relay PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 44 of 1825

AIR CONDITIONING 1B-1

SECTION 1B

R COND

When performing air conditioning diagnosis on vehicles equipped with a catalytic converter, it will be necessary to

WARM the engine to a NORMAL operating temperature BEFORE attempting to idle the engine for periods greater

than five

(5) minutes. Once the engine attains normal idle, diagnosis and adjustments can be made.

CONTENTS

.................. General Description .................................. 1B-1 Accumulator Assembly Service .1B-19

.......................... C.C.O.T. A!C System ................................ 1B-1 On-Vehicle Sewice ..... 1B-20

....................................... System Components - Functional ................. 1B-2 Blower Motor .1B-20

..................................... System Components - Control ..................... 1B-3 Hi-Blower Relay 1B-20

...................................... Relays and Switches ................................... 1B-3 Blower Resistor 1B-20

Diagnosis ................................................. 1B-5 Controller, Blower Switch or Vacuum

................................................ Testing the Refrigerant System ...................... 1B-5 Valve .lB-20

Insufficient Cooling "Quick-Check Temperature Control Cable ....................... .1B-20

.................................... Procedure.. ............................................. 1B-5 Vacuum

Harness .lB-20

C.C.O.T. A/C System Diagnostic Control Wiring Harness ........................... .1B-20

..... ................................. Procedure.. ............................................. 1B-8 Heater

Core .. .lB-21

................................ Leak Testing ........................................... 1B-12 Lower Heater Outlet 1B-21

............................... Service Procedures ................................. .1B-12 Heater Module Case .lB-21

.......................... O-Ring Replacement ................................ .1B- 12 Pressure Cycling Switch .1B-21

....................................... Handling Refrigerant- 12 ............................ .1B- 13 Vacuum Tank .lB-21

Discharging, Adding Oil, Evacuating Liquid Line .......................................... .1B-23

and

Charging Procedures - AIC Accumulator ......................................... .1B-23

.................................... Systems .............................................. .1B-14 Evaporator Core .1B-24

In-Line Air Conditioning Evaporator Case .................................... .1B-24

.......................................... Filter

Installation.. .................................. .1B- 18 Compressor .lB-24

.............................................

................ Expansion Tube (Orifice) Service .1 B- 19 Condenser IB-24

GENERAL DESCRIPTION

All engines are equipped with a fixed displace- evaporator temperature. The pressure cycling switch

ment (R-4) air conditioning compressor. This

com- is the freeze protection device in the system and

pressor may cycle on and off under normal air

senses refrigerant pressure on the suction side of the

conditioning demand. system. This switch is located on a standard

Schrader- -

All air conditioning systems that use the fixed

displacement R-4 compressor are referred to as

C. C.O.T. (Cycling Clutch, Orifice Tube) type sys-

tems. This is the same system that has been used on

all General Motors vehicles in the past several years.

The C.C.O.T. NG System

The Cycling Clutch Orifice Tube (C.C.O.T.)

refrigeration system is designed to cycle a compressor

on and off to maintain desired cooling and to prevent

evaporator freeze. Passenger compartment comfort is

maintained by the temperature lever on the controller.

Control of the refrigeration cycle (on and off

operation of the compressor) is done with a switch

which senses low-side pressure as an indicator of type

valve low-side fitting. During air temperatures

over 10°C

(50°F), the equalized pressures within the

charged

A/C system will close the contacts of the

pressure switch. When an air conditioning mode

(max, norm, bi-level, defrost) is selected, electrical

energy is supplied to the compressor clutch coil. AS

the compressor reduces the evaporator pressure

to

approximately 175 kPa (25 psi), the pressure switch

will open, de-energizing the compressor clutch.

As

the system equalizes and the pressure reaches approxl-

mately 315 kPa (46 psi), the pressure switch contacts

close, re-energizing the clutch coil. This cycling

coy

tinues and maintains average evaporator discharge air

temperature at approximately 1°C (33°F). Because of

this cycling, some slight increases and decreases of

engine speedlpower may be noticed under certain con-

ditions. This is normal as the system is designed

to

cycle to maintain desired cooling, thus preventing

evaporator freeze-up.

Page 46 of 1825

AIR CONDITIONING 1 B-3

A low-side pressure Schrader valve service fit-

ting is located near the top of the accumulator. A

similar Schrader fitting may be provided for mounting

the pressure cycling switch. It is not necessary to dis-

charge the system to replace the switch. The accumu-

lator is serviced only as a replacement assembly.

Heater Core

The heater core heats the air before it enters the

car. Engine coolant is circulated through the core to

heat the outside air passing over the fins of the core.

The core is functional at all times (no water valve) and

may be used to temper conditioned air in

A/C mode,

as well as heat or vent mode.

SYSTEM COMPONENTS --- CON"FOL

Controller

The operation of the A/C system is controlled by

the switches and the lever on the control head. The

compressor clutch and blower are connected electri-

cally to the control head by a wiring harness. The

blower circuit is open in the off mode and air flow is

provided by the four blower speeds available in the

remaining modes. Cooled and dehumidified air is

available in the max, normal, bi-level and defrost

modes.

Temperature is controlled by the position of the

temperature lever on the control head. A cable con-

nects this lever to the temperature door which controls

air flow through the heater core. As the temperature

lever is moved through its range of travel, a sliding

clip on the cable at the temperature valve connection

should assume a position assuring that the temperature

door will seat in both extreme positions. Temperature

door position is independent of mode selection. The

temperature cable attaches to the right side of the air

conditioning module. The temperature door on some

models is controlled electrically, thereby eliminating

the need for the temperature cable.

The electric engine cooling fan on some cars is

not part of the

A/C system; however, the fan is

operational any time the

A/C control is in Max.,

Norm, or Bi-Level modes. Some models provide for

engine cooling fan operation when the controller is in

the defrost mode. This added feature is part of the

A/C

controller function and is aimed at preventing exces-

sive compressor head temperatures. It also allows the

A/C system to function more efficiently. On some

models during road speed (above

35 mph) conditions

when air flow through the condenser coil is adequate

for efficient cooling, the engine cooling fan will be

turned off. The operation of the cooling fan is con-

trolled by the ECM through the cooling fan relay.

Complete wiring diagrams and diagnosis for the

AIC Electrical System are in Section 8A. Section 8A

also contains additional diagnostic information

regarding air flows and vacuum logic.

Vacuum Lines

Vacuum lines are molded to a connector which

is attached to a vacuum control switch on the control

head assembly.

In case of leakage or hose collapse, it will not be

necessary to replace the entire harness assembly.

Replacement can be made by cutting the hose and

inserting a plastic connector. If an entire hose must be

replaced, cut all hoses off at the connector and then

attach hoses directly to the control head vacuum

switch. (NOTE: The Fiero uses an electric motor to

control mode selection. Therefore, it will not have a

vacuum harness.

)

Vacuum Tank

During heavy acceleration, the vacuum supply

from the carburetor drops. A check valve in the vac-

uum tank maintains vacuum so that, under load condi-

tions, vacuum will be available for continuous use.

REWVS AND SWITCHES

High-Pressure Compresssr Gut-OFF Switch

The high-side, high-pressure cut-off switch in

the rear head of the compressor is a protective device

intended to prevent excessive compressor head pres-

sures and reduce the chance of refrigerant escape

through a safety relief valve. Normally closed, this

switch will open the circuit at a high-side pressure of

approximately 2700

kPa (430 psi 9 20 psi) and

reclose the circuit at approximately 1379 kPa (200 psi

9 50 psi).

Lsw-Pressure Cut-On Switch

Compressor protection is provided on some cars

by a low-pressure cut-off switch which will open in

the event of a low-charge condition. This switch can

be located in the liquid line or in the rear head of the

compressor. This switch will also keep the compres-

sor from running during cold weather.

Pressure eyesing Switch

The refrigeration cycle (on and off operation of

the compressor) is controlled by a switch which

senses the low-side pressure as an indicator of evapo-

rator temperature. The pressure cycling switch is the

freeze protection device in the system and senses

refrigerant pressure on the suction side of the system.

This switch is located on a standard Schrader-type

valve low-side fitting. This switch also provides com-

pressor cut-off during cold weather.

Additional compressor protection results from

the operating characteristics of the low-side pressure

cycling system. If a massive discharge occurs or the

orifice tube becomes plugged, low-side pressures

could be insufficient to close the contacts of the pres-

sure switch. In the event of a low charge, insufficient

cooling accompanied by rapid compressor clutch

cycling will be noticed at high air temperatures.

Page 47 of 1825

18-4 AIR CONDITIONING

If replacement of the pressure cycling switch is

necessary, it is important to note that this may be done

without removing the refrigerant charge.

A Schrader-

type valve is located in the pressure switch fitting.

During replacement of the pressure switch, a new

oiled O-ring must be installed and the switch assem-

bled to the specified torque of

6- 13 N*m (5- 10 lb. ft.).

Power Steering Gut-OH, or Anticipate

Switch

Engine idle quality on some cars is maintained

by cutting off the compressor (switch normally

closed) when high power steering loads are imposed.

On other cars the switch (normally open) provides a

signal to the ECM to allow engine control systems to

compensate for high-power steering loads.

Wide-Open Tkroale (WOT) Compressor

Cut-Out

Switch

A switch located on the throttle corltrols of some

carburetor equipped cars opens the circuit to the com-

pressor clutch during full throttle acceleration. The

switch activates a relay that controls the compressor

clutch. During full throttle acceleration

on cars

equipped with TBI or

Em, the TPS sends a signal to

the ECM, thereby controlling the compressor clutch.

Air Conditioning Time Delay Relay

This relay on some cars controls the current to

the entire air conditioning system and provides a short

delay of air conditioning operation upon start-up.

Constant Run Relay

Engine idle quality on some cars is maintained

by a "constant run" system (constant run relay) that

eliminates compressor cycling during engine idle for a

predetermined time after the vehicle has come to rest

from road speed.

If the idle period continues for an

extended time, the

A/C system may return to a con-

ventional C.C.O.T. mode for a short time to prevent

system freeze-up. The

A/C control relay and constant

run relays are both controlled by the Electronic Con-

trol Module (ECM) which determines operating con-

ditions by evaluating input from the distributor

(engine speed), vehicle speed sensor, air sensor and

A/C compressor "on" signal.

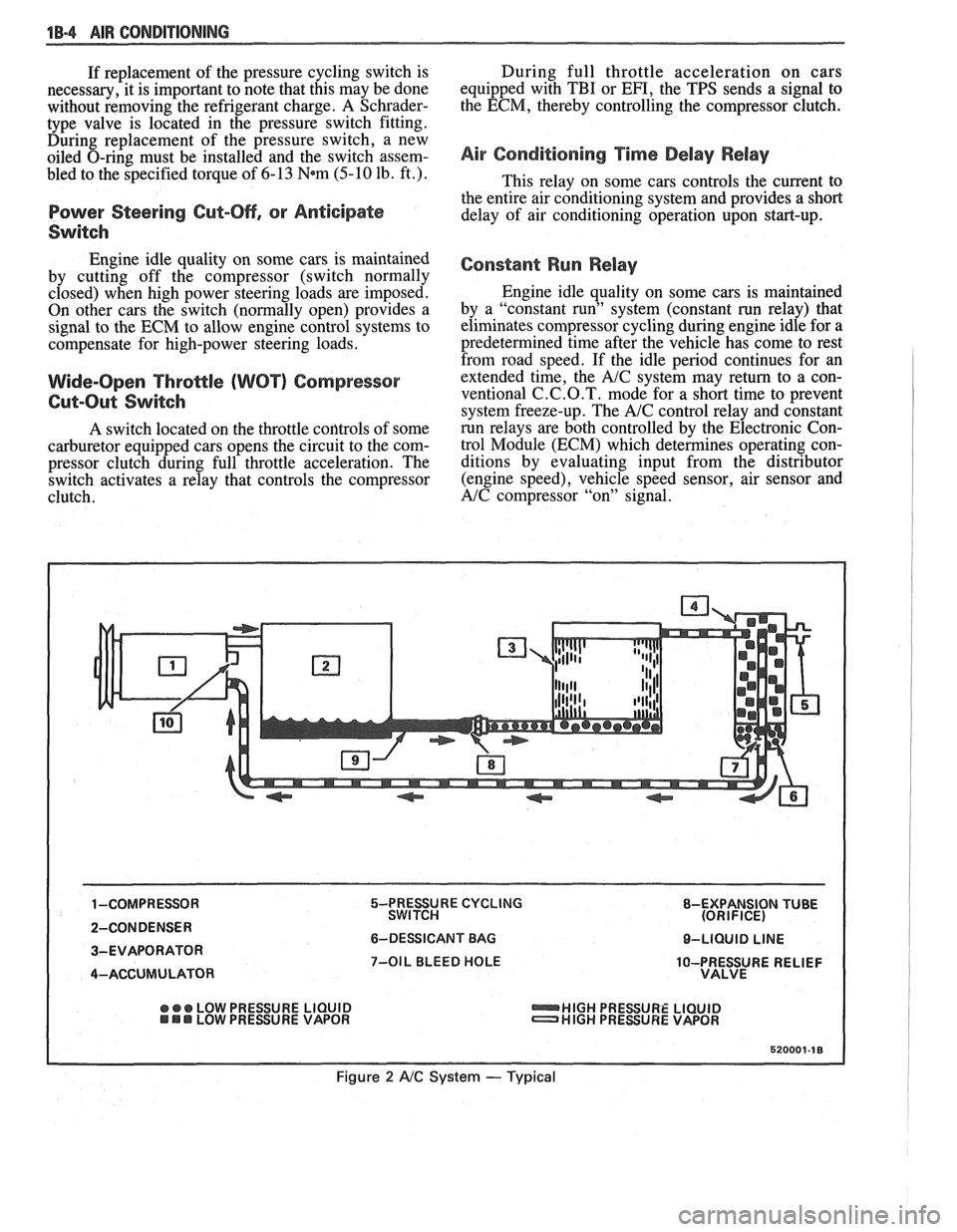

5-PRESSURE CYCLING 8-EXPANSION TUBE

SWITCH (ORIFICE)

6-DESSICANT BAG O-LIQUID LINE

7-OIL BLEED HOLE

10-PRESSURE RELIEF

VALVE

@ ee LOW PRESSURE LIQUID HIGH PRESSURE LIQUID LOW PRESURE VAPOR HIGH PRESSURE VAPOR

Figure 2 A/C System - Typical

Page 63 of 1825

18-28 AIR CONDITIONING

DO NOT REPLACE the accumulator assembly

when:

1. Merely a dent is found in the outer shell of the

accumulator.

2. A

vehicle is involved in a collision and no phys-

ical perforation to the accumulator is found.

OM-VEHICLE SERVICE

R-"1 CHARGING CAPACITIES

The 420ml (14 fl. oz.) disposable can of R-12

refrigerant is equivalent to .399 kg (. 88 lb.).

BLOWER MOTOR

a Remove or Disconnect

1. Disconnect negative battery cable.

2. Remove motor cooling tube.

3. Disconnect electrical connections.

4. Remove blower motor attaching screws, remove

motor and case assembly.

5. Loosen retaining nut and remove blower cage

from motor shaft.

6. Inspect blower cage for broken vanes, etc.

Replace if necessary.

Install or Connect

1. Reverse removal procedure to reinstall. Replace

seals or sealant as required.

HI-BLOWER RELAY

Relay is a plug-in type with connector mounted

on top of the evaporator case.

BLOWER RESISTOR

Remove or Disconnect

1. Disconnect negative battery cable.

2. Disconnect electrical connections.

3. Remove two (2) screws, remove resistor.

Install or Connect

1. Reverse removal procedure to reinstall.

CONTROLLER, BLOWER SWITCH OR

WCUUM VALVE

Remove or Disconnect

1. Disconnect negative battery cable.

2. Remove NC control-radio console trim plate.

3. Remove three (3) NC control retaining screws.

4. Pull A/C control out and disconnect electrical

and vacuum connections and remove tempera-

ture cable.

5. Remove A/C control and replace vacuum valve

or blower switch as required.

Install or Connect

1. Reverse removal procedure to reinstall. Install

lower right screw in controller first to align con-

troller in console.

TEMPERATURE CONTROL CABLE,

VACUUM HARNESS

Remove or Disconnect

1. Remove the following hush panel(s):

a. Vacuum Harness - R.H. and L.H. hush

panel.

b. Temperature Cable

- R.H. hush panels.

Remove

controller/radio console trim plate.

Remove three (3) controller screws and pull

controller partially out of console.

Disconnect controller

end(s) of temperature

cable

andlor vacuum harness.

Disconnect component

end(s) of temperature

cable

andlor vacuum harness.

Install or Conned

1. Reverse removal procedure to reinstall. When

installing controller, install lower right screw

first to align controller location. Replace any

retaining straps, etc. removed.

2. Perform functional check of controller.

CONTROL WlRlNG HARNESS

a Remove or Disconnect

1. Disconnect negative battery cable.

2. Remove

control/radio console trim plate and

hush panels (see Section

8C).

3. Remove three (3) screws holding control in con-

sole and pull control out far enough to discon-

nect electrical and vacuum connector. Remove

controller.

4. Remove instrument panel carrier (see Section

8C).

5. Remove heater case covers (core and mode door

sides).

6. Remove two (2) interior screws and one (1)

exterior nut holding case to cowl. Pull left side

of case back to gain access to harness at cowl.

Case will still be retained by one (I) screw

behind the evaporator core

- do not attempt

complete removal of case. -

7. Loosen cowl grommet and disconnect purple

vacuum line.

Page 64 of 1825

AIR CONDITIONING 18-21

8. Disconnect blower motor

and blower resistor

electrical connection.

9. Remove hi-blower relay connector from evapo-

rator case.

10. Carefully pull

cowl grommet from cowl and pull

wiring

hmess into engine compartment.

Install or Connect

1. Reverse removal procedure to

reinstall. When

reinstalling controller, install lower right screw

first to align controller.

ACNENTILATIONIDEFROSVER DUCTS

See section 8C for removal.

HEATER CORE

Remove or Disconnect

1. Negative battery cable.

2. Drain cooling system.

3. Remove heater inlet and outlet hoses

from

heater core.

4. Remove right lower hush panel (see Section

8C).

5. Remove right

lower I.P. trim panel (see Section

8C) .

6. Remove lower right I.P. carrier to cowl screw.

7. Remove ECM attaching screws and move to the

side.

8. Remove four

(4) heater case cover screws.

Upper left screw may be reached with a long

318 ' socket extension through the I.P. openings

exposed by removal of the lower right I.P. trim

panel. Carefully lift the lower right corner of the

I.P. to align socket extension.

9. Remove heater case cover.

10. Remove core support plate

and baffle screws.

- -

11. Remove

heater core, support plate and baffle

from case.

Install or Conned

1. Reverse removal procedure to reinstall. Restore

all seals

and/or sealant disturbed during removal

procedure.

2. Refill cooling system and check for leaks.

LOWER (FLOOR) )-IEA"FEB$OU"fET

Remove or Disconnect

1. Console. (See Section 8C.)

2. L.H. and R.H. hush panels.

3. Two (2) floor outlet retaining screws.

4. Floor outlet from core case.

lnstall or Connect

1. Floor outlet to core case.

2. Two (2) floor outlet retaining screws.

3. L.H. and R.H. hush panels.

4. Console.

HEATER MODULE (CASE)

Remove or Disconnect

1. Disconnect negative battery cable.

2. Drain cooling system.

3. Remove hush panels and instrument panel car-

rier (see Section

8C).

4. Remove lower heater outlets.

5. Disconnect control cables and vacuum hoses at

module and controller.

6. Remove heater core.

7. Remove two (2) interior screws and one (I)

exterior nut holding case to cowl.

8. Remove evaporator core.

9. Remove screw holding case to cowl from engine

compartment side.

10. Remove case (module).

11. Transfer usable parts to new case (module).

lnstall or Conned

1. Reverse removal procedure to reinstall.

2. Refill coolant system.

3. Recharge

A/C system.

4. Inspect A/C and cooling system for leaks.

NC PRESSURE CYCLING SWITCH

Do not discharge A/C system. Pressure cycling

switch is mounted on

a Schrader-type valve.

Remove or Disconnect

1. Disconnect switch electrical connection.

2. Remove switch.

Install or Connect

1. Reverse removal procedure to reinstall. Tighten

switch to

4-5.5 N*m (35-49 in. lb.).

Ale CONTROL VACUUM TANK

Remove or Disconnect

1 . Disconnect vacuum hoses.

2. Remove vacuum

tank attaching screws, remove

tank.

lndall or Connect

1. Reverse removal procedure to

reinstall.

Page 67 of 1825

1B-24 AIR CONDPTIBNING

EVAPORATOR CORE

Remove QP Disconnect

1. Discharge A/C system.

2. Remove accumulator.

3. Remove two (2) screws and remove hi-blower

relay terminal.

4. Remove upper case screws.

5. Relocate wiring harness and remove dipstick.

6. Disconnect liquid line fitting.

7. Remove upper case and lift evaporator core out

of case (retain foam wedge).

Install or Connect

1. Reverse removal procedure to reinstall.

2. Recharge and test system for proper operation.

EVAPBRAWORCASE

Remove or Disconnect

1. Remove accumulator.

2. Remove blower motor.

3. Remove evaporator core.

Remove lower case to cowl screws (three driven from engine compartment, three driven from

interior).

Remove case from cowl.

Install or Connect

Reverse removal procedure to reinstall. Rein-

stall or replace gaskets, seal and sealant

removed during disassembly.

Recharge and test system for proper operation.

NG COMPRESSOR (TYPICAL)

Remove or Disconnect

1. Discharge A/C system.

2. Remove fitting block (coupled hose assembly)

bolt at rear of compressor.

3. Remove mounting bracket bolt(s) .

4. Remove drive belt (route lower loop behind har-

monic balancer to gain additional slack if

required).

5. Remove compressor. If complete compressor is

to be replaced, transfer usable switches, etc. to

new compressor.

Install or Connect

1. Reverse removal

procedure to reinstall. Use

new O-rings lubricated with

525 viscosity

refrigerant oil. Refer to Section

6B for drive belt

tension.

2. Evacuate and recharge system.

CONDENSER

a Remove or Disconnect

1. Discharge A/C system.

2. Disconnect coupled hose and liquid line fittings.

3, Remove screws retaining top radiator shield.

4. Remove top condenser retaining screws.

5. Carefully move (tilt) radiator rearward and lift

condenser out of radiator support.

6. Transfer brackets and mounts to new condenser

if replacement is necessary.

Install or Connect

1. Reverse removal procedure to reinstall. Use

new O-rings lubricated with

525 viscosity

refrigerant oil.

2. Recharge and test system for proper operation.

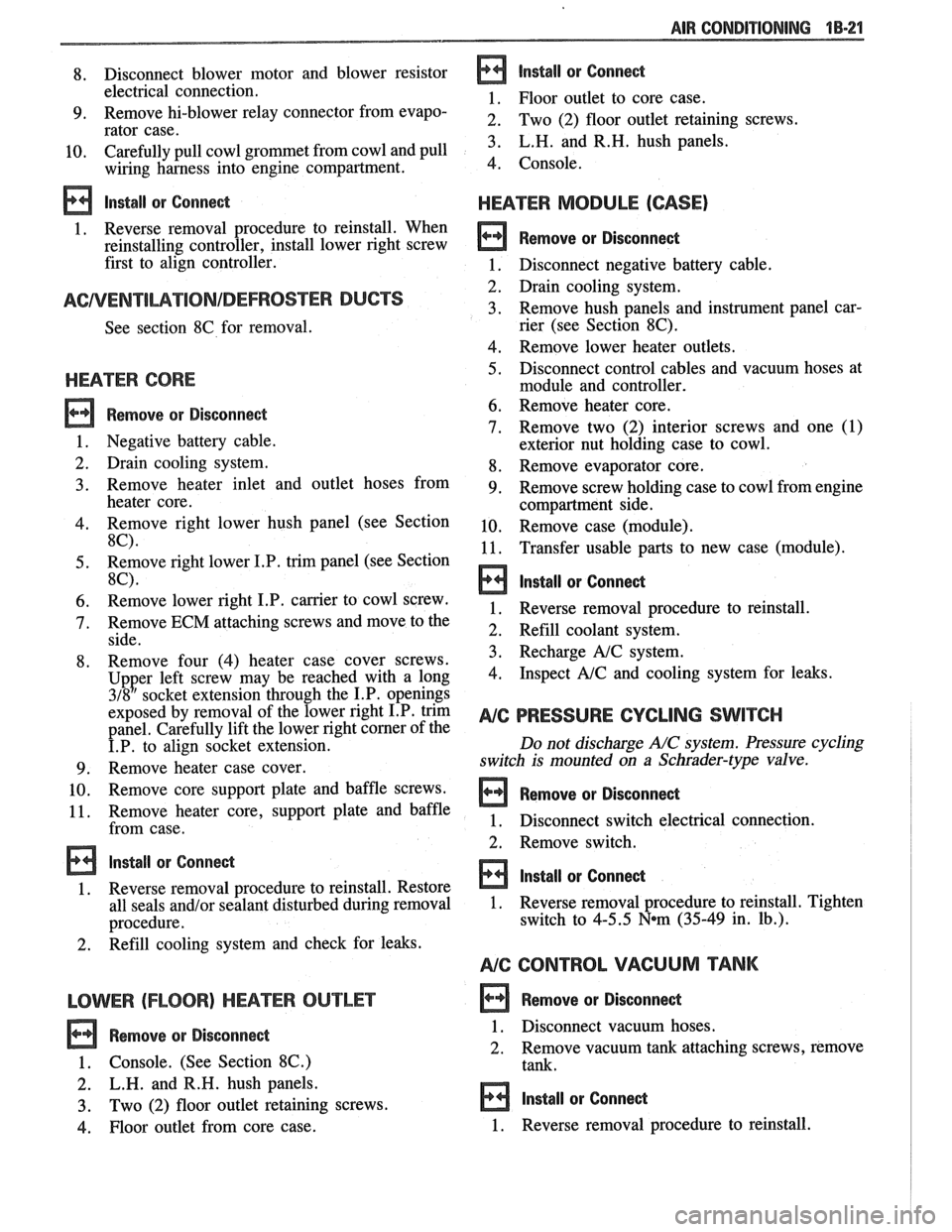

1. HEATER AND DEFROSTER ASSEMBLY

2. 1.4

N.m (12 LBS. IN.) INSTALL FIRST

3. CONSOLE ASSEMBLY

4.

1.4 Narn (12 LBS. IN.)

5. FLOOR OUTLET ASSEMBLY

Figure 21 Floor Outlet

Page 72 of 1825

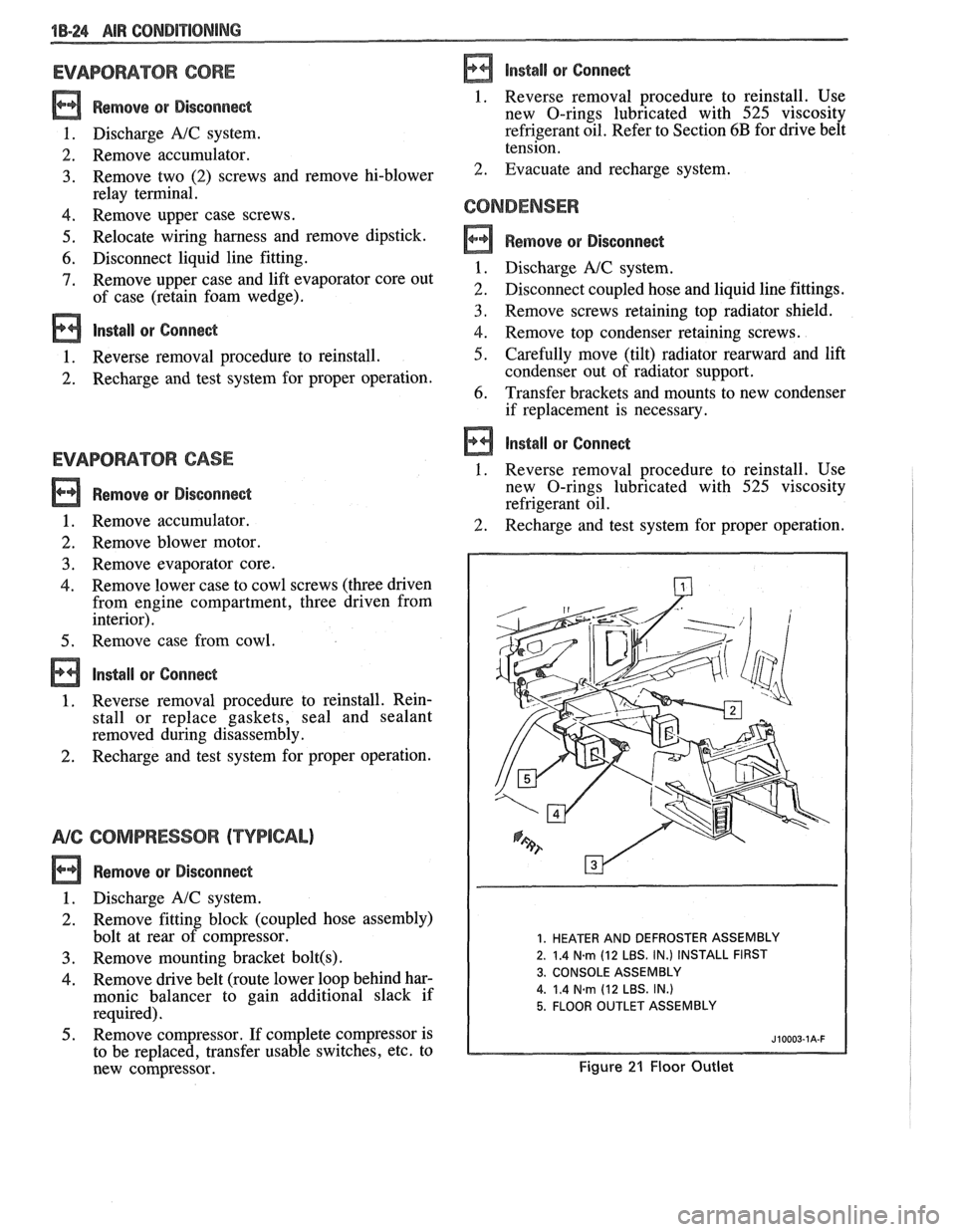

AIR CONDITIONING 1B-29

1. 1.5 N.m (13 LBS. IN.) 8. BRACKET

2. SWITCH

9. AJC COMPRESSOR RELAY

3. ACCUMULATOR 10. BRAKE BOOSTER

4. HARNESS 11.

FUEL PUMP RELAY

5. BLOWER RESISTOR 12. FAN RELAY

6. HI BLOWER RELAY 13. AJC CONTROL

RELAY

7. BLOWER RELAY 14. BULK HEAD

J10255-18-F

Figure 27 A/C Module and Cowl Wiring

Page 188 of 1825

STEERING LINKAGE 3B6-1

SECTION 3B6

STEERING LINKAGE

The following notice applies to one or more steps in the assembly

procedure of components in this portion of the manual as Notice indicated at

appropriate locations by the terminology "See Caution on Page

1 of this

Section

" .

NOTICE: These fasteners are important attaching parts in that they

could affect the performance of vital components and systems,

andlor could

result in major repair expense. They must be replaced with one of the same

part number or with an equivalent part if replacement becomes necessary. Do

not use a replacement part of lesser quality or substitute design. Torque

values must be used as specified during reassembly to assure proper retention

of these parts. For prevailing torque

nut(s) and bolt(s), refer to the "Reuse of

Prevailing Torque

Nut(s) and Bolt(s)" chart in Section 10.

CONTENTS

General Description ........................................... 3B6- 1 Relay Rod ............................................................ 3B6-3

Maintenance and Adjustments ............................... 3B6- I Idler Arm ............................................................. 3B6-4

On-Car Service ........................................................ 3B6-2 Pitman Arm ......................................................... 3B6-5

Tie Rods .............................................................. 3B6-2 Specifications ........................................................... 3B6-6

GENERAL DESCRIPTION

A parallelogram type steering linkage connects both

steering gear. The right end of the relay rod is supported by

front wheels to the steering gear through the

pitman arm,

the idler arm which pivots on a support attached to the

The right and left tie rods are attached to the steering arms

frame rail. The

pitman arm and idler arm remain parallel to

and to the relay rod by ball studs. The left end of the relay

each other while they move through symmetrical arcs. See

rod is supported by the

pitman arm, which is driven by the Fig. 3B6-2.

MAONTENANCE AND ADJUSTMENTS

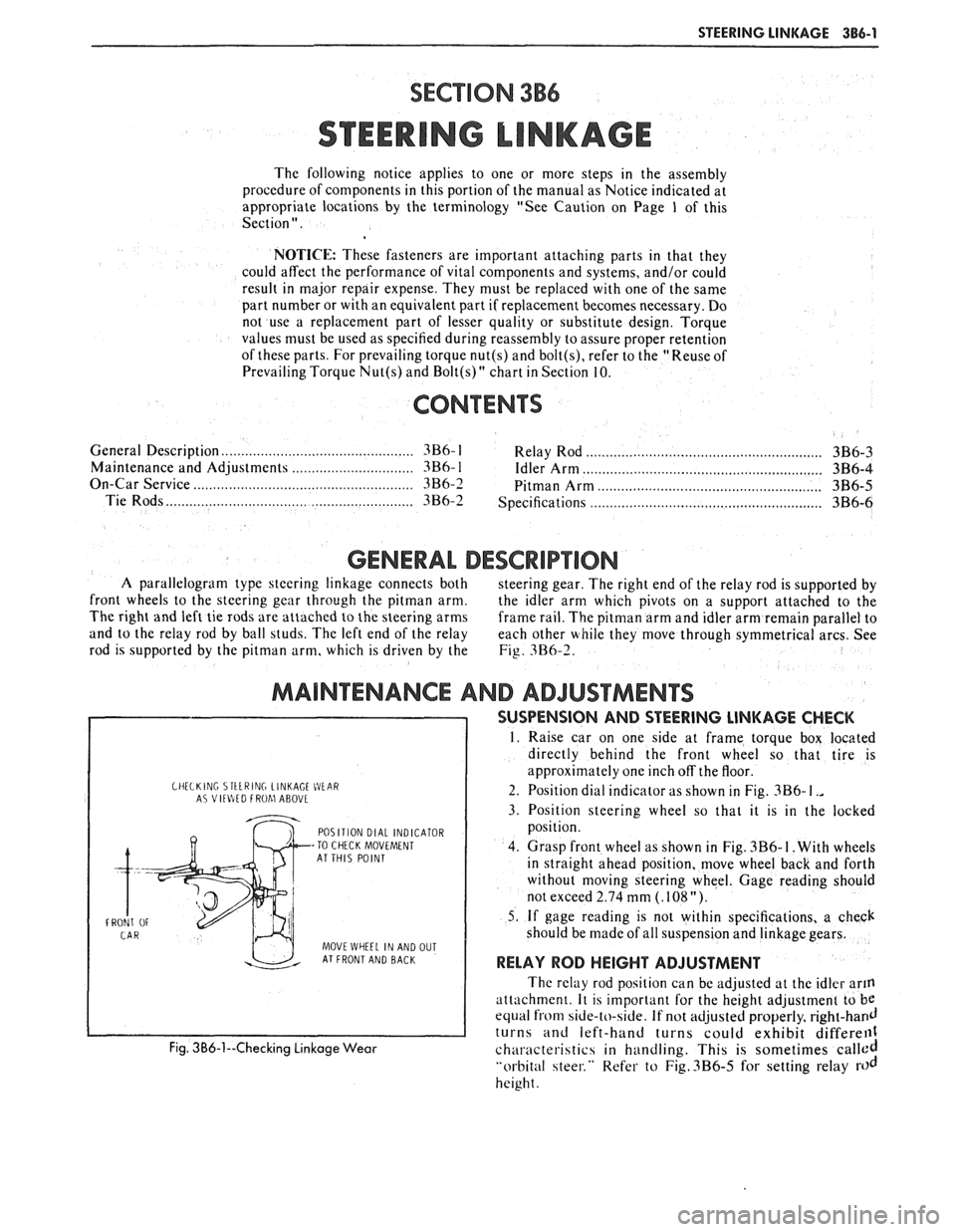

CHELKlNC STtLRING LINKAGE WEIR A? VltlItD FROhl ABOVL

POSITION DIAL INDICATOR

-TO CHECK MOVEMENT

AT THIS POINT

FRONT

OF

MOVE WHEEL IN AND OUT AT FRONT AND BACK

Fig. 3B6-1--Checking Linkage Wear

SUSPENSION AND STEERING LINKAGE CHECK

1. Raise car on one side at frame torque box located

directly behind the front wheel so that tire is

approximately one inch off the floor.

2. Position dial indicator as shown in Fig.

3B6- I .,

3. Position steering wheel so that it is in the locked

position.

4. Grasp front wheel as shown in Fig.

3B6- I. With wheels

in straight ahead position, move wheel back and forth

without moving steering wheel. Gage reading should

not exceed 2.74 mm

(. 108 ").

5. If gage reading is not within specifications, a check

should be made of all suspension and linkage gears.

RELAY ROD HEIGHT ADJUSTMENT

The relay rod position can be adjusted at the idler arm

attach men^. It is important for the height adjustment to be

equal from side-to-side. If not adjusted properly, right-hand

turns and left-hand turns could exhibit differell1

characteristics in handling. This is sometimes called

"orbital steer." Refer to Fig.3B6-5 for setting relay rod

height.

Page 189 of 1825

386-2 STEERING LINKAGE

LUBRICATION ADJUSTMENTS

The steering linkage should be lubricated with any

water resistant

EP type chassis lubricant at specified Toeein

intervals. Lubrication points and additional information on Adjust

the steering linkage for proper toe-in setting as

chassis lubrication can be found in Section

OB. outlined in Section 3A.

ON-CAR SERVICE 3. To remove outer ball stud, use a tool such as

RELAY ROD

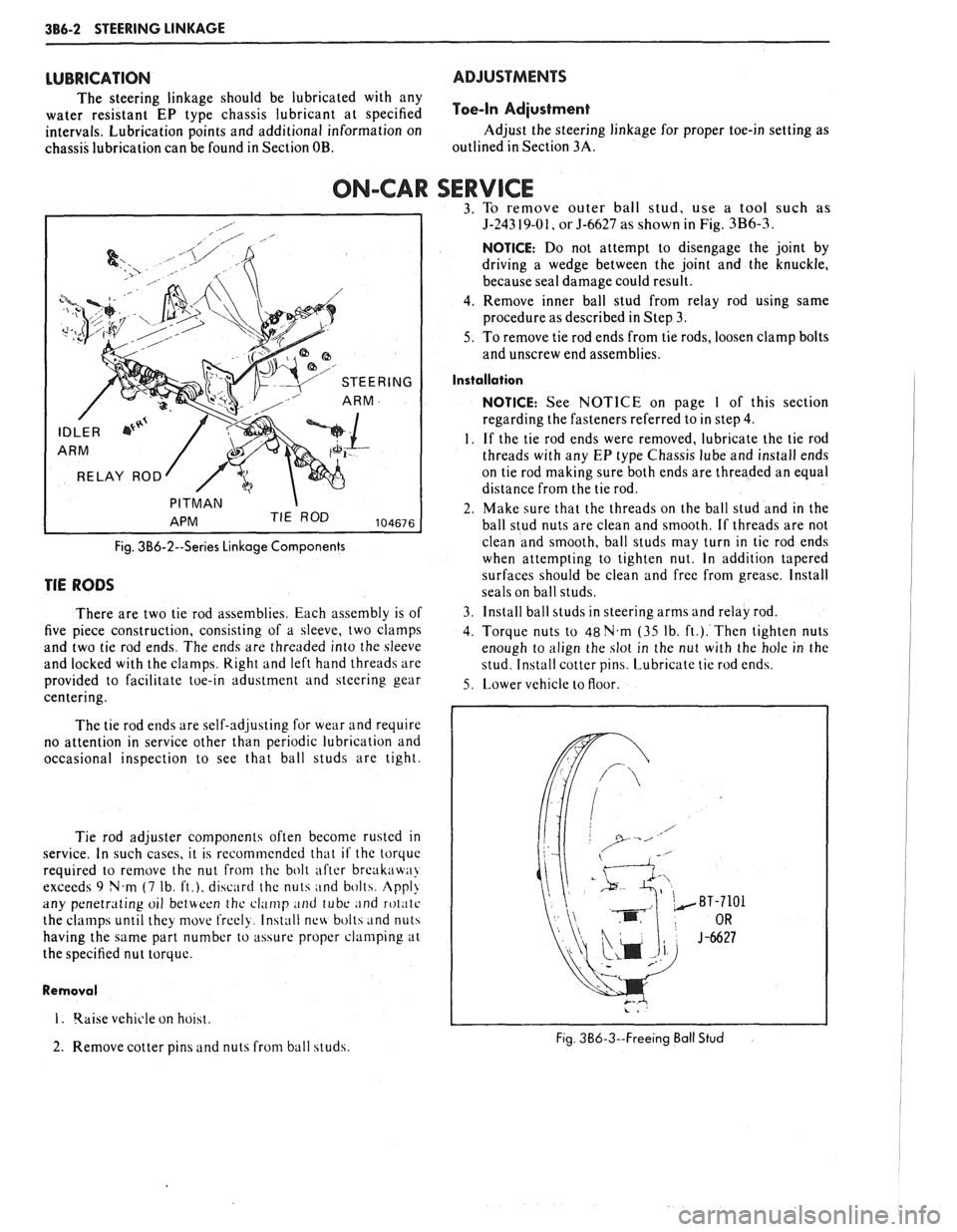

Fig. 3B6-2--Series Linkage Components

TIE RODS

There are two tie rod assemblies. Each assembly is of

five piece construction, consisting of a sleeve, two clamps

and two tie rod ends. The ends are threaded into the sleeve

and locked with the clamps.

Right and left hand threads are

provided to facilitate toe-in adustment and steering gear

centering.

The tie rod ends are self-adjusting for wear and require

no attention in service other than periodic lubrication and

occasional inspection to see that ball studs are tight.

Tie rod adjuster components often become rusted

in

service. In such cases, it is recommended that if the torquc

required to remove the nut from thc bolt after break:iw:~>

exceeds 9 N.m (7 Ib, ft.), discard the nuts and bolth. Appl!

any penetrating oil betwoon thc clamp and tube ;~nd roliitc

the clamps until they movt. frcely. Install nc\4 bolts and nuts

having the same part number to assure proper clamping at

the specified nut torque.

Removal

I. qaise vehicle on hoiht.

2. Remove cotter pins and nuts from ball studs.

5-243 19-01, or 5-6627 as shown in Fig. 3B6-3

NOTICE: Do not attempt to disengage the joint by

driving a wedge between the joint and the knuckle,

because seal damage could result.

4. Remove inner ball stud from relay rod using same

procedure as described in Step 3.

5. To remove tie rod ends from tie rods, loosen clamp bolts

and unscrew end assemblies.

Installation

NOTICE: See NOTICE on page I of this section

regarding the fasteners referred to in step

4.

1. If the tie rod ends were removed, lubricate the tie rod

threads with any

EP type Chassis lube and install ends

on tie rod making sure both ends are threaded an equal

distance from the tie rod.

2. Make sure that the threads on the ball stud and in the

ball stud nuts are clean and smooth. If threads are not

clean and smooth, ball studs may turn in tie rod ends

when attempting to tighten nut. In addition tapered

surfaces should be clean and free from grease. Install

seals on ball studs.

3. Install ball studs in steering arms and relay rod.

4. Torque nuts to 48N.m (35 Ib. ft.). Then tighten nuts

enough to align the slot in the nut with the hole in the

stud. Install cotter pins. Lubricate tie rod

end\.

5. Lower vehicle to floor.

Fig. 3B6-3--Freeing Ball Stud

Page 190 of 1825

STEERING LINKAGE 386-3

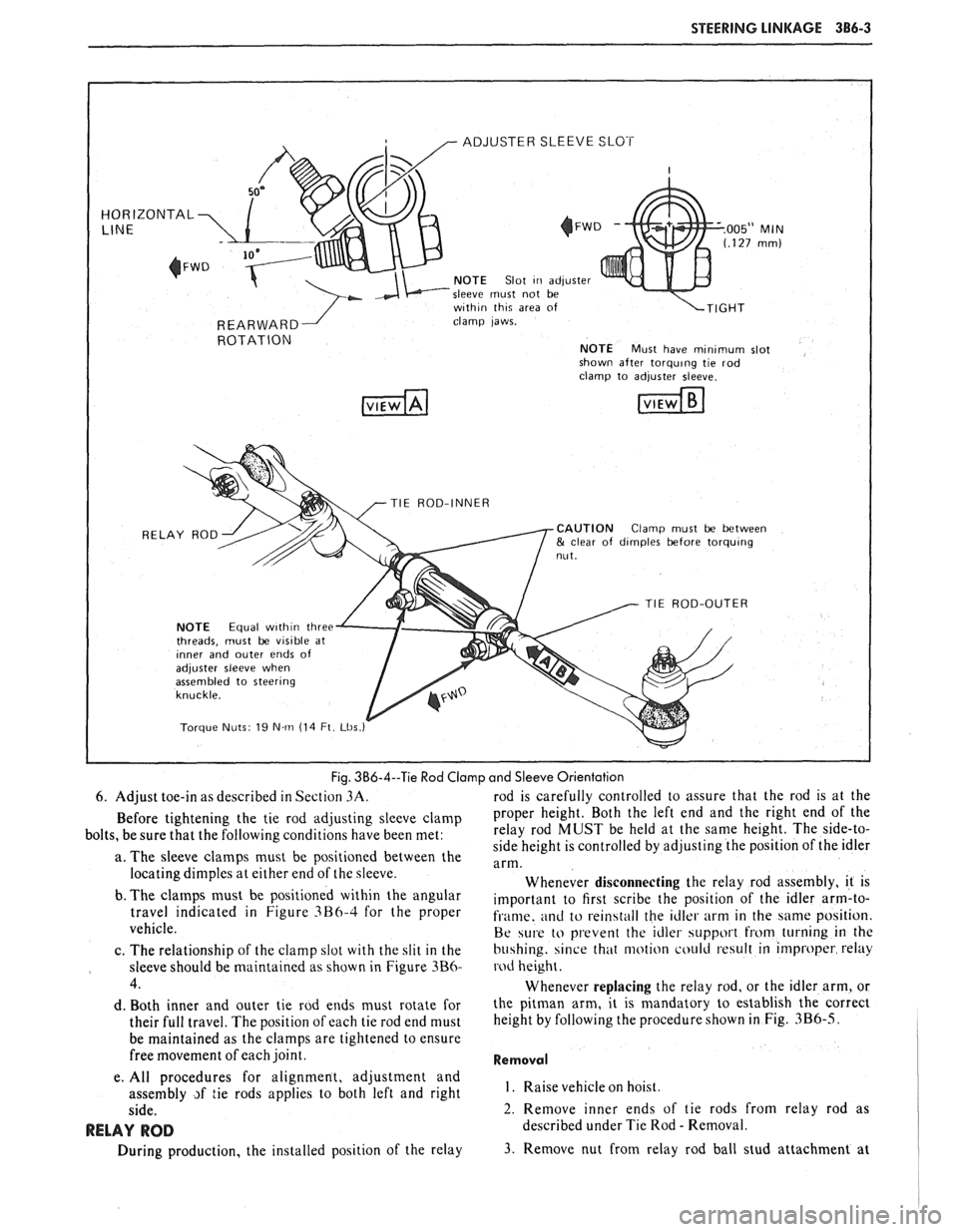

ADJUSTER SLEEVE SLOT

HORIZONTAL

NOTE Slot Iri adjuster

sleeve must not be

w~th~n th~q area of

clamp laws.

ROTATION NOTE Must have mlnlmum slot

shown after torqulng tie rod

TIE ROD-INNER

RELAY ROD

CAUTION Clamp must be between & clear of d~mples before torqulng

TIE ROD-OUTER

NOTE Equal w~th~n three

threads, must be vis~ble at Inner and outer ends of adjuster sleeve when

assembled to steerlng

Torque Nuts 19 N m (14 Ft Lbs

Fig. 3B6-4--Tie Rod Clamp and Sleeve Orientation

6. Adjust toe-in as described in Section

3A. rod is carefully controlled to assure that the rod is at the

Before tightening the tie rod adjusting sleeve clamp Proper height. Both the left end and the right end of the

bolts, be sure that the following conditions have been met: relay

rod MUST be held at the same height. The side-to-

side height is controlled by adjusting the position of the idler

a. The sleeve clamps must be positioned between the

arm. locating dimples at either end of the sleeve.

Whenever disconnecting the relay rod assembly, it is

b. The

clalnps must be positioned within the angular important to first scribe the position of the idler arm-to- travel indicated in Figure 3B6-4 for the Proper fi.ame. and to rein4tall the idler arm in the same position.

vehicle.

Be w1.e to prevent the idler support hom turning in the

c. The relationship of the clamp slot with the slit in the

bu4hing. since that motion could result in improper relay

sleeve should be maintained as shown in Figure

3B6- rod height.

4. Whenever replacing the relay rod, or the idler arm, or

d. Both inner and outer tie rod ends must rotate for the pitman arm, it is mandatory to establish the correct

their full travel. The position of each tie rod end must height

by following the procedure shown

in Fig. 3B6-5.

be maintained as the clamps are tightened to ensure

free movement of each joint.

Removal

e. All procedures for alignment, adjustment and

assembly

~f tie rods applies to both left and right I. Raise vehicle hoist.

side. 2. Remove inner ends of tie rods from relay rod as

RELAY ROD described under Tie Rod - Removal.

During production, the installed position of the relay

3. Remove nut from relay rod ball stud attachment at