relay PONTIAC FIERO 1988 Service User Guide

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 191 of 1825

386-4 STEERING LINKAGE

DIMENSION "B"

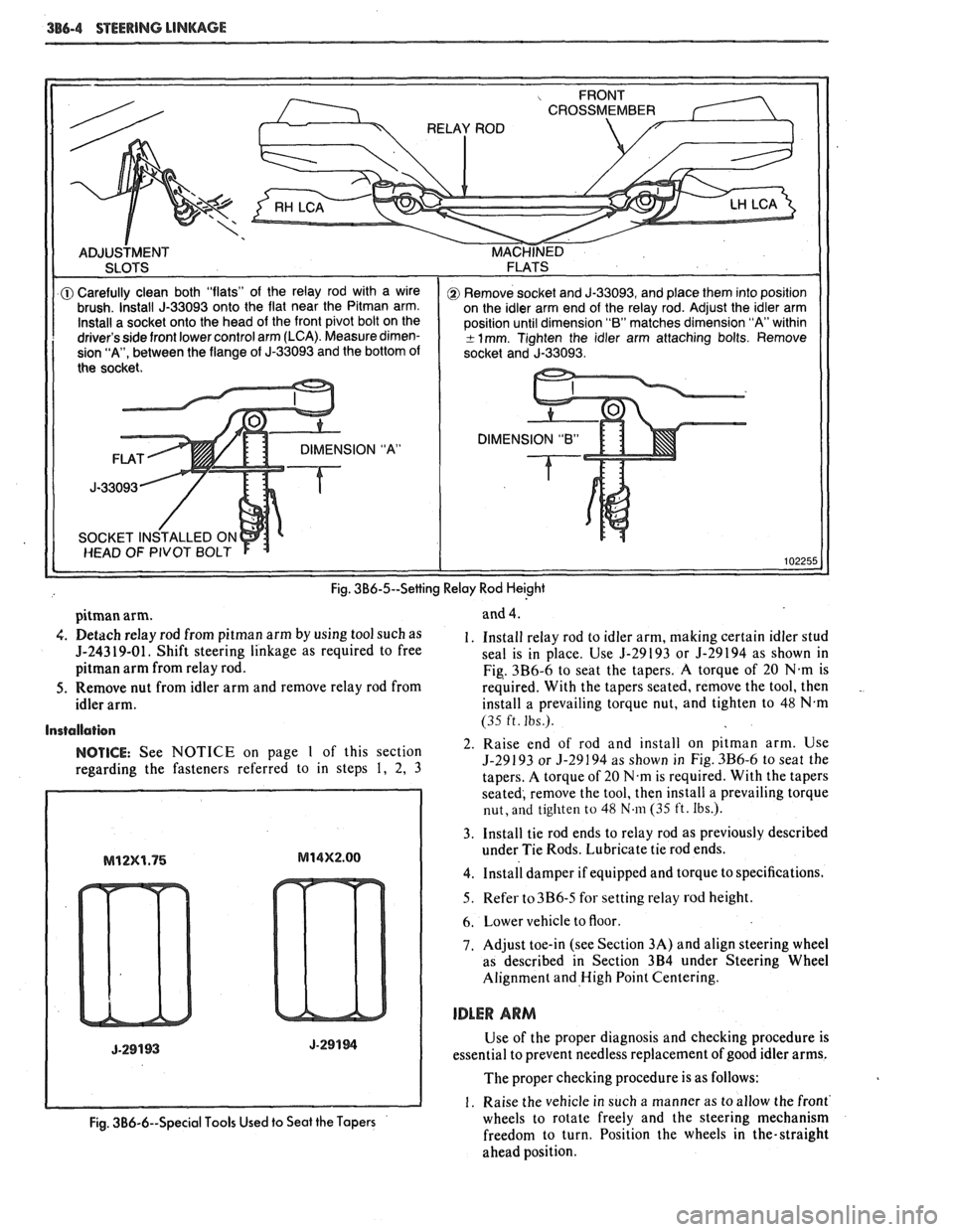

Fig. 3B6-5--Setting Relay Rod Heighi

pitman arm.

4. Detach relay rod from pitman arm by using tool such as

5-24319-01. Shift steering linkage as required to free

pitman arm from relay rod.

5. Remove nut from idler arm and remove relay rod from

idler arm.

Installation

NOTICE: See NOTICE on page 1 of this section

regarding the fasteners referred to in steps

1, 2, 3 and

4.

1. Install relay

rod to idler arm, making certain idler stud

seal is in place. Use

5-29193 or 5-29194 as shown in

Fig. 3B6-6 to seat the tapers. A torque of

20 N.m is

required. With the tapers seated, remove the tool, then

.

install a prevailing torque nut, and tighten to 48 N.m

(35 ft. Ibs.).

2. Raise end of rod and install on pitman arm. Use

5-29193 or 3-29194 as shown in Fig. 3B6-6 to seat the

tapers. A torque of

20 N.m is required. With the tapers

seated, remove the tool, then install a prevailing torque

nut, and tighten to 48 N.111 (35 ft. Ibs.).

3. Install tie rod ends to relay rod as previously described

under Tie Rods. Lubricate tie rod ends.

4. ~nstall damper if equipped and torque to specifications.

5. Refer to3B6-5 for setting relay rod height.

6. Lower vehicle to floor

7. Adjust toe-in (see Section 3A) and align steering wheel

as described in Section

3B4 under Steering Wheel

Alignment and High Point Centering.

IDLER ARM

Use of the proper diagnosis and checking procedure is

essential to prevent needless replacement of good idler arms.

The proper checking procedure is as follows:

1. Raise the vehicle in such a manner as to allow the front'

Fig. 3B6-6--Special Tools Used to Seat the Tapers wheels to rotate freely and the steering mechanism

freedom to turn. Position the wheels in the-straight

ahead position.

Page 192 of 1825

STEERING LINKAGE 386-5

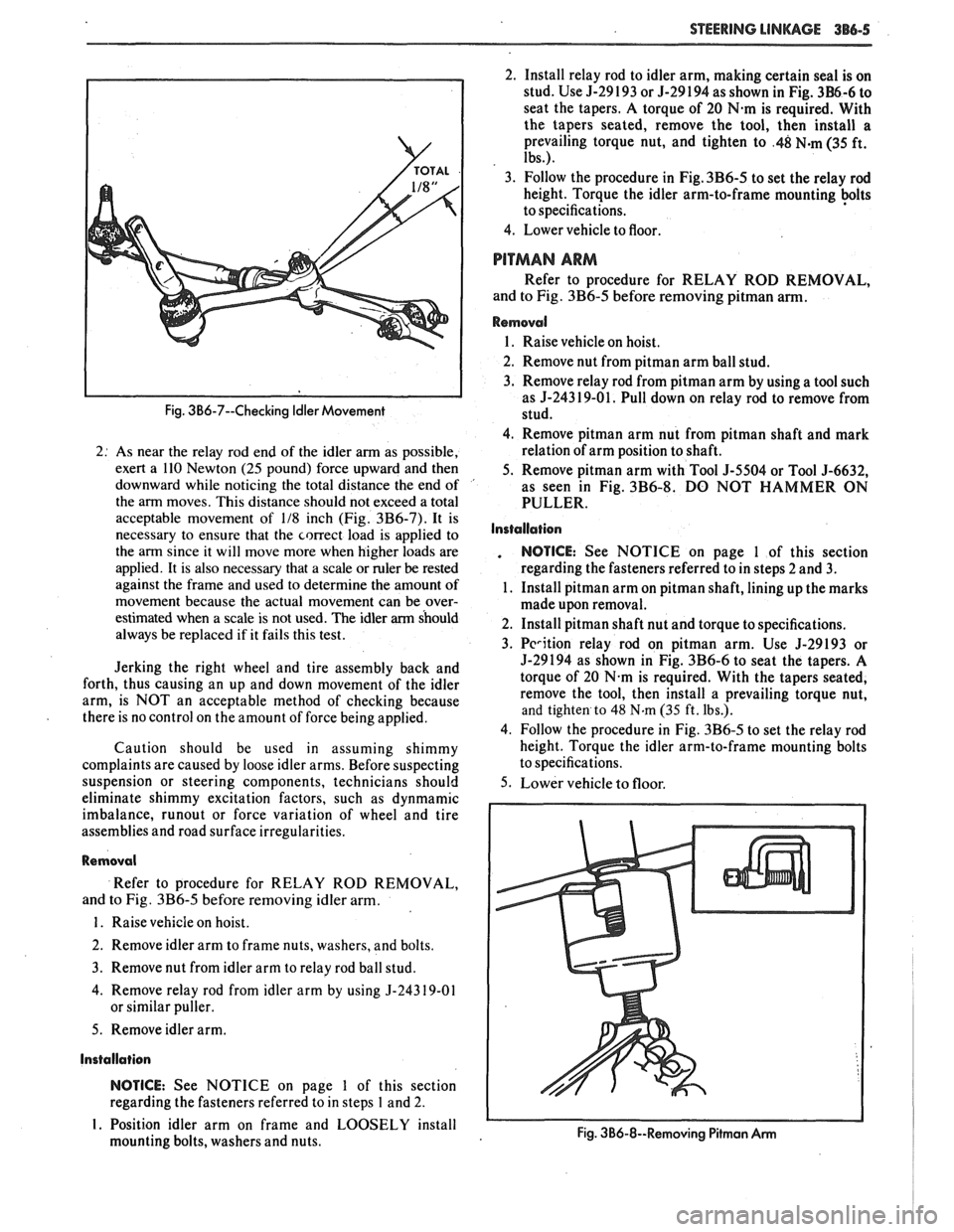

Fig. 3B6-7--Checking Idler Movement

2: As near the relay rod end of the idler arm as possible,

exert a 110 Newton

(25 pound) force upward and then

downward while noticing the total distance the end of '

the arm moves. This distance should not exceed a total

acceptable movement of

118 inch (Fig. 3B6-7). It is

necessary to ensure that the correct load is applied to

the arm since it will move more when higher loads are

applied. It is also necessary that a scale or ruler

be rested

against the frame and used to determine the amount of

movement because the actual movement can be over-

estimated when a scale is not used. The idler

arm should

always be replaced if it fails this test.

Jerking the right wheel and tire assembly back and

forth, thus causing an up and down movement of the idler

arm, is NOT an acceptable method of checking because

there is no control on the amount of force being applied.

Caution should be used in assuming shimmy

complaints are caused by loose idler arms. Before suspecting

suspension or steering components, technicians should

eliminate shimmy excitation factors, such as dynmamic

imbalance,

runout or force variation of wheel and tire

assemblies and road surface irregularities.

Removal

Refer to procedure for RELAY ROD REMOVAL,

and to Fig.

3B6-5 before removing idler arm.

1. Raise vehicle on hoist.

2. Remove idler arm to frame nuts, washers, and bolts.

3. Remove nut from idler arm to relay rod ball stud.

4. Remove relay rod from idler arm by using

5-24319-01

or similar puller.

5. Remove idler arm.

Installation

NOTICE: See NOTICE on page 1 of this section

regarding the fasteners referred to in steps

1 and 2.

I. Position idler arm on frame and LOOSELY install

mounting bolts, washers and nuts. 2.

Install relay rod to idler arm, making certain seal is on

stud. Use 5-29 193 or 5-29 194 as shown in Fig.

3B6-6 to

seat the tapers. A torque of 20

N.m is required. With

the tapers seated, remove the tool, then install a

prevailing torque nut, and tighten to

.48 N-m (35 ft.

Ibs.).

3. Follow the procedure in Fig. 3B6-5 to set the relay rod

height. Torque the idler arm-to-frame mounting

+Its

to specifications.

4. Lower vehicle to floor.

PITMAN ARM

Refer to procedure for RELAY ROD REMOVAL,

and to Fig.

3B6-5 before removing pitman arm.

Removal

1. Raise vehicle on hoist.

2. Remove nut from

pitman arm ball stud.

3. Remove relay rod from pitman arm by using a tool such

as

5-243 19-01. Pull down on relay rod to remove from

stud.

4. Remove pitman arm nut from pitman shaft and mark

relation of arm position to shaft.

5. Remove

pitman arm with Tool 5-5504 or Tool 5-6632,

as seen in Fig.

3B6-8. DO NOT HAMMER ON

PULLER.

Installation

. NOTICE: See NOTICE on page 1 of this section

regarding the fasteners referred to in steps 2 and

3.

1. Install pitman arm on pitman shaft, lining up the marks

made upon removal.

2. Install pitman shaft nut and torque to specifications.

3.

Pcrition relay rod on pitman arm. Use 5-29193 or

5-29194 as shown in Fig. 3B6-6 to seat the tapers. A

torque of 20

N.m is required. With the tapers seated,

remove the tool, then install a prevailing torque nut,

and tighten to 48 N.m (35 ft. Ibs.).

4. Follow the procedure in Fig.

3B6-5 to set the relay rod

height. Torque the idler arm-to-frame mounting bolts

to specifications.

5. Lower vehicle to floor.

Fig. 3B6-8--Removing Pitmon Arm I I

Page 212 of 1825

FRONT SUSPENSION 3C-1

SEC"T0RI 3C

FRONT SUSPENS

NOTICE: All front suspension fasteners are an important attaching part in that it could affect the

performance of vital parts and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified during reassembly

to assure proper retention of this part.

NOTICE: Never attempt to heat, quench or straighten any front suspension part. Replace it with a new part

or

damage to the part may result.

CONTENTS

General lnformation ....................................................................................................... 3C-I

On-Car Service ................................................................................................................... 3C- I

Specifications ..................................................................................................................... 3C- 10

GENERAL INFORMATION

The front suspension is designed to allow each

wheel to compensate for changes in the road surface ON-CAR SERVICE

level without appreciably affecting the opposite wheel. WHEEL BEARINGS

Each wheel is independently connected to the frame by

The proper functioning of the front suspension

a steering

kunckle, strut assembly, ball joint, and lower cannot be maintained unless the front wheel tapered arm. The steering in a roller bearings are correctly adjusted. The bearings

prescribed three dimensional arc. The front wheels are

must be a slip fit on the spindle and the inside diameter held in proper relationship to each other by two tie rods of the bearings should be lubricated to insure proper which are connected to steering arms on the knuckles ~h~ spindle nut must be a free-running fit and to the relay rod assembly.

on the threads.

Coil chassis springs are mounted between the

spring housings on the front crossmember and the

lower control arms. Ride control is provided by double,

direct acting strut assemblies. The upper portion of

each strut assembly extends through the fender well

and attaches to the upper mount assembly with a nut.

Side roll of the front suspension is controlled by

a spring steel stabilizer shaft. It is mounted in rubber

bushings which are held to the frame side rails by

brackets. The ends of the stabilizer are connected to the

lower control arms by link bolts and are isolated by

rubber grommets.

The inner ends of the lower control arms have

pressed in bushings. Bolts (passing through the

bushings) attach the arm to the suspension

crossmember. The lower ball joint assembly is a press

fit in the arm and attaches to the steering knuckle with

a torque prevailing nut.

Rubber grease seals are provided at ball socket

assemblies to keep dirt and moisture from entering the

joint and damaging bearing surfaces.

Adjustment

Figure 602

NOTICE: See NOTICE on Page 3C-1

of this

section.

1. Remove dust cap from hub.

2. Remove cotter pin from spindle and spindle nut.

3. Tighten the spindle nut to 16 Nsm (12 lb. ft.)

while turning the wheel assembly forward by

hand to fully seat the bearings. This will remove

any grease or burrs which could cause excessive

wheel bearing play later.

4. Back off the nut to the "just loose" position.

5. Hand tighten the spindle nut. Loosen spindle nut

until either hole in the spindle lines up with a slot

in the nut. Not

nlore than 1/2 flat.

6. Install

new cotter pin. Bend the ends of the cotter

pin against nut, cut off extra length to ensure ends

will not interfere with the dust cap.

7. Measure the looseness in the hub assembly. There

will be

from .03 to . l3mm (.001 to .005 inches)

end play when properly adjusted.

8. Install dust cap on hub.

FRONT SUSPENSION

Refer to Fig. 610 for illustration of attachment

provisions for the bolted-on front suspension

suspension

crossmember.

Page 414 of 1825

ENGINE COOLING 88.3

since a small oil pump driven by the separator plate

forces the silicone oil into a reservoir between the

separator plate and the front cover assembly. In this

position, the passage from this cavity to the clutch area

is closed by a slide valve. As operating conditions

produce a high radiator air temperature discharge,

above approximately 66°C

(150"F), the temperature

sensitive bi-metal coil tightens to move the slide valve

(attached to the coil) which opens a port in the

separator plate. This allows a flow of silicone oil into

the clutch chamber to engage the clutch, providing a

maximum fan speed of approximately 2200 rpm. The

clutch coil is calibrated so that, with a road load at an

ambient temperature of approximately 32°C

(90T), the

clutch is just at a point of shift between high and low

fan speed. No attempt should be made to disturb the

calibration of the engine clutch fan assembly as each

assembly is individually calibrated at the time of

manufacture. Under certain temperature conditions

there is a lateral movement at the fan tip which should

not be considered as a hub or bearing failure. This

condition is a design feature of the clutch assembly

which allows up to approximately

1/4" lateral

movement measured at the fan tip.

Testing a clutch fan by holding the small hub

with one hand and rotating the aluminum housing in

a

clockwise/counter-clockwise motion will cause the

clutch to freewheel, which is a normal condition when

operated in this manner. This should not be considered

a test by which replacement is determined.

Temperature Switch

This switch activates a warning lamp in the

instrument cluster if the engine overheats. With

optional instrumentation, a temperature gage replaces

the warning lamp and the temperature switch is

replaced with a transducer. See Section

8A for

Temperature Switch location and diagnosis.

Coolant Temperature Fan Switch

This switch regulates voltage to the coolant fan

relay, which operates the fan whenever the engine

coolant temperature exceeds 230"

F (110" C). For

location and diagnosis see Section 8A for Coolant

Temperature Fan Switch.

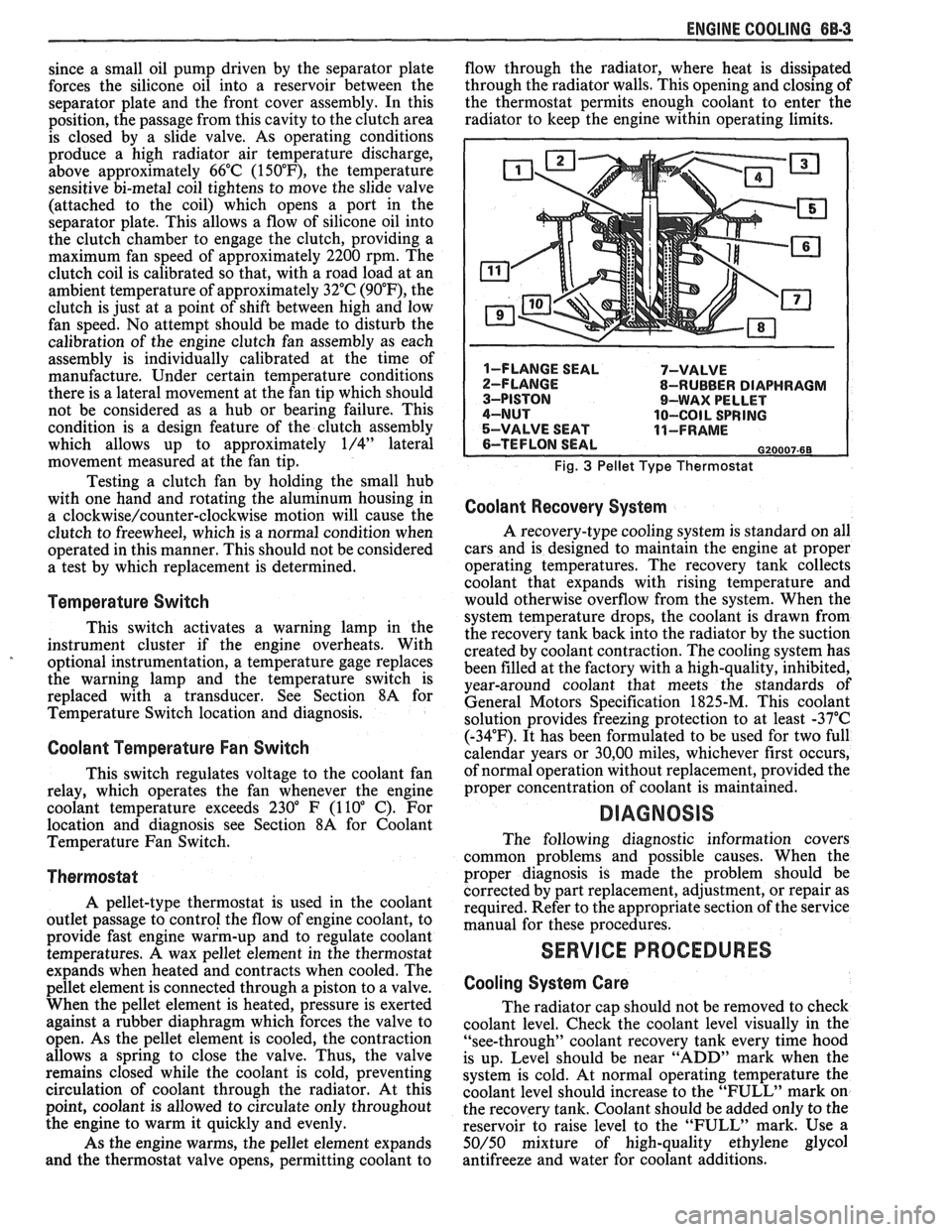

Thermostat

A pellet-type thermostat is used in the coolant

outlet passage to control the flow of engine coolant, to

provide fast engine warm-up and to regulate coolant

temperatures.

A wax pellet element in the thermostat

expands when heated and contracts when cooled. The

pellet element is connected through a piston to a valve.

When the pellet element is heated, pressure is exerted

against a rubber diaphragm which forces the valve to

open. As the pellet element is cooled, the contraction

allows a spring to close the valve. Thus, the valve

remains closed while the coolant is cold, preventing

circulation of coolant through the radiator. At this

point, coolant is allowed to circulate only throughout

the engine to warm it quickly and evenly.

As the engine warms, the pellet element expands

and the thermostat valve opens, permitting coolant to flow

through the radiator, where heat is dissipated

through the radiator walls. This opening and closing of

the thermostat permits enough coolant to enter the

radiator to keep the engine within operating limits.

Fig. 3 Pellet Type Thermostat

Coolant Recovery System

A recovery-type cooling system is standard on all

cars and is designed to maintain the engine at proper

operating temperatures. The recovery tank collects

coolant that expands with rising temperature and

would otherwise overflow from the system. When the

system temperature drops, the coolant is drawn from

the recovery tank back into the radiator by the suction

created by coolant contraction. The cooling system has

been filled at the factory with a high-quality, inhibited,

year-around coolant that meets the standards of

General Motors Specification 1825-M. This coolant

solution provides freezing protection to at least -37°C

(-34°F). It has been formulated to be used for two full

calendar years or

30,OO miles, whichever first occurs,

of normal operation without replacement, provided the

proper concentration of coolant is maintained.

DIAGNOSIS

The following diagnostic information covers

common problems and possible causes. When the

proper diagnosis is made the problem should be

corrected by part replacement, adjustment, or repair as

required. Refer to the appropriate section of the service

manual for these procedures.

SERVICE PROCEDURES

Cooling System Care

The radiator cap should not be removed to check

coolant level. Check the coolant level visually in the

"see-through" coolant recovery tank every time hood

is up. Level should be near "ADD" mark when the

system is cold. At normal operating temperature the

coolant level should increase to the "FULL" mark on

the recovery tank. Coolant should be added only to the

reservoir to raise level to the "FULL" mark. Use a

50/50 mixture of high-quality ethylene glycol

antifreeze and water for coolant additions.

Page 432 of 1825

ENGINE FUEL BC-1

SECTION 6C

NE FUEL

CONTENTS

General Description ..................................... 6C-1 Fuel

Cap ........................................................... 6C-3

.................................................. ............................................. Alcohol-In-Fuel 6C- 1 Fuel Filter Neck 6C-3

................... ............ Fuel Metering .................................................. 6C-2 Fuel Gage Sending Unit .. 6C-4

....................... ............................... Throttle Body Injection (TBI) .... 6C-2 Diagnosis ,. 6C-4 ................... Service

Procedures ............................................. 6C-4

Port Fuel Injection ...................................... 6C-2

Pressure Relief ........................................... 6C-4

Fuel Feed and Return Pipe

............................... 6C-2

Flow Test .................................................... 6C-4

Fuel Pipes (MPFI)

.......................................... 6C-3

Pressure Test - TBI ................................... 6C-4

Fuel and Vapor Hoses

....................................... 6C-3

Pressure Test - MPFI .................................... 6C-4

Fuel Pump ........................................................ 6C-3 ...................................................... Fuel Pump Relay .............................................. 6C-3 Fuel Tank 6C-4

Fuel Filter

......................................................... 6C-3 Accelerator Controls ...................................... 6C-5

Fuel Tank

....................................................... 6C-3

All new General Motors vehicles are certified by

the United States Environmental Protection Agency as

conforming to the requirements of the regulations for

the control of air pollution from new motor vehicles.

This certification is contingent on certain adjustments

being set to factory standards. In most cases, these

adjustment points either have been permanently

sealed and/or made inaccessible to prevent

indiscriminate or routine adjustment in the field. For

this reason, the factory procedure for temporarily

removing plugs, caps, etc., for purposes of servicing the

product must be strictly followed and, wherever

practicable, returned to the original intent of the

design.

GENERAL DESCRIPTION

All gasoline engines are designed to use only

unleaded gasoline. Unleaded gasoline must be used for

proper emission control system operation. Its use will

also minimize spark plug fouling and extend engine oil

life. Using leaded gasoline can damage the emission

control system and could result in loss of emission

warranty coverage.

All cars are equipped with an Evaporative

Emission System. The purpose of the system is to

minimize the escape of fuel vapors to the atmosphere.

Information on this system will be found in Section

6E2, or 6E3.

When working on the fuel system, there are

several things to keep in mind.

@ Any time fuel system is being worked on,

disconnect the negative battery cable

except for those tests where battery

Adhere to all Notices and Cautions.

Always keep a dry chemical (Class B) fire

extinguisher near the work area.

-

Always use a backup wrench when loosening or

tightening a screw couple fitting.

The torque on a screw fitting is

30 N-m (22 lb.

ft.).

Pipe is used on all MPFI, TPI, SFI, and TBI

applications. Fittings require the use of an

"0"

Ring. Replace all pipe with the same type of pipe

and fittings that were removed.

All fuel pipes must meet GM Specification

124-M, or its equivalent.

All fuel hoses must meet GM Specification

6163-M, or its equivalent.

Do not replace fuel pipe with fuel hose.

voltage is required.

@ On MPFI, TPI, SF1 and TBI systems, always A1cohol-ln-Fuel

relieve the line pressure before servicing any fuel Certain driveability complaints such as

system components. hesitation, lack of power, stall, no start, etc., may be

@ Do not repair the fuel system until you have read caused

by an excessive amount of alcohol-in-fuel. The

the copy and checked the illustrations relating to complaints

may be due to fuel system corrosion and

that repair. subsequent

fuel filter plugging, deterioration of rubber

Page 434 of 1825

ENGINE FUEL 6C.3

a Fuel feed and return pipes are secured to the

underbody with clamps and screw assemblies.

The pipes should be inspected occasionally for

leaks, kinks or dents.

e Follow the same routing as the original pipe.

e Pipes must be properly secured to the frame to

prevent chafing. A minimum of 6 mm

(1/4")

clearance must be maintained around a pipe to

prevent contact and chafing.

MPFl Fuel Pipes

Due to the fact that fuel pipes are under high

pressure, these systems require special consideration for service.

Many feed and return pipes use screw couplings

with

"0" Rings. Any time these fittings are loosened

to service or replace components, ensure that:

a A backup wrench is used while loosening and

tightening the fitting.

e Check all "0" rings at fitting locations (if

applicable) for cuts or any damage and replace

any that appear worn or damaged.

e Use correct torque when tightening fittings.

If pipes are replaced always use original

equipment parts, or parts that meet GM

specifications.

Fuel and Vapor Hoses

NOTICE: Fuel and vapor hoses are specially

manufactured. If replacement becomes necessary,

it is important to use only replacement hoses

meeting GM Specification 6163-M. These hoses

are identified with the words "Fluoroelastomer"

on them. Hoses not so marked could cause early

failure, or fail to meet emission standards.

e Do not use rubber hose within 4" of any part of

the exhaust system, or within

10" of the catalytic

converter.

FUEL PUMP

The electric fuel pump is in the fuel tank. The

tank has an outlet for a vapor return system. Any vapor

which forms is returned to the fuel tank along with hot

fuel through a separate line. This greatly reduces any

possibility of vapor lock by keeping cool fuel from the

tank constantly circulating through the fuel pump.

FUEL PUMP RELAY

To control fuel pump operation, a fuel pump

relay is used.

When the ignition switch is turned to "RUN"

position, the fuel pump relay activates the electric fuel

pump for

1.5 to 2.0 seconds to prime the injector(s). If

the ECM does not receive reference pulses from the

distributor after this time, the ECM signals the relay

to turn off the fuel pump. The relay will once again

activate the fuel pump when the

ECM receives

distributor reference pulses.

Fuel Filter

CAUTION: To reduce the risk of fire

and personal injury, it is necessary

to

relieve the fuel system pressure

before servicing fuel system

components. (See Fuel System

Pressure Relief.)

The inline filters can be found on the rear

crossmember of the vehicle. Always use a backup

wrench any time that the fuel filter is removed or

installed. Also make sure that a good

"0" Ring is used

at all screw couple locations. Torque on fittings is

30

N-m (22 lb. ft.).

FUEL TANK

The fuel tank is usually located under the rear of

the vehicle and a number of shapes and sizes are used

depending on the application.

The tank is held in place by two metal straps,

hinged (with a bolt through the hinge) and secured at

the opposite end with a nut and bolt assembly.

Anti-squeak pieces are used on top of the tank to

reduce rattles and other annoying noises.

The fuel tank, cap and lines should be inspected

for road damage, whch could cause leakage. Inspect

fuel cap for correct sealing and indications of physical

damage. Replace any damaged or malfunctioning

parts.

Before attempting service of any type on the fuel

tank, always

(1) remove negative battery cable from

battery, (2) place "no smoking" signs near work areas,

(3) be sure to have C02 fire extinguisher handy, (4)

wear safety glasses and

(5) siphon or pump fuel into an

explosion proof container.

Fuel Filler Gap

The fuel tank filler neck is equipped with a

screw-type cap. The threaded part of the cap requires

several turns counterclockwise to remove. The long

threaded area is designed to allow any remaining fuel

tank pressure to escape while the cap is being removed.

A built-in torque-limiting device prevents

overtightening. To install, turn the cap clockwise until

a clicking noise is heard. This signals that the correct

torque has been reached and the cap is fully seated.

N OTI G E: If a fuel filler cap requires replacement,

use only a cap with the same features. Failure to

use the correct cap can result in a serious

malfunction of the system.

Available on some models is an electric locking

fuel filler cap. Information on this option will be found

in Section

9E.

FUEL TANK FILLER NECK

To help prevent refueling with leaded gasoline,

the fuel filler neck on gasoline engine cars has a built-in

restrictor and deflector. The opening in the restrictor

will only admit the smaller unleaded gas nozzle spout,

which must be fully inserted to bypass the deflector.

Attempted refueling with a leaded gas nozzle or failure

Page 439 of 1825

6C-8 ENGINE FUEL

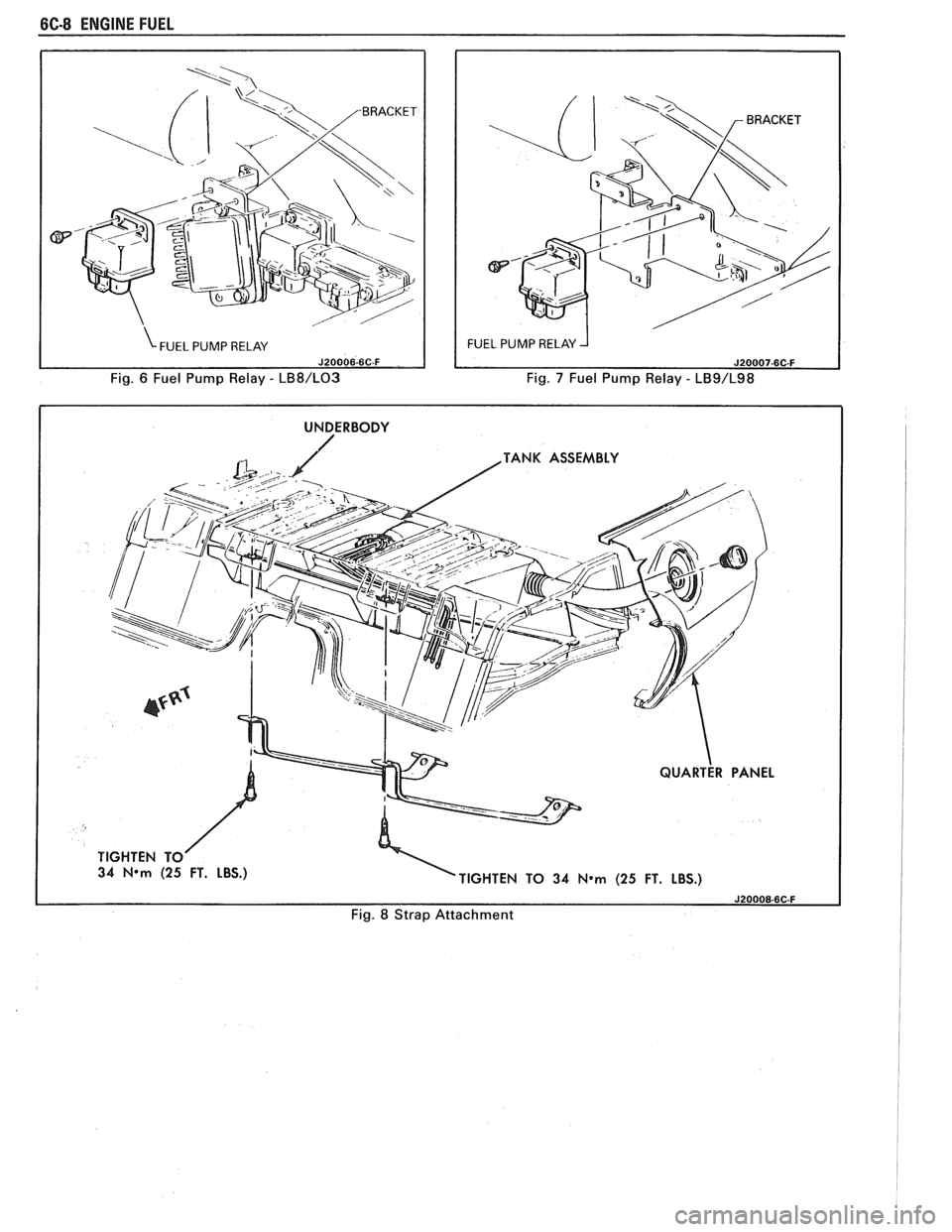

Fig. 6 Fuel Pump Relay - LB8/L03 Fig. 7 Fuel Pump Relay - LB9/L98

I UNDERBODY I

TANK ASSEMBLY

34

N*m (25 FT. LBS.)

TIGHTEN TO 34 N*m (25 FT. LBS.)

Fig. 8 Strap Attachment

Page 480 of 1825

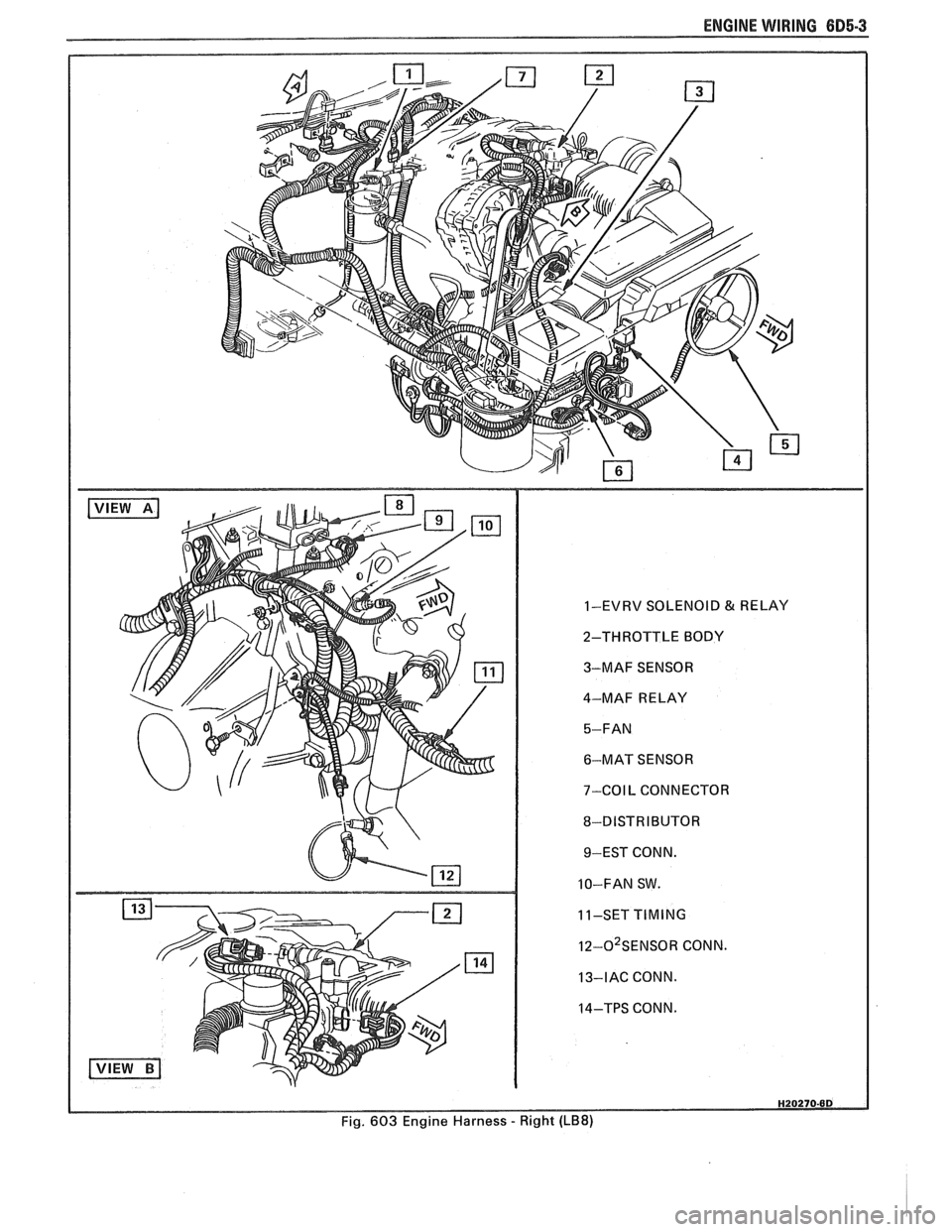

ENGINE WIRING 605.3

1-EVRV SOLENOID & RELAY

2-THROTTLE BODY

3-MAF SENSOR

4-MAF RELAY

6-MAT SENSOR

7-COIL CONNECTOR

8-DISTRIBUTOR 9-EST CONN.

10-FAN SW.

11-SET

TIMING

I~-O~SENSOR CONN.

13-IAC CONN.

14-TPS CONN.

Fig. 603 Engine Harness

- Right (LB8)

Page 481 of 1825

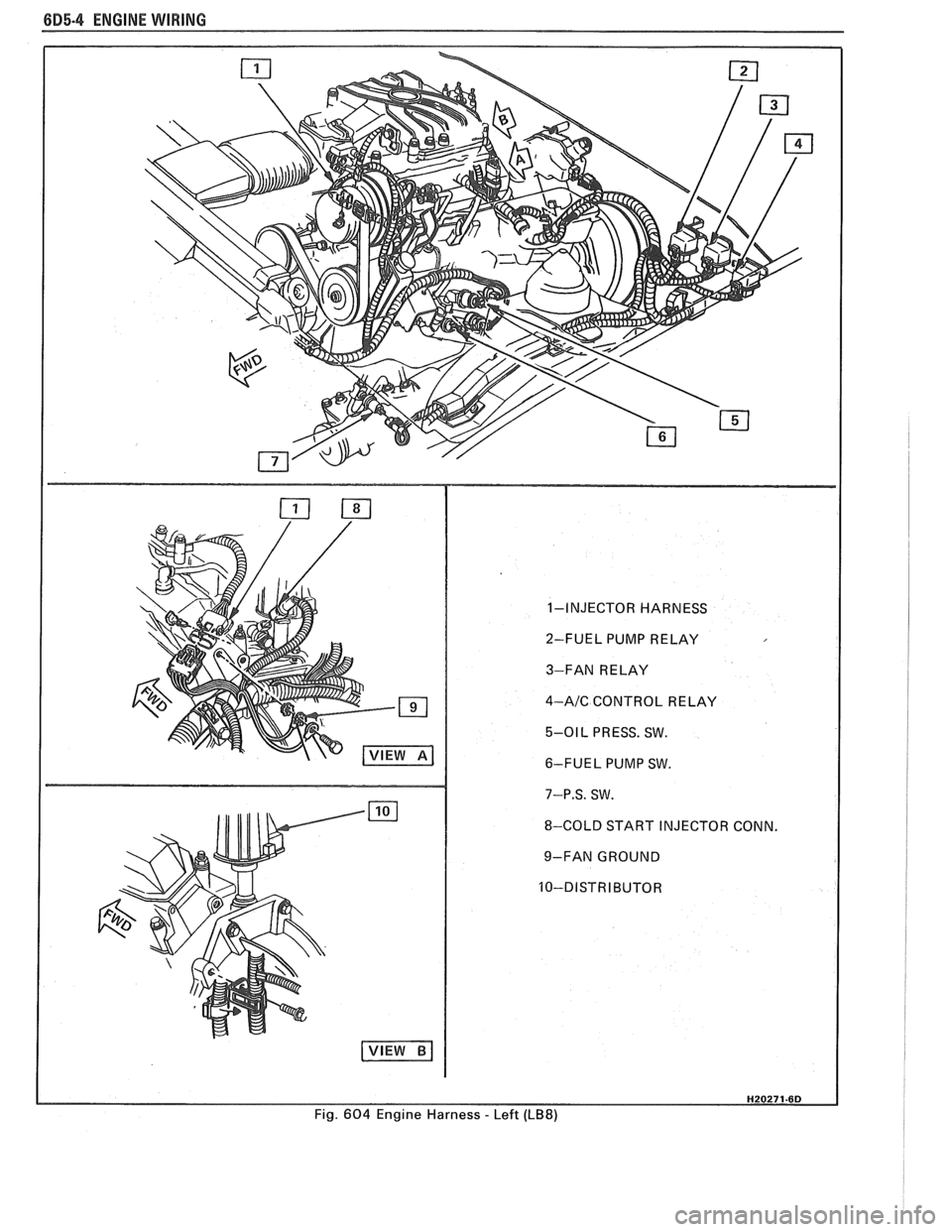

6D5-4 ENGINE WIRING

1-INJECTOR HARNESS

2-FUEL PUMP RELAY

3-FAN RELAY

4-AIC CONTROL RELAY

5-01 L PRESS. SW.

6-FUEL PUMP SW.

7-P.S. SW.

8-COLD START INJECTOR CONN.

9-FAN GROUND

Fig.

604 Engine Harness - Left (LB8)

Page 488 of 1825

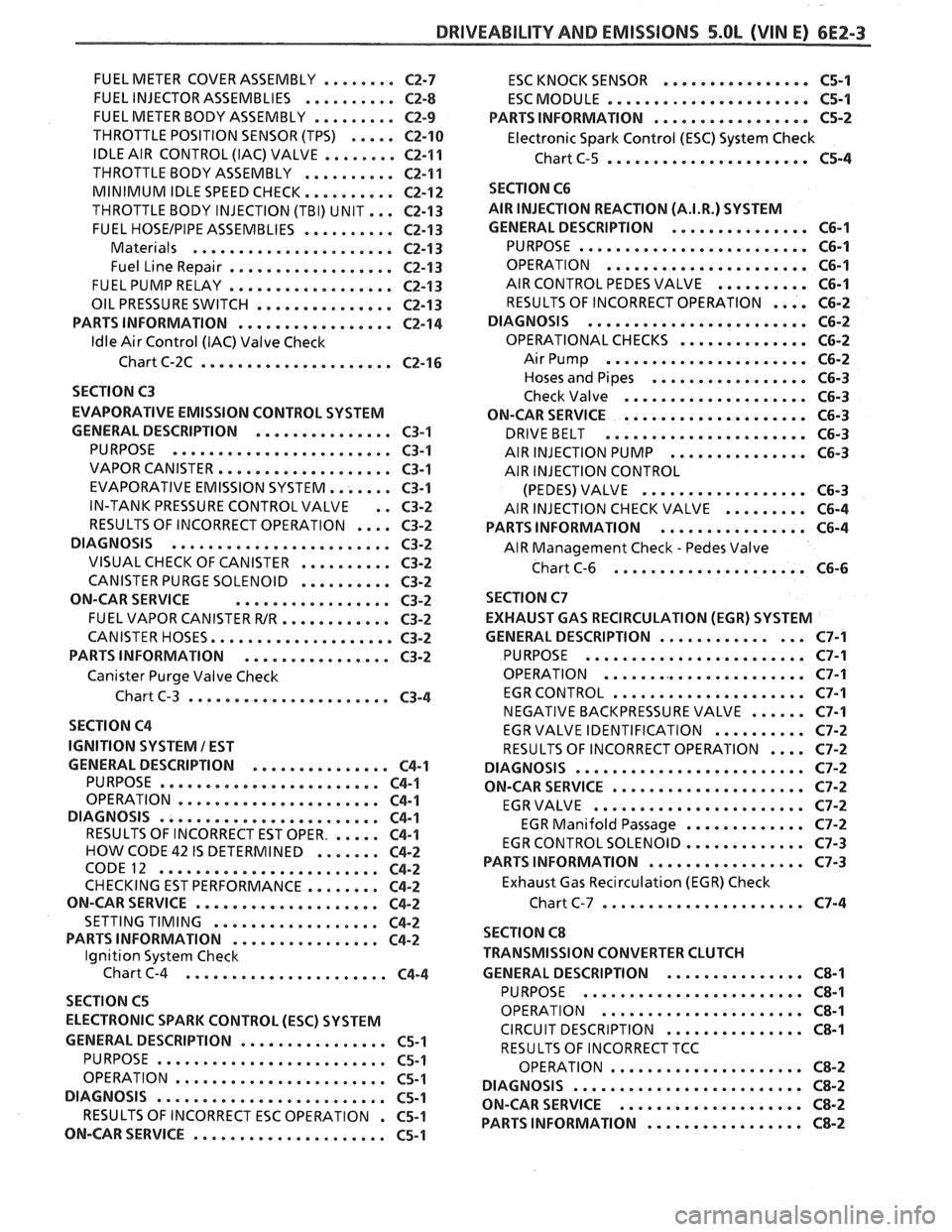

DRIVEABILITY AND EMISSIONS 5.OL (VIN E) 6E2-3

........ FUEL METER COVER ASSEMBLY C2-7

FUEL INJECTOR ASSEMBLIES .......... C2-8

FUEL METER BODY ASSEMBLY ......... C2-9

..... THROTTLE POSITION SENSOR (TPS) C2-10

IDLE AIR CONTROL (IAC) VALVE ........ 62-1 1

THROTTLE BODY ASSEMBLY

.......... C2-11

MINIMUM IDLE SPEED CHECK .......... C2-12

... THROTTLE BODY INJECTION (TBI) UNIT C2-13

FUEL

HOSEIPIPE ASSEMBLIES .......... C2-13

Materials ...................... C2-13

Fuel Line Repair .................. C2-13

FUEL PUMP RELAY .................. C2-13

............... OILPRESSURESWITCH C2-13

PARTS INFORMATION ................. C2-14

Idle Air Control (IAC) Valve Check

Chart C-2C

..................... C2-16

SECTION C3

EVAPORATIVE EMISSION CONTROL SYSTEM

GENERAL DESCRIPTION

............... C3-1

........................ PURPOSE C3-1

VAPOR CANISTER

................... C3-1

EVAPORATIVE EMISSION SYSTEM

....... C3-1

IN-TANK PRESSURE CONTROL VALVE

. . C3-2

.... RESULTS OF INCORRECT OPERATION C3-2

........................ DIAGNOSIS C3-2

VISUAL CHECK OF CANISTER

.......... C3-2

CANISTER PURGE SOLENOID

.......... C3-2

ON-CAR SERVICE ................. C3-2

FUEL VAPOR CANISTER

R/R ............ C3-2

CANISTER HOSES

.................... C3-2

PARTS INFORMATION ................ C3-2

Canister Purge Valve Check

Chart C-3

...................... C3-4

SECTION

C4

IGNITION SYSTEM I EST

GENERAL DESCRIPTION

............... C4-1

PURPOSE ........................ C4-1

OPERATION ...................... C4-1

.. DIAGNOSIS ................... ... C4-1

RESULTS OF INCORRECT EST OPER ...... C4-1

HOW CODE 42 IS DETERMINED ....... C4-2

CODE12 ........................ C4-2

CHECKING EST PERFORMANCE ........ C4-2

ON-CAR SERVICE .................... C4-2

SETTINGTIMING .................. C4-2

PARTS INFORMATION ................ C4-2

Ignition System Check

Chart C-4

................... .. . C4-4

SECTION C5

ELECTRONIC SPARK CONTROL (ESC) SYSTEM

GENERAL DESCRIPTION

................ C5-1

PURPOSE ..*...................... C5-1

OPERATION

....................... C5-1

DIAGNOSIS

......................... C5-1

RESULTS OF INCORRECT ESC OPERATION

. C5-1

ON-CAR SERVICE

..................... C5-1 ESC

KNOCK SENSOR

................ C5-1

ESCMODULE

...................... C5-1

PARTS INFORMATION ................. C5-2

Electronic Spark Control (ESC) System Check

Chart C-5

...................... C5-4

SECTION C6

AIR INJECTION REACTION (A.I.R.) SYSTEM

GENERAL DESCRIPTION

............... C6-1

PURPOSE

.*....................... C6-1

OPERATION

...................... C6-1

AIR CONTROL PEDES VALVE .......... C6-1

RESULTS OF INCORRECT OPERATION

.... C6-2

DIAGNOSIS

........................ C6-2

OPERATIONAL CHECKS

.....*........ C6-2

AirPump ...................... C6-2

Hoses and Pipes

................. C6-3

Check Valve

.................... C6-3

ON-CAR SERVICE

.................... C6-3

DRIVEBELT ...................... C6-3

AIR INJECTION PUMP

............... C6-3

AIR INJECTION CONTROL

(PEDES) VALVE

.................. C6-3

AIR INJECTION CHECK VALVE ......... C6-4

PARTS INFORMATION

................ C6-4

AIR Management Check

. Pedes Valve

Chart C-6

..................... C6-6

SECTION C7

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

GENERAL DESCRIPTION

............... C7-1

PURPOSE

........................ C7-1

OPERATION

...................... C7-1

EGRCONTROL

..................... C7-1

NEGATIVE BACKPRESSURE VALVE

...... C7-1

EGR VALVE IDENTIFICATION

.......... C7-2

RESULTS OF INCORRECT OPERATION

.... C7-2

DIAGNOSIS

......................... C7-2

ON-CAR SERVICE

..................... C7-2

EGRVALVE

....................... C7-2

EGR Manifold Passage

............. C7-2

EGR CONTROL SOLENOID

............. C7-3

PARTS INFORMATION

................. C7-3

Exhaust Gas Recirculation (EGR) Check

Chart C-7

...................... C7-4

SECTION

C8

TRANSMISSION CONVERTER CLUTCH

GENERAL DESCRIPTION

............... C8-1

PURPOSE

........................ C8-1

OPERATION

...................... C8-1

CIRCUIT DESCRIPTION

............... C8-1

RESULTS OF INCORRECT TCC

OPERATION

..................... C8-2

DIAGNOSIS

......................... C8-2

ON-CAR SERVICE .................... C8-2

PARTS INFORMATION ................. C8-2