lock PEUGEOT BOXER 2021 Service Manual

[x] Cancel search | Manufacturer: PEUGEOT, Model Year: 2021, Model line: BOXER, Model: PEUGEOT BOXER 2021Pages: 212, PDF Size: 6.37 MB

Page 122 of 212

120

In the event of a breakdown

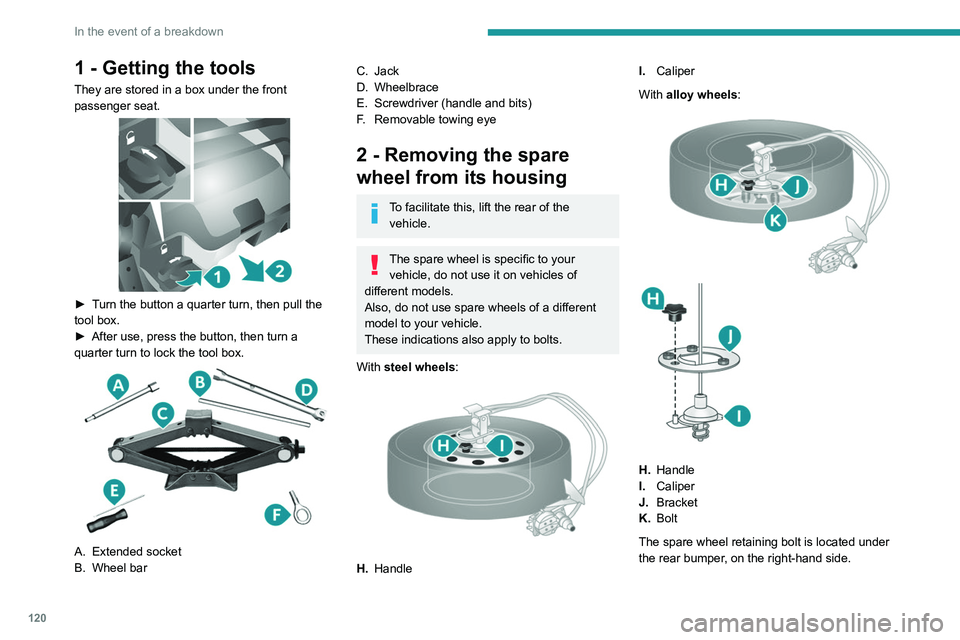

1 - Getting the tools

They are stored in a box under the front

passenger seat.

► Turn the button a quarter turn, then pull the

tool box.

►

After use, press the button, then turn a

quarter turn to lock the tool box.

A. Extended socket

B. Wheel bar

C. Jack

D. Wheelbrace

E. Screwdriver (handle and bits)

F. Removable towing eye

2 - Removing the spare

wheel from its housing

To facilitate this, lift the rear of the

vehicle.

The spare wheel is specific to your vehicle, do not use it on vehicles of

different models.

Also, do not use spare wheels of a different

model to your vehicle.

These indications also apply to bolts.

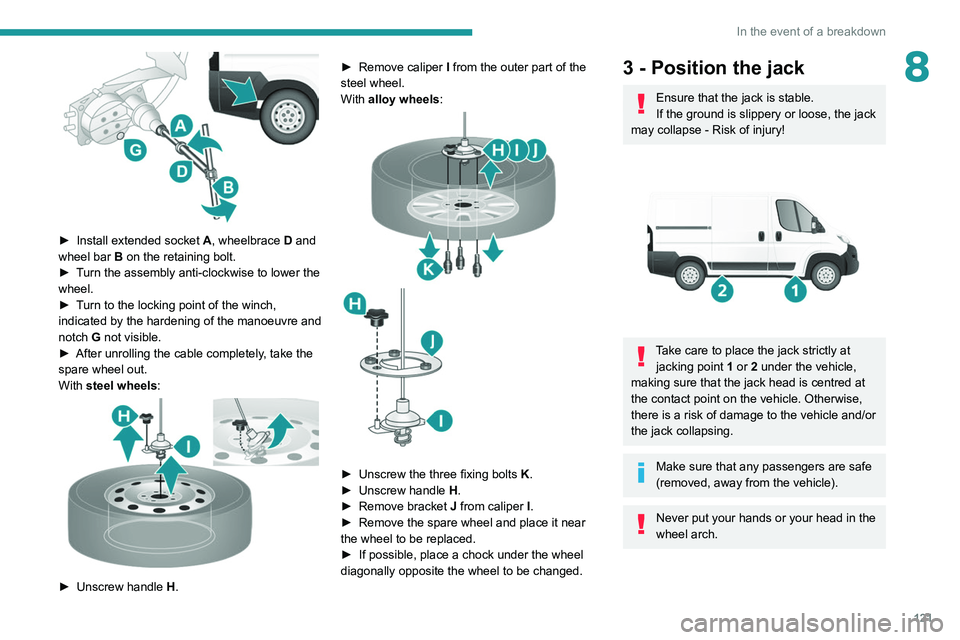

With steel wheels:

H. Handle I.

Caliper

With alloy wheels:

H. Handle

I. Caliper

J. Bracket

K. Bolt

The spare wheel retaining bolt is located under

the rear bumper, on the right-hand side.

Page 123 of 212

121

In the event of a breakdown

8

► Install extended socket A , wheelbrace D and

wheel bar B on the retaining bolt.

►

T

urn the assembly anti-clockwise to lower the

wheel.

►

T

urn to the locking point of the winch,

indicated by the hardening of the manoeuvre and

notch G not visible.

►

After unrolling the cable completely

, take the

spare wheel out.

With steel wheels:

► Unscrew handle H . ►

Remove caliper

I

from the outer part of the

steel wheel.

With alloy wheels:

► Unscrew the three fixing bolts K .

► Unscrew handle H

.

►

Remove bracket J

from caliper I.

►

Remove the spare wheel and place it near

the wheel to be replaced.

►

If possible, place a chock under the wheel

diagonally opposite the wheel to be changed.

3 - Position the jack

Ensure that the jack is stable.

If the ground is slippery or loose, the jack

may collapse - Risk of injury!

Take care to place the jack strictly at jacking point 1 or 2 under the vehicle,

making sure that the jack head is centred at

the contact point on the vehicle. Otherwise,

there is a risk of damage to the vehicle and/or

the jack collapsing.

Make sure that any passengers are safe

(removed, away from the vehicle).

Never put your hands or your head in the

wheel arch.

Page 126 of 212

124

In the event of a breakdown

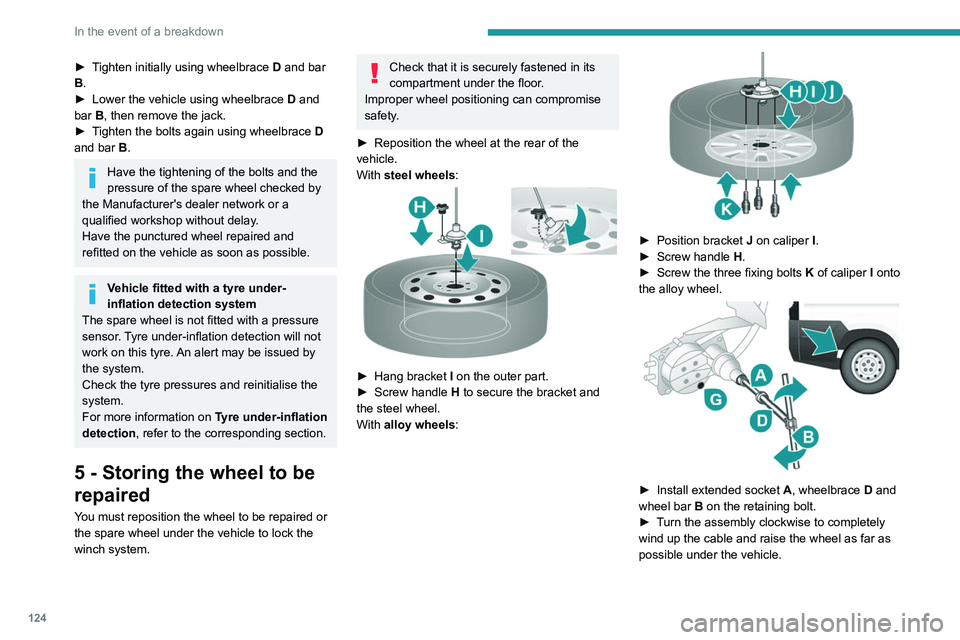

► Tighten initially using wheelbrace D and bar

B.

►

Lower the vehicle using wheelbrace D

and

bar B, then remove the jack.

►

T

ighten the bolts again using wheelbrace D

and bar B.

Have the tightening of the bolts and the

pressure of the spare wheel checked by

the Manufacturer's dealer network or a

qualified workshop without delay.

Have the punctured wheel repaired and

refitted on the vehicle as soon as possible.

Vehicle fitted with a tyre under-

inflation detection system

The spare wheel is not fitted with a pressure

sensor. Tyre under-inflation detection will not

work on this tyre. An alert may be issued by

the system.

Check the tyre pressures and reinitialise the

system.

For more information on Tyre under-inflation

detection, refer to the corresponding section.

5 - Storing the wheel to be

repaired

You must reposition the wheel to be repaired or

the spare wheel under the vehicle to lock the

winch system.

Check that it is securely fastened in its

compartment under the floor.

Improper wheel positioning can compromise

safety.

►

Reposition the wheel at the rear of the

vehicle.

With

steel wheels:

► Hang bracket I on the outer part.

► Screw handle H

to secure the bracket and

the steel wheel.

With alloy wheels:

► Position bracket J on caliper I .

► Screw handle H

.

►

Screw the three fixing bolts

K

of caliper I onto

the alloy wheel.

► Install extended socket A , wheelbrace D and

wheel bar B on the retaining bolt.

►

T

urn the assembly clockwise to completely

wind up the cable and raise the wheel as far as

possible under the vehicle.

Page 127 of 212

125

In the event of a breakdown

8► Check that the wheel is flat against the floor

of the vehicle and that the notch G

of the winch

is visible.

►

Store the tools and the wheel trim (depending

on version).

For more information on

the Identification markings of the

vehicle, and in particular the tyre pressure

label, refer to the corresponding section.

Changing a bulb

The headlamps have polycarbonate lenses with a protective coating:

►

do not clean them using a dry or

abrasive cloth, nor with a detergent or

solvent product,

►

use a sponge and soapy water or a pH

neutral product,

►

when using a high pressure washer on

persistent marks, do not keep the lance

directed towards the lamps or their edges for

too long, so as not to damage their protective

coating and seals.

Changing a bulb must only be done with

the ignition off and after the lamp has

been switched off for several minutes - Risk

of serious burns!

►

Do not touch the bulb directly with your

fingers, use a lint-free cloth.

It is essential only to use anti-ultraviolet

(UV) type bulbs, so as not to damage the

headlamp.

Always replace a failed bulb with a new bulb

with the same type and specification.

In some weather conditions (e.g. low

temperature or humidity), the presence

of misting on the internal surface of the glass

of the headlamps and rear lamps is normal; it

disappears after the lamps have been on for a

few minutes.

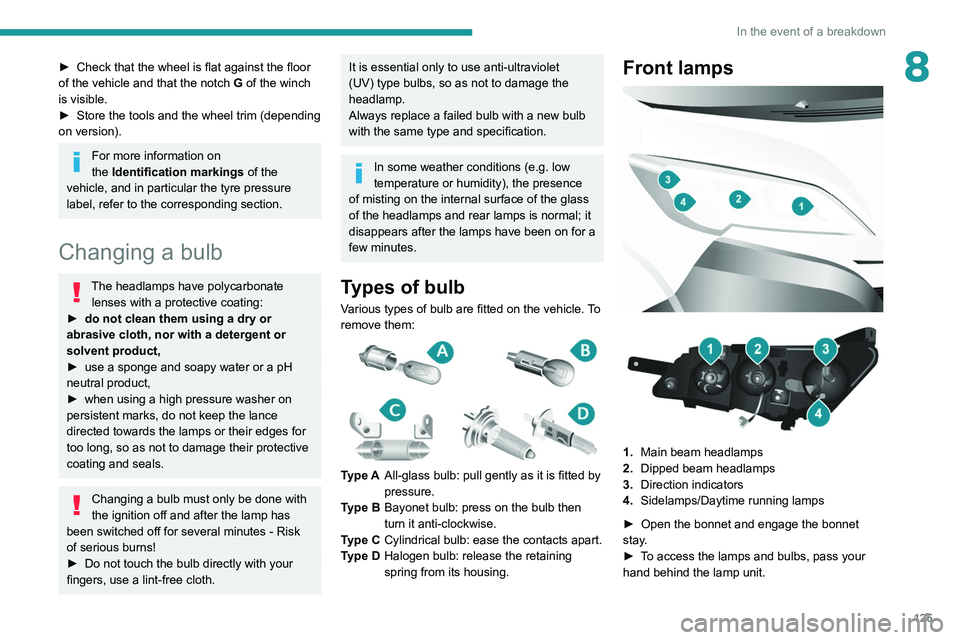

Types of bulb

Various types of bulb are fitted on the vehicle. To

remove them:

Type A All-glass bulb: pull gently as it is fitted by

pressure.

Type B Bayonet bulb: press on the bulb then

turn it anti-clockwise.

Type C Cylindrical bulb: ease the contacts apart.

Type D Halogen bulb: release the retaining

spring from its housing.

Front lamps

1. Main beam headlamps

2. Dipped beam headlamps

3. Direction indicators

4. Sidelamps/Daytime running lamps

►

Open the bonnet and engage the bonnet

stay

.

►

T

o access the lamps and bulbs, pass your

hand behind the lamp unit.

Page 128 of 212

126

In the event of a breakdown

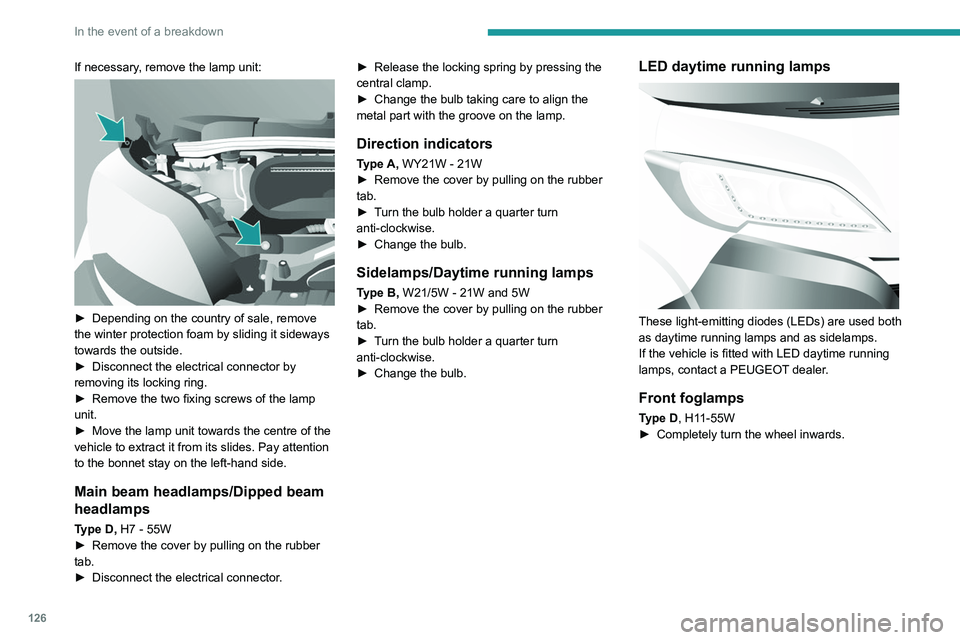

If necessary, remove the lamp unit:

► Depending on the country of sale, remove

the winter protection foam by sliding it sideways

towards the outside.

►

Disconnect the electrical connector by

removing its locking ring.

►

Remove the two fixing screws of the lamp

unit.

►

Move the lamp unit towards the centre of the

vehicle to extract it from its slides. Pay attention

to the bonnet stay on the left-hand side.

Main beam headlamps/Dipped beam

headlamps

Type D, H7 - 55W

► Remove the cover by pulling on the rubber

tab.

►

Disconnect the electrical connector

.►

Release the locking spring by pressing the

central clamp.

►

Change the bulb taking care to align the

metal part with the groove on the lamp.

Direction indicators

Type A, WY21W - 21W

► Remove the cover by pulling on the rubber

tab.

►

T

urn the bulb holder a quarter turn

anti-clockwise.

►

Change the bulb.

Sidelamps/Daytime running lamps

Type B, W21/5W - 21W and 5W

► Remove the cover by pulling on the rubber

tab.

►

T

urn the bulb holder a quarter turn

anti-clockwise.

►

Change the bulb.

LED daytime running lamps

These light-emitting diodes (LEDs) are used both

as daytime running lamps and as sidelamps.

If the vehicle is fitted with LED daytime running

lamps, contact a PEUGEOT dealer.

Front foglamps

Type D, H11-55W

► Completely turn the wheel inwards.

Page 130 of 212

128

In the event of a breakdown

Front/Rear

► Press the points indicated by the arrows, then

remove the courtesy lamp.

►

Open the protective flap.

►

Remove the bulb by separating the two

contacts.

►

Check that the new bulbs are securely held

between the two contacts.

►

Close the protective flap.

►

Fix the courtesy lamp in its housing and

make sure it is locked.

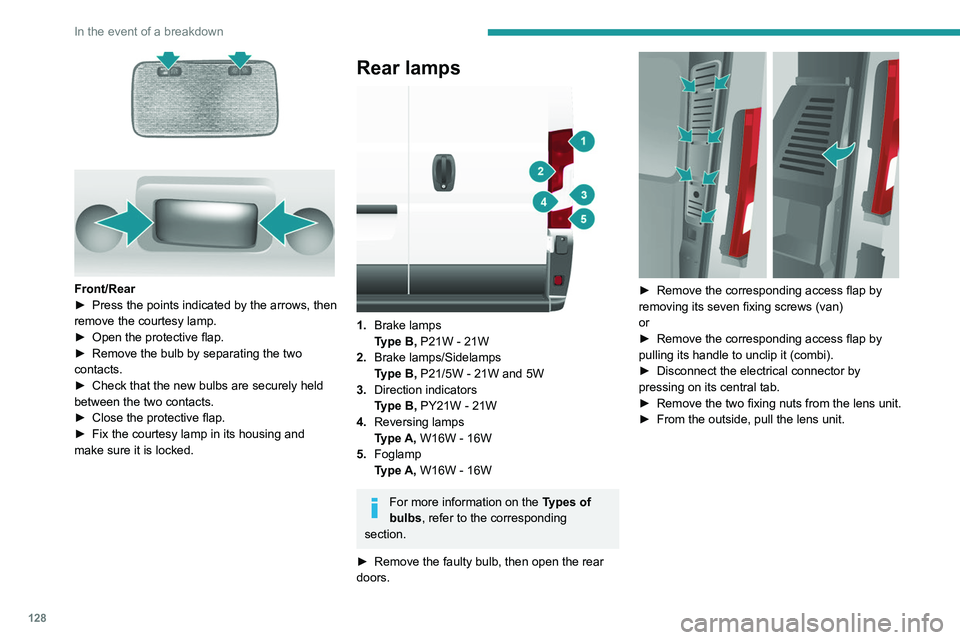

Rear lamps

1. Brake lamps

Type B, P21W - 21W

2. Brake lamps/Sidelamps

Type B, P21/5W - 21W and 5W

3. Direction indicators

Type B, PY21W - 21W

4. Reversing lamps

Type A, W16W - 16W

5. Foglamp

Type A, W16W - 16W

For more information on the Types of

bulbs, refer to the corresponding

section.

►

Remove the faulty bulb, then open the rear

doors.

► Remove the corresponding access flap by

removing its seven fixing screws (van)

or

►

Remove the corresponding access flap by

pulling its handle to unclip it (combi).

►

Disconnect the electrical connector by

pressing on its central tab.

►

Remove the two fixing nuts from the lens unit.

►

From the outside, pull the lens unit.

Page 131 of 212

129

In the event of a breakdown

8

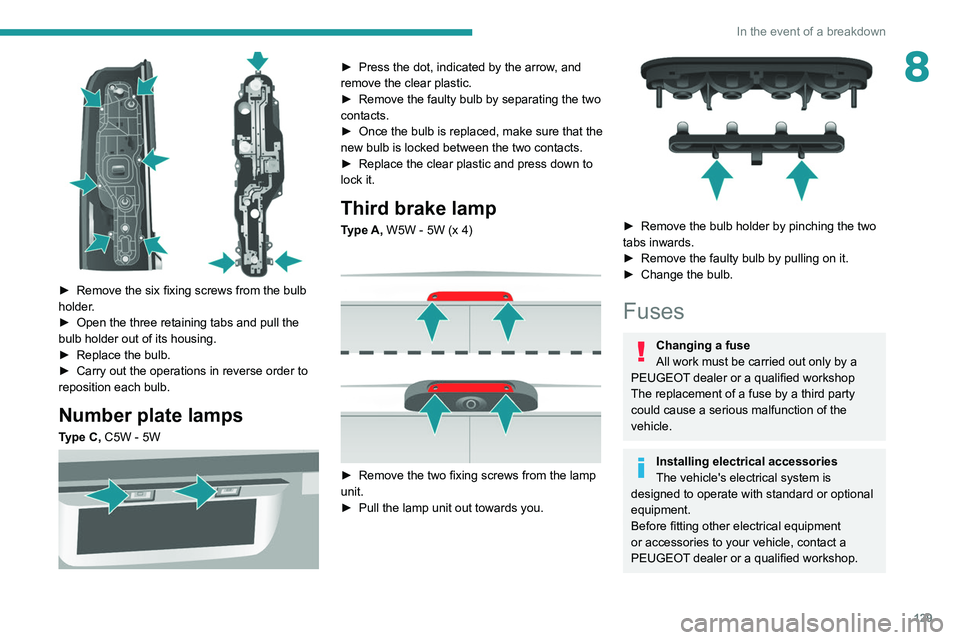

► Remove the six fixing screws from the bulb

holder .

►

Open the three retaining tabs and pull the

bulb holder out of its housing.

►

Replace the bulb.

►

Carry out the operations in reverse order to

reposition each bulb.

Number plate lamps

Type C, C5W - 5W

► Press the dot, indicated by the arrow , and

remove the clear plastic.

►

Remove the faulty bulb by separating the two

contacts.

►

Once the bulb is replaced, make sure that the

new bulb is locked between the two contacts.

►

Replace the clear plastic and press down to

lock it.

Third brake lamp

Type A, W5W - 5W (x 4)

► Remove the two fixing screws from the lamp

unit.

►

Pull the lamp unit out towards you.

► Remove the bulb holder by pinching the two

tabs inwards.

►

Remove the faulty bulb by pulling on it.

►

Change the bulb.

Fuses

Changing a fuse

All work must be carried out only by a

PEUGEOT dealer or a qualified workshop

The replacement of a fuse by a third party

could cause a serious malfunction of the

vehicle.

Installing electrical accessories

The vehicle's electrical system is

designed to operate with standard or optional

equipment.

Before fitting other electrical equipment

or accessories to your vehicle, contact a

PEUGEOT dealer or a qualified workshop.

Page 133 of 212

131

In the event of a breakdown

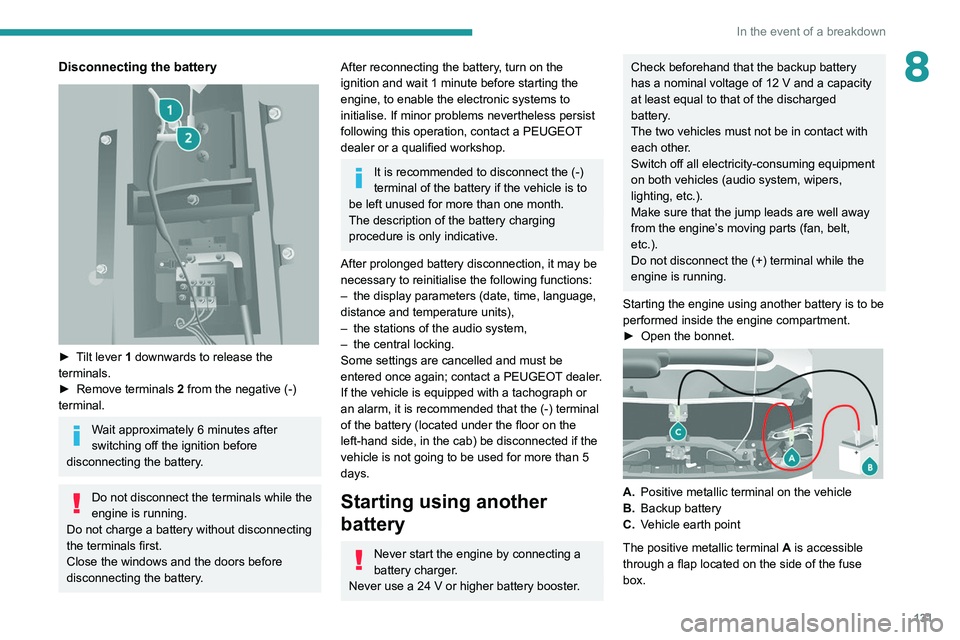

8Disconnecting the battery

► Tilt lever 1 downwards to release the

terminals.

►

Remove terminals

2

from the negative (-)

terminal.

Wait approximately 6 minutes after

switching off the ignition before

disconnecting the battery.

Do not disconnect the terminals while the

engine is running.

Do not charge a battery without disconnecting

the terminals first.

Close the windows and the doors before

disconnecting the battery.

After reconnecting the battery, turn on the

ignition and wait 1 minute before starting the

engine, to enable the electronic systems to

initialise. If minor problems nevertheless persist

following this operation, contact a PEUGEOT

dealer or a qualified workshop.

It is recommended to disconnect the (-)

terminal of the battery if the vehicle is to

be left unused for more than one month.

The description of the battery charging

procedure is only indicative.

After prolonged battery disconnection, it may be

necessary to reinitialise the following functions:

–

the display parameters (date, time, language,

distance and temperature units),

–

the stations of the audio system,

–

the central locking.

Some settings are cancelled and must be

entered once again; contact a PEUGEOT

dealer.

If the vehicle is equipped with a tachograph or

an alarm,

it is recommended that the (-) terminal

of the battery (located under the floor on the

left-hand side, in the cab) be disconnected if the

vehicle is not going to be used for more than 5

days.

Starting using another

battery

Never start the engine by connecting a

battery charger.

Never use a 24 V or higher battery booster.

Check beforehand that the backup battery

has a nominal voltage of 12 V and a capacity

at least equal to that of the discharged

battery.

The two vehicles must not be in contact with

each other.

Switch off all electricity-consuming equipment

on both vehicles (audio system, wipers,

lighting, etc.).

Make sure that the jump leads are well away

from the engine’s moving parts (fan, belt,

etc.).

Do not disconnect the (+) terminal while the

engine is running.

Starting the engine using another battery is to be

performed inside the engine compartment.

►

Open the bonnet.

A. Positive metallic terminal on the vehicle

B. Backup battery

C. Vehicle earth point

The positive metallic terminal A is accessible

through a flap located on the side of the fuse

box.

Page 135 of 212

133

In the event of a breakdown

8Ensure that the weight of the towing vehicle is

higher than that of the towed vehicle.

The driver must remain at the wheel of the

towed vehicle and must have a valid driving

licence.

When towing a vehicle with all four wheels on

the ground, always use an approved towing

arm; rope and straps are prohibited.

The towing vehicle must move off gently.

When the vehicle is towed with its engine

off, there is no longer braking and steering

assistance.A professional towing service must be

called if:

–

Broken down on a motorway or main road.

–

Not possible to put

the gearbox into neutral,

unlock the steering, or release the parking

brake.

–

Not possible to tow a vehicle with an

automatic gearbox, with the engine running.

–

T

owing with only two wheels on the ground.

–

Four-wheel drive vehicle.

–

No approved towbar available.

Before towing the vehicle, it is essential

to put the vehicle in free-wheeling mode.

Electric motor

An electric vehicle cannot under any

circumstances be used to tow another

vehicle.

However, it may be used, for example, to exit

a rut.

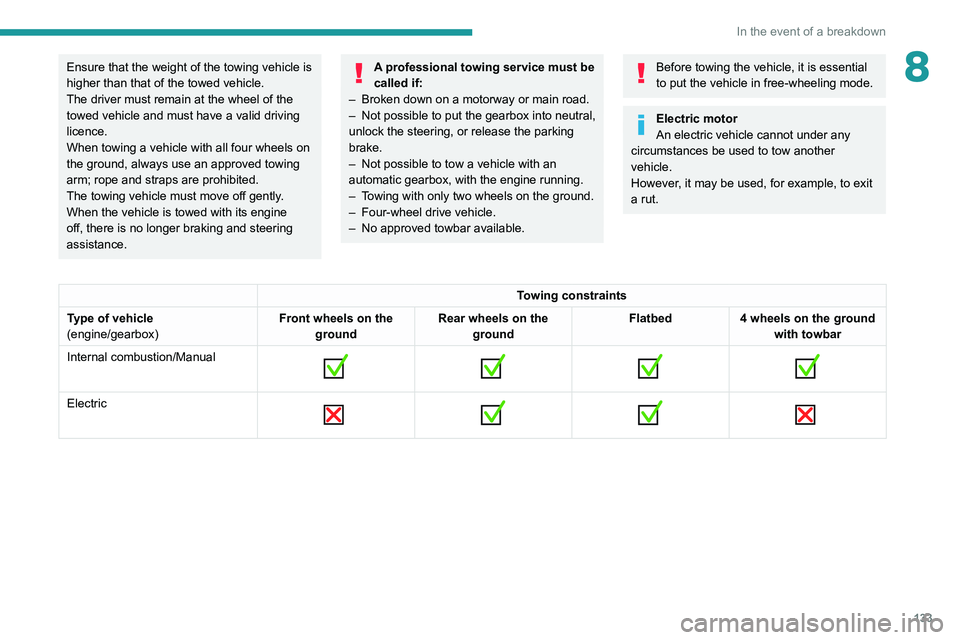

Towing constraints

Type of vehicle

(engine/gearbox) Front wheels on the

ground Rear wheels on the

ground Flatbed

4 wheels on the ground

with towbar

Internal combustion/Manual

Electric

Page 159 of 212

157

Special features

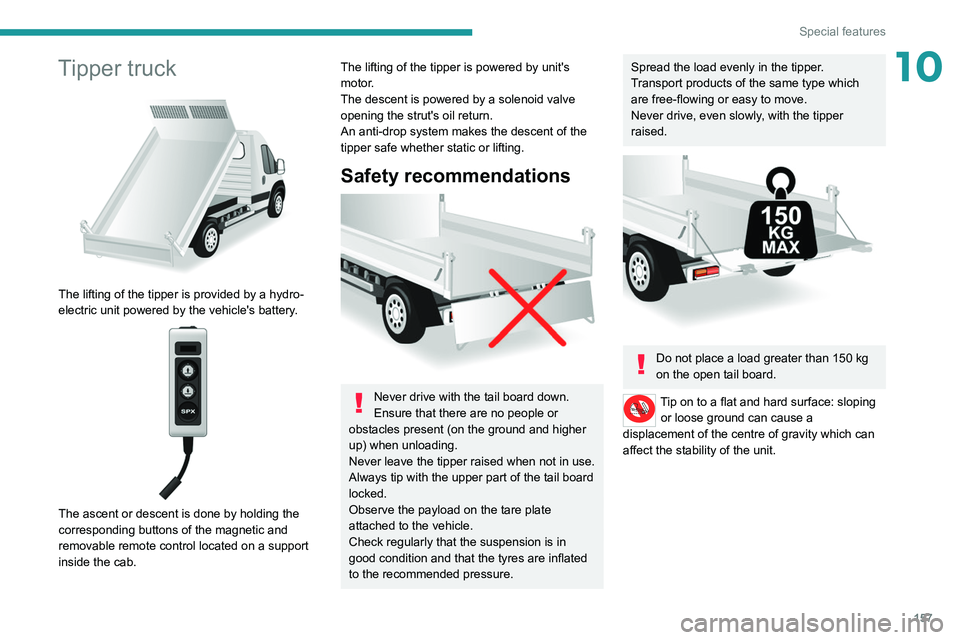

10Tipper truck

The lifting of the tipper is provided by a hydro-

electric unit powered by the vehicle's battery.

The ascent or descent is done by holding the

corresponding buttons of the magnetic and

removable remote control located on a support

inside the cab.

The lifting of the tipper is powered by unit's

motor.

The descent is powered by a solenoid valve

opening the strut's oil return.

An anti-drop system makes the descent of the

tipper safe whether static or lifting.

Safety recommendations

Never drive with the tail board down.

Ensure that there are no people or

obstacles present (on the ground and higher

up) when unloading.

Never leave the tipper raised when not in use.

Always tip with the upper part of the tail board

locked.

Observe the payload on the tare plate

attached to the vehicle.

Check regularly that the suspension is in

good condition and that the tyres are inflated

to the recommended pressure.

Spread the load evenly in the tipper.

Transport products of the same type which

are free-flowing or easy to move.

Never drive, even slowly, with the tipper

raised.

Do not place a load greater than 150 kg

on the open tail board.

Tip on to a flat and hard surface: sloping or loose ground can cause a

displacement of the centre of gravity which can

affect the stability of the unit.