Peugeot 206 Dag 2002.5 Owner's Manual

Manufacturer: PEUGEOT, Model Year: 2002.5, Model line: 206 Dag, Model: Peugeot 206 Dag 2002.5Pages: 156, PDF Size: 2.01 MB

Page 121 of 156

24-02-2003

PRACTICAL INFORMATION

116

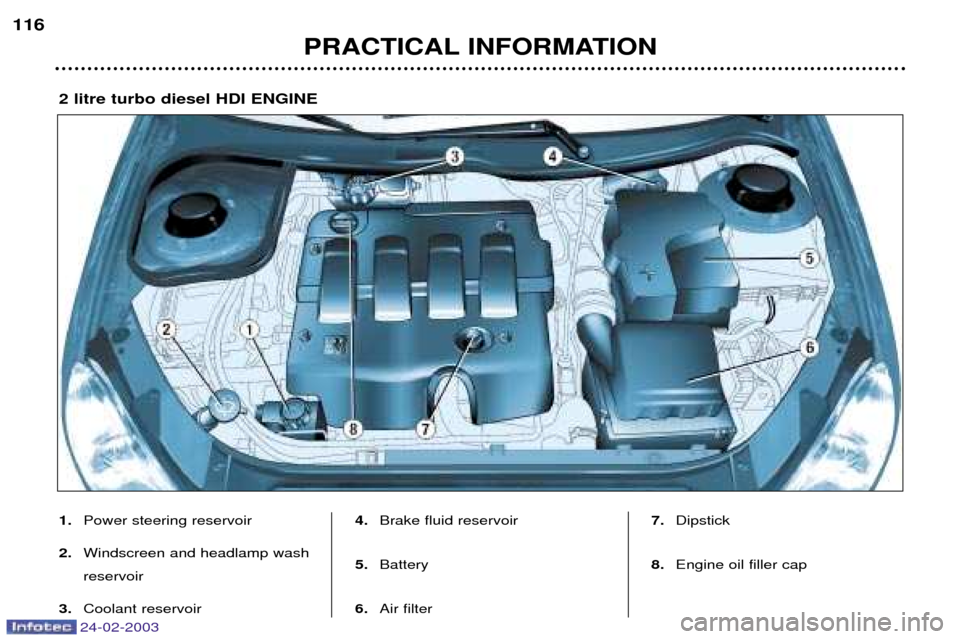

1.

Power steering reservoir

2. Windscreen and headlamp wash reservoir

3. Coolant reservoir 4.

Brake fluid reservoir

5. Battery

6. Air filter 7.

Dipstick

8. Engine oil filler cap

2 litre turbo diesel HDI ENGINE

Page 122 of 156

24-02-2003

PRACTICAL INFORMATION117

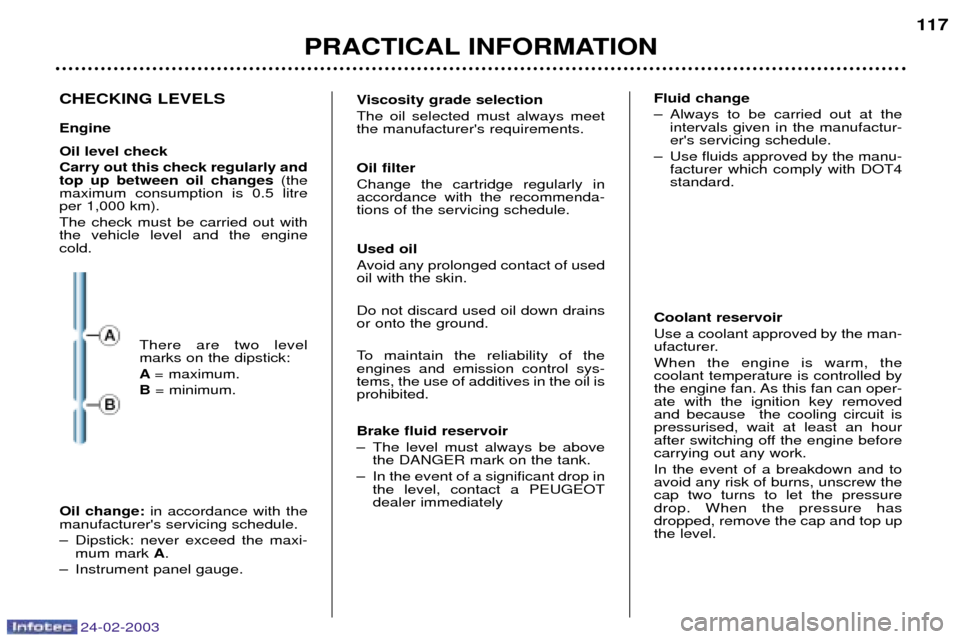

CHECKING LEVELS Engine Oil level check Carry out this check regularly and top up between oil changes (the

maximum consumption is 0.5 litreper 1,000 km). The check must be carried out with the vehicle level and the enginecold.

There are two levelmarks on the dipstick: A= maximum.

B = minimum. Viscosity grade selectionThe oil selected must always meet the manufacturer's requirements. Oil filter Change the cartridge regularly in accordance with the recommenda-tions of the servicing schedule. Used oil

Avoid any prolonged contact of used oil with the skin. Do not discard used oil down drains or onto the ground.

To maintain the reliability of the engines and emission control sys-tems, the use of additives in the oil isprohibited. Brake fluid reservoir

Ð The level must always be above

the DANGER mark on the tank.

Ð In the event of a significant drop in the level, contact a PEUGEOT dealer immediately Fluid change

Ð Always to be carried out at the

intervals given in the manufactur- er's servicing schedule.

Ð Use fluids approved by the manu- facturer which comply with DOT4standard.

Coolant reservoir Use a coolant approved by the man-

ufacturer. When the engine is warm, the coolant temperature is controlled by

the engine fan. As this fan can oper-ate with the ignition key removedand because the cooling circuit ispressurised, wait at least an hour

after switching off the engine beforecarrying out any work. In the event of a breakdown and to avoid any risk of burns, unscrew thecap two turns to let the pressuredrop. When the pressure hasdropped, remove the cap and top upthe level.

Oil change: in accordance with the

manufacturer's servicing schedule.

Ð Dipstick: never exceed the maxi- mum mark A.

Ð Instrument panel gauge.

Page 123 of 156

24-02-2003

PRACTICAL INFORMATION

118

Power steering reservoir

Open the reservoir, with the engine

cold. The level should always beabove the MINI mark, close to theMAXI mark. Manual gearbox

This does not need an oil change.

Check the level according to themanufacturer's servicing schedule.

Windscreen and headlamp washreservoir

For best quality cleaning and for your

safety, we recommend that you useproducts approved by PEUGEOT(capacity 2.8 litres or 6.6 litres withheadlamp wash).

Air filter Regular replacement of the filter ele- ment is essential. If you drive in verydusty conditions, change it twice asoften.

Battery

At the start of winter, have your battery

checked by a PEUGEOT dealer Brake pads Brake pad wear depends on the style of driving, in particular for vehi-cles used in town, for short journeys.It may be necessary to check thethickness of the pads even betweenservices. Autoadaptive automatic gearbox

This does not need an oil change:have the level checked by a PEU-

GEOT dealer according to the manu-facturer's servicing schedule.

Only use products

approved by PEUGEOT.

To ensure best perform- ance from components

as important as the power steer-ing and the braking system, PEUGEOT selects and offersquite specific products.

RUNNING OUT OF FUEL (DIESEL) If you should run out of fuel, it is necessary to re-prime the circuit: 1.4 litre HDI engine

Ð fill the fuel tank with at least five litres of diesel,

Ð operate the manual re-priming pump, until fuel appears in the transparent pipe under the bonnet,

Ð operate the starter until the engine starts.

Page 124 of 156

24-02-2003

PRACTICAL INFORMATION

118

Power steering reservoir

Open the reservoir, with the engine

cold. The level should always beabove the MINI mark, close to theMAXI mark. Manual gearbox

This does not need an oil change.

Check the level according to themanufacturer's servicing schedule.

Windscreen and headlamp washreservoir

For best quality cleaning and for your

safety, we recommend that you useproducts approved by PEUGEOT(capacity 2.8 litres or 6.6 litres withheadlamp wash).

Air filter Regular replacement of the filter ele- ment is essential. If you drive in verydusty conditions, change it twice asoften.

Battery

At the start of winter, have your battery

checked by a PEUGEOT dealer Brake pads Brake pad wear depends on the style of driving, in particular for vehi-cles used in town, for short journeys.It may be necessary to check thethickness of the pads even betweenservices. Autoadaptive automatic gearbox

This does not need an oil change:have the level checked by a PEU-

GEOT dealer according to the manu-facturer's servicing schedule.

Only use products

approved by PEUGEOT.

To ensure best perform- ance from components

as important as the power steer-ing and the braking system, PEUGEOT selects and offersquite specific products.

RUNNING OUT OF FUEL (DIESEL) If you should run out of fuel, it is necessary to re-prime the circuit: 1.4 litre HDI engine

Ð fill the fuel tank with at least five litres of diesel,

Ð operate the manual re-priming pump, until fuel appears in the transparent pipe under the bonnet,

Ð operate the starter until the engine starts.

Page 125 of 156

24-02-2003

PRACTICAL INFORMATION119

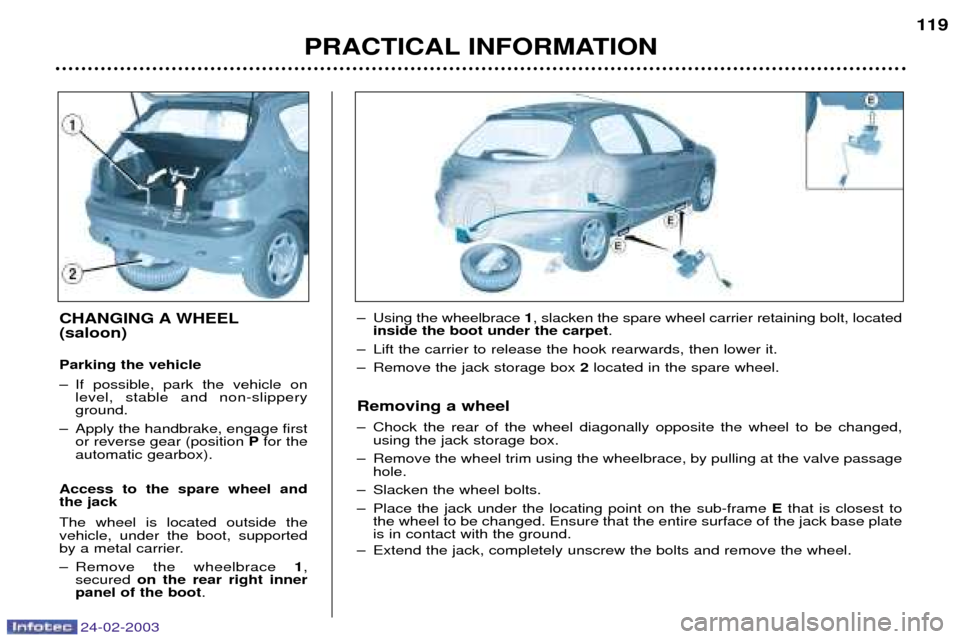

CHANGING A WHEEL (saloon) Parking the vehicle

Ð If possible, park the vehicle on

level, stable and non-slippery ground.

Ð Apply the handbrake, engage first or reverse gear (position Pfor the

automatic gearbox).

Access to the spare wheel andthe jack The wheel is located outside the vehicle, under the boot, supported

by a metal carrier.

Ð Remove the wheelbrace 1,

secured on the rear right inner

panel of the boot . Ð Using the wheelbrace

1, slacken the spare wheel carrier retaining bolt, located

inside the boot under the carpet .

Ð Lift the carrier to release the hook rearwards, then lower it.

Ð Remove the jack storage box 2located in the spare wheel.

Removing a wheel

Ð Chock the rear of the wheel diagonally opposite the wheel to be changed, using the jack storage box.

Ð Remove the wheel trim using the wheelbrace, by pulling at the valve passage hole.

Ð Slacken the wheel bolts.

Ð Place the jack under the locating point on the sub-frame Ethat is closest to

the wheel to be changed. Ensure that the entire surface of the jack base plate is in contact with the ground.

Ð Extend the jack, completely unscrew the bolts and remove the wheel.

Page 126 of 156

24-02-2003

PRACTICAL INFORMATION121

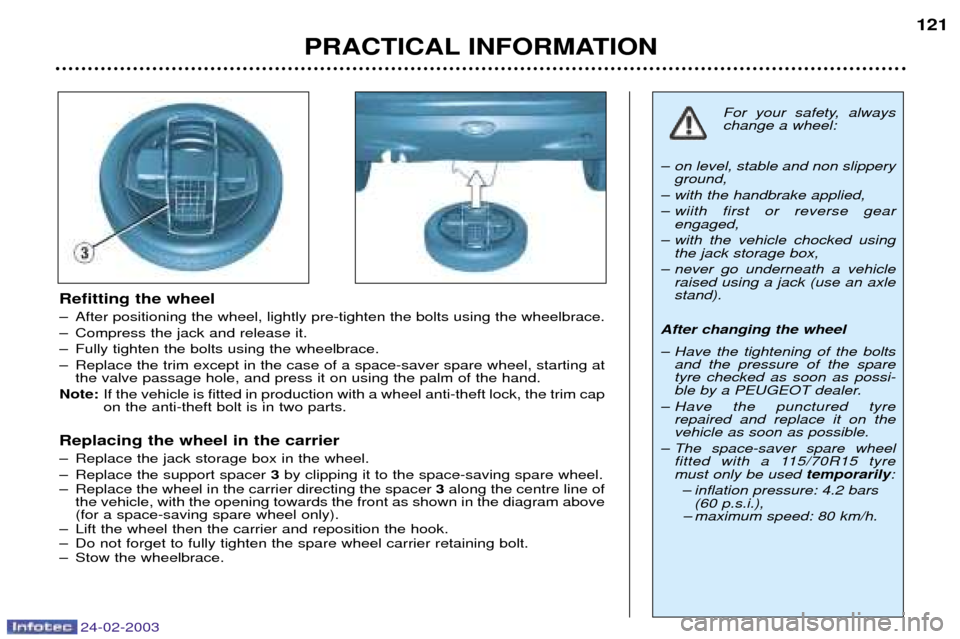

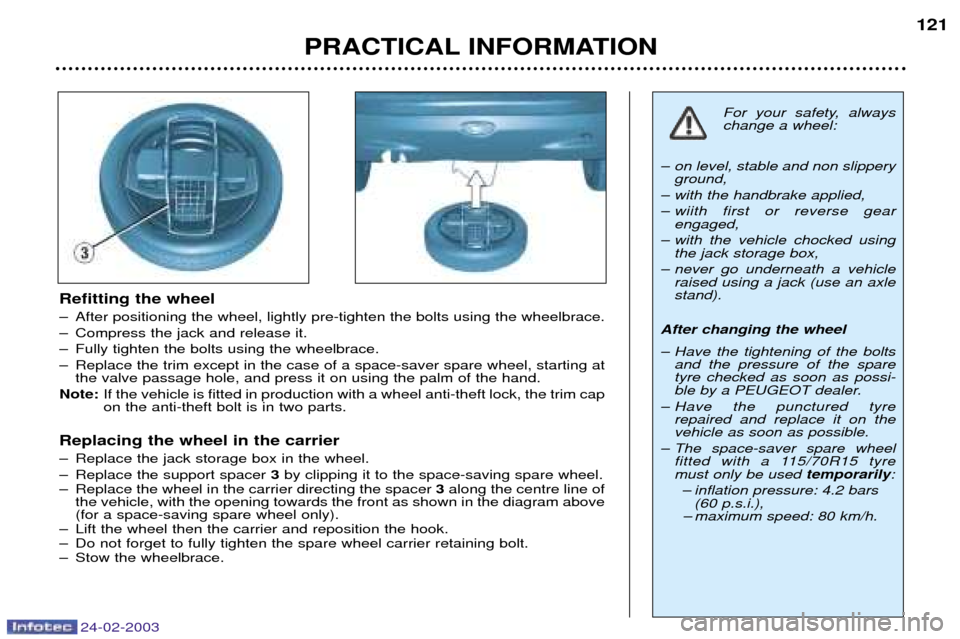

Refitting the wheel

Ð After positioning the wheel, lightly pre-tighten the bolts using the wheelbrace.

Ð Compress the jack and release it.

Ð Fully tighten the bolts using the wheelbrace.

Ð Replace the trim except in the case of a space-saver spare wheel, starting at the valve passage hole, and press it on using the palm of the hand.

Note: If the vehicle is fitted in production with a wheel anti-theft lock, the trim cap on the anti-theft bolt is in two parts.

Replacing the wheel in the carrier

Ð Replace the jack storage box in the wheel.

Ð Replace the support spacer 3by clipping it to the space-saving spare wheel.

Ð Replace the wheel in the carrier directing the spacer 3along the centre line of

the vehicle, with the opening towards the front as shown in the diagram above (for a space-saving spare wheel only).

Ð Lift the wheel then the carrier and reposition the hook.

Ð Do not forget to fully tighten the spare wheel carrier retaining bolt.

Ð Stow the wheelbrace.

For your safety, always change a wheel:

Ð on level, stable and non slippery ground,

Ð with the handbrake applied,

Ð wiith first or reverse gear engaged,

Ð with the vehicle chocked using the jack storage box,

Ð never go underneath a vehicle raised using a jack (use an axle stand).

After changing the wheel

Ð Have the tightening of the bolts and the pressure of the spare tyre checked as soon as possi-

ble by a PEUGEOT dealer.

Ð Have the punctured tyre repaired and replace it on thevehicle as soon as possible.

Ð The space-saver spare wheel fitted with a 115/70R15 tyremust only be used temporarily:

Ð inflation pressure: 4.2 bars(60 p.s.i.),

Ð maximum speed: 80 km/h.

Page 127 of 156

24-02-2003

PRACTICAL INFORMATION

122

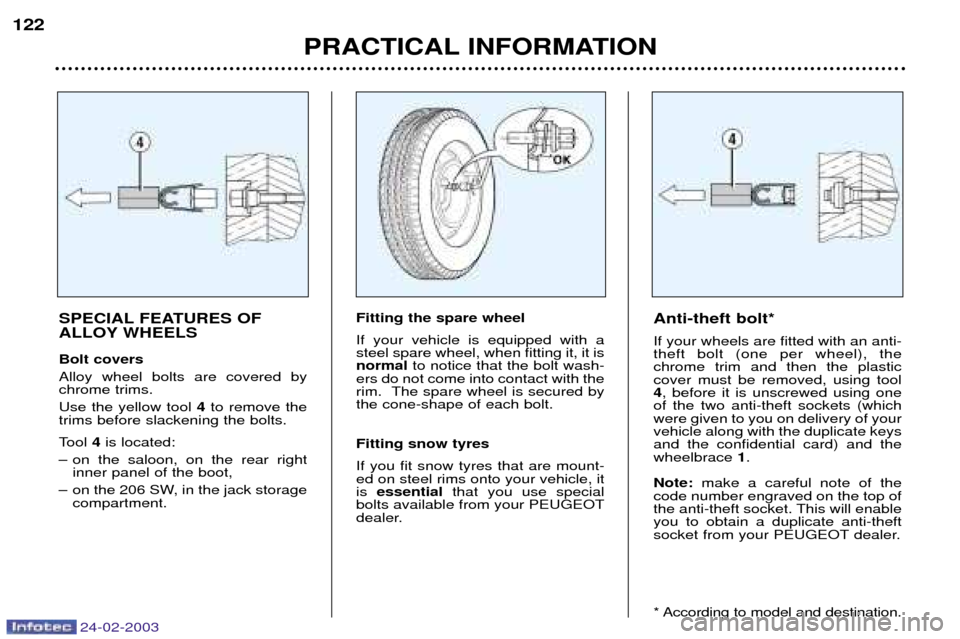

SPECIAL FEATURES OF

ALLOY WHEELS Bolt covers Alloy wheel bolts are covered by chrome trims. Use the yellow tool 4to remove the

trims before slackening the bolts.

Tool 4is located:

Ð on the saloon, on the rear right inner panel of the boot,

Ð on the 206 SW, in the jack storage compartment. Fitting the spare wheelIf your vehicle is equipped with a steel spare wheel, when fitting it, it isnormal

to notice that the bolt wash-

ers do not come into contact with the

rim. The spare wheel is secured bythe cone-shape of each bolt. Fitting snow tyres If you fit snow tyres that are mount- ed on steel rims onto your vehicle, itis essential that you use special

bolts available from your PEUGEOT

dealer. Anti-theft bolt* If your wheels are fitted with an anti- theft bolt (one per wheel), thechrome trim and then the plasticcover must be removed, using tool4

, before it is unscrewed using one

of the two anti-theft sockets (whichwere given to you on delivery of yourvehicle along with the duplicate keysand the confidential card) and thewheelbrace 1.

Note: make a careful note of the

code number engraved on the top of

the anti-theft socket. This will enableyou to obtain a duplicate anti-theft

socket from your PEUGEOT dealer.

* According to model and destination.

Page 128 of 156

24-02-2003

PRACTICAL INFORMATION

120

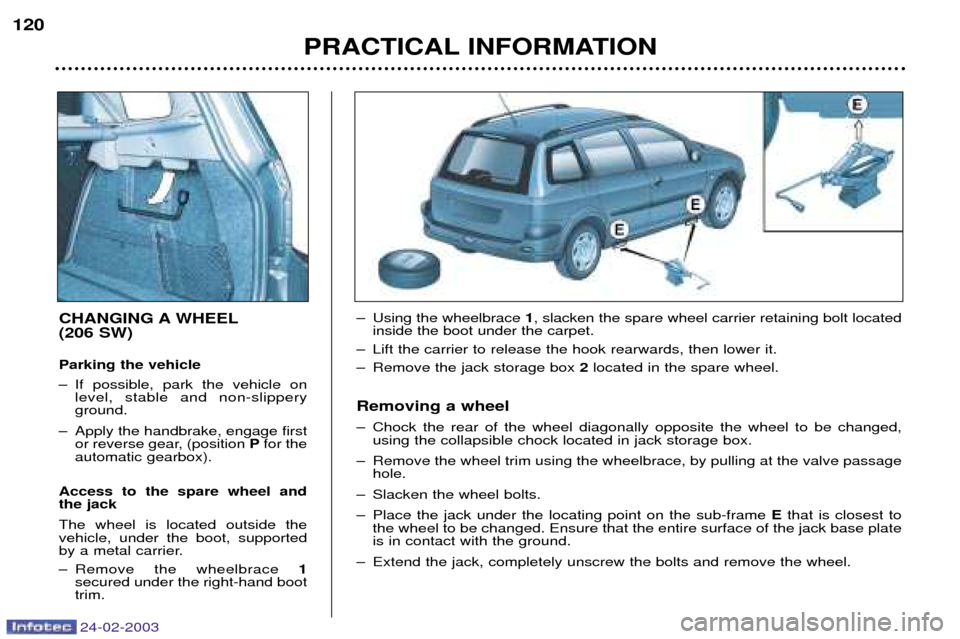

CHANGING A WHEEL (206 SW) Parking the vehicle

Ð If possible, park the vehicle on

level, stable and non-slippery ground.

Ð Apply the handbrake, engage first or reverse gear, (position Pfor the

automatic gearbox).

Access to the spare wheel andthe jack The wheel is located outside the vehicle, under the boot, supported

by a metal carrier.

Ð Remove the wheelbrace 1

secured under the right-hand boot trim. Ð Using the wheelbrace

1, slacken the spare wheel carrier retaining bolt located

inside the boot under the carpet.

Ð Lift the carrier to release the hook rearwards, then lower it.

Ð Remove the jack storage box 2located in the spare wheel.

Removing a wheel

Ð Chock the rear of the wheel diagonally opposite the wheel to be changed, using the collapsible chock located in jack storage box.

Ð Remove the wheel trim using the wheelbrace, by pulling at the valve passage hole.

Ð Slacken the wheel bolts.

Ð Place the jack under the locating point on the sub-frame Ethat is closest to

the wheel to be changed. Ensure that the entire surface of the jack base plate is in contact with the ground.

Ð Extend the jack, completely unscrew the bolts and remove the wheel.

Page 129 of 156

24-02-2003

PRACTICAL INFORMATION121

Refitting the wheel

Ð After positioning the wheel, lightly pre-tighten the bolts using the wheelbrace.

Ð Compress the jack and release it.

Ð Fully tighten the bolts using the wheelbrace.

Ð Replace the trim except in the case of a space-saver spare wheel, starting at the valve passage hole, and press it on using the palm of the hand.

Note: If the vehicle is fitted in production with a wheel anti-theft lock, the trim cap on the anti-theft bolt is in two parts.

Replacing the wheel in the carrier

Ð Replace the jack storage box in the wheel.

Ð Replace the support spacer 3by clipping it to the space-saving spare wheel.

Ð Replace the wheel in the carrier directing the spacer 3along the centre line of

the vehicle, with the opening towards the front as shown in the diagram above (for a space-saving spare wheel only).

Ð Lift the wheel then the carrier and reposition the hook.

Ð Do not forget to fully tighten the spare wheel carrier retaining bolt.

Ð Stow the wheelbrace.

For your safety, always change a wheel:

Ð on level, stable and non slippery ground,

Ð with the handbrake applied,

Ð wiith first or reverse gear engaged,

Ð with the vehicle chocked using the jack storage box,

Ð never go underneath a vehicle raised using a jack (use an axle stand).

After changing the wheel

Ð Have the tightening of the bolts and the pressure of the spare tyre checked as soon as possi-

ble by a PEUGEOT dealer.

Ð Have the punctured tyre repaired and replace it on thevehicle as soon as possible.

Ð The space-saver spare wheel fitted with a 115/70R15 tyremust only be used temporarily:

Ð inflation pressure: 4.2 bars(60 p.s.i.),

Ð maximum speed: 80 km/h.

Page 130 of 156

24-02-2003

PRACTICAL INFORMATION

122

SPECIAL FEATURES OF

ALLOY WHEELS Bolt covers Alloy wheel bolts are covered by chrome trims. Use the yellow tool 4to remove the

trims before slackening the bolts.

Tool 4is located:

Ð on the saloon, on the rear right inner panel of the boot,

Ð on the 206 SW, in the jack storage compartment. Fitting the spare wheelIf your vehicle is equipped with a steel spare wheel, when fitting it, it isnormal

to notice that the bolt wash-

ers do not come into contact with the

rim. The spare wheel is secured bythe cone-shape of each bolt. Fitting snow tyres If you fit snow tyres that are mount- ed on steel rims onto your vehicle, itis essential that you use special

bolts available from your PEUGEOT

dealer. Anti-theft bolt* If your wheels are fitted with an anti- theft bolt (one per wheel), thechrome trim and then the plasticcover must be removed, using tool4

, before it is unscrewed using one

of the two anti-theft sockets (whichwere given to you on delivery of yourvehicle along with the duplicate keysand the confidential card) and thewheelbrace 1.

Note: make a careful note of the

code number engraved on the top of

the anti-theft socket. This will enableyou to obtain a duplicate anti-theft

socket from your PEUGEOT dealer.

* According to model and destination.