transmission fluid PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 8 of 1825

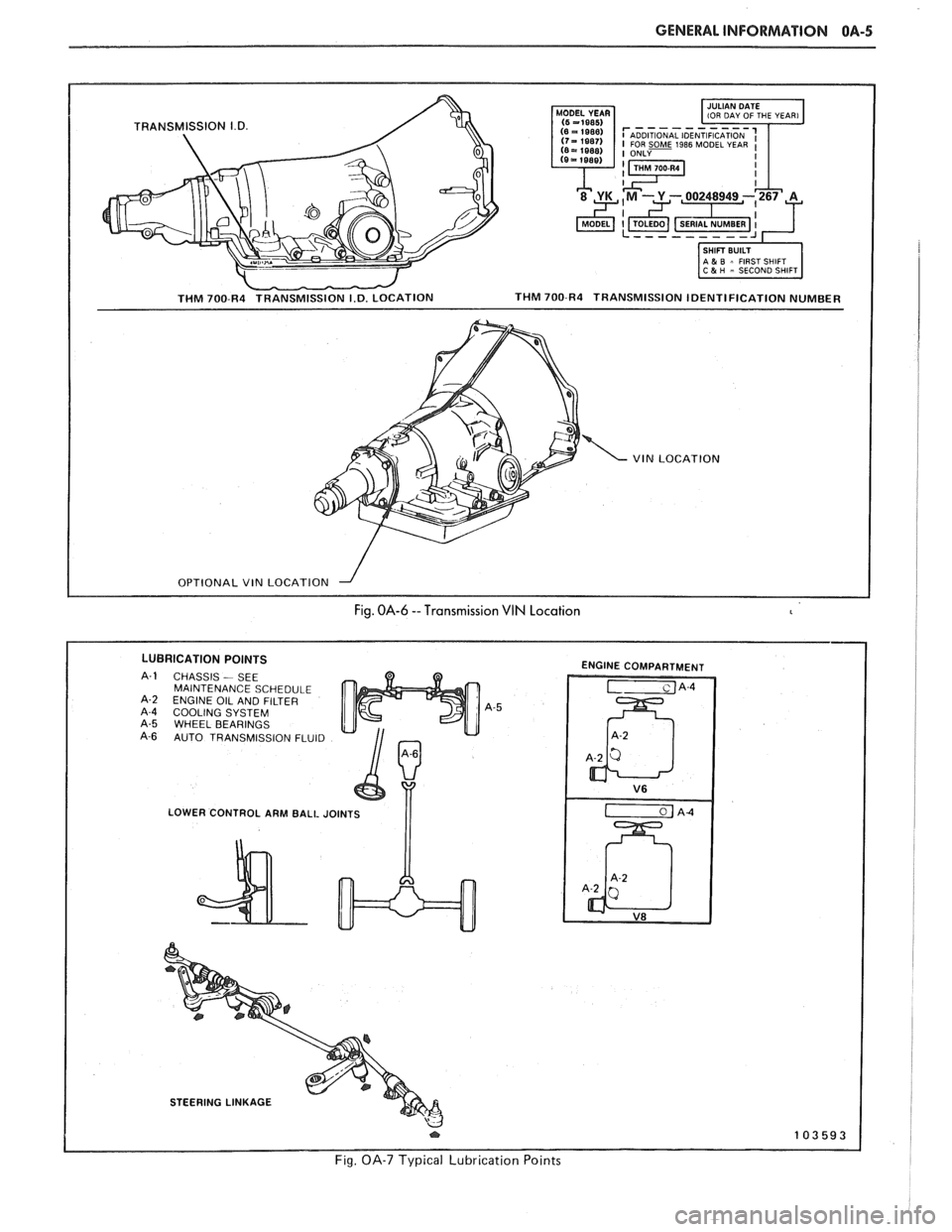

GENERAL INFORMATION OA-5

- THM 700-R4 TRANSMISSION I.D. LOCATION

1-1 IOU DAY OF THE YEAR1

I SHIFT BUILT 1 1 A & B = FIRST SHIFT 1 C 5 H - SECOND SHIFT

THM 700-R4 TRANSMISSION IDENTIFICATION NUMBER

VIN LOCATION

I OPTIONAL VIN LOCATION --I I

Fig. OA-6 --Transmission VIN Location

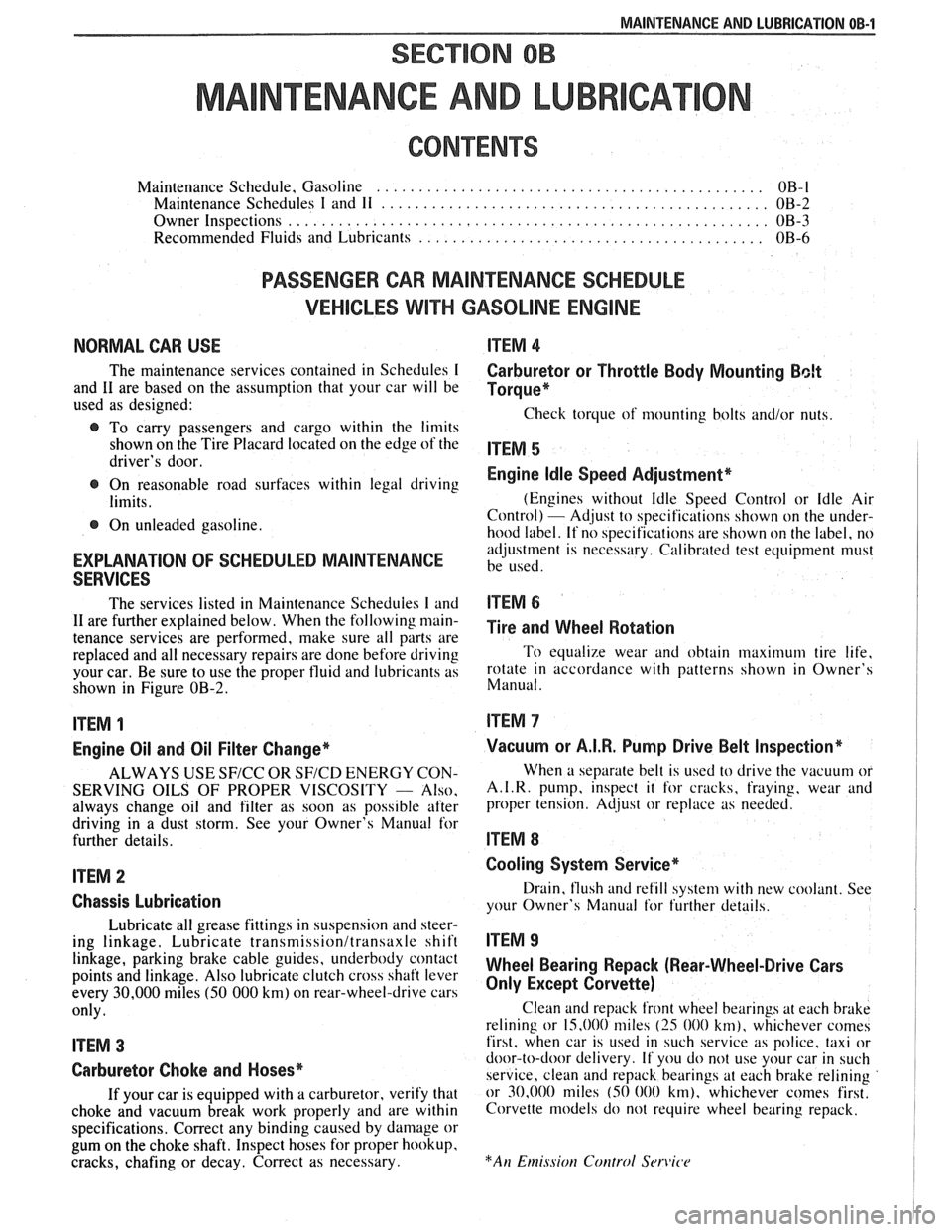

LUBRICATION POINTS

CHASSIS - SEE

MAINTENANCE SCHEDULE

ENGINE OIL AND FILTER

COOLING SYSTEM WHEEL BEARINGS

AUTO TRANSMISSION FLUID

LOWER CONTROL ARM BALL JOINTS

I I

ENGINE COMPARTMENT

STEERING LINKAGE

Fig. OA-7 Typical Lubrication Points

Page 18 of 1825

MAINTENANCE AND LUBRICATION OB-1

SECTION OB

NTENANCE AND LUBR

CONTENTS

Maintenance Schedule, Gasoline .............................................. OB-l

Maintenance Schedules I and 11 .............................................. OB-2

Owner Inspections

......................................................... OB-3

Recommended Fluids and Lubricants ......................................... OB-6

PASSENGER CAR MAINTENANCE SCHEDULE

VEHICLES

WITH GASOLINE ENGINE

NORMAL CAR USE ITEM 4

The maintenance services contained in Schedules I Carburetor or Throttle Body Mounting Bolt

and 11 are based on the assumption that your car will be Torque* used as designed:

Check torque of mounting bolts and/or nuts. @ To carry passengers and cargo within the limits

shown on the Tire Placard located on the edge of the ITEM 5 driver's door.

@ On reasonable road surfaces within legal driving Engine Idle Speed Adjustment*

limits. (Engines

without Idle Speed Control or Idle Air

Control) - Adjust to specifications shown on the under- @ On unleaded gasoline.

hood label. If no specifications are shown on the label, no

adjustment is necessary. Calibrated test equipment must

EXPLANATION OF SCHEDULED MAINTENANCE be used. SERVICES

The services listed in Maintenance Scheduies I and ITEM 6

11 are further explained below. When the following main- ~i~~ and wheel aotation tenance services are performed, make sure all parts are

replaced and all necessary repairs are done before driving To equalize wear and obtain maximum tire life,

your car. Be sure to use the proper fluid and lubricants as rotate in accordance with patterns shown in Owner's

shown in Figure OB-2. Manual.

ITEM 1

Engine Oil and Oil Filter Change*

ALWAYS USE SFICC OR SF/CD ENERGY CON-

SERVING OILS OF PROPER VISCOSITY

- Also.

always change oil and filter as soon as possible after

driving in a dust storm. See your Owner's Manual for

further details.

ITEM 2

Chassis Lubrication

Lubricate all grease fittings in suspension and steer-

ing linkage. Lubricate

transmissionltransaxle shift

linkage, parking brake cable guides, underbody contact

points and linkage. Also lubricate clutch cross shaft lever

every

30,000 miles (50 000 km) on rear-wheel-drive cars

only.

ITEM 3

Carburetor Choke and Hoses*

If your car is equipped with a carburetor, verify that

choke and vacuum break work properly and are within

specifications. Correct any binding caused by damage or

gum on the choke shaft. Inspect hoses for proper hookup,

cracks, chafing or decay. Correct as necessary.

Vacuum or A.I.R. Pump Drive Belt Inspection*

When a separate belt is used to drive the vacuum or

A.I.R.

pump, inspect it for cracks, fraying, wear and

proper tension. Adjust or replace as needed.

ITEM 8

Cooling System Service*

Drain, flush and refill system with new coolant. See

your Owner's Manual

for further details.

ITEM 9

Wheel Bearing Repack (Rear-Wheel-Drive Cars

Only Except Corvette)

Clean and repack front wheel bearings at each brake

relining or 15,000 miles

(25 000 km), whichever comes

first, when car is used in such service as police, taxi or

door-to-door delivery. If you do not use your car in such

service, clean and repack bearings at each brake relining

or 30,000 miles

(50 000 km), whichever comes first.

Corvette models do not require wheel bearing repack.

Page 20 of 1825

F CARLINE

ITEM 10

TransmissionRransaxle Service

The manual transmission or transaxle fluid does not

require changing. (Corvette only.) Change fluid in over-

drive unit every 30,000 miles (50 000 km).

For automatic transmissions or transaxles, change

both the fluid and filter every 15,000 miles (25 000 km) if

the car is mainly driven under one or more of these

conditions:

@ In heavy city traffic where the outside temperature

regularly reaches 90°F (32°C) or higher.

@ In hilly or mountainous terrain.

@ Frequent trailer pulling.

@ Uses such as found in taxi, police car or delivery

service.

If you do not use your car under any of these condi-

tions, change both the fluid and filter every 100,000 miles

(160 000 km). See you Owner's Manual for further

details.

ITEM 11

Spark Plug Service*

Replace spark plugs with type listed in your Owner's

Manual.

ITEM 12

Spark Plug Wire Inspection*

Clean wires and inspect for burns, cracks or other dam-

age. Check the wire boot fit at distributor and at spark plugs.

Replace wires as needed.

ITEM 13

Positive Crankcase Ventilation (PCV) Valve

Inspection*

Inspect valve for proper function. Replace valve if

necessary as well as any worn, plugged or collapsed

hoses.

ITEM 14

EGR System Service*

Conduct EGR System Service as referenced in the

EGR System Chart shown in the appropriate 6E Section.

Also, refer to your GM maintenance schedule booklet for

specific applications.

ITEM 15

Air Cleaner and PCV Filter Replacement*

On 1.6 and 2.0 liter engines, replace every 50,000

miles (80 000 km). On all other engines, replace every

30,000 miles (50 000 km). Replace more often under

dusty conditions. Ask your dealer for the proper replace-

ment interval for your driving conditions.

MAINTENANCE AND LUBRICATION 08-3

ITEM 16

Engine Timing Check*

Adjust timing to underhood label specifications. If

no specifications are shown, no adjustment is needed.

ITEM 17

Fuel Tank, Cap and Lines Inspection*

Inspect fuel tank, cap and lines (including fuel rails

and injection assembly, if so equipped) for damage or

leaks. Inspect fuel cap gasket for an even filler neck

imprint or any damage. Replace parts as needed.

ITEM 18

Thermostatically Controlled Air Cleaner

Inspection*

If your car is equipped, inspect all hoses and ducts

for proper hookup. Make sure valve works properly.

OWNER INSPECTIONS AND SERVICES

Listed below are inspections and services which

should be made by either you or a qualified technician at

the intervals shown to help ensure proper safety, emission

performance and dependability of your car. Take any

problems promptly to your dealer or another qualified

technician for service advice. Whenever repairs are neces-

sary, have them completed at once. For your safety and

that of others, any safety-related parts that could have

been damaged in an accident should be inspected and all

needed repairs should be done before operating your car.

Be sure to use the proper fluids and lubricants as shown in

Figure OB-2.

WHILE OPERATING YOUR VEHICLE

Automatic transmissionltransaxle shift indi-

cator operation - Make sure the indicator points to the

gear chosen.

Horn operation - Blow the horn occasionally to

make sure it works. Check all button locations.

I

Brake system operation -- Be alert to abnormal

sounds, increased brake pedal travel or repeated pulling to

one side when braking. Also, if a brake warning light

comes on or flashes, or the anti-lock warning light (if

equipped) comes on or remains on, something may be

wrong with part of the brake system. Have it inspected and

repaired at once.

Exhaust system operation - Be alert to any

changes in the sound of the system or any smell of fumes.

These are signs the system may be leaking or overheating.

.

Have it inspected and repaired at once. Also see "Engine

Exhaust Gas Caution (Carbon Monoxide)" and "Catalytic

Converter" in your Owner's Manual.

*An Emission Control Service

Page 21 of 1825

OB-4 MAINTENANCE AND LUBRICATION

Tire and wheel operation - Be alert to a vibra-

tion of the steering wheel or seat at normal highway

speeds. This may mean a wheel balance is needed. Also, a

pull right or left on a straight, level road may show the

need for

a tire pressure adjustment or wheel alignment.

Steering system operation - Be alert to

changes in steering action. An inspection is needed when

the steering wheel is harder to turn or has too much free

play or if unusual sounds are noted when turning or

parking.

Headlight aim operation - Take note of light

pattern occasionally. If beam aim doesn't look right,

headlights should be adjusted.

AT EACH FUEL FILL

Engine oil level check - Check engine oil level

and add if necessary. See your Owner's

Manual for further

details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Engine coolant level and condition - Check

engine coolant level in coolant reservoir tank and add if

necessary. Replace if dirty or rusty. See your Owner's

Manual for further details.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Windshield washer fluid level check -- Check

washer fluid level in container and add if necessary.

Hood latch operation - When opening hood on

cars equipped with hoods that open from the front, note

the operation of secondary latch. It should keep hood from

opening all the way when primary latch is released. Make

sure that hood closes firmly.

AT LEAST MONTI-ILY

Tire and wheel inspection and pressure

check--

Check tires for abnormal wear or damage. Also,

check for damaged wheels. Keep pressures as shown on

Tire Placard on the driver's door (include spare unless it is

a stowaway). Pressure should b\: checked when tires are

"cold". See "Tires" in Owner's Manual for further

infomation.

Light operation check - Check operation of

license plate light, side-marker lights, headlights includ-

ing high beams, parking lights, taillights, brake lights.

turn signals, backup lights, instrument panel and interior

lights and hazard warning flashers.

Fluid leak check - After the car has been parked

for a while, inspect the surface beneath the car for water,

oil, fuel or other fluids. Water dripping from the air

conditioning system after use is normal. If you notice fuel

leaks or fumes, the cause should be found and corrected at

once.

AT LEAST TWICE A YEAR (FOR EXAMPLE,

EVERY SPRING AND FALL)

Power steering pump fluid level check --

Check power steering pump fluid level in accordance with

Owner's Manual instructions and keep at proper level.

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Brake master cylinder reservoir fluid level

check ---- Check fluid and keep at proper level. Note: It is

normal for the brake fluid level to go down slightly as the

brake pads wear

- so be sure to keep reservoir filled.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Clutch system service --- manual transmis-

sionltransaxle --- For cars equipped with hydraulic

clutch system, check the reservoir fluid level and add fluid

as required. All others, check clutch pedal free travel and

adjust as necessary. See your Owner's Manual for further

details.

~

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Weatherstrip Lubrication - Clean surface and

then apply a thin film of silicone grease with a clean cloth.

EACH TIME OIL IS CHANGED

Automatic and manual transmissionltrans-

axle fluid level check - Check transmission/transaxle

fluid level and add as required. (Corvette only) if equipped

with manual transmission

- check fluid in the overdrive

unit and add as required.

NOTICE: A large loss in this system may indicate a

problem. Have

it inspected and repaired at once.

Brake systems inspection - For convenience,

the following should be done when wheels are removed

for rotation: Inspect lines and hoses for proper hookup,

binding, leaks, cracks, chafing, etc. Inspect disc brake

pads for wear and rotors for surface condition. Also in-

spect drum brake linings for wear and cracks. Inspect

other brake parts, including drums, wheel cylinders, park-

ing brake, etc. at the same time. Check parking brake

adjustment.

INSPECT BRAKES MORE OFTEN IF DRIVING

HABITS OR CONDITIONS RESULT IN FREQUENT

BRAKING.

Steering, suspension and front drive axle

boot and seal inspection

- Inspect front and rear

suspension and steering system for damaged, loose or

missing parts, signs of wear or lack of lubrication. Inspect

power steering lines and hoses for proper hookup, bind-

ing, leaks, cracks, chafing, etc. (On cars equipped with

manual steering gear, check for seal leakage.) On

front-

wheel-drive cars, clean then inspect drive axle boot seals

for damage, tears or leakage. Replace seals if necessary.

Exhaust system inspection - Inspect complete

system. Inspect body near the exhaust system. Look for

broken, damaged, missing or out-of-position parts as well

as open seams, holes, loose connections or other condi-

tions which could cause a heat buildup in the tloor pan or

could let exhaust fumes seep into the trunk or passenger

compartment.

Page 22 of 1825

MAINTENANCE AND LUBRICATION OB-5

Throttle linkage inspection -- Inspect for inter-

ference, binding, damaged or missing parts.

Engine drive belts inspection - Inspect all

belts for cracks, fraying and wear. Adjust or replace as

needed.

Rear axle service (if equipped) - Check gear

lubricant level and add if needed. For cars equipped with a

limited slip rear axle, fluid does not require changing

(except Caprice and Corvette

- change fluid and required

additive at first

7,500 miles (12 500 km). See your

Owner's Manual or "Recommended Fluids

& Lubricants

Chart" in this section.

IF YOU USE YOUR GAR TO PULL A TRAILER,

CHANGE GEAR LUBRICANT EVERY 7,500 MILES

(12 500 KM).

NOTICE: A large loss in this system may indicate a

problem. Have it inspected and repaired at once.

Power antenna - Clean and then lubricate power

antenna mast. The proper lubricant as shown in Figure

OB-2 should be used.

AT LEAST ONCE A YEAR

Lap and shoulder belts condition and opera-

tion

- Inspect belt system, including webbing, buckles,

latch plates, retractors, guide loops and anchors.

Moveable head restraint operation - On cars

with moveable restraints, make sure restraints stay in the

desired position. (See adjustment instructions in your

Owner's Manual.)

Seatback latch and recliner operation on

cars equipped

with recliner seat --- Be sure seat-

backs latch on those cars with folding seats using mechan-

ical latches. Make sure the recliner is holding by pushing

and pulling on the top of the

seatback while it is reclined.

See your Owner's Manual for seat operating information.

Spare tire and jack storage- Be alert to rattles

in rear of car. Make sure the space tire, all jacking equip-

ment, any tire inflator and any covers or doors are securely

stowed at all times. Oil jack ratchet or screw mechanism

after each use.

Key lock service - Lubricate key lock cylinder at

least annually.

Body lubrication service - Lubricate all body

door hinges including the tailgate or hatchback lid (if

equipped). Also lubricate the body hood, fuel door and

rear compartment hinges and latches including interior

glove box and counsel doors, and any folding seat

hardware.

"Fansmissionltransaxle neutral or clutch

starl switch operation

CAUnON: Before pedorming the follow-

ing safety switch check, be sure to have

enough room around the car. Then, firmly

apply both the parking brake (see your

Owner's Manual for procedure) and the

regular brakes. Do not use the accelerator pedal.

If the engine

starls, be ready to turn

off the ignition promptly. Take these pre-

cautions because the car could move

without warning and possibly cause per-

sonal injury or properly damage. On auto-

matic transmissionltransaxle cars, try to

starl the engine in each gear. The starler

should crank only in "Park" or "Neutral."

On manual transmissionltransaxle cars,

place the

shiR lever in "Neutral," push the

clutch halfway and try to starl. The starler

should crank only when the clutch is fully

depressed.

Steering column lock operation

- While

parked, try to turn key to "Lock" in each gear range. The

key should turn to "Lock" only when gear is in "Park" on

automatic or "Reverse" on manual

transmissionltransax-

le. On cars with key release lever, try to turn key toULock"

without depressing the lever. The key should turn to

"Lock" only with the key lever depressed. On all vehicles,

the key should come out only in "Lock."

Parking brake and transmissionltransaxle

"Park" mechanism operation

CAUT1ON:Before checking the holding

ability of the parking brake and automatic

transmissionltransaxle "Park" mecha-

nism, park on a fairly steep hill with

enough room for movement in the down-

hill direction. To reduce the risk of person-

al injury or property damage, be prepared

to apply the regular brakes promptly if the

car begins to move.

To check the parking brake, with the engine running and

transmission/transaxle in "Neutral." slowly remove foot

pressure from the regular brake pedal (until the car is held

by only the parking brake).

To check the automatic transmissionltransaxle "Park"

mechanism holding ability, release all brakes after shift-

ing the transmissionltransaxle to "Park."

ljnderbody flushing - At least every spring,

tlush from the underbody with plain water any corrosive

materials used for ice and snow removal and dust control.

Take care to thoroughly clean any areas where mud and

other debris can collect.

Sediment packed in closed areas

of the vehicle should be loosened before being flushed.

Engine cooling system service - Inspect

coolant and freeze protection. If dirty or rusty, drain, flush

and refill with new coolant. Keep coolant

at the proper

mixture as specified in your Owner's Manual. This pro-

vides proper freeze protection. corrosion inhibitor level

and engine operating temperature. Inspect hoses and re-

place if cracked. swollen or deteriorated. Tighten hose

clamps. Clean outside of radiator and air conditioning

condensor. Wash radiator filler cap and neck.

To help

ensure proper operation. a pressure test of both the cooling

system and cap is also recommended. (See maintenance

schedule charts in Figure

OB-l for the recommended

coolant change interval.)

Page 242 of 1825

PROPELLER SHAFT 4A-1

PROPELLER SHAFT

NOTICE: The propeller shaft to pinion flange or slip yoke fasteners are important attaching parts in that

they may affect the performance of vital components and systems, which may result in a major repair expense.

They must be replaced with one of the same part number or with an equivalent part, if replacement becomes

necessary. Do not use a replacement part of lesser quality or substitute design. Torque values must be used as

specified during reassembly to assure proper retention of these parts.

CONTENTS

GENERAL DESCRIPTION ........................ 4A-1

DIAGNOSIS ......................... ............ 4A-1

ON-VEHICLE SERVICE ........................... 4A-I

Propeller Shaft Run-Out

....................................... Measurement 4A- 1

Companion Flange Run-Out

Measurement

............................................. 4A-2

........... Universal Joint Angle Measurement 4A-3

............................ Propeller Shaft Balancing 4A-4

.............................................. Propeller Shaft 4A-8

Removal

.................... .. ............................. 4A-8

GENERAL DESCRIPTION

Figure 4A- I

.............................................. Installation 4A-8

UNIT REPAIR ............................................... 4A-9

Universal Joints

...................... ... ............ 4A-9

....................... Nylon Injected Ring Type 4A-9

..... ....................... Disassembly .... 4A-9

.......................................... Assembly 4A-9

......................... External Snap Ring Type 4A- l 1

............. .................... Disassembly .. 4A- 1 1

........................................... Assembly

4A- 1 1

.................... TORQUE SPECIFICATIONS 4A-12

.................................. SPECIAL TOOLS 4A-12

DIAGNOSIS

Figures 4A-2 and 4A-3

Obiectional vibration, roughness, rumble or

boom

can be caused by the input from a number of

shaft. use a One piece propeller systems. The following diagnostic charts provide a

systematic approach to finding the vehicle problem.

A universal joint and splined slip yoke are located at

the transmission end of the propeller shaft, where they are

held in alignment by a bushing in the transmission exten-

sion housing. The slip yoke permits fore and aft move-

ment of the propeller shaft, as the differential assembly

moves up and down. The spline is lubricated internally by

transmission fluid. A seal in the transmission extension

housing prevents fluid leakage and protects the slip yoke

from dust,

dirt, and other harmful material.

A second universal joint is used where the

propeller shaft connects to the rear axle pinion

companion flange.

The universal joints are lubricated for life and

cannot be lubricated while on the vehicle.

If it becomes

necessary to replace a universal joint, the entire

propeller shaft must be removed from the vehicle. Care

should be taken to avoid jamming, bending or

over-angulating of any parts of the assembly.

On vehicles with steel propeller shafts, production

universal joint bearing caps are retained by nylon injected

rings. Aluminum propeller shafts and all service replace-

ment universal joints use snap rings to retain the bearing

caps.

If a vehicle is to be undercoated, the propeller

shaft must be kept completely free of undercoating

material. Undercoating material or any other foreign

material will upset the propeller shaft balance and

produce serious vibration. To

determine whether the propeller shaft is

causing the problem, drive the vehicle through speed

range and note at which vehicle speed the problem is

most pronounced. Shift the transmission into a lower

gear range and drive the vehicle at the same speed as

when problem was most pronounced.

If the problem is still present at the same vehicle

speed, the propeller shaft may be at fault. Refer to the

propeller shaft diagnostic charts.

ON-VEHICLE SERVICE

PROPELLER SHAFT RUN-OUT MEASUREMENT

Figure 4A-4

If a noise or vibration is present at high speed it

might be caused by a bent shaft, or if a shaft has been

damaged through handling or a collision, it may be

checked for straightness as follows:

1. Raise vehicle on a twin post hoist so that the rear

is supported on the rear axle housing with wheels

free to rotate.

2. Mount

a dial indicator on a movable support that

is high enough to permit contact of the indicator

button with the propeller shaft or mount dial

indicator to a magnetic base and attach to a

suitable smooth place on the underbody of the

vehicle. Readings are to be taken at points

indicated, as shown.

3. With transmission in neutral, check for runout by

turning a rear wheel to rotate the propeller shaft.

Page 257 of 1825

481-4 REAR AXLE

Gear Noise

Gear noise (whine) is audible from 20 to 55 mph

under four driving conditions:

1. Light Acceleration - Accelerate slowly.

2. Road Load

- Car

driving load or constant speed.

3. Float - Using enough throttle to keep the car from

driving the engine

- car slows down gradually but

engine still pulls slightly.

4. Coast - Throttle closed and car in gear.

Bearing Noise

Bad bearings generally produce more of a rough

growl or grating sound, rather than the whine typical

of gear noise. Bearing noise frequently "wow-wows" at

bearing rpm, indicating a defective pinion or rear axle

case side bearing. This noise could easily be confused

with rear wheel bearing noise. Inspect and replace as

required.

Rear Wheel Bearing Noise

A rough rear wheel bearing produces a noise

which continues with car coasting at low speed and

transmission in neutral. Noise may diminish some by

gentle braking. With rear wheels jacked up, spin rear

wheels by hand while listening at hubs for evidence of

rough (noisy) wheel bearing.

Knock At Low Speeds

Low speed knock can be caused by worn

universal joints or a side gear hub counterbore in a case

that has worn oversize. Inspect and replace universal

joint or case and side gear as required.

Backlash Clunk

Excessive clunk with acceleration and deceleration

is caused by worn differential pinion gear shaft, excessive

clearance between axle shaft and side gear splines, exces-

sive clearance between side gear hub and counterbore in

case, worn pinion and side gear teeth, worn thrust washers

and excessive drive pinion and ring gear backlash. Re-

move worn parts and replace as required, selecting close

fitting parts when possible. Adjust pinion and ring gear

backlash.

DIAGNOSIS

1. Noise

is the same in "Light Acceleration" or

"Coast".

a. Road noise.

b. Tire noise.

c. Front wheel bearing noise.

d. Rear axle bearing noise.

2. Noise changes on a different type of road.

a. Road noise.

b. Tire noise.

3. Noise tone lowers as car speed is lowered.

a. Tire noise.

b. Front

wheel bearings and rear axle bearings.

c. Gear noise.

4. Similar noise is produced with car standing and

driving. a.

Engine noise.

b. Transmission noise.

c. Exhaust noise.

5. Vibration.

a. Rough rear axle bearing.

b. Unbalanced or damaged propeller shaft.

c. Tire unbalance.

d. Worn universal joint in propeller shaft.

e. Mis-indexed propeller shaft at pinion

flange.

f. Pinion flange runout too great.

6. A knock or click approximately every two

revolutions of the rear wheel.

a. A rear axle bearing.

b. Worn case.

7. Noise most pronounced on turns.

a. Rear axle side gear and pinion noise,

differential gear noise.

b. Axle bearings.

8. A continuous low pitch whirring or scraping

noise starting at relatively low speed.

a. All bearing noise.

9. Drive noise, coast noise or float noise.

a. Ring

and pinion gear noise.

b. Front

pinion bearing noise, coast or drive.

c. Axle bearing noise.

10. Clunk

on

acceleration or deceleration.

a. Worn

rear axle pinion shaft splines.

b. Side

gear hub counterbore in case worn

oversize.

c. Worn U-joints.

d. Excessive transmission backlash.

e. Worn axle shaft splines.

11. Chatter on turns.

a. Wrong

lube in rear axle.

b. Clutch

cone worn or spalled.

12. Clunk

or knock on rough road operation.

a. Worn suspension bushings.

PRE-REPAIR INVESTIGATION AND TROUBLE

DIAGNOSIS

A carefull diagnosis of the rear axle prior to

disassembly will often reveal valuable information as to

the extent and type of repairs or adjustments necessary.

Since frequent causes of axle noises are improper

backlash, pinion bearing pre-load, or side bearing

pre-load, or a combination, a few simple adjustments

may be all that are necessary to correct a problem.

Before disassembling the rear axle, the following

checks should be made with the results recorded and

analyzed: 1) Backlash;

2) Total Assembly Preload; 3)

Tooth Contact Pattern Test; 4) Fluid Level; and 5)

Fluid Contamination.

If axle shaft end play is excessive then check

bearings, retainer, and bolts securing backing plate.

The axle bearings could be worn and need replacement.

The four bolts or nuts securing the brake backing plate

may be loose, stripped, or missing. If the inner bearing

retainer worked loose it must be replaced.

Use care at all times to keep dirt and other foreign

matter, such as grinder dust, soot or sand, away from

differential to prevent possibility of subsequent failure.

Page 277 of 1825

4B-4 REAR AXLE

d. Incorrect driveline angle.

Noise changes on a different type of road.

a. Road noise.

b. Tire noise.

Noise tone lowers as car speed is lowered.

a. Tire noise.

Similar noise is produced with car standing and

driving.

a. Engine noise.

b. Transmission noise.

Vibration. a. Rough rear wheel bearing.

b. Unbalanced

or damaged propeller shaft.

c. Tire unbalance.

d. Worn

universal joint in propeller shaft.

e. Incorrect driveline angle.

f. Mis-indexed propeller shaft at pinion

flange.

g. Pinion

flange

runout too great.

A knock or click approximately every two

revolutions of the rear wheel.

a. A rear wheel bearing.

Noise most pronounced on turns.

a. Rear

axle side gear and pinion noise.

A continuous low pitch whirring or scraping

noise starting at relatively low speed.

a. Pinion bearing noise.

Drive noise, coast noise or float noise.

a. Ring and

pinion gear noise.

Clunk on acceleration or deceleration.

a. Worn rear

axle pinion shaft in case or side

gear hub counterbore in case worn oversize.

b. Insufficient

lubrication on propeller shaft

slip yoke.

c. Worn U-joints on

propeller shaft. Front or

rear.

Groan in "Forward" or "Reverse".

a. Wrong

or contaminated lube in rear axle.

b. Worn bushings.

Chatter on turns.

a. Wrong

or contaminated lube in rear axle.

b. Clutch

cone worn and/or

spring(s) worn.

Clunk or knock on rough road operation.

a. Excessive end play of axle shafts to

differential cross shaft.

b. Worn bushings.

PRE-REPAIR INVESTIGATION AND TROUBLE

DIAGNOSIS

A careful1 diagnosis of the rear axle prior to

disassembly will often reveal valuable information as to

the extent and type of repairs or adjustments necessary.

Since frequent causes of axle noises are improper

backlash, pinion bearing pre-load, or side bearing

pre-load, or a combination, a few simple adjustments

may be all that are necessary to correct a problem.

Therefore, before removing the rear axle from the

housing, the following checks should be made with the

results recorded and analyzed:

1) Backlash; 2) Total Assembly

Preload; 3) Tooth Contact Pattern Test;

4)

Fluid Level; and 5) Fluid Contamination.

Use care at all times to keep dirt and other foreign

matter, such as grinder dust, soot or sand, away from

differential to prevent possibility of subsequent failure.

The pinion and ring gear must be completely

assembled, installed and all pre-load and backlash

adjustments completed prior to the start of this method

of pinion depth setting. The following procedure can

be used in place of the gage method of pinion depth

setting.

Gear Tooth Nomenclature

The side of the ring gear tooth which curves

outward, or is convex, is referred to as the "drive" side.

The concave side is the "coast" side. The end of the

tooth nearest center of ring gear is referred to as the

"toe" end. The end of the tooth farthest away from the

center is the "heel" end. Toe end of tooth is smaller

than heel end.

It is very important that tooth contact be tested

before the rear axle carrier assembly is disassembled.

Variations in the carrier or pinion rear bearing may

cause the pinion to be too far away from, or close to,

the ring gear. Thus, the tooth contact must be tested

and corrected, if necessary, or the gears may be noisy.

Tooth Contact Pattern Test

1. Wipe oil out of carrier and carefully clean each

tooth of ring gear.

2. Use gear marking compound part number

1052351 or equivalent and apply this mixture

sparingly to all ring gear teeth, using a medium

stiff brush. When properly used, the area of

pinion tooth contact will be visible when hand

load is applied.

3. Tighten bearing cap bolts to 75

N.m (55 lb. ft.).

4. Expand

brake shoes using parking brake cables

until a torque of 54 to

70 N-m (40-50 lb. ft.) is

required to turn the pinion.

A test made without loading the gears will not

give a satisfactory pattern. Turn pinion flange

with wrench so that ring gear rotates one full

revolution, then reverse rotation so that ring gear

rotates one revolution in opposite direction.

5. Observe

pattern on ring gear teeth and compare

with Fig. 3.

Effects of Increasing Load on Teeth Contact

Pattern

When "load" on ring and pinion gear is

increased, such as when car is accelerated forward

from standstill or from normal drive, the tooth contact

will tend to spread out and, under very heavy load, will

extend from near toe to near heel on the drive side. The

entire contact also tends to shift toward heel under

increasingly heavier loads and will become somewhat

broader with respect to tops and bottoms of teeth. The

patterns obtained by this tooth contact pattern test

approximate a light load and, for this reason, they will

extend only about halfway.

Page 296 of 1825

BRAKES 5-3

DIAGNOSIS AND INSPECTION

BRAKE SYSTEM TESTING

(Figures

2 through 4)

Brakes should be tested on dry, clean, reasonably

smooth and level roadway. A true test of brake performance

cannot be made if the roadway is wet, greasy or covered

with loose dirt so that all tires do not grip the road equally.

Testing will also be affected if the roadway is crowned

which would throw the weight of the car toward the wheels

on one side. If the roadway is too rough, the wheels will tend

to bounce. Test brakes at different car speeds with both light and

heavy pedal pressure, avoid locking the brakes and sliding

the tires. Locked brakes and sliding tires do not indicate

brake efficiency, because heavily braked, but turning

wheels will stop the car in less distance than locked brakes.

More tire-to-road friction is present with a heavily braked

turning tire than with a sliding tire. The brake system is designed and balanced to avoid

locking the wheels, except at very high deceleration levels.

The shortest stopping distance and best control is achieved

without brake lock-up.

Because of high deceleration capability, a firmer pedal

may be felt at higher deceleration levels.

External Conditions That Affect Brake Performance

1. Tires. Tires having unequal contact and grip on road

will cause unequal braking. Tires must be equally

inflated and tread pattern of right and left tires must

be approximately equal.

2. Car Loading. A heavily loaded car requires more

braking effort. When a car has unequal loading, the

most heavily loaded wheels require more braking

power than others.

3. Wheel Alignment. Misalignment of the wheels, par-

ticularly excessive camber and caster, will cause the

brakes to pull to one side.

4. Front Wheel Bearings. A loose front wheel bearing

BRAKE FLUID LEAKS

With engine running at idle and the transmission in neu-

tral, depress the brake pedal and hold a constant foot pres-

sure.

If the pedal gradually falls away with the constant

pressure, the hydraulic system may be leaking. Perform a

visual check to confirm any suspected leak.

Check the master cylinder fluid levels. While a slight drop

in reservoir level does result from normal lining wear, an

abnormally low level in either reservoir indicates

a leak in

the system. The hydraulic system may be leaking either

internally or externally. See "Master Cylinder Check."

Also, the system may appear to pass this test but still have

slight leakage.

If fluid levels are normal, check the vacuum booster

pushrod length. If an incorrect length pushrod is found,

adjust or replace the

pushrod. Check the service brake

pedal travel and the parking brake adjustment.

When checking the fluid levels, the master cylinder reser-

voir may be as low as

25 mm (1 inch) from the top if the front

linings are worn. This is not abnormal.

MASTER CYLINDER CHECK

These checks will help locate some master cylinder mal-

functions. Use the Brake Diagnosis Charts to help isolate

the problem if it is not found by using these tests.

1. Check for a cracked master cylinder casting or brake

fluid around the master cylinder. Leaks are indicated

only if there is at least a drop of fluid. A damp condi-

tion is not abnormal.

2. Check for a binding pedal linkage.

3. Disassemble the master cylinder and check for swol-

len or stretched piston

seal(s). If swollen seals are

found, substandard or contaminated brake fluid

should be suspected.

If contaminated, all compo-

nents should be disassembled and cleaned. All rub-

ber components should be replaced and all the pipes

should be flushed.

permits the front wheel to tilt and lose contact with the

SUBSTANDARD OR CONTAMINATED brake shoe linings causing erratic brake operation. BRAKE FLUID

WARNING LAMP OPERATION

The brake system uses a single red "BRAKE" warning

lamp located in the instrument panel cluster. When the

ignition switch is in the "START" position, the "BRAKE"

warning lamp should come on. It should go off when the

ignition switch returns to the "RUN" position.

The following conditions will activate the "BRAKE"

warning lamp:

1. Parking brake applied. The lamp should be on when

tfie parking brake is applied and the ignition switch is

"ON."

2. Pressure differential switch detects a failure. See

"Brake Pressure Differential Warning Switch" in this

section. Improper

brake fluid, mineral oil or water in the fluid may

cause the brake fluid to boil or the rubber components to

deteriorate.

If piston cups are swollen, the rubber parts have dete-

riorated. This deterioration may also be seen by swollen

wheel cylinder piston cups on the drum brake wheels or a

swollen master cylinder cover diaphragm.

If rubber deterioration is evident, disassemble all hydrau-

lic parts and wash with alcohol. Dry these parts with com-

pressed air before assembly to keep alcohol out of the

system. Replace all rubber parts in the system, including

hoses. Check for fluid on the linings. If excessive fluid is

found, replace the linings.

If master cylinder piston seals are satisfactory, check for

leakage or excessive heat conditions. If condition is not

found, drain fluid, flush with brake fluid, fill and bleed the

system.

Page 412 of 1825

ENGINE COOLING 6B-1

SECTION 6B

NE COOL

General Description ................................ 6B- 1 Off-Vehicle Leak Testing ............................... 6B-9

Radiator

...................................................... 6B- 1 Repairable Leaks ........................ ... .......... 6B- 10

Radiator Cap

......................... .. ............... 6B- 1 Repair Methods ................................................ 6B- 10

Recovery Bottle ......................................... 6B-2 Cooling Fin Removal ................................ 6B- 10 - ............................................. Fans ............................................................... 6B-2 Tube Blocking 6B- 1 1 ............ Header Repair ....................... .... 6B- 1 1 Temperature Switch ..................................... 6B-2 General Core Repair 6B- 1 1 ....................................

........................... Coolant Temperature Fan Switch ................ 6B-2 Tank

Gasket ~eik Repair 6B- 12

................... Thermostat .. 6B-3 Oil

Cooler Gasket Replacement

6B- 13 ............... ................................

...........................................................

Coolant Recovery System 6B-3 Recore 6B- 14 ............................. Special Tools ..................................................... 6B- 14 Diagnosis ..................................................... 6B-3

.............................. ..................................... Service Procedures 6B-3 On-Vehicle Service 6B-14

Cooling System Care

............................... 6B-3 Thermostat ....................................... 6B-14

Draining and Refilling the Cooling Electric Cooling Fan ............................. 6B-15

System

................................................... 6B-7 Water Pump .................... .... ......... 6B-15

Drive Belt

...................... .. .......................... 6B-7 Coolant Recovery Bottle ........................ 6B-16

.......................................... Aluminum Radiator Service .................... 6B-8 Radiator 6B-17

Diagnosis .................................................... 6B-8

Leak Testing

.............................................. 6B-8

On-Vehicle Pressure Testing

...................... .... 6B-9

GENERAL DESCRIPnIBN

The cooling system maintains engine temperature

5" below the filler neck which reads, "Important - for

at an efficient level during all engine operating repair see Harrison Service Manual". Service

conditions. When the engine is cold the system cools procedures for the aluminum plastic radiator are

slowly, or not at all, to allow the engine to warm up described in that manual and in this section.

quickly.

The cooling system includes a radiator and

Radiator Cap

recovery sub-system, cooling fan, thermostat and

housing, water pump, and drive belts.

Operation of the cooling system requires proper

functioning of all components. Coolant is drawn from

the radiator by the water pump and circulated through

water jackets in the engine block, intake manifold, and

cylinder

head(s), and then directed back to the radiator

where it's cooled.

This system directs some coolant through hoses

to the heater core, to provide for heating and

defrosting. A recovery bottle is connected to the

radiator to recover coolant displaced by expansion

from high temperatures and maintain correct coolant

level. As the coolant cools and contracts it is drawn

back into the radiator by vacuum.

RADIATOR

A cross-flow radiator is used on all models. Tanks

in this type radiator are located to the right and left of

the core, instead of above and below.

Radiators used with automatic transmissions

have oil coolers with inlet and outlet fittings for

transmission fluid circulation. Cars with manual

transmissions use radiators without oil coolers.

Vehicles equipped with air conditioning use a radiator

with extra cooling capability.

An aluminum-plastic radiator, used on some

models, can be identified by a note on the outlet tank A pressure-vent

cap is used on the cross-flow

radiator to allow a buildup of

103 kPa (15 psi) in the

cooling system. This pressure raises the boiling point

of coolant to approximately 125°C (262°F) at sea level.

Do not remove radiator cap to check engine

coolant level; check coolant visually at the

see-through coolant reservoir. Coolant should

be added only

to the reservoir.

CAUTION: As long as there

is

pressure in the cooling system, the

temperature can be considerably

higher than the boiling temperature

of

the solution in the radiator without

causing the solution to boil. Removal

of the radiator cap while engine is hot

and pressure is high will cause

the

solution to boil instantaneously and

possibly with explosive

force, spewing

the solution over engine, fenders and

person removing cap. If the solution

contains flammable antifreeze, such

as alcohol (not recommended for use

at any time), there is also the

possibility

of causing a serious fire.

The pressure-type radiator filler cap contains a

blow off or pressure valve and a vacuum or

atmospheric valve (Figure

1). The pressure valve is

held against its seat by a spring of pre-determined