, check belts for cracks, fraying, wear and

tension. Adjust or replace as necessary. It is recom-

mended that belts be replaced every 24 months or

24,C00 miles, whichever occurs first.

Suspension and SteeringCheck for damaged, loose or missing parts, or parts

showing visible signs of excessive wear or lack of

lubrication in front and rear suspension and steering

system. Questionable parts noted should be replaced

without delay.

Safety Checks to be Performed by OwnerListed below are the safety checks that should be

made by the owner (items a thru t). These checks

should be made at least every 4 months or

6,ooOmiles, whichever occurs first, or more often when the

need is indicated. Any deficiencies should be brought

to the attention of your dealer or another service

outlet, as soon as possible, so the advise of a qualified

mechanic is available regarding the need for repairs

or replacements.

A. Steering Column Lock

_ Check for proper operat-

ion by attempting to turn key to LOCK position and

turning steering wheel with car stationary. Steering

wheel should turn as long as key remains in lock.

When key is removed steering wheel should lock.

Key should be removable only in LOCK position.

B. Lap and Shoulder Belts

- Check belts, buckles,

retractors and anchors for cuts, fraying or weakened

portions, loose connections, damage, and for proper

operation. Check to make certain that anchor

mounting bolts are tight.

C. Steering

- Be alert to any changes in steering

action. The need for inspection or servicing may

beindicated by “hard” steering, excessive free play or

unusual sounds when turning or parking.

D. Windshield Wipers and Washers

- Check operat-

ion of wipers, as well as condition and alignment of

Page 58 of 625

WINDSHIELD WIPERSlE- 37WINDSHEILD WIPERS

ALL MODELS

CONTENTS

Subject

DESCRIPTION AND OPERATION:

Windshield Wiper Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

Windshield Wiper

. . . . . . . . . . . . . . . . . . . , , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .MAINTENANCE AND ADJUSTMENTS: (Not

Applicable)

MAJOR REPAIR:Wiper Transmission

- 1900 and Manta. . . . . . . . . . . . . . . . . . . .W/per Transmission

- GT. . . . . a.* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Disassembly of Wiper Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cleaning and Inspection of Parts

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Assembly of Wiper Motor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS:

GeneralSpecifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Torque Specifications

. . . . . . . a.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DESCRIPTIOfV AND OPERATION

GENERAL;DESCRlPTlDNThe two-sbeed wiper consists of a round shaped per-

manent magnet type motor and speed reduction gear

box. IOPERATldN

=The wipei motor is controlled through a dash

mounted &itch on all cars. The Rallye and GT, in

addition tb the dash mounted switch, also have a

switch moimted in conjunction with the windshield

washer fodt pump. Depressing the washer pump will

allow the bipers to operate while the pump is de-

pressed. i

DIAGNO;SIS

PRELIMINj9RY INSPECTION

1. Make

c&in of firm wire connections at wiper

motor fuse block and wiper switch.

Page No.

1 E-37

1 E-37E-38

E-38

E-40

E-41

E-4 1E-42

1 E-43

1 E-432. Check to see that the fuse is not blown.

3. Be sure wiper motor is not loose on fire wall.

4. With the yellow wire disconnected from terminal

No. 53 on the

wi@er motor, turn the ignition switch

and wiper switch to the on position and check volt-

age available to the wiper motor. There should be 12

volts available at the durple wire with a properly

charged battery.

Checking Wiper Operation1. Turn ignition switch on and engage wiper switch

to see if wiper motor will operate.

2. If wiper action is slow or inoperative, turn swit-

ches off and detach wiper control

inn from crank

arm.3. Operate wiper manually checking for excessive

bind in linkage. Correct if necessary.

Page 60 of 625

WINDSHIELD WIPERSlE- 39

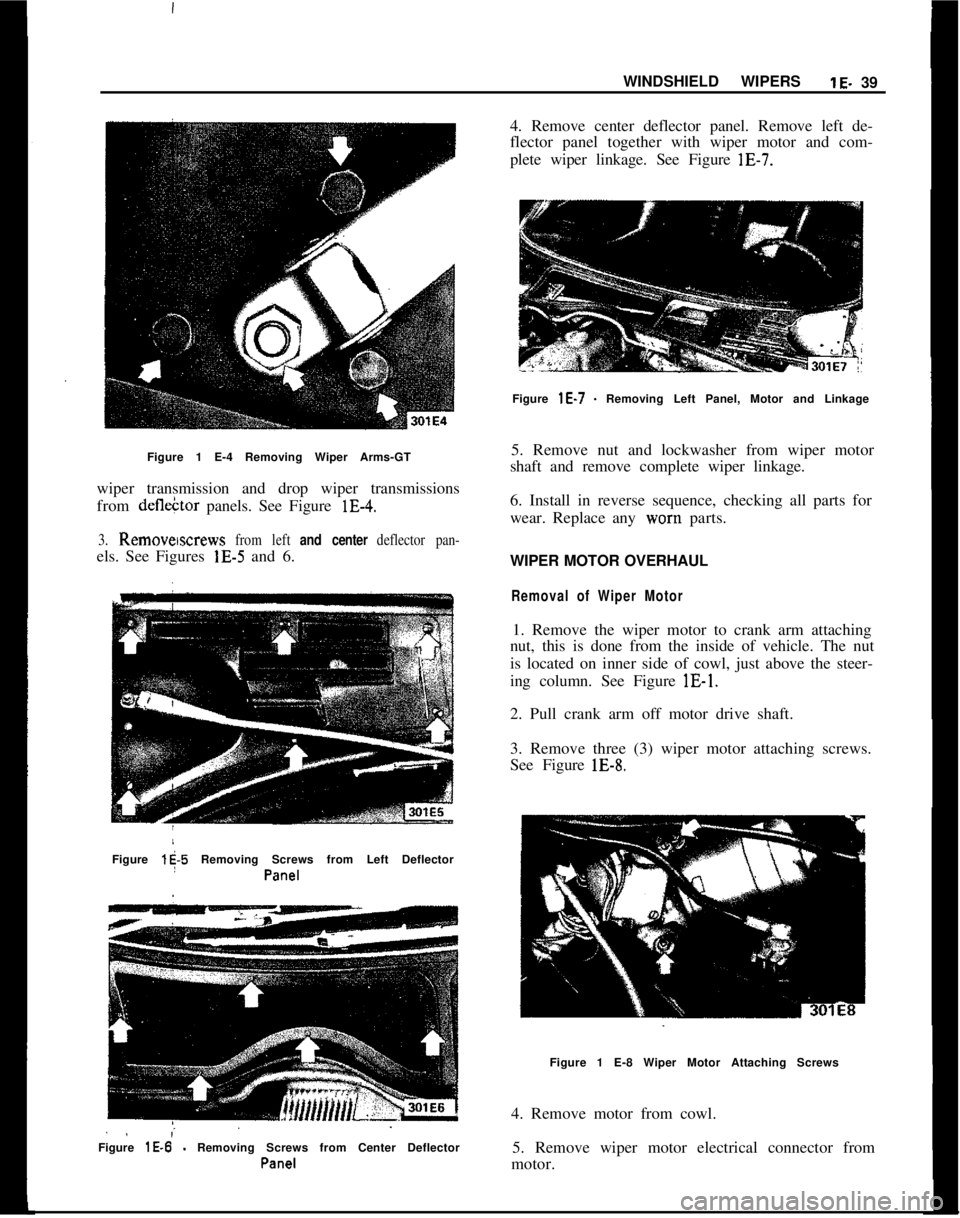

Figure 1 E-4 Removing Wiper Arms-GT

wiper transmission and drop wiper transmissions

from defleCtor panels. See Figure lE-4.3. Remowscrews from left and center deflector pan-els. See Figures lE-5 and 6.

Figure

l$-5 Removing Screws from Left Deflector

I

Pa%?1

. .;Figure

lE-6 - Removing Screws from Center Deflector

Pall-Z!14. Remove center deflector panel. Remove left de-

flector panel together with wiper motor and com-

plete wiper linkage. See Figure lE-7.

Figure

lE-7 - Removing Left Panel, Motor and Linkage

5. Remove nut and lockwasher from wiper motor

shaft and remove complete wiper linkage.

6. Install in reverse sequence, checking all parts for

wear. Replace any worn parts.

WIPER MOTOR OVERHAUL

Removal of Wiper Motor1. Remove the wiper motor to crank arm attaching

nut, this is done from the inside of vehicle. The nut

is located on inner side of cowl, just above the steer-

ing column. See Figure lE-1.

2. Pull crank arm off motor drive shaft.

3. Remove three (3) wiper motor attaching screws.

See Figure lE-8.

Figure 1 E-8 Wiper Motor Attaching Screws

4. Remove motor from cowl.

5. Remove wiper motor electrical connector from

motor.

Page 62 of 625

WINDSHIELD WIPERSlE-41

Figurk 1 E-l 3 Cut Off Positive Brush Leads

i

Figure iE-14 Remove Negative Brush Retaining

S.X?WI

Cleaning apd Inspection of PartsWith the ekception of electrical parts and bushings,

clean all components in a cleaning solvent.

1. Check irmatare windings for ground, or open

circuit. If

b ground or open circuit is evident, the

armature must be replaced. If the armature checks

out, the c

brushes should be 6.35 to 8.47 ounces. Spring pres-

sure of worn brushes should be at least 3.5 ounces.

In case of /ower spring pressure, replace springs.

3. Check blushes for wear and replace if necessary.

Minimum brush length should be

.24’inch.4. Check d$ven gear for wear and replace if neces-

sary.

Assembly

02383. I

2. Install

d&en gear into housing3. Apply a small amount of grease to ball cavity of

driven gear and insert ball. See Figure lE-15.

Figure lE-15 Insert Ball into Driven Gear

4. Install transmission housing cover. See Figure

lE-

16.2. DRIVEN GEAR

3. CONTACT SPRINGS

4. TRANSMISSION

HOUSING COVER

Figure 1 E-l 6 Install Transmission Housing

Cover5. Solder positive brush lead(s) to brush holder(s).

Hold brush lead with needle nose pliers to prevent

solder from running up wire strands. See Figure

lE-

17.6. Install negative brush

7. Apply a small amount of grease to end of armature

shaft. Lightly oil armature shaft.

8. Insert brush springs and brushes into brush hold-

ers. Slide armature into housing, taking care not to

damage brushes.

Page 64 of 625

WINDSHIELD WIPERSlE-43SPEhFlCATlONS

IGENEPAL SPECIFICATIONSiRated Voltage .

..__.,,,.,,,......................................,.,,... ~ __..__...__...._..................................... 12 VDC

,Test Voltage ___..................................................,...................,..,..................................... 13 VDC

Current Draw (Amps)

;No Load_, Low Speed

..__...__..__..,_,,..,,,.,,,,..,....................,,.................................................................. 1.5

I Hieh

SDeed .___,,...,,..,,._.._..............,...............................,,,..,,,.............................................. 2.2lLock:d

’

:Low Speed ___.,._,,,..,,,....................................,,.........,,..,,,.,,,,..................,,,........................... 16

,

High Speed . . . . . . . ..___.._........................................................................................................... 17

~Minimum Commutator Diameter __.................,,,,........................................................... .86 in.

‘Brush Spring Pressure

:New Brush

. . . . . . .._...__...................................................................................... 6.35 to 8.47 oz.Used Brush

..__,,,...,,.,,..................,...............................,,.,,,,.,,....................... 3.5 oz. minimum‘MinimumBrushLength

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24in.The windshield wiper motor instead of field coils has a permanent magnet

(oxide magnet). This motor design is sturdier and consumes less current.TORQirE SPECIFICATIONS

‘CrankArmtoMotorDriveShaft. . . . . . . . . . . . . . . . . . . . . . . . . .70to87in.lbs.iper Motor to Cowl

,

,.,,,.,,,,..,,............,..,,.,,.........................................14 to 17 in.lbs.

Page 77 of 625

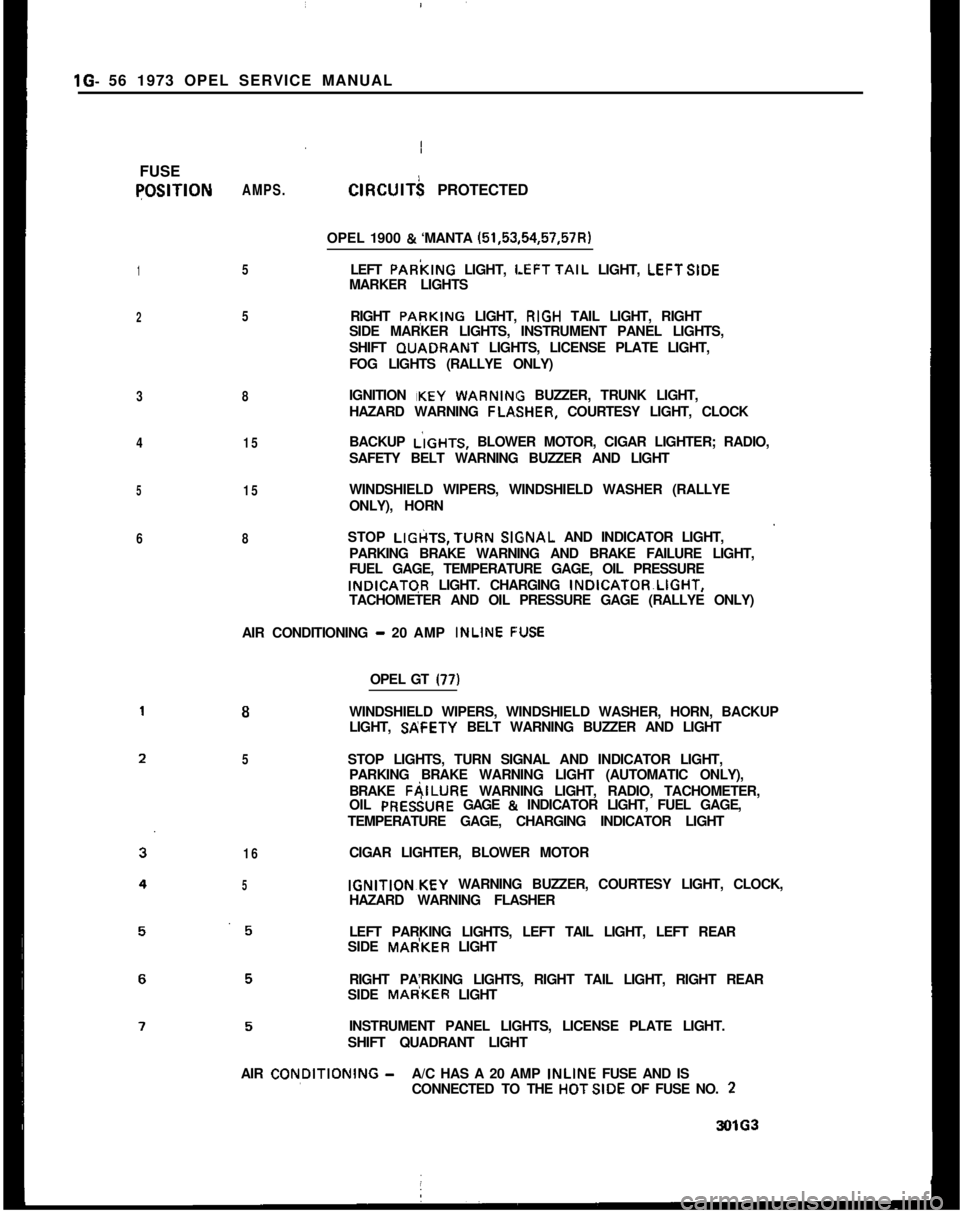

:lG- 56 1973 OPEL SERVICE MANUAL

I

FUSEqOSlTlON

1

2

3

4

5

6AMPS.

5

5

8

15

15

8ClRClJlT$ PROTECTED

OPEL 1900

& ‘MANTA (51,53,54,57,57R)

LEFT PARkING LIGHT,

LEFTTAIL LIGHT, LEFTSIDE

MARKER LIGHTS

RIGHT PApKING LIGHT, RIGH TAIL LIGHT, RIGHT

SIDE MARKER LIGHTS, INSTRUMENT PANEL LIGHTS,

SHIFT GUADRANT LIGHTS, LICENSE PLATE LIGHT,

FOG LIGHTS (RALLYE ONLY)

IGNITION IKEY

WARNIN BUZZER, TRUNK LIGHT,

HAZARD WARNING FLA,SHER, COURTESY LIGHT, CLOCK

BACKUP L’IGHTS, BLOWER MOTOR, CIGAR LIGHTER; RADIO,

SAFETY BELT WARNING BUZZER AND LIGHT

WINDSHIELD WIPERS, WINDSHIELD WASHER (RALLYE

ONLY), HORN

STOP LIGtiTS,TURN

SlGsNAL AND INDICATOR LIGHT,

PARKING BRAKE WARNING AND BRAKE FAILURE LIGHT,

FUEL GAGE, TEMPERATURE GAGE, OIL PRESSUREINDICATGR LIGHT. CHARGING INDICATOR~LIGHT,

TACHOMETER AND OIL PRESSURE GAGE (RALLYE ONLY)

AIR CONDITIONING

- 20 AMP INLINE F:USE

8

5

16

5OPEL GT

(77)WINDSHIELD WIPERS, WINDSHIELD WASHER, HORN, BACKUP

LIGHT, SP;FETY BELT WARNING BUZZER AND LIGHT

STOP LIGHTS, TURN SIGNAL AND INDICATOR LIGHT,

PARKING BRAKE WARNING LIGHT (AUTOMATIC ONLY),

BRAKE FAILURE WARNING LIGHT, RADIO, TACHOMETER,

OIL PRESiURE GAGE

& INDICATOR LIGHT, FUEL GAGE,

TEMPERATURE GAGE, CHARGING INDICATOR LIGHT

CIGAR LIGHTER, BLOWER MOTORIGNITION~KEY WARNING BUZZER, COURTESY LIGHT, CLOCK,

HAZARD WARNING FLASHER

LEFT PARKING LIGHTS, LEFT TAIL LIGHT, LEFT REAR

SIDE MAdKER LIGHT

RIGHT PA’RKING LIGHTS, RIGHT TAIL LIGHT, RIGHT REAR

SIDE MAdKER LIGHT

INSTRUMENT PANEL LIGHTS, LICENSE PLATE LIGHT.

SHIFT QUADRANT LIGHT

AIR CON,DlTlONlNG

-A/C HAS A 20 AMP INLINE FUSE AND IS

CONNECTED TO THE HOTSIDE OF FUSE NO. 23OlG3

Page 78 of 625

,I

IINSTRUMENT PANEL

lH- 57

/

/SubjectPage No. INSTRUMENT PANEL

CONTENTS

DESCRIPTION AND OPERATION:

Instrument Panel

- Opel 1900 - Manta. . . . . . . . . . . . . . . . . . . . . .Instrument

Panel-GT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DIAGNOSIS:

MAINTENANCE AND ADJUSTMENTS:

MAJOR REPAIR:

Instrument Cluster Housing

- Opel 1900 - Manta . .

Windshield Wiper Switch

. , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .InstrumentCluster

Bulbs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .InstrumentCluster

Housing-GT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Combined Switch Assemblies

. . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CigarLighter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SPECIFICATIONS: (Not Applicable)

I H-57

1H-58

1H-59

1H-61

lH-61

1H-61

1H-63

1H-64

DESCF(lPTlON AND OPERATION2. The fog light toggle switch lower half is pushed in.INSTRUFENT PANEL (OPEL 1900. MANTA)

Headligl$ Switch

3. The parking lights and/or low beam headlights are

on.The thr& position light switch controls the head-

lights, @lights, parking lights, side marker lights,

license

plate light and instrument panel lights and is

located

4t the lower left on the instrument panel.

With thk switch knob pulled outward to the first

stop,

thi parking lights, side marker lights, license

plate

ligiit and instrument panel lights will light. Theinstrumdnt panel lights can be turned off by turning

the

lightSwitch knob counterclockwise past the first

detent. IThe fog lights are automatically turned off if the

ignition switch is on and the headlights are on high

beam.

Windshield Wiper Switch

The windshield wiper switch is located on the instru-ment panel to the right of the headlight switch.

By pull&g the lightswitch knob out all the way, the

headlights will also be turned on.

IBy pushing the lower half of this switch in to the first

stop, the wipers will operate at slow speed. By push-ing in to the second stop, the wipers will operate at

fast speed.

Fog

Ligh) Switch (Rallye)The fog

iight toggle switch is located in the instru-

ment cluster to the left of the temperature and fuel

gauge

cl+ster. The fog lights can be turned off at any

time by

t,he toggle switch, but can only be turned on

when: ,

Electrically Heated Rear Window Switch (If

Equipped)The heated rear

wind&v switch is located in the

instrument panel to the right of the clock opening.

1. The ignition switch is on or the engine running.

ITo operate (only possible with the engine running),

push in on the lower half of the switch. When the

rear window is being heated, the switch will

belighted.