light OPEL MERIVA 2009 Workshop Manual

[x] Cancel search | Manufacturer: OPEL, Model Year: 2009, Model line: MERIVA, Model: OPEL MERIVA 2009Pages: 248, PDF Size: 4.46 MB

Page 153 of 248

147

Driving and operation

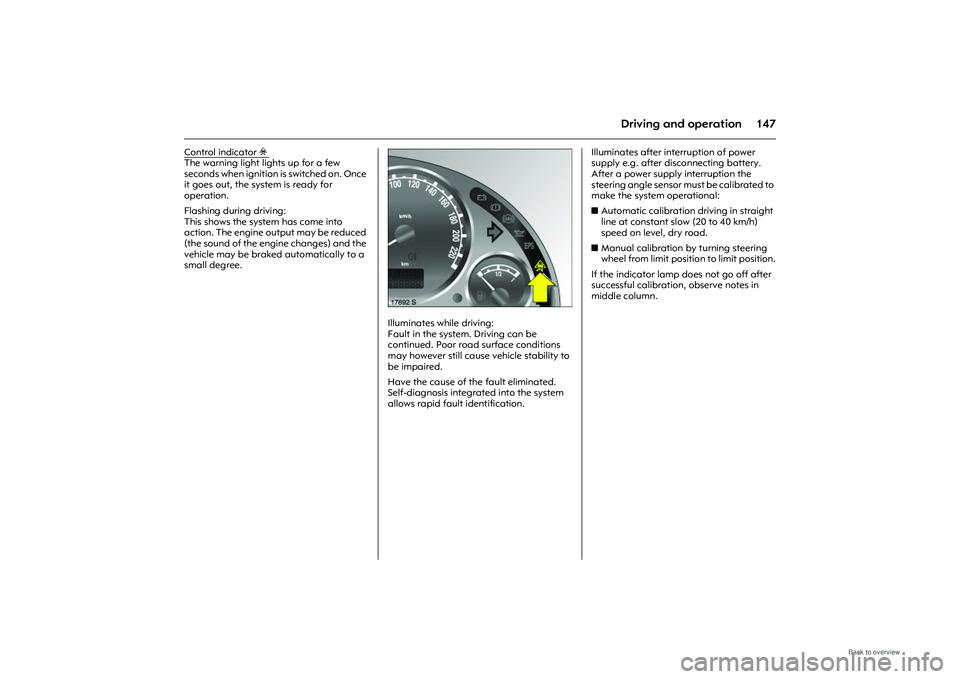

Control indicator

v

The warning light lights up for a few

seconds when ignition is switched on. Once

it goes out, the system is ready for

operation.

Flashing during driving:

This shows the system has come into

action. The engine output may be reduced

(the sound of the engine changes) and the

vehicle may be braked automatically to a

small degree.

Picture no: 17892s.tif

Illuminates while driving:

Fault in the system. Driving can be

continued. Poor road surface conditions

may however still cause vehicle stability to

be impaired.

Have the cause of the fault eliminated.

Self-diagnosis integrated into the system

allows rapid fault identification. Illuminates after interruption of power

supply e.g. after disconnecting battery.

After a power supply interruption the

steering angle sensor must be calibrated to

make the system operational:

z

Automatic calibration driving in straight

line at constant slow (20 to 40 km/h)

speed on level, dry road.

z Manual calibration by turning steering

wheel from limit position to limit position.

If the indicator lamp does not go off after

successful calibration , observe notes in

middle column.

Page 154 of 248

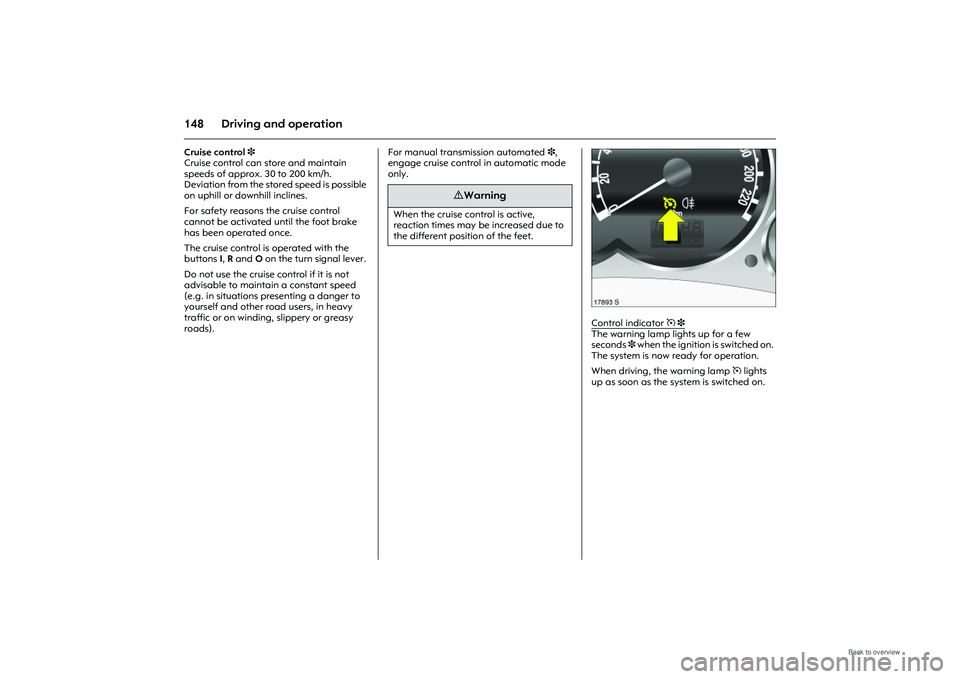

148 Driving and operationCruise control 3

Cruise control can store and maintain

speeds of approx. 30 to 200 km/h.

Deviation from the stored speed is possible

on uphill or downhill inclines.

For safety reasons the cruise control

cannot be activated until the foot brake

has been operated once.

The cruise control is operated with the

buttons I, R and O on the turn signal lever.

Do not use the cruise control if it is not

advisable to maintain a constant speed

(e.g. in situations presenting a danger to

yourself and other road users, in heavy

traffic or on winding, slippery or greasy

roads). For manual transmission automated

3,

engage cruise control in automatic mode

only.

Picture no: 17893s.tif

Control indicator

m 3

The warning lamp lights up for a few

seconds 3 when the ignition is switched on.

The system is now ready for operation.

When driving, th e warning lamp m lights

up as soon as the sy stem is switched on.

9 Warning

When the cruise control is active,

reaction times may be increased due to

the different position of the feet.

Page 159 of 248

153

Driving and operation

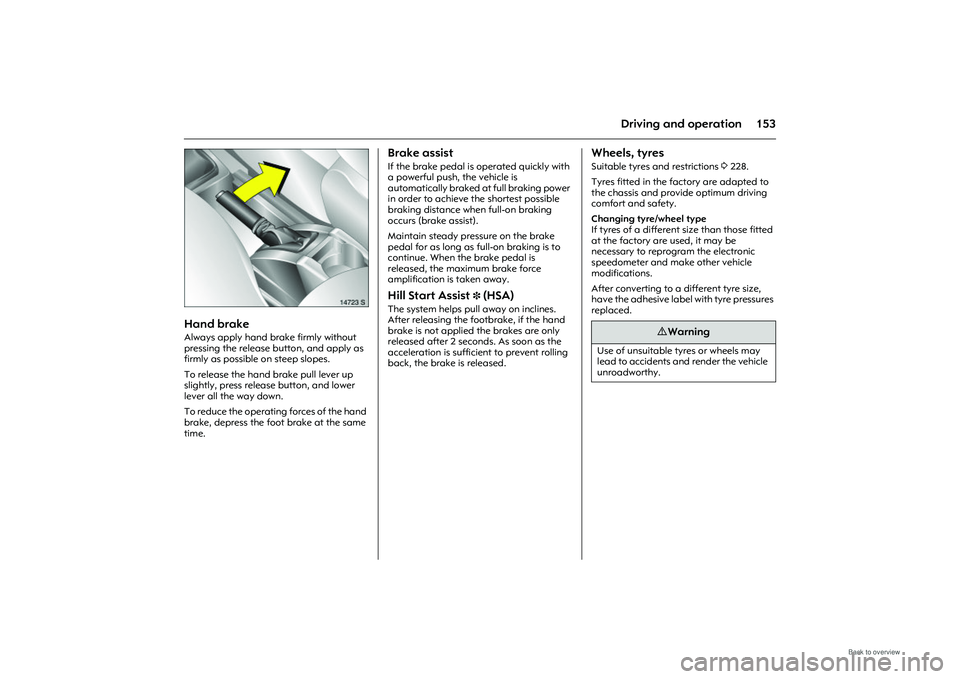

Picture no: 14723s.tif

Hand brake Always apply hand brake firmly without

pressing the release button, and apply as

firmly as possible on steep slopes.

To release the hand brake pull lever up

slightly, press release button, and lower

lever all the way down.

To reduce the operating forces of the hand

brake, depress the foot brake at the same

time.

Brake assist If the brake pedal is operated quickly with

a powerful push, the vehicle is

automatically braked at full braking power

in order to achieve the shortest possible

braking distance when full-on braking

occurs (brake assist).

Maintain steady pressure on the brake

pedal for as long as full-on braking is to

continue. When the brake pedal is

released, the maximum brake force

amplification is taken away. Hill Start Assist

3 (HSA)

The system helps pull away on inclines.

After releasing the footbrake, if the hand

brake is not applied the brakes are only

released after 2 seconds. As soon as the

acceleration is sufficient to prevent rolling

back, the brake is released.

Wheels, tyresSuitable tyres and restrictions 3 228.

Tyres fitted in the factory are adapted to

the chassis and provide optimum driving

comfort and safety.

Changing tyre/wheel type

If tyres of a different size than those fitted

at the factory are used, it may be

necessary to reprogram the electronic

speedometer and make other vehicle

modifications.

After converting to a different tyre size,

have the adhesive label with tyre pressures

replaced.

9 Warning

Use of unsuitable tyres or wheels may

lead to accidents and render the vehicle

unroadworthy.

Page 168 of 248

162 Driving and operation

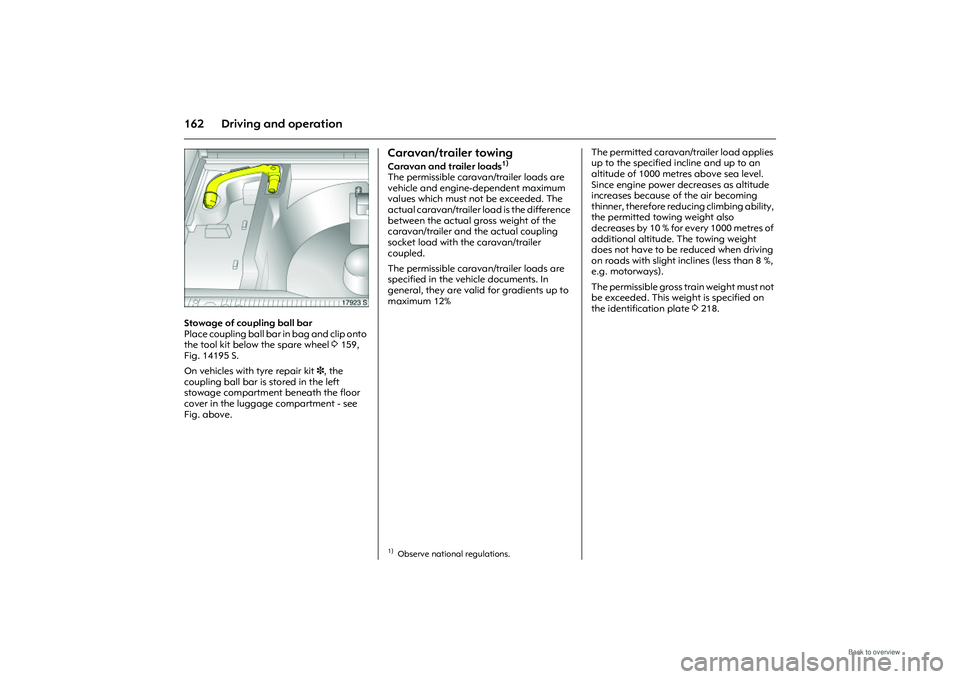

Picture no: 17923s.tif

Stowage of coupling ball bar

Place coupling ball bar in bag and clip onto

the tool kit below the spare wheel 3159,

Fig. 14195 S.

On vehicles with tyre repair kit 3, the

coupling ball bar is stored in the left

stowage compartment beneath the floor

cover in the luggage compartment - see

Fig. above.

Caravan/trailer towingCaravan and trailer loads

1)

The permissible caravan/trailer loads are

vehicle and engine-dependent maximum

values which must not be exceeded. The

actual caravan/trailer load is the difference

between the actual gross weight of the

caravan/trailer and the actual coupling

socket load with the caravan/trailer

coupled.

The permissible caravan/trailer loads are

specified in the vehi cle documents. In

general, they are valid for gradients up to

maximum 12% The permitted caravan/trailer load applies

up to the specified incline and up to an

altitude of 1000 metres above sea level.

Since engine power decreases as altitude

increases because of the air becoming

thinner, therefore reducing climbing ability,

the permitted towing weight also

decreases by 10 % for

every 1000 metres of

additional altitude. The towing weight

does not have to be reduced when driving

on roads with slight inclines (less than 8 %,

e.g. motorways).

The permissible gross train weight must not

be exceeded. This weig ht is specified on

the identification plate 3218. 1)Observe national regulations.

Page 169 of 248

163

Driving and operation

Coupling socket load

The coupling socket load is the load

exerted by the trailer/caravan on the

coupling ball. It can be varied by changing

the weight distribution when loading the

trailer/caravan.

The maximum permissible coupling socket

load (55 kg) of the towing vehicle is

specified on the towing equipment

identification plate and in the vehicle

documents. This must always be complied

with, particularly in the case of heavy

caravans/trailers. The coupling socket load

should be no less than 25 kg.

When measuring the coupling socket load,

make sure that the drawbar of the loaded

trailer/caravan is at the same height as it

will be when the trailer/caravan is coupled

with the towing vehicle loaded. Particularly

important for trailers/caravans with

tandem axle. Rear axle load during towing

With the trailer connected and the towing

vehicle fully loaded including all

occupants, the permitted rear axle load

(specified on the identification plate and

vehicle documents) must be exceeded by

no more than 25 kg and the maximum

permitted gross vehicle weight by no more

than 30 kg. If the maximum permitted rear

axle load is exceeded, a maximum speed

of 100 km/h applies, and 80 km/h for

commercial vehicles.

Driving characteristics, towing tips

Before attaching th

e trailer/caravan,

lubricate the ball of the trailer/caravan

towing device. However, do not lubricate

the ball if a stabiliser, which acts on the

coupling ball, is being used to damp

hunting.

Check caravan/traile r lighting before

starting to drive. The fog tail lamps on the

vehicle are deactivated when towing a

caravan or trailer.

Trailers with LED turn signals must have a

provision enables lamp monitoring for

commercial bulbs.

Handling is greatly influenced by the

loading of the trailer/caravan. Loads

should therefore be secured so that they

cannot slip and be placed in the centre of

the trailer/caravan if possible, i.e. above

the axle.

In the case of trailers with low driving

stability, do not exceed a speed of 80 km/h;

the use of a friction-type stabiliser is

strongly recommended.

Page 174 of 248

168 Self-help, vehicle careRoute the leads so that they cannot catch

on rotating parts in the engine

compartment.

To start the engine:

1. Start the engine of the vehicle providing the jump start.

2. After 5 minutes, start the other engine. Start attempts shou ld be made at

intervals of 1 minute not last longer

than 15 seconds.

3. Allow both engines to idle for approx. 3 minutes with the leads connected.

4. Switch on electrical consumers (e.g. light, heated rear window) of the vehicle

receiving the jump start.

5. Reverse above sequence exactly when removing leads.

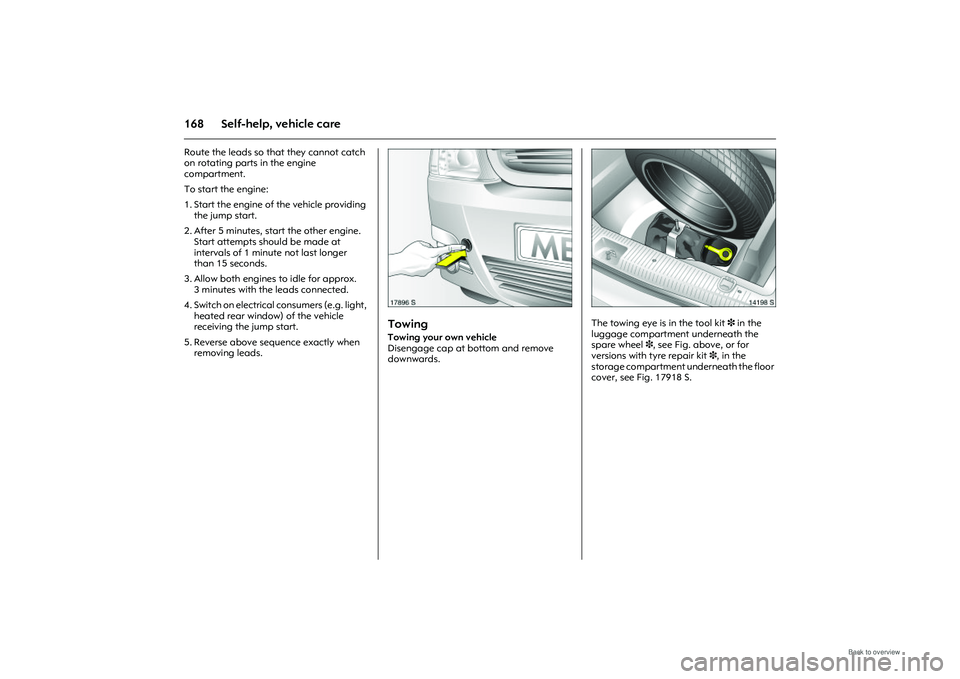

Picture no: 17896s.tif

Towing Towing your own vehicle

Disengage cap at bottom and remove

downwards.

Picture no: 14198s.tif

The towing eye is in the tool kit 3 in the

luggage compartment underneath the

spare wheel 3, see Fig. above, or for

versions with tyre repair kit 3, in the

storage compartment underneath the floor

cover, see Fig. 17918 S.

Page 180 of 248

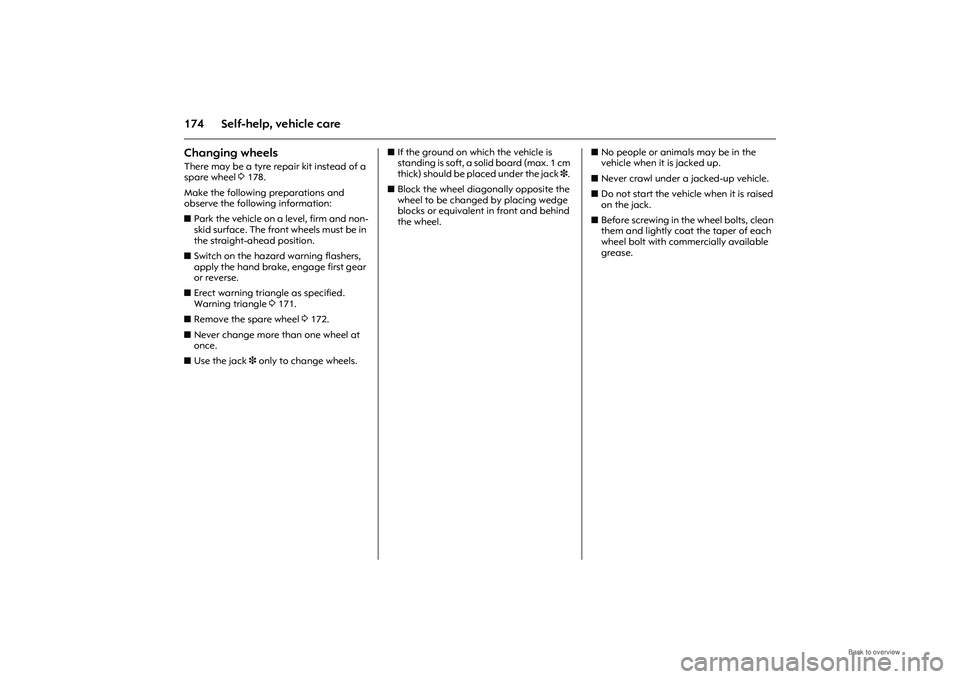

174 Self-help, vehicle careChanging wheels There may be a tyre repair kit instead of a

spare wheel 3178.

Make the following preparations and

observe the following information:

z Park the vehicle on a level, firm and non-

skid surface. The front wheels must be in

the straight-ahead position.

z Switch on the hazard warning flashers,

apply the hand brake, engage first gear

or reverse.

z Erect warning triangle as specified.

Warning triangle 3171.

z Remove the spare wheel 3 172.

z Never change more than one wheel at

once.

z Use the jack 3 only to change wheels. z

If the ground on which the vehicle is

standing is soft, a solid board (max. 1 cm

thick) should be placed under the jack 3.

z Block the wheel diagonally opposite the

wheel to be changed by placing wedge

blocks or equivalent in front and behind

the wheel. z

No people or animals may be in the

vehicle when it is jacked up.

z Never crawl under a jacked-up vehicle.

z Do not start the vehicle when it is raised

on the jack.

z Before screwing in the wheel bolts, clean

them and lightly coat the taper of each

wheel bolt with comm ercially available

grease.

Page 183 of 248

177

Self-help, vehicle care

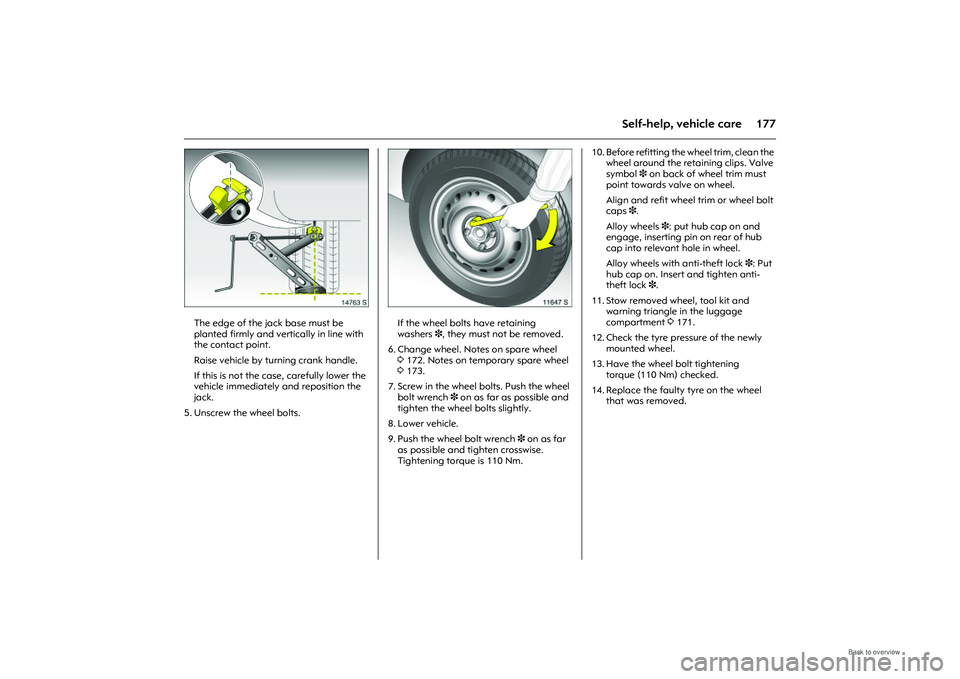

Picture no: 14763s.tif

The edge of the jack base must be

planted firmly and vertically in line with

the contact point.

Raise vehicle by turning crank handle.

If this is not the case, carefully lower the

vehicle immediately and reposition the

jack.

5. Unscrew the wheel bolts.

Picture no: 11647s.tif

If the wheel bolt s have retaining

washers 3, they must not be removed.

6. Change wheel. Notes on spare wheel 3172. Notes on temporary spare wheel

3 173.

7. Screw in the wheel bolts. Push the wheel bolt wrench 3 on as far as possible and

tighten the wheel bolts slightly.

8. Lower vehicle.

9. Push the wheel bolt wrench 3 on as far

as possible and tighten crosswise.

Tightening torque is 110 Nm. 10. Before refitting the wheel trim, clean the

wheel around the retaining clips. Valve

symbol 3 on back of wheel trim must

point towards valve on wheel.

Align and refit wheel trim or wheel bolt

caps 3.

Alloy wheels 3: put hub cap on and

engage, inserting pin on rear of hub

cap into relevant hole in wheel.

Alloy wheels with anti-theft lock 3: Put

hub cap on. Insert and tighten anti-

theft lock 3.

11. Stow removed wheel, tool kit and warning triangle in the luggage

compartment 3171.

12. Check the tyre pressure of the newly mounted wheel.

13. Have the wheel bolt tightening torque (110 Nm) checked.

14. Replace the faulty tyre on the wheel that was removed.

Page 185 of 248

179

Self-help, vehicle care

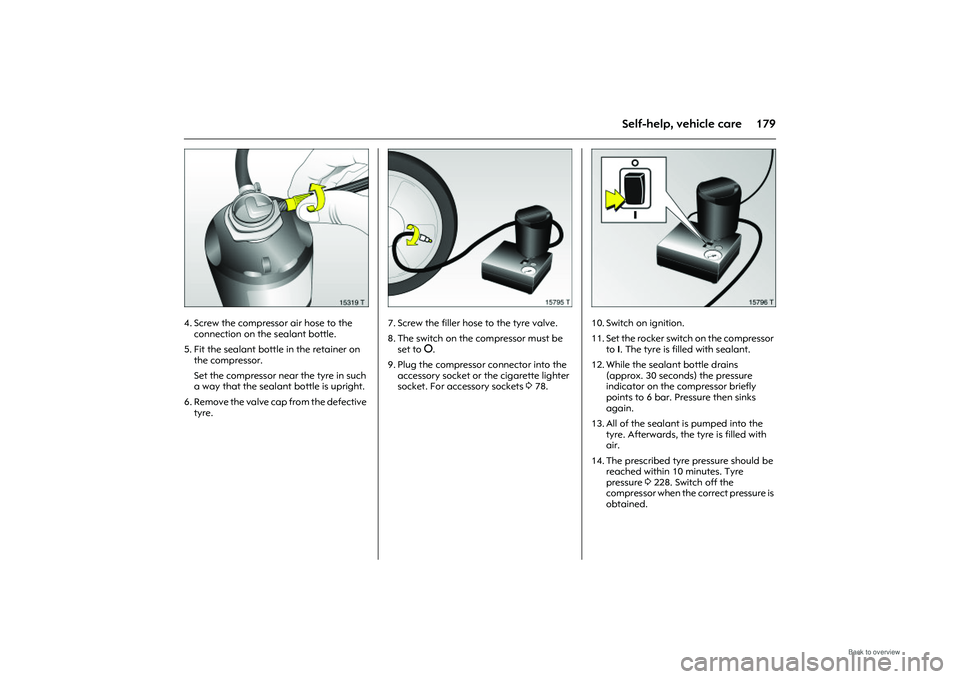

Picture no: 15319t.tif

4. Screw the compressor air hose to the connection on the sealant bottle.

5. Fit the sealant bottle in the retainer on the compressor.

Set the compressor near the tyre in such

a way that the sealant bottle is upright.

6. Remove the valve cap from the defective tyre.

Picture no: 15795t.tif

7. Screw the filler hose to the tyre valve.

8. The switch on the compressor must be set to §.

9. Plug the compressor connector into the accessory socket or the cigarette lighter

socket. For accessory sockets 378.

Picture no: 15796t.tif

10. Switch on ignition.

11. Set the rocker switch on the compressor

to I. The tyre is filled with sealant.

12. While the sealant bottle drains (approx. 30 seconds) the pressure

indicator on the compressor briefly

points to 6 bar. Pressure then sinks

again.

13. All of the sealant is pumped into the tyre. Afterwards, the tyre is filled with

air.

14. The prescribed tyre pressure should be reached within 10 minutes. Tyre

pressure 3228. Switch off the

compressor when the correct pressure is

obtained.

Page 188 of 248

182 Self-help, vehicle care

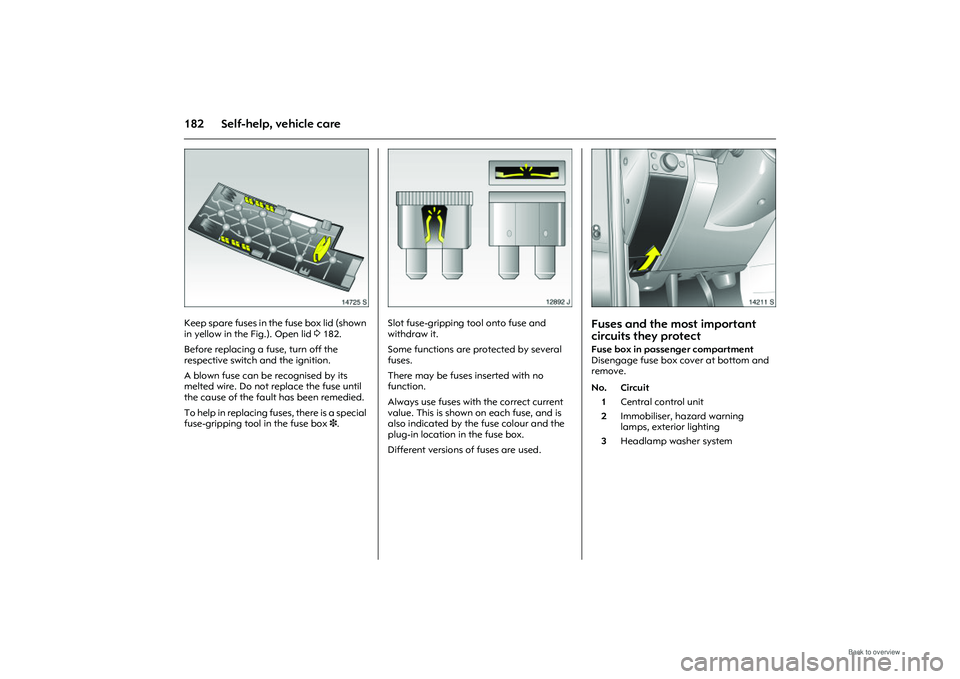

Picture no: 14725s.tif

Keep spare fuses in the fuse box lid (shown

in yellow in the Fig.). Open lid 3182.

Before replacing a fuse, turn off the

respective switch and the ignition.

A blown fuse can be recognised by its

melted wire. Do not replace the fuse until

the cause of the fault has been remedied.

To help in replacing fuses, there is a special

fuse-gripping tool in the fuse box 3.

Picture no: 12892j.tif

Slot fuse-gripping tool onto fuse and

withdraw it.

Some functions are protected by several

fuses.

There may be fuses inserted with no

function.

Always use fuses with the correct current

value. This is shown on each fuse, and is

also indicated by the fuse colour and the

plug-in location in the fuse box.

Different versions of fuses are used.

Picture no: 14211s.tif

Fuses and the most important

circuits they protect Fuse box in passenger compartment

Disengage fuse box cover at bottom and

remove. No. Circuit

1 Central control unit

2 Immobiliser, hazard warning

lamps, exterior lighting

3 Headlamp washer system