transmission fluid PONTIAC FIERO 1988 Service User Guide

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 418 of 1825

ENGINE COOLING BB-7

NOTICE: If recommended quality antifreeze is

used, supplemental inhibitors or additives claiming

to provide increased cooling capability are not

necessary. They may be detrimental to the efficient

operation of the system, and represent an

unnecessary operating expense.

Every 12 months or 15,000 miles, the cooling

system should be serviced as follows;

1. Wash radiator cap and filler neck with clean

water.

2. Check coolant for proper level and freeze

protection.

3. Pressure test system and radiator cap for proper

pressure holding capacity, 103

kPa (15 psi). If

replacement of cap is required, use the proper cap

specified for car model.

4. Tighten hose clamps and inspect all hoses. Replace

hoses whenever cracked, swollen or otherwise

deteriorated.

5. Clean frontal area of radiator core and air

conditioning condenser.

DRAINING AND REFILLING THE COOLING

SYSTEM

Replace hoses every 24 months or 30,000 miles or

earlier if cracked, swollen or otherwise deteriorated.

Every two years or 30,000 miles, whichever first

occurs, the cooling system should be flushed and

refilled using the following recommended procedure:

1. Remove radiator cap, or thermostat housing cap

(VIN

0, J, R and U), when engine is cool by:

a. Slowly

rotating cap counterclockwise to

detent. (Do not press down while rotating.)

b. Wait until any

residual pressure (indicated

by a hissing sound) is relieved.

c. After all hissing ceases, press down on cap

while continuing to rotate

counterclockwise.

CAUTION: To avoid the danger of

being burned, do not remove radiator

cap while engine and radiator are still

hot. Scalding fluid and steam may be

blown out under pressure.

2. Remove the thermostat by using the wire handle

to lift it out of the housing (VIN

0, J, R and U).

3. With the thermostat removed, reinstall the

thermostat housing cap (VIN

0, J, R and U).

4. Open radiator drain valve and block drain plugs

to drain coolant. On VIN R and

9 (P series)

engines, open coolant pipe plugs.

5. Close valve. Reinstall drain plugs, and add

sufficient water to fill system.

6. Run engine, drain and refill the system, as

described in steps

4 and 5 a sufficient number of

times, until the drained liquid is nearly colorless.

Important

BLOCK DRIVE WHEELS, place

transmission in PARK (automatic

transmission) or NEUTRAL (manual

transmission) and set the parking brake. 7.

Allow system to drain completely. Then close

radiator drain valve tightly, and reinstall block

drain plugs.

8. Remove recovery cap leaving hoses in place.

Remove coolant recovery tank and empty of

fluid. Flush tank with clean water, drain and

reinstall.

9. Add sufficient ethylene glycol coolant, meeting

GM specification 1825-M, to provide the

required freezing and corrosion protection

- at

least 50 percent solution -37°C (-34°F). Fill

radiator to the base of the radiator fill neck and

add sufficient coolant to the recovery tank to

raise level to the "FULL" mark. Reinstall

recovery tank cap.

10. Run engine, with radiator cap or thermostat

housing cap removed, until normal operating

temperature is reached. (Radiator upper hose

becomes hot.)

11. With engine idling, add coolant until level

reaches bottom of filler neck and reinstall cap,

making certain arrows line up with overflow tube.

CAUTION: Under some conditions, the

ethylene glycol in engine coolant is

flammable. To help avoid being

burned when adding coolant, DO NOT

spill

it on the exhaust system or hat

engine parts.

It is the owner's responsibility to keep the freeze

protection at a level appropriate to the

temperatures which may occur in the area of

vehicle operation.

a. Maintain

cooling system freeze protection

at

-37°C (-34"F), to ensure protection

against corrosion and loss of coolant from

boiling, even though freezing temperatures

are not expected.

b. Add ethylene glycol base coolant that meets

GM Specification 1825-M, when coolant

additions are required because of coolant

loss, or to provide additional protection

against

freezing at temperatures lower than

-37°C (-34°F).

NOTICE: Alcohol or methanol base coolants, or

plain water, are not recommended at any time.

DRlVE BELT

NOTICE: Routine inspection of the belt may

reveal cracks in the belt ribs. These cracks will

not impair belt performance and therefore should

not be considered a problem requiring belt

replacement. However, the belt should be

replaced if belt slip occurs or if sections of the

belt ribs are missing.

A single (serpentine) belt is used to drive all

engine accessories formerly driven by multiple drive

belts. All belt driven accessories are ridgedly mounted

with belt tension maintained by a spring loaded

tensioner.

The drive belt tensioner has the ability to control

belt tension over a fairly broad range of belt lengths.

Page 419 of 1825

68-8 ENGINE COOLING

However, there are limits to the tensioner's ability to

The tensioner has rovisions for a visual check to

compensate for varying lengths of belts. With the

ten- verify that it is in t e "operating range" (see Figures

sioner outside of its operating range, poor tension

608 and 609). R

control andlor damage to the tensioner may result.

ALUMINUM RADIATOR REPAIR

This radiator utilizes an aluminum core with

plastic side tanks. The core and side tanks can be

replaced separately and core repair is easily made with

the hot melt adhesive method. A transaxle oil cooler

is located in one of the side tanks. The oil cooler can

be replaced. The drain cock is located on the lower part

of one of the tanks. The drain cock is also serviceable.

Core

The core is made of aluminum and is of the

crossflow design. It utilizes large tubes that resist

plugging, and repairs to the tubes and core are easily

made using the hot melt adhesive method.

The core is attached to the tanks by clinched tabs

on the core that can be bent back if tank or core

replacement is required.

If the damage to a tube is too severe, a tube can

be blocked or plugged as explained in "Tube Blocking.

" No more than two tubes should ever be blocked on

a core. Also replace the core if more than three tabs are

broken on one side, or if two adjacent tabs are broken.

Tanks

The tanks are attached to the core by the use of

clinched tabs. The clinched tabs can be bent back if the

tanks need to be removed from the core. Bend the tabs

back only enough to remove the tank. Overbending

will weaken the tabs.

A high temperature rubber gasket is used to seal

the mating surface between the core and the tank. (See

Fig. 8). The gasket must be replaced any time a tank

is removed from the core.

Transaxle Oil Cooler

The transaxle oil cooler is located in one of the

radiator side tanks. The oil cooler can be replaced by

removing the tank from the core.

A leaking oil cooler gasket can be replaced

without removing the tank from the core.

Drain Cock

The aluminum/plastic radiator utilizes a two

piece plastic drain cock and a rubber seal. The drain

cock is serviceable (See Fig.

9).

ALUMINUM RADIATOR SERVICE

The aluminum-plastic radiator can be repaired at

the dealership. The following components are easily

replaced:

e Core

e Tanks and gaskets

o Oil coolers and gaskets

e Drain cock and gasket The

tanks cannot be repaired if broken or

cracked. The radiator core can be replaced and the new

core used with the original tanks and oil cooler.

Precautions

As with all cooling system service, take measures

to prevent personal injury and damage to the system.

CAUTION: To help avoid the danger of

being burned, do not remove the

radiator cap while the engine and

radiator are

still hot. Scalding fluid

and steam can be blown out under

pressure if the

cap is taken off too

soon.

NOTICE: DO NOT USE "BOIL OUT" TANKS

OR VATS. Common service methods may

actually destroy an aluminum radiator. Caustic or

lye cleaning solutions must NOT be used for

aluminum radiators.

e Do not open the hood if you can see, or hear,

steam or coolant escaping from the engine

compartment.

e Do not remove radiator cap if radiator feels

warm.

e Do not remove the radiator cap or coolant

recovery tank cap if the coolant in the recovery

tank looks like it is boiling.

Wear eye protection.

e Wear gloves to protect your hands against

excessive heat, or the effects of chemicals on your

skin.

o Prevent dirt and water from entering the

transmission oil cooler.

e Do not use boil-out tanks, or vats, or other tanks

that have been used for copper and brass

radiators. The flux, acid, and caustic cleaners

remaining in these tanks will attack the

aluminum and cause radiator failure.

A separate

test tank containing clean water is strongly

recommended for servicing aluminum-plastic

radiators.

RIOTICE: Never use shop air that is not regulated

at

20 psi (138 kPa) to pressure test radiator.

Pressures over

20 psi (138 kPa) will damage the

radiator.

DIAGNOSIS

Leak Testing

Some core leaks can be detected by merely adding

water to the radiator. It is helpful to clean the core so

that the damaged area can be more easily found.

Page 428 of 1825

ENGINE COOLING 68.17

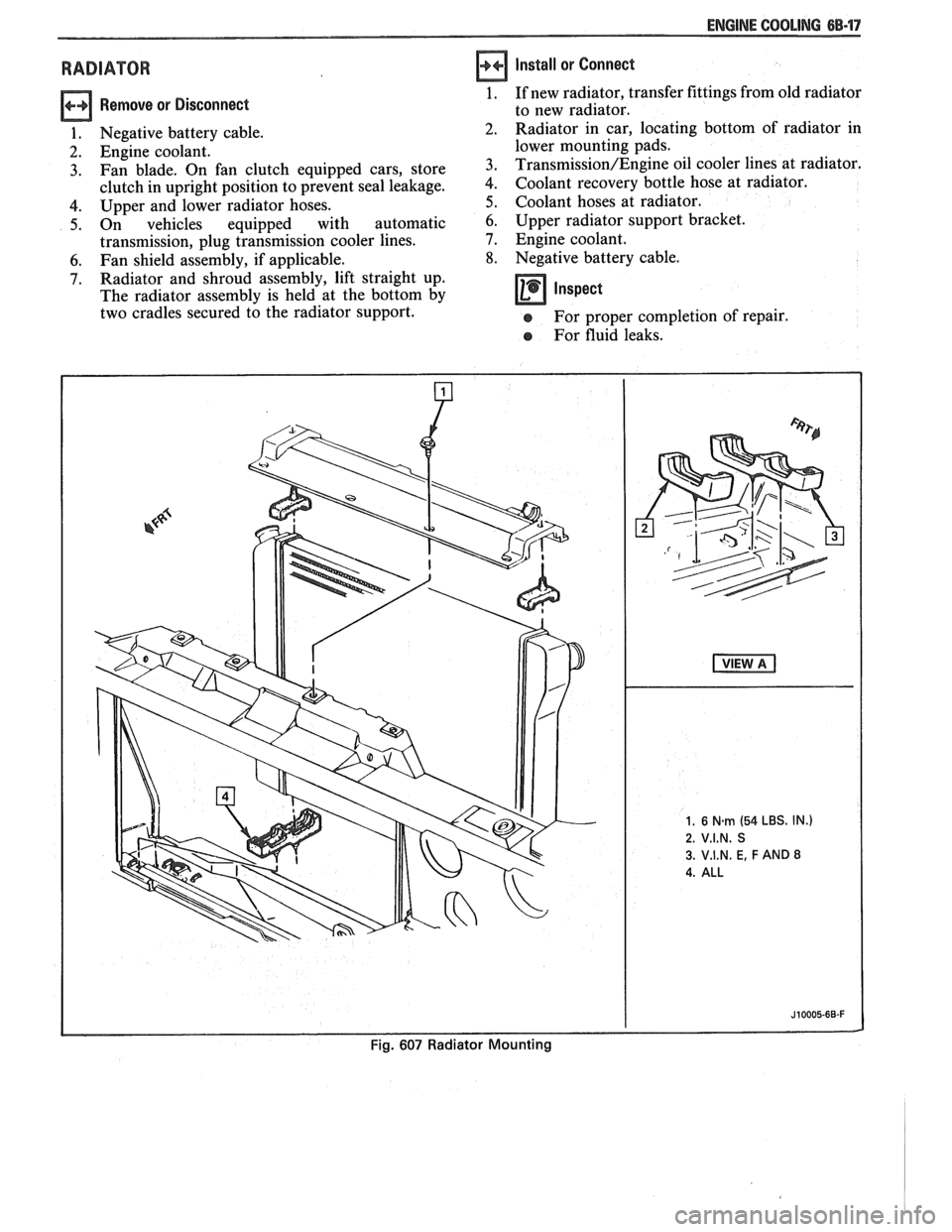

RADIATOR

Remove or Disconnect

1. Negative battery cable.

2. Engine coolant.

3. Fan blade. On fan clutch equipped cars, store

clutch in upright position to prevent seal leakage.

4. Upper and lower radiator hoses.

5. On vehicles equipped with automatic

transmission, plug transmission cooler lines.

6. Fan shield assembly, if applicable.

7. Radiator and shroud assembly, lift straight up.

The radiator assembly is held at the bottom by

two cradles secured to the radiator support.

Install or Connect

1. If new radiator, transfer fittings from old radiator

to new radiator.

Radiator in car, locating bottom of radiator in

lower mounting pads.

Transmission/Engine oil cooler lines at radiator.

Coolant recovery bottle hose at radiator.

Coolant hoses at radiator.

6. Upper radiator support bracket.

7. Engine coolant.

8. Negative battery cable.

Inspect -

e For proper completion of repair.

e For fluid leaks.

Page 447 of 1825

6D1-4 BATTERY

VOLTAGE

A. 16.0 or more

B. 14.0

- 15.9

C. 13.9 or less HOURS

1. Set parking brake and place automatic

Up to 4 Hours transmission in "PARK" (NEUTRAL for

Up to 8 Hours manual transmission.) Turn off the ignition,

Up to 16 Hours turn off lights, and all other electrical

If the charge current is still not

measurable

at the end of the above charging

times, the battery should be replaced.

If the charge current is measurable during

the charging time, the battery is considered to be

good and charging should be completed in the

normal manner.

5. It

is important to remember that a completely

discharged battery must be recharged for a

sufficient number of ampere hours (AH) to

restore it to a usable state. As a general rule of

thumb, using the reserve capacity rating (RC) of

the battery as the number of ampere hours of

charge will usually bring the green dot into view.

For example, if battery is rated at 75 RC minutes,

it would be completely recharged as follows:

10 ampere charge x 7-1/2 hours

= 75 AH

25 ampere charge x 3 hours = 75 AH, etc.

6. It

is recommended that any battery recharged by

this procedure be

LOAD TESTED to establish

serviceability.

JUMP STARTING IN CASE OF EMERGENCY

WITH AUXILIARY (BOOSTER) BAVEEWY

NOTICE: Do not push or tow the vehicle to start.

Damage to the emission system, or to other parts

of the vehicle may result.

Both booster and discharged battery should be

treated carefully when using jumper cables. Follow the

procedure outlined below, being careful not to cause

sparks:

CAUTION: Departure from these

conditions or the procedure below

could result in:

(1) Serious personal

injury (particularly to eyes) or property

damage from such causes as battery

explosion, battery acid, or electrical

burns; and/or

(2) damage to electronic

components of either vehicle.

Never expose battery to open flame or electric

spark

- batteries generate a gas which is flammable and

explosive.

Remove rings, watches, and other jewelry. Wear

approved eye protection.

Do not allow battery fluid to contact eyes, skin,

fabrics, or painted surfaces

- fluid is a corrosive acid.

Flush any contacted area with water immediately and

thoroughly. Be careful that metal tools or jumper

cables do not contact the positive battery terminal (or

metal in contact with it) and any other metal on the

car, because a short circuit could occur. Batteries

should always be kept out of the reach of children.

loads.

2. Check the built-in hydrometer. If it is clear or

light yellow, replace the battery.

3. Attach the end of one jumper cable to the positive

terminal of the booster battery and the other end

of the same cable to the positive terminal of the

discharged battery. Do not permit vehicles to

touch each other as this could cause a ground

connection and counteract the benefits of this

procedure. (Use 12-volt battery only to jump start

the engine).

4. Attach one end of the remaining negative cable

to the negative terminal of the booster battery,

and the other end to a solid engine ground (such

as

A/C compresser bracket or generator

mounting bracket) at least 18 inches from the

battery of the vehicle being started (DO NOT

CONNECT DIRECTLY TO THE NEGATIVE

TERMINAL OF THE DEAD BATTERY).

5. Start the engine of the vehicle that is providing

the jump start and turn off electrical accessories.

Then start the engine in the car with the

discharged battery.

6. Reverse these directions exactly when removing

the jumper cables. The negative cable must be

disconnected from the engine that was jump

started first.

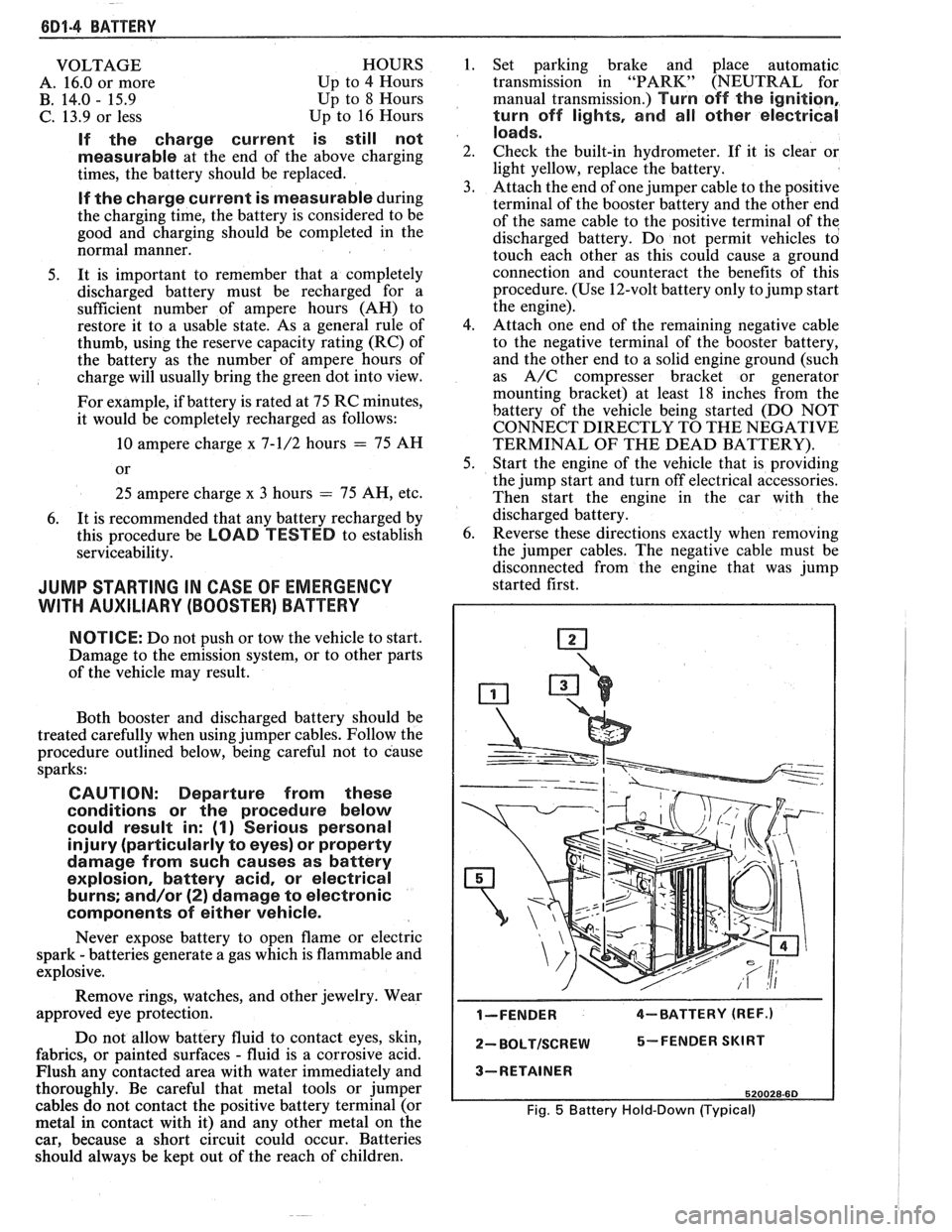

I-FENDER 4-BATTERY (REF.)

2- BOLTISCREW 5-FENDER SKIRT

3-RETAINER

520028-60

Fig. 5 Battery Hold-Down (Typical)

Page 584 of 1825

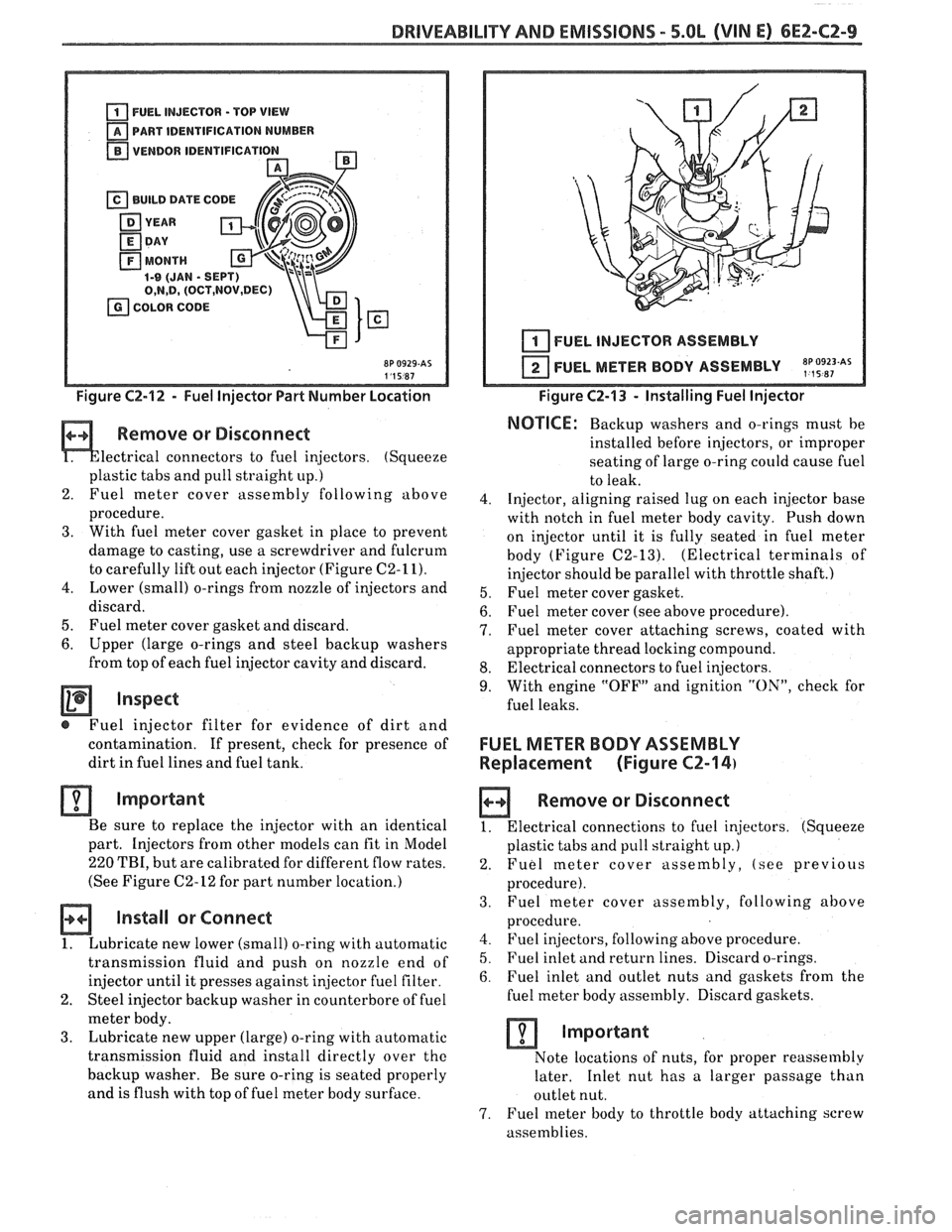

DRIVEABILITY AND EMISSIONS - 5.OL (VIN El CEZ-C2-9

u PART IDENTIFICATION NUMBER

VENDOR IDENTlFlCATl

Figure C2-12 - Fuel Injector Part Number Location

Remove or Disconnect

lectrical connectors to fuel injectors. (Squeeze

plastic tabs and pull straight

up.)

2. Fuel meter

cover assembly following above

procedure.

3. With fuel meter cover gasket in place to prevent

damage to casting, use a screwdriver and fulcrum

to carefully lift out each injector (Figure

C2-11).

4. Lower (small) o-rings from nozzle of injectors and

discard.

5. Fuel meter cover gasket and discard.

6. Upper (large o-rings and steel backup washers

from top of each fuel injector cavity and discard.

Inspect

@ Fuel injector filter for evidence of dirt and

contamination.

If present, check for presence of

dirt in fuel lines and fuel tank.

Important

Be sure to replace the injector with an identical

part. Injectors from other models can fit in Model

220 TBI, but are calibrated for different flow rates.

(See Figure

C2-12 for part number location.)

Install or Connect

1. Lubricate new lower (small) o-ring with automatic

transmission fluid and push on nozzle end of

injector until it presses against

in,jector fuel filter.

2. Steel injector backup washer in counterbore of fuel

meter body.

3. Lubricate new upper (large) o-ring with automatic

transmission fluid and install directly over

the

backup washer. Be sure o-ring is seated properly

and is flush with top of fuel meter body surface.

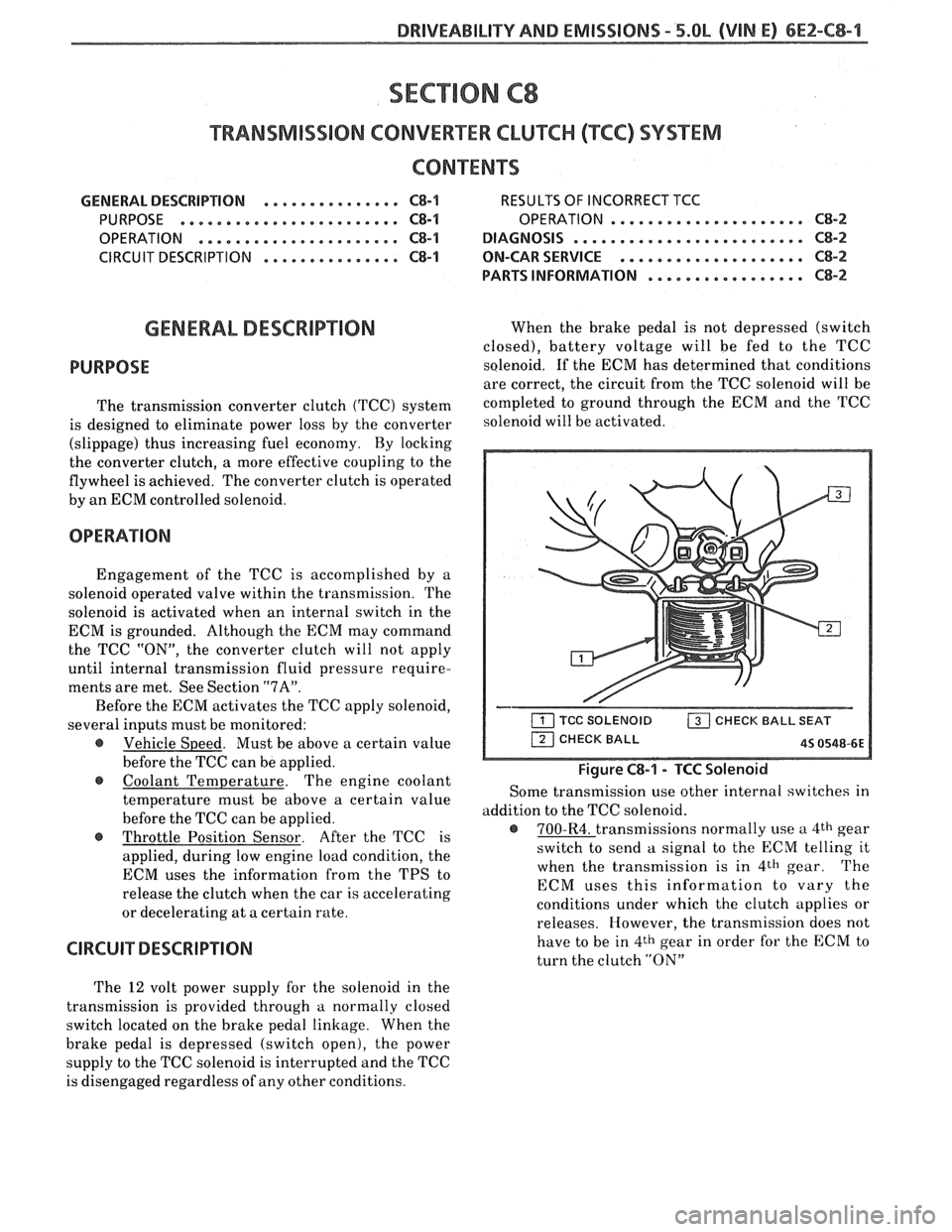

I I 1 I FUEL INJECTOR ASSEMBLY

FUEL METER BODY ASSEMBLY

~p,~9~~~As

Figure C2-13 - Installing Fuel Injector

NOTICE: Backup washers and o-rings must be

installed before injectors, or improper

seating of large o-ring

could cause fuel

to leak.

4. Injector, aligning raised lug on each injector base

with notch in fuel meter body cavity. Push down

on injector until it is fully seated in fuel meter

body (Figure

C2-13). (Electrical terminals of

injector should be parallel with throttle shaft.)

5. Fuel meter cover gasket.

6. Fuel meter cover (see above procedure).

7. Fuel meter cover attaching screws, coated with

appropriate thread locking compound.

8. Electrical connectors to fuel injectors.

9. With engine "OFF" and ignition "ON", check for

fuel leaks.

FUEL METER BODY ASSEMBLY

Replacement (Figure

CZ-14)

a Remove or Disconnect

1. Electrical connections to fuel injectors. (Squeeze

plastic tabs and pull straight up.)

2. Fuel meter cover assembly, (see previous

procedure).

3. Fuel

meter cover assembly, following above

procedure.

4. Fuel injectors, following above procedure.

5. Fuel inlet and return lines. Discard o-rings.

6. Fuel inlet and outlet nuts and gaskets from the

fuel meter body assembly. Discard gaskets.

Important

Note locations of nuts, for proper reassembly

later. Inlet nut has a larger passage than

outlet nut.

7. Fuel meter body to throttle body attaching screw

assemblies.

Page 626 of 1825

DRIVEABILITY AND EMISSIONS - 5.0L (VIM E) 6E2-C8-1

SECTION C8

"FRANSMISSIBN CONVERnEW CLUTCH (TCC) SYSTEM

CONTENTS

GENERAL DESCRIPTION ............... C8-1 RESULTS OF INCORRECT TCC

PURPOSE

........................ C8-1 OPERATION ..................... C8-2

......................... OPERATION ...................... C8-1 DIAGNOSIS CS-2

.................... CIRCUIT DESCRIPTION ....e.e..eea..e C8-1 ON-CAR SERVICE C8-2

................. PARTS INFORMATION C8-2

GENERAL DESCRIPTION

PURPOSE

The transmission converter clutch (TCC) system

is designed to eliminate power loss by the converter

(slippage) thus increasing fuel economy. By locking

the converter clutch,

a more effective coupling to the

flywheel is achieved. The converter clutch is operated

by an ECM controlled solenoid.

OPERATION

Engagement of the TCC is accomplished by a

solenoid operated valve within the transmission. The

solenoid is activated when an internal switch in the

ECM is grounded. Although the ECM may command

the TCC

"ON", the converter clutch will not apply

until internal transmission fluid pressure require-

ments are met. See Section

"7A".

Before the ECM activates the TCC apply solenoid,

several inputs must be monitored:

e Vehicle Speed. Must be above a certain value

before the TCC can be applied.

Coolant Temperature. The engine coolant

temperature must be above a certain value

before the TCC can be applied.

@ Throttle Position Sensor. After the TCC is

applied, during low engine load condition, the

ECM uses the information from the TPS to

release the clutch when the car is accelerating

or decelerating at a certain rate.

CIRCUIT DESCRIPTION

When the brake pedal is not depressed (switch

closed), battery voltage will be fed to the TCC

solenoid. If the ECM has determined that conditions

are correct, the circuit from the TCC solenoid will be

completed to ground through the ECM and the TCC

solenoid will be activated.

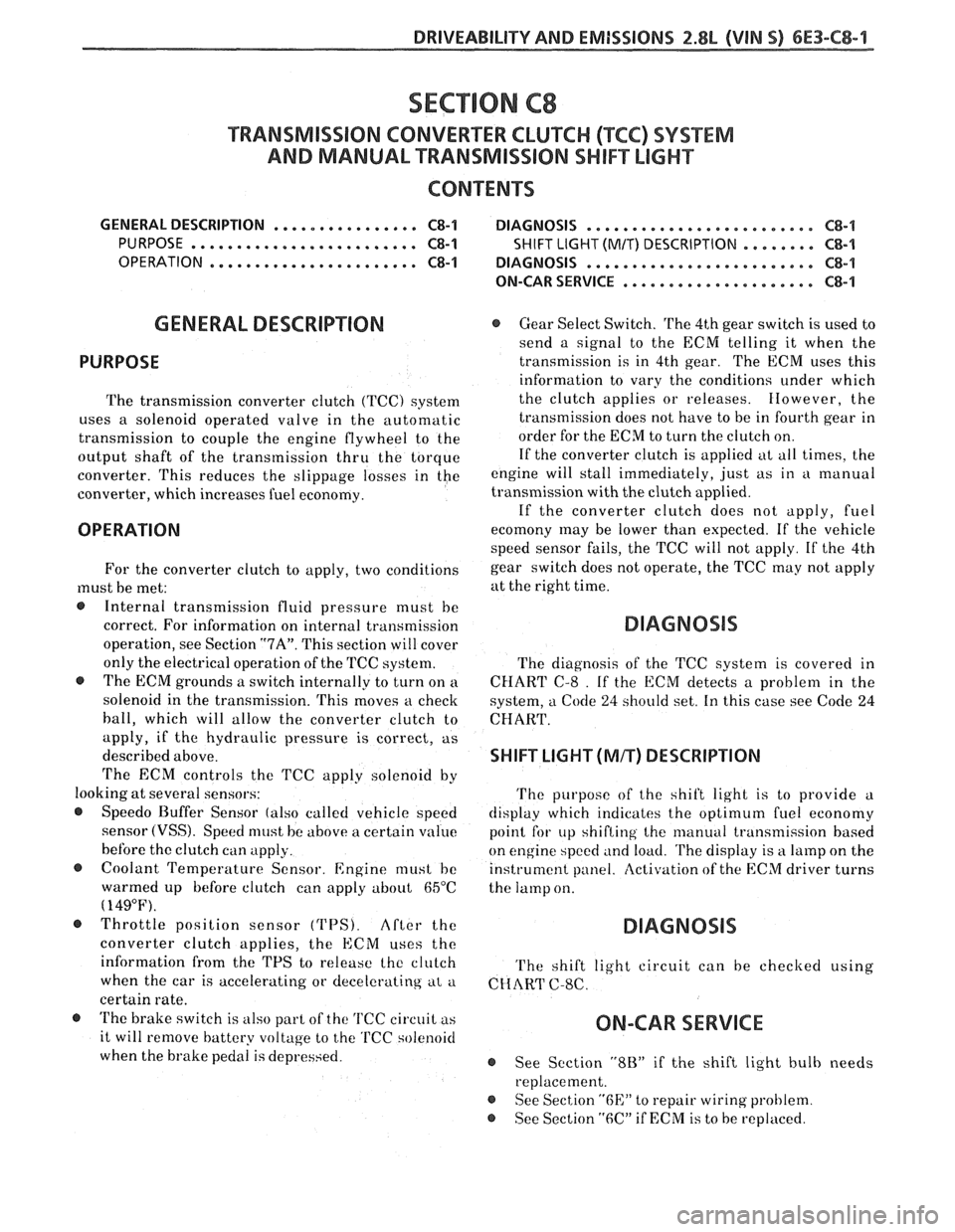

Figure C8-1 - TCC Solenoid

Some transmission use other internal switches in

addition to the TCC solenoid.

@ 700-R4. transmissions normally use a 4th gear

switch to send

a signal to the ECM telling it

when the transmission is in

4th gear. The

ECM uses this information to vary the

conditions under which the clutch applies or

releases. However, the transmission does not

have to be in

4th gear in order for the ECM to

turn the clutch

"ON"

The 12 volt power supply for the solenoid in the

transmission is provided through

a normally closed

switch located on the brake pedal linkage. When the

brake pedal is depressed (switch open), the power

supply to the TCC solenoid is interrupted and the TCC

is disengaged regardless of any other conditions.

Page 786 of 1825

DRIVEABILITY AND EMlSSlONS 2.8L (VIN %I 6E3-C8-1

TRANSMISSION CONVERTER CLUTCH (KC) SYSTEM

AND MANUAL

TRANSMISSION SHIFT LIGHT

CONTENTS

GENERAL DESCRIPTION ................ C8-1 DIAGNOSIS ..........ee...ee....e.e. C8-1

PURPOSE ......................... C8-1 SHIFT LIGHT (MIT) DESCRIPTION ........ C8-1

OPERATION ....................... C8-1 DIAGNOSIS ....................... .. C8-1

ON-CAR SERVICE ...................*. C8-1

GENERAL DESCRIPTION

PURPOSE

The transmission converter clutch (TCC) svstem

uses a solenoid operated valve in the automatic

transmission to couple the engine flywheel to the

output shaft of the transmission thru the torque

converter. This reduces the slippage losses in the

converter, which increases fuel economy.

OPERATION

For the converter clutch to apply, two conditions

must be met:

o Internal transmission fluid pressure must be

correct. For information on internal transmission

operation, see Section

"7A". This section will cover

only the electrical operation of the TCC system.

@ The ECM grounds a switch internally to turn on a

solenoid in the transmission. This moves a check

ball, which will allow the converter clutch to

apply, if the hydraulic pressure is correct, as

described above.

The ECM controls the TCC apply solenoid by

looking at several sensors:

@ Speedo Buffer Sensor (also called vehicle speed

sensor

(VSS). Speed must be above a certain value

before the clutch can apply.

@ Coolant Temperature Sensor. Engine must be

warmed up before clutch can apply about

65OC

(149°F').

Throttle position sensor ('I'PS). After the

converter clutch applies, the

HCM uses the

information from the TPS to release thc clutch

when the car is accelerating or decelerating at a

certain rate.

@ 'I'he brake switch is also part of the 'I'CC circuit as

it will remove battery voltage to the 'KC solenoid

when the brake pedal is depressed.

@ Gear Select Switch. The 4th gear switch is used to

send a signal to the

ECM telling it when the

transmission is in 4th gear. The ECM uses this

information to vary the conditions under which

the clutch applies or releases.

IIowever, the

transmission does not have to be in fourth gear in

order for the ECM to turn the clutch on.

If the converter clutch is applied at all times. the

engine will stall immediately, just as in

u manual

transmission with the clutch applied.

If the converter clutch does not apply, fuel

ecomony

may be lower than expected. If the vehicle

speed sensor fails, the TCC will not apply. If the 4th

gear switch does not operate, the TCC may not apply

at the right time.

DIAGNOSIS

The diagnosis of the TCC system is covered in

CHART C-8

. If the ECM detects a problem in the

system,

a Code 24 should set. In this case see Code 24

CHART.

SHIFT LIGHT (MiT) DESCRIPTION

'The purpose of the shift light is to provide a

display which indicates the optimum fuel economy

point for up

shifling the manual transmission based

on engine speed

and load. 'I'he display is a lamp on the

instrument panel. Activation of the ECM driver turns

the lamp

on.

'I'he shift light circuit can he checlted using

CHAR?' C-8C.

ON-CAR SERVICE

@ See Section "8B" if the shift light bulb needs

replacement.

@ See Section "6E" to repair wiring problem.

@ See Section "6C" if ECM is to be replaced.

Page 787 of 1825

6E3-C8-2 2.8L (VIN S) DRIVEABILITY AND EMISSIONS

VEHICLE SPEED SIGNAL

SPEED INPUT

CONNECTOR

aTH GEAR SIGNAL

422 TAN/BLK

4TH GEAR SW.

TRANSMISSION

ALDL CONNECTOR

TCC APPLY SOLENOID

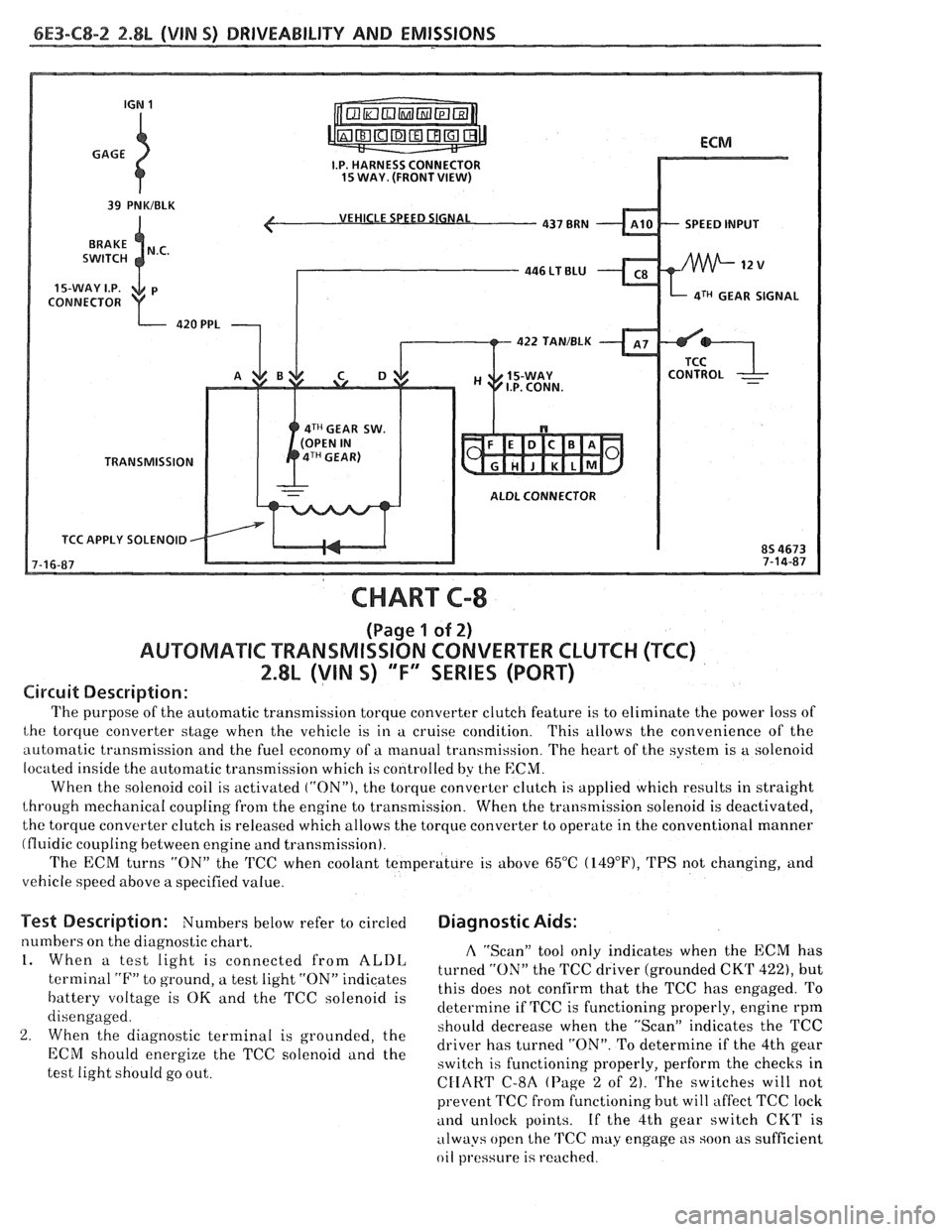

CHART C-8

(Page 1 of 2)

AUWBMATIC TRANSMISSION CONVERTER CLUTCH (TCC)

2.8L (VIN S) "F" SERIES (PORT)

Circuit Description:

The purpose of the automatic transmission torque converter clutch feature is to eliminate the power loss of

the torque converter stage when the vehicle is in a cruise condition. This allows the convenience of the

automatic transmission and the fuel economy of a manual transmission. The heart of the system is

a solenoid

located inside the automatic transmission which is controlled by the

ECM.

When the solenoid coil is activated ("ON"), the torque converter clutch is applied which results in straight

through mechanical coupling from the engine to transmission. When the transmission solenoid is deactivated,

the torque converter clutch is released which allows the torque converter to operate in the conventional manner

(fluidic coupling between engine and transmission).

The ECM turns

"ON" the 'KC when coolant temperature is above 65°C (14g°F), TPS not changing, and

vehicle speed above a specified value.

Test Description: Numbers below refer to circled Diagnostic Aids:

numbers on the diagnostic chart. A "Scan" tool only indicates when the ECM has 1. When a test light is connected from ALDL turned the TCC driver (grounded CKT 422), but terminal "F" to ground, a test light "ON" indicates

this does not confirm that the TCC has engaged. To battery voltage is OK and the TCC solenoid is

determine if TCC is functioning properly, engine rpm

disengaged.

should decrease when the "ScanJ' indicates the TCC

2. When the diagnostic terminal is grounded, the

driver has turned "ON". To determine if the 4th gear ECM energize the TCC "Ienoid and the switch is functioning properly, perform the checks in

test light should go out.

CIIART C-8A (Page 2 of 2). The switches will not

prevent TCC fi-om functioning but will affect TCC lock

and unlock points. If the 4th gear switch CKT is

always open the

TCC may engage as soon as sufficient

oil

pl.essure is reached.

Page 942 of 1825

DWlVEABlLlTV AND EMISSIONS 5.01, QVIN F) & 5.71 (VIN 8) 6E3-C8-1

TRANSMISSION CONVERTER CLUTCH (KC) SYSTEM

AND MANUAL "TRANSMISSION SHlFT LBGH"O"=Ob ONLY

CONTENTS

................ GENERAL DESCRIPTION C8-1 DIAGNOSIS ....................... .. C8-1

........ PURPOSE ......................... CS-1 SHIFT LIGHT (MIT) DESCRIPTION C8-1

....................... OPERATION C8-1 DIAGNOSIS ......................... CS-1

OM-CAR SERVICE ..................... C8-1

GENERAL DESCRIPTION

PURPOSE

The transmission converter clutch (TCC) system

uses

a solenoid operated valve in the automatic

transmission to couple the engine flywheel to the

output shaft of the transmission thru the torque

converter. This reduces the slippage losses in the

converter, which increases fuel economy.

OPERATION

For the converter clutch to apply, two conditions

must be met:

e Internal transmission fluid pressure must be

correct. For information on internal transmission

operation, see Section

"7A". This section will

cover only the electrical operation of the TCC

system.

@ The ECM grounds a switch internally to turn

"ON" a solenoid in the transmission. This moves a

check ball, which will allow the converter clutch

to apply, if the hydraulic pressure is correct, as

described above.

The ECM controls the TCC apply solenoid by

looking at several sensors:

@ Speedo Buffer Sensor (also called Vehicle Speed

Sensor

(VSS) Speed must be above a certain value

before the clutch can apply.

@ Coolant Temperature Sensor Engine must be

warmed

LIP before clutch can apply about 65" C

(149°F).

Throttle Position Sensor (TPS) After the

converter clutch applies, the ECM uses the

information

from the TPS to release the clutch

when the car is accelerating or decelerating at

a

certain rate.

The brake switch

is also part of the 'I'CC circuit as

it will remove battery voltage to the

'FCC solenoid

when the brake pedal is depressed.

@ Gear Select Switch The 4th gear switch is used to

send a signal to the ECM telling it when the

transmission is in 4th

gear

The ECM uses this information to vary the conditions

under which the clutch applies or releases. However,

the transmission does not have to be in fourth gear in

order for the ECM to turn the clutch "ON".

If the converter clutch is applied at all times, the

engine will stall immediately, just as in a manual

transmission with the clutch applied.

If the converter

clutch does not apply, fuel

ecomony may be lower than expected. If the vehicle

speed sensor fails, the TCC will not apply. If the 4th

gear switch does not operate, the TCC may not apply

at the right time.

DIAGNOSIS

The diagnosis of the TCC system is covered in

CHART C-$A. If the ECM detects a problem in the

system, a Code 24 should set. In this case, see Code 24

CHART.

SHIFT LIGHT (MR) DESCRIPTION

The purpose of the shift light is to provide a

display which indicates the optimum fuel economy

point for up shifting the manual transmission based

on engine speed and load. The display is

a lamp on the

instrument panel. Activation

of the ECM driver turns

the lamp "ON".

DIAGNOSIS

The shift light circuit can be checked using

CEIAR'I' C-8B.

ON-CAR SERVICE

See Section "8B" if the shift light bulb needs

replacement.

See Section

"GE" to repair wiring problem.

@ See Section "C- 1" if ECM is to be replaced.

Page 943 of 1825

6E3-C8-2 5.OL (VIN F) & 5.7L (VIN 8) DRIVEABILITY AND EMISSIONS

15-WAY I.P. CONNECTOR

VEHICLE SPEED SIGNAL

SPEED INPUT

4TH GEAR SIGNAL

422

TANIBLK

4TH GEAR SW.

TRANSMISSION ALDL CONNECTOR

TCC APPLY SOLENOID

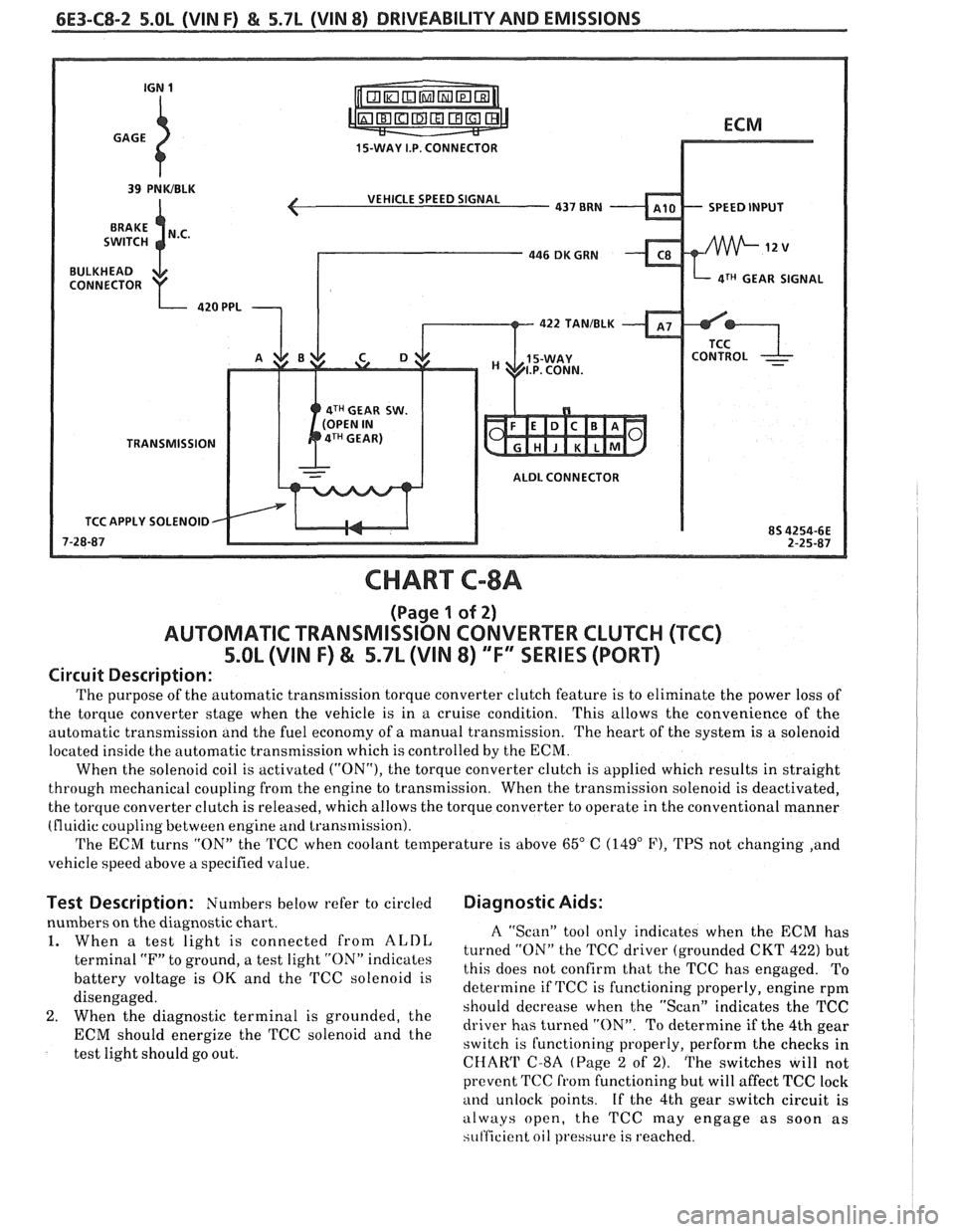

CHART C-8A

(Page 1 of 2)

AUTOMATIC TRANSMISSION CONVERTER CLUTCH (TCC)

5.OL (VIN F) & 5.7L (VIN 8) "F'" SERIES (PORT)

Circuit Description:

The purpose of the automatic transmission torque converter clutch feature is to eliminate the power loss of

the torque converter stage when the vehicle is in a cruise condition. This allows the convenience

of the

automatic transmission and the fuel economy of

a manual transmission. The heart of the system is a solenoid

located inside the automatic transmission which is controlled by the ECM.

When the solenoid coil is activated

("ON"), the torque converter clutch is applied which results in straight

through mechanical coupling from the engine to transmission. When the transmission solenoid is deactivated,

the torque converter clutch is released, which allows the torque converter to operate in the conventional manner

(fluidic coupling between engine

and transmission).

The ECM turns "ON" the TCC when coolant temperature is above

65" C (149" F), TPS not changing ,and

vehicle speed above

a specified value.

Test Description: Numbers below refer to circled Diagnostic Aids:

nbers on the diagnostic chart.

When

a test light is connected from ALDL

terminal "F" to ground, a test light "ON" indicates

battery voltage is

OK and the TCC solenoid is

disengaged.

When the diagnostic terminal is grounded, the

ECM should energize the TCC solenoid and the

test light should go out.

A "Scan" tool only indicates when the ECM has

turned "ON" the TCC driver (grounded CKT

422) but

this does not confirm that the TCC has engaged. To

determine if TCC is functioning properly, engine rpm

should decrease when the "Scan" indicates the TCC

driver has turned "ON". To determine if the 4th gear

switch is functioning properly, perform the checks in

CHAW C-8A (Page 2 of 2). The switches will not

prevent TCC

from functioning but will affect TCC lock

and unlock points. If the 4th gear switch circuit is

always open, the TCC may engage as soon as

si~t'ficient oil pressure is reached.