brake Peugeot Bipper 2011 - RHD (UK, Australia) Owner's Guide

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2011, Model line: Bipper, Model: Peugeot Bipper 2011Pages: 180, PDF Size: 5.13 MB

Page 134 of 180

132

Towing a trailer

In certain cases of particularly arduous

use (towing the maximum load up a steep

slope in high temperatures), the engine

automatically limits its power. In this case,

automatic cutting off of the air conditioning

allows the engine power to be saved.

If the coolant temperature

warning lamp comes on, stop the

vehicle and switch off the engine

as soon as possible.

See the "Levels" section of chapter 7.

Tyres:

check the tyre pressures of the

towing vehicle (see the "Identification

markings" section of chapter 7) and of

the trailer, observing the recommended

pressures.

Brakes:

towing increases the braking

distance. Drive at a moderate speed,

change down early and brake gradually.

Side wind:

sensitivity to side wind is

increased. Drive smoothly and at a

moderate speed.

ABS:

the system only controls the vehicle,

not the trailer.

Rear parking sensors:

the sensors

will be deactivated automatically when

an genuine PEUGEOT towbar is used

(see the "Rear parking sensors" section of

chapter 3).

Towbar

We recommend the use of original

PEUGEOT towbars and their harnesses,

which have been tested and approved from

the design stage of your vehicle, and that

the fitting of this equipment is entrusted to a

PEUGEOT dealer or a qualified workshop.

If this equipment is not fitted by a PEUGEOT

dealer, it is essential that it is fitted using

the electrical pre-equipment located at

the rear of the vehicle and following the

manufacturer's instructions.

The operation of the rear parking sensors is

deactivated automatically when the trailer

cable connector is inserted in the towbar

socket.

When the trailer cable is removed, the rear

parking sensors are re-activated.

Distribution of loads

Distribute the load in the trailer so that the

heaviest objects are as close as possible

to the axle and the nose weight is close to

the maximum authorised without, however,

exceeding it. The air density decreases with

altitude, so reducing the performance of

the engine. The maximum towed load must

be reduced by 10 % for each 1 000 metres

of altitude. Refer to the "Technical data"

chapter for details of the weights and towed

loads applicable to your vehicle and also to

the administrative documents

(V5 registration document, ...).

Page 140 of 180

138

Changing a wheel

CHANGING A WHEEL

Parking the vehicle

As far as possible, park the vehicle on level,

stable and non-slippery ground.

Apply the parking brake, switch off the

ignition and engage first gear (on a hill).

It is imperative that you ensure that the

occupants get out of the vehicle and wait in

a safe location.

If possible, place a chock under the

wheel diagonally opposite the wheel to be

changed.

Tools

The tools required are stored in a tool kit

located behind the driver’s seat (Light van)

or behind the rear bench seat (Combi).

1.

Wheelbrace.

2.

Centring guide.

3.

Screwdriver.

4.

Jack with handle.

5.

Removable towing eye.

The jack and all of the tools are specific

to your vehicle. Do not use them for other

purposes.

Never go underneath the vehicle when it is

raised only by the jack; use an axle stand.

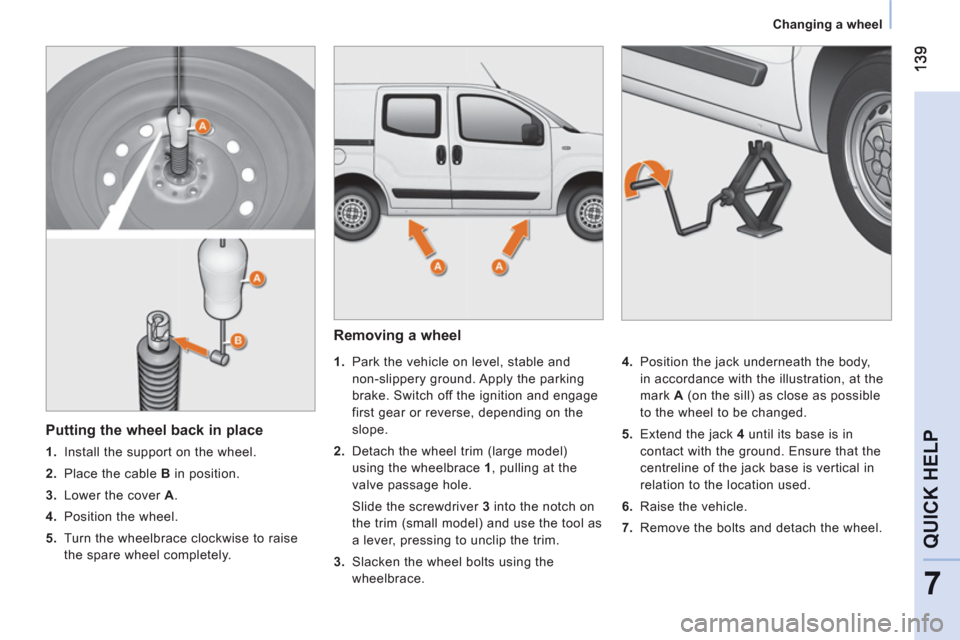

Taking out the spare wheel

The spare wheel retaining bolt is located on

the rear left part of the loading sill.

1.

Slacken the wheel retaining bolt using the

wheelbrace.

2.

Unscrew fully to unwind the winch cable.

3.

Take out the spare wheel using the

wheelbrace.

4.

Raise the cover A

.

5.

Remove the cable B

from its housing.

6.

Release the spare wheel and place it

near the wheel to be changed.

Page 141 of 180

7

QUICK HEL

P

Changing a wheel

Removing a wheel

1.

Park the vehicle on level, stable and

non-slippery ground. Apply the parking

brake. Switch off the ignition and engage

first gear or reverse, depending on the

slope.

2.

Detach the wheel trim (large model)

using the wheelbrace 1

, pulling at the

valve passage hole.

Slide the screwdriver 3

into the notch on

the trim (small model) and use the tool as

a lever, pressing to unclip the trim.

3.

Slacken the wheel bolts using the

wheelbrace.

4.

Position the jack underneath the body,

in accordance with the illustration, at the

mark A

(on the sill) as close as possible

to the wheel to be changed.

5.

Extend the jack 4

until its base is in

contact with the ground. Ensure that the

centreline of the jack base is vertical in

relation to the location used.

6.

Raise the vehicle.

7.

Remove the bolts and detach the wheel.

Putting the wheel back in place

1.

Install the support on the wheel.

2.

Place the cable B

in position.

3.

Lower the cover A

.

4.

Position the wheel.

5.

Turn the wheelbrace clockwise to raise

the spare wheel completely.

Page 143 of 180

14

1

7

QUICK HEL

P

Changing a wheel

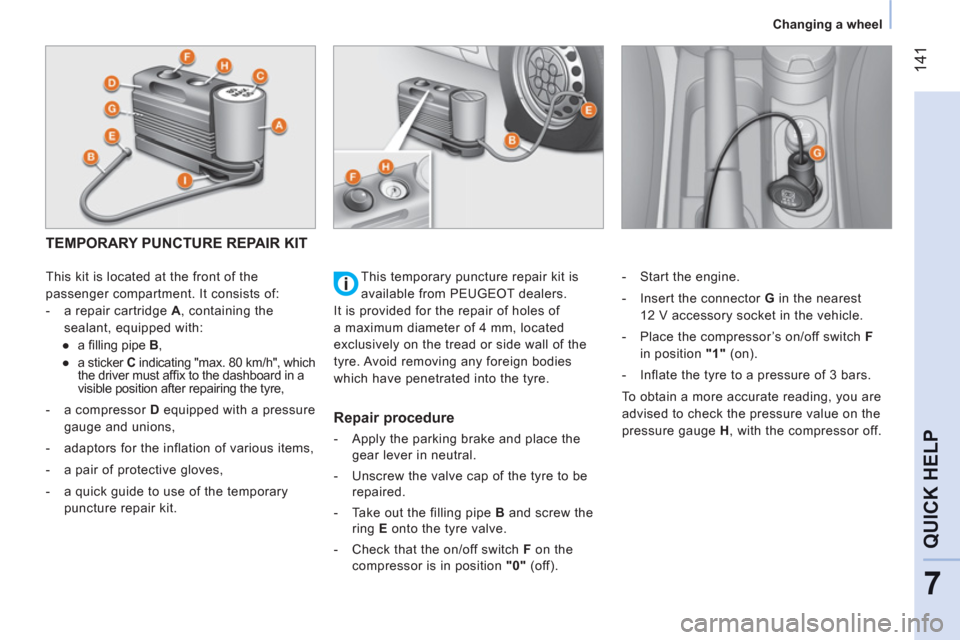

TEMPORARY PUNCTURE REPAIR KIT

This kit is located at the front of the

passenger compartment. It consists of:

- a repair cartridge A

, containing the

sealant, equipped with:

●

a fi lling pipe B

,

●

a sticker C

indicating "max. 80 km/h", which

the driver must affi x to the dashboard in a

visible position after repairing the tyre,

- a compressor D

equipped with a pressure

gauge and unions,

- adaptors for the inflation of various items,

- a pair of protective gloves,

- a quick guide to use of the temporary

puncture repair kit.

Repair procedure

- Apply the parking brake and place the

gear lever in neutral.

- Unscrew the valve cap of the tyre to be

repaired.

- Take out the filling pipe B

and screw the

ring E

onto the tyre valve.

- Check that the on/off switch F

on the

compressor is in position "0"

(off).

- Start the engine.

- Insert the connector G

in the nearest

12 V accessory socket in the vehicle.

- Place the compressor’s on/off switch F

in position "1"

(on).

- Inflate the tyre to a pressure of 3 bars.

To obtain a more accurate reading, you are

advised to check the pressure value on the

pressure gauge H

, with the compressor off. This temporary puncture repair kit is

available from PEUGEOT dealers.

It is provided for the repair of holes of

a maximum diameter of 4 mm, located

exclusively on the tread or side wall of the

tyre. Avoid removing any foreign bodies

which have penetrated into the tyre.

Page 148 of 180

14

6

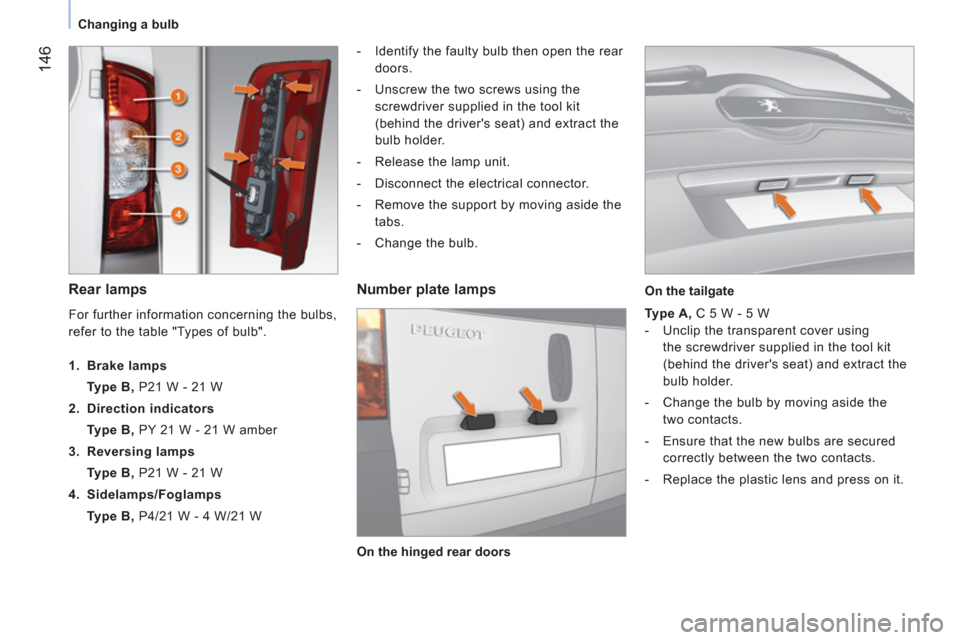

Changing a bulb

Rear lamps

- Identify the faulty bulb then open the rear

doors.

- Unscrew the two screws using the

screwdriver supplied in the tool kit

(behind the driver's seat) and extract the

bulb holder.

- Release the lamp unit.

- Disconnect the electrical connector.

- Remove the support by moving aside the

tabs.

- Change the bulb.

Number plate lamps

Type A, C 5 W - 5 W

- Unclip the transparent cover using

the screwdriver supplied in the tool kit

(behind the driver's seat) and extract the

bulb holder.

- Change the bulb by moving aside the

two contacts.

- Ensure that the new bulbs are secured

correctly between the two contacts.

- Replace the plastic lens and press on it.

For further information concerning the bulbs,

refer to the table "Types of bulb".

1. Brake lamps

Type B, P21 W - 21 W

2. Direction indicators

Type B, PY 21 W - 21 W amber

3. Reversing lamps

Type B, P21 W - 21 W

4. Sidelamps/Foglamps

Type B, P4/21 W - 4 W/21 W

On the hinged rear doors

On the tailgate

Page 149 of 180

14

7

7

QUICK HEL

P

Changing a bulb

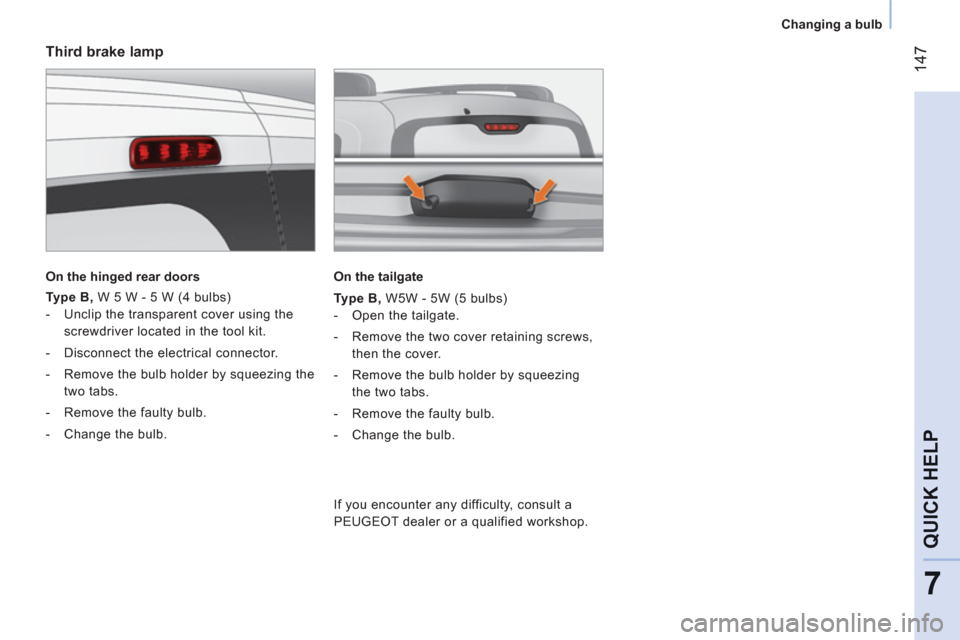

Third brake lamp

On the hinged rear doors

Type B,

W 5 W - 5 W (4 bulbs)

- Unclip the transparent cover using the

screwdriver located in the tool kit.

- Disconnect the electrical connector.

- Remove the bulb holder by squeezing the

two tabs.

- Remove the faulty bulb.

- Change the bulb.

On the tailgate

Type B,

W5W - 5W (5 bulbs)

- Open the tailgate.

- Remove the two cover retaining screws,

then the cover.

- Remove the bulb holder by squeezing

the two tabs.

- Remove the faulty bulb.

- Change the bulb.

If you encounter any difficulty, consult a

PEUGEOT dealer or a qualified workshop.

Page 152 of 180

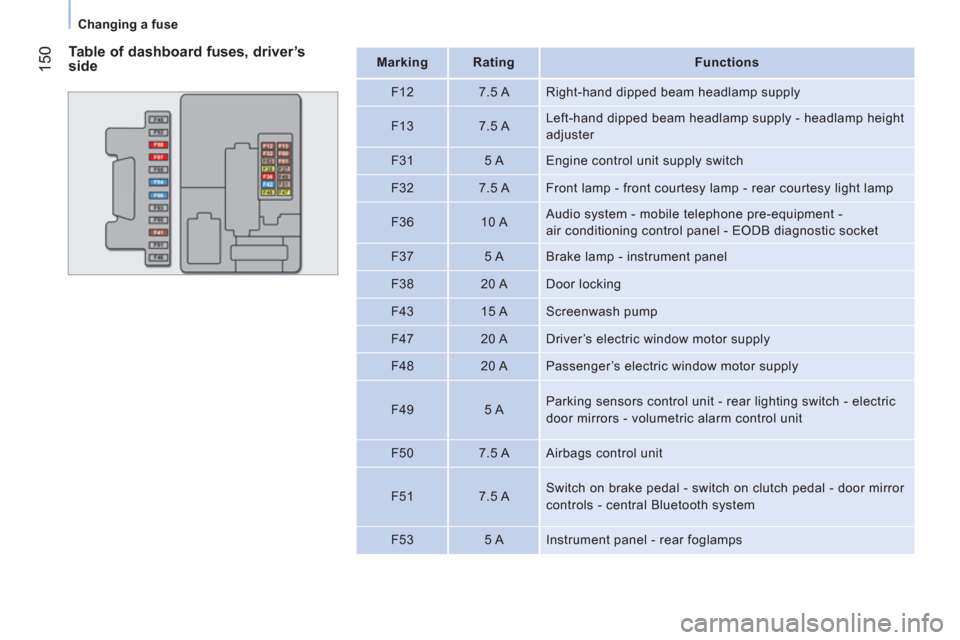

150

Changing a fuse

Table of dashboard fuses, driver’s

side

Mark

ing

Rating

Functions

F12

7.5 A Right-hand dipped beam headlamp supply

F13

7.5 A Left-hand dipped beam headlamp supply - headlamp height

adjuster

F31

5 A Engine control unit supply switch

F32

7.5 A Front lamp - front courtesy lamp - rear courtesy light lamp

F36

10 A Audio system - mobile telephone pre-equipment -

air conditioning control panel - EODB diagnostic socket

F37

5 A Brake lamp - instrument panel

F38

20 A Door locking

F43

15 A Screenwash pump

F47

20 A Driver’s electric window motor supply

F48

20 A Passenger’s electric window motor supply

F49

5 A Parking sensors control unit - rear lighting switch - electric

door mirrors - volumetric alarm control unit

F50

7.5 A Airbags control unit

F51

7.5 A Switch on brake pedal - switch on clutch pedal - door mirror

controls - central Bluetooth system

F53

5 A Instrument panel - rear foglamps

Page 156 of 180

154

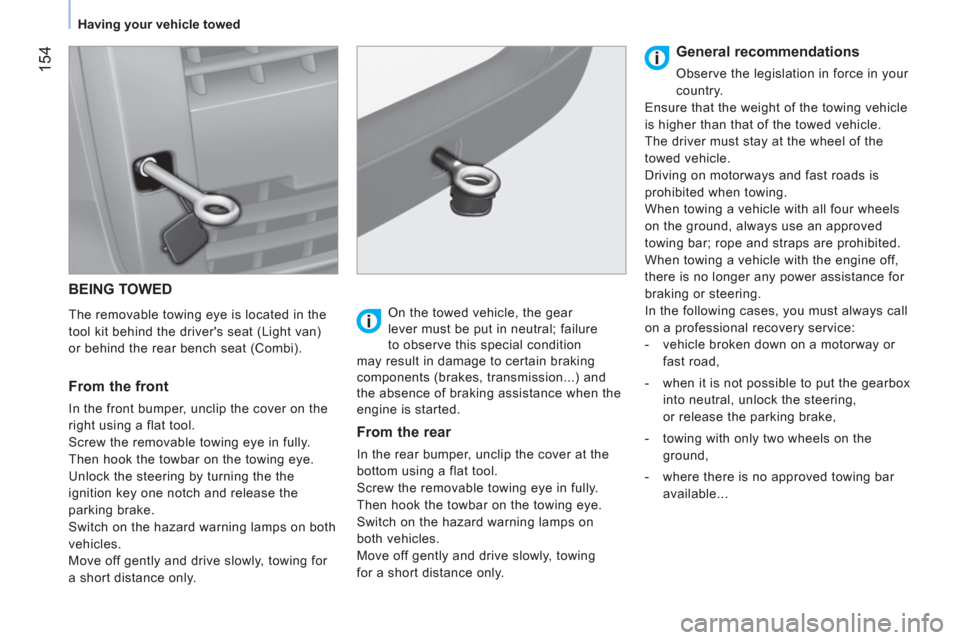

Having your vehicle towed

BEING TOWED

The removable towing eye is located in the

tool kit behind the driver's seat (Light van)

or behind the rear bench seat (Combi).

From the front

In the front bumper, unclip the cover on the

right using a flat tool.

Screw the removable towing eye in fully.

Then hook the towbar on the towing eye.

Unlock the steering by turning the the

ignition key one notch and release the

parking brake.

Switch on the hazard warning lamps on both

vehicles.

Move off gently and drive slowly, towing for

a short distance only.

On the towed vehicle, the gear

lever must be put in neutral; failure

to observe this special condition

may result in damage to certain braking

components (brakes, transmission...) and

the absence of braking assistance when the

engine is started.

From the rear

In the rear bumper, unclip the cover at the

bottom using a flat tool.

Screw the removable towing eye in fully.

Then hook the towbar on the towing eye.

Switch on the hazard warning lamps on

both vehicles.

Move off gently and drive slowly, towing

for a short distance only.

General recommendations

Observe the legislation in force in your

country.

Ensure that the weight of the towing vehicle

is higher than that of the towed vehicle.

The driver must stay at the wheel of the

towed vehicle.

Driving on motorways and fast roads is

prohibited when towing.

When towing a vehicle with all four wheels

on the ground, always use an approved

towing bar; rope and straps are prohibited.

When towing a vehicle with the engine off,

there is no longer any power assistance for

braking or steering.

In the following cases, you must always call

on a professional recovery service:

- vehicle broken down on a motorway or

fast road,

- when it is not possible to put the gearbox

into neutral, unlock the steering,

or release the parking brake,

- towing with only two wheels on the

ground,

- where there is no approved towing bar

available...

Page 162 of 180

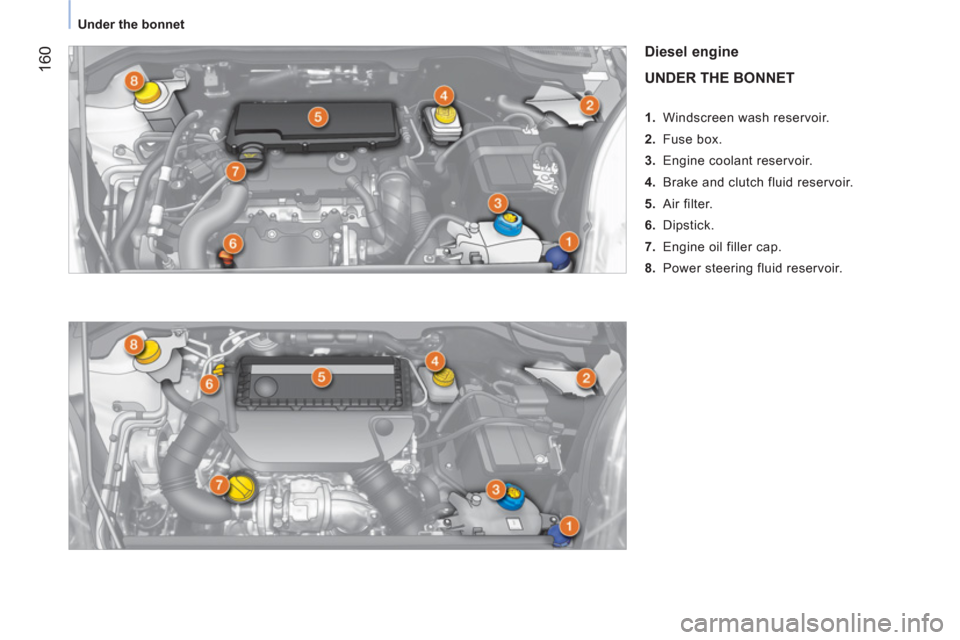

160

Under the bonnet

Diesel engine

UNDER THE BONNET

1. Windscreen wash reservoir.

2. Fuse box.

3. Engine coolant reservoir.

4. Brake and clutch fluid reservoir.

5. Air filter.

6. Dipstick.

7. Engine oil filler cap.

8. Power steering fluid reservoir.

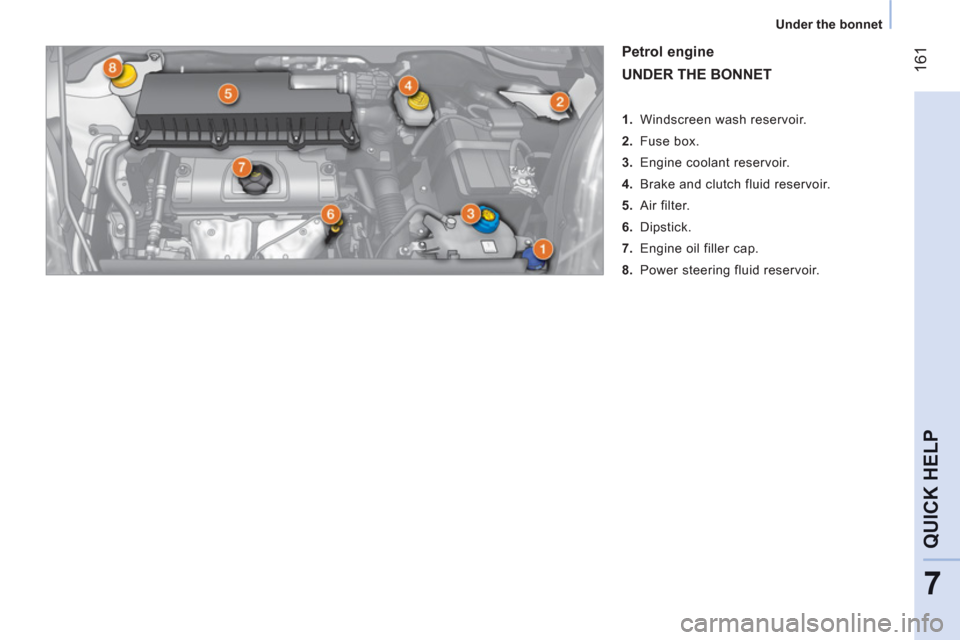

Page 163 of 180

161

7

QUICK HEL

P

Under the bonnet

Petrol engine

UNDER THE BONNET

1. Windscreen wash reservoir.

2. Fuse box.

3. Engine coolant reservoir.

4. Brake and clutch fluid reservoir.

5. Air filter.

6. Dipstick.

7. Engine oil filler cap.

8. Power steering fluid reservoir.