check engine Peugeot Bipper 2015 User Guide

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2015, Model line: Bipper, Model: Peugeot Bipper 2015Pages: 192, PDF Size: 7.97 MB

Page 62 of 192

60

Bipper_en_Chap03_pret-a-partir_ed02-2014

HILL START ASSIST

An integral part of the DSC system, it

facilitates starting on a gradient by keeping

your vehicle immobilised temporarily

(approximately 2 seconds), the time it takes

to move your foot from the brake pedal to

the accelerator pedal.

t

his function is only active when:

-

the vehicle is completely stationary

, with

your foot on the brake pedal,

-

the engine is running,

-

the gradient is steeper than 5 %, Operation

On a slope, with engine running and the

vehicle stationary, the vehicle is held

for a brief moment when you release the

brake pedal:

-

provided you are in first gear or neutral

with a manual gearbox,

-

provided you are in position

A or M with

an electronic gearbox,

On a descending slope, with the vehicle

stationary, the engine running and reverse gear

engaged, the vehicle is held for a brief moment

when you release the brake pedal. After 2 seconds, if the vehicle has not

moved off, the system is deactivated

automatically by gradually reducing the

brake pressure. During this phase, the

characteristic sound of brakes being

released will be heard, indicating the

imminent movement of the vehicle. Do not leave the vehicle while it is

being held in the hill start assist phase.

If you need to leave the vehicle while the

engine is running, apply the parking brake

manually.

t

hen ensure that the parking

brake warning lamp is on (not flashing) in

the instrument panel.

Operating fault

If a fault occurs with the system,

these warning lamps come on in

the instrument panel. Contact a

P

euge O t

dealer or a qualified

workshop to have the system

checked.

In S

t

OP

mode of Stop & Start, hill start

assist is inactive.

Starting and stopping

Page 65 of 192

63

Bipper_en_Chap03_pret-a-partir_ed02-2014

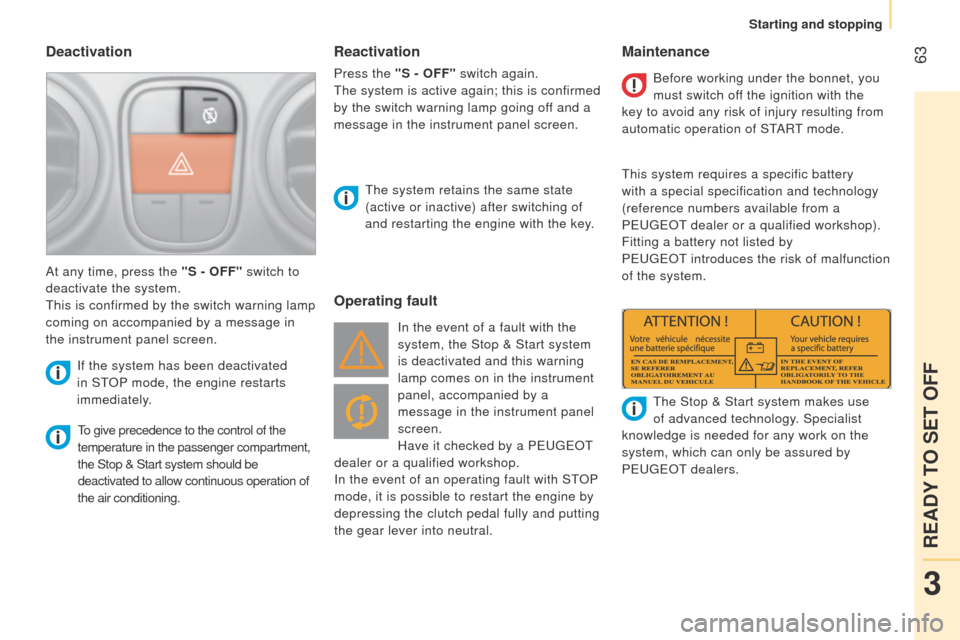

Deactivation

to give precedence to the control of the

temperature in the passenger compartment,

the Stop & Start system should be

deactivated to allow continuous operation of

the air conditioning.

t

he system retains the same state

(active or inactive) after switching of

and restarting the engine with the key.

At any time, press the "S - OFF" switch to

deactivate the system.

t

his is confirmed by the switch warning lamp

coming on accompanied by a message in

the instrument panel screen.

If the system has been deactivated

in St

OP

mode, the engine restarts

immediately.

Operating fault Maintenance

In the event of a fault with the

system, the Stop & Start system

is deactivated and this warning

lamp comes on in the instrument

panel, accompanied by a

message in the instrument panel

screen.

Have it checked by a P

euge O t

dealer or a qualified workshop.

In the event of an operating fault with S

t

OP

mode, it is possible to restart the engine by

depressing the clutch pedal fully and putting

the gear lever into neutral. Before working under the bonnet, you

must switch off the ignition with the

key to avoid any risk of injury resulting from

automatic operation of S t

ARt mode.

t

his system requires a specific battery

with a special specification and technology

(reference numbers available from a

P euge O t

dealer or a qualified workshop).

Fitting a battery not listed by

P euge O t introduces the risk of malfunction

of the system.

t

he Stop & Start system makes use

of advanced technology. Specialist

knowledge is needed for any work on the

system, which can only be assured by

P

euge O t

dealers.

Reactivation

Press the "S - OFF" switch again.

t

he system is active again; this is confirmed

by the switch warning lamp going off and a

message in the instrument panel screen.

3

READY TO SET OFF

Starting and stopping

Page 115 of 192

11 3

Bipper_en_Chap06_securite_ed02-2014

Emergency braking assistance*

System which, in an emergency, enables

you to reach the optimum braking pressure

more quickly, thus reducing the stopping

distance.

t

he emergency braking assistance

is an integral part of the DSC system

Activation

It is brought into play by the speed at which

the brake pedal is pressed.

t

he effect of this is a reduction in the

resistance of the pedal and an increase in

braking efficiency.

When braking in an emergency, press firmly

without releasing the pressure.

Good practice

t

his system cannot be deactivated by the

driver.

* Depending on country of sale.

TRAJECTORY CONTROL SYSTEMS

Dynamic stability control

(DSC)

the dynamic stability control system acts on

the brake of one or more wheels and on the

engine to keep the vehicle on the trajectory

required by the driver, within the limits of the

laws of physics.

Activation

t

his system is activated automatically each

time the vehicle is started and cannot be

deactivated.

It comes into operation in the event of a grip

or trajectory problem.

Illumination of this warning lamp,

accompanied by a message in the

instrument panel screen, indicates

a fault with the system, which is

deactivated automatically.

Have it checked by a P

euge O t

dealer or a

qualified workshop.

Anti-slip regulation (ASR) and engine

control (MSR)

Anti-slip regulation (also known as traction

control) optimises traction, avoiding wheel

spin by acting on the brakes of the driving

wheels and the engine.

e

ngine control is an integral part of the ASR

system and intervenes when a sudden gear

change is made or of one of the driving

wheels looses grip, by reducing engine

torque to avoid loss of stability of the vehicle.

Activation

t

hese systems are activated automatically

every time the vehicle is started.

In the event of a problem od adhesion or

trajectory, these systems come into play.

Deactivation

In exceptional conditions (starting a vehicle

which is bogged down, stuck in snow,

on soft ground...), it may be advisable to

deactivate the ASR system, so that the

wheels can spin freely and regain grip.

t

his is indicated by flashing of this

warning lamp in the instrument

panel.

Operating fault

6

SAFETY

Driving safely

Page 120 of 192

11 8

Bipper_en_Chap06_securite_ed02-2014

FRONT SEAT BELTS

the front seats are fitted with pre-tensioners

and force limiters.

Fastening

Pull the strap, then insert the tongue into the

buckle.

Check that the seat belt is fastened correctly

by pulling the strap.

t

he lap belt must be positioned as low as

possible on the pelvis.

t

he chest belt must

pass over the hollow of the shoulder.

Inertia reel seat belts

these are fitted with a device which locks

automatically in the event of a collision or

emergency braking.

Safety in the event of a front impact has

been improved by the introduction of

pretensioning and force limiting seat belts.

Depending on the seriousness of the

impact, the pretensioning system instantly

tightens the seat belt against the body of the

occupant.

t

he pretensioning seat belts are active when

the ignition is on.

t

he force limiter reduces the pressure of the

seat belt against the body of the occupant in

the event of an accident.

Driver's seat belt not fastened warning

lamp

When the vehicle is started, this

warning lamp comes on if the

driver has not fastened their seat

belt.

REAR SEAT BELTS (COMBI)

the 3-seat bench is fitted with three-point

inertia reel seat belts with force limiter .

t

he centre seat has a seat belt guide and

inertia reel, integrated with the seat back.

When a seat belt is not in use, you can

store its buckle in the housing provided

in the bench seat cushion.

If the driver's seat belt is unfastened,

the S

t

ARt mode of Stop & Start will

not be invoked.

t

he engine can only be

restarted using the ignition key.

Seat belts

Page 140 of 192

138

Bipper_en_Chap07_accessoire_ed02-2014

In certain cases of particularly arduous

use (towing the maximum load up a steep

slope in high temperatures), the engine

automatically limits its power. In this case,

automatic cutting off of the air conditioning

allows the engine power to be saved.If the coolant temperature

warning lamp comes on, stop the

vehicle and switch off the engine

as soon as possible.

ChecksSee the "

l evels" section of

chapter 7.

Tyres: check the tyre pressures on the

towing vehicle and the trailer, observing the

recommended pressures.

Brakes: towing increases the braking

distance. Drive at a moderate speed,

change down early and brake gradually. Side wind: sensitivity to side wind is

increased. Drive smoothly and at a

moderate speed.

ABS: the system only controls the vehicle,

not the trailer.

Distribution of loads

Distribute the load in the trailer so that the

heaviest objects are as close as possible

to the axle and the nose weight is close to

the maximum authorised without, however,

exceeding it.

t

he air density decreases with

altitude, so reducing the performance of the

engine.

t

he maximum towed load must be

reduced by 10 % for each 1 000 metres of

altitude.

Refer to the "

t

echnical data -

Identification markings" section. Rear parking sensors: the sensors will be

deactivated automatically when an genuine

P

euge O t towbar is used.

Towbar

We recommend the use of genuine

P

euge O t towbars and their harnesses,

which have been tested and approved from

the design stage of your vehicle, and that

the fitting of this equipment is entrusted to a

P

euge O t

dealer or a qualified workshop.

If this equipment is not fitted by a P

euge O t

dealer

, it is essential that it is fitted using

the electrical pre-equipment located at

the rear of the vehicle and following the

manufacturer's instructions.

t

he operation of the rear parking sensors is

deactivated automatically when the trailer

cable connector is inserted in the towbar

socket.

When the trailer cable is removed, the rear

parking sensors are re-activated.

Refer to the "

t

echnology on board -

Parking sensors" section.

For information on the maximum

weights and towed loads applicable to

your vehicle, refer to the "

t

echnical data -

Weights" section.

Towing a trailer

Page 143 of 192

141

Bipper_en_Chap08_verifications_ed02-2014

PeugeOt & t O tAl,

A PARtNeRSHIP tO De lI Ve R

Be

tte R

P

e

RFORMANC

e

!

Innovation, the key to success

the tOtAl Research and Development and

Pe ugeOt teams work together to develop high

quality lubricants that meet the requirements

of P

e

uge

Ot

vehicles. For you, this is the

assurance that the performance of your engine

is optimised while also ensuring its durability.

The 208 HYbrid FE demonstrates the ability of

P

e

uge

Ot

and

tOtAl

to develop innovative

technologies and provide other ways of moving

towards the future.

208 HYbrid FE, a technology demonstrator with exceptional characteristics:

1.9 l/100 km (148.7 mpg) and 0 to 100 km/h (0 to 62 mph) in 8 seconds.

Reduced exhaust emissions,

a true reality

tOtAl lubricants are formulated to optimise the

efficiency of engines and the protection of the

emissions post-treatment systems. It is important

to observe the servicing recommendations

made by P

e

uge

Ot

to assure correct operation.

RECOMMENDS

8

CHECKS

Maintenance with TOTAL

Page 144 of 192

142

Bipper_en_Chap08_verifications_ed02-2014

FILLING WITH FUEL

Capacity of the fuel tank: approximately 45 litres.

Low fuel level

When the minimum fuel tank level

is reached, this warning lamp

comes on. When it first comes on,

you have approximately 6 litres

of fuel remaining. Refuel without delay to

avoid running out of fuel.

An arrow in the instrument panel indicates

which side of the vehicle the filler flap is

located.

Refuelling must be done with the engine off.

-

Open the fuel filler flap.

-

Hold the filler cap with one hand.

-

With the other hand, insert the key

, then

turn it a third of a turn.

-

Remove the filler cap and hang it on the

hook, located on the inside of the filler

flap.

FUEL CUT-OFF

In the event of a serious collision, a device

automatically cuts off the fuel supply to the

engine and the vehicle's electrical supply.

It also automatically unlocks the doors

and switches on of the courtesy lamps. A

message appears in the instrument panel

screen according to version.

turn the key to the

STOP position to prevent

discharging of the battery.

Check that there is no smell or leak of fuel

outside the vehicle.

With Stop & Start, never refuel with the

system in S

t

OP

mode; you must switch

off the ignition with the key. When the fuel filler flap is open, a

safety system prevents sliding of the

side door (Combi).

A label affixed to the inside of the flap

reminds you of the type of fuel to be used.

Opening the filler cap may cause a noise

resulting from the inrush of air.

t

his vacuum

is quite normal and results from the sealing

of the fuel system.

When filling the fuel tank, do not continue

after the 3rd cut-off of the nozzle; this could

cause malfunctions.

After filling the fuel tank, lock the filler cap

and close the flap.

Fuel

Page 145 of 192

143

Bipper_en_Chap08_verifications_ed02-2014

Resetting

to set off again, restore the fuel supply and

the electrical supply manually:

-

with the key in the

STOP position, turn

the key to the RUNNING position,

-

push the direction indicator control stalk

fully upwards,

-

place it in the "Of

f" position,

-

press the direction indicator control stalk

fully downwards,

-

return it to the "Of

f" position,

-

push it fully upwards again,

-

return it to the "Of

f" position,

-

press it fully downwards again,

-

return it to the "Of

f" position,

-

turn the key to the

STOP position.

Fuel used for petrol engines

the petrol engines are compatible with

e

10 bio-petrol (containing 10 % ethanol),

conforming to European standards EN 228

and

e N 15376.

E85 type fuels (containing up to 85 %

ethanol) are reserved exclusively for

vehicles marketed for the use of this type

of fuel (BioFlex vehicles).

t

he quality of

the ethanol must comply with

e uropean

standard EN 15293.

Fuel used for Diesel engines

the Diesel engines are perfectly with

biofuels which conform to current and future

e

uropean standards (Diesel fuel which

complies with standard EN 590 mixed with

a biofuel which complies with standard

e

N 14214) available at the pumps

(containing up to 7 % Fatty Acid Methyl

e

ster).

t

he B30 biofuel can be used in certain

Diesel engines; however, this use is subject

to strict application of the special servicing

conditions indicated in the warranty and

maintenance record. Contact a P

euge O t

dealer or a qualified workshop.

t

he use of any other type of (bio)fuel

(vegetable or animal oils, pure or diluted,

domestic fuel...) is strictly prohibited (risk of

damage to the engine and fuel system).

8

CHECKS

Fuel

Page 147 of 192

145

Bipper_en_Chap08_verifications_ed02-2014

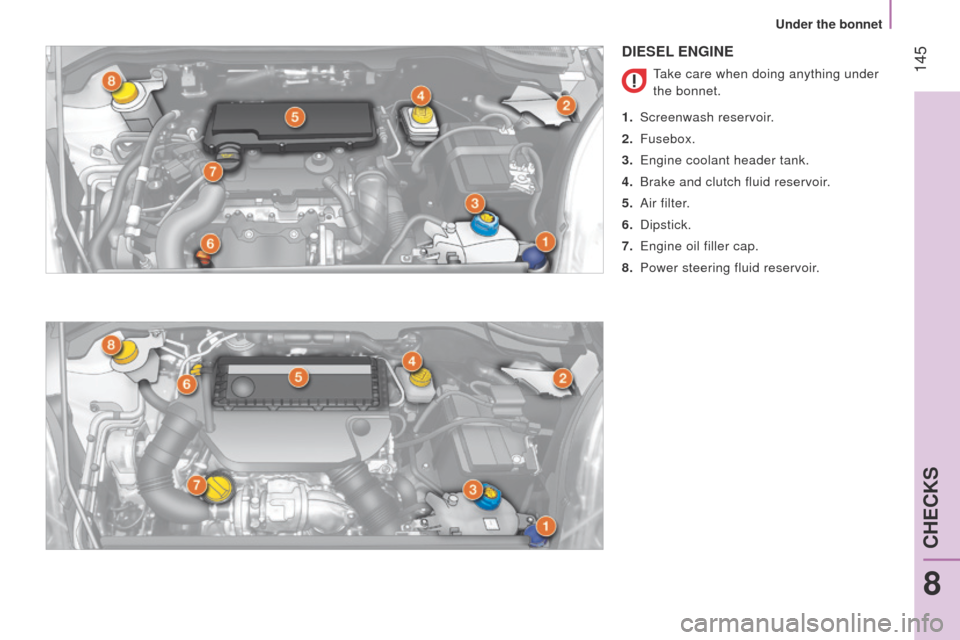

DIESEL ENGINE

take care when doing anything under

the bonnet.

1.

Screenwash reservoir

.

2.

Fusebox.

3.

e

ngine coolant header tank.

4.

Brake and clutch fluid reservoir

.

5.

Air filter

.

6.

Dipstick.

7.

e

ngine oil filler cap.

8.

Power steering fluid reservoir

.

8

CHECKS

Under the bonnet

Page 149 of 192

147

Bipper_en_Chap08_verifications_ed02-2014

these regular maintenance operations will

keep your vehicle in good working order .

Ask for advice from a P

euge O t

dealer or a

qualified workshop or refer to the warranty

and maintenance record provided in the

handbook pack.

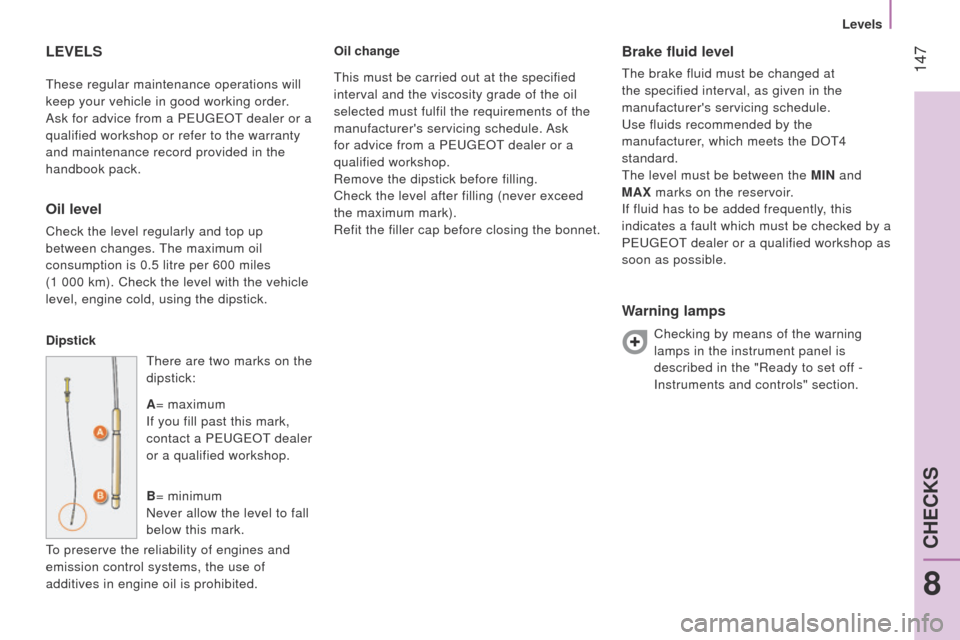

LEVELS

Oil level

Check the level regularly and top up

between changes.

t

he maximum oil

consumption is 0.5 litre per 600 miles

(1 000

km). Check the level with the vehicle

level, engine cold, using the dipstick.

Dipstick

t

here are two marks on the

dipstick:

A = maximum

If you fill past this mark,

contact a P

euge O t

dealer

or a qualified workshop.

B = minimum

Never allow the level to fall

below this mark.

to preserve the reliability of engines and

emission control systems, the use of

additives in engine oil is prohibited. Oil change

Brake fluid level

the brake fluid must be changed at

the specified interval, as given in the

manufacturer's servicing schedule.

u

se fluids recommended by the

manufacturer, which meets the DO

t 4

standard.

t

he level must be between the MIN and

MAX marks on the reservoir.

If fluid has to be added frequently, this

indicates a fault which must be checked by a

P

euge O t

dealer or a qualified workshop as

soon as possible.

Warning lamps

Checking by means of the warning

lamps in the instrument panel is

described in the "Ready to set off -

Instruments and controls" section.

t

his must be carried out at the specified

interval and the viscosity grade of the oil

selected must fulfil the requirements of the

manufacturer's servicing schedule. Ask

for advice from a P

euge

O

t

dealer or a

qualified workshop.

Remove the dipstick before filling.

Check the level after filling (never exceed

the maximum mark).

Refit the filler cap before closing the bonnet.

8

CHECKS

Levels