brake sensor PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 16 of 1825

- -

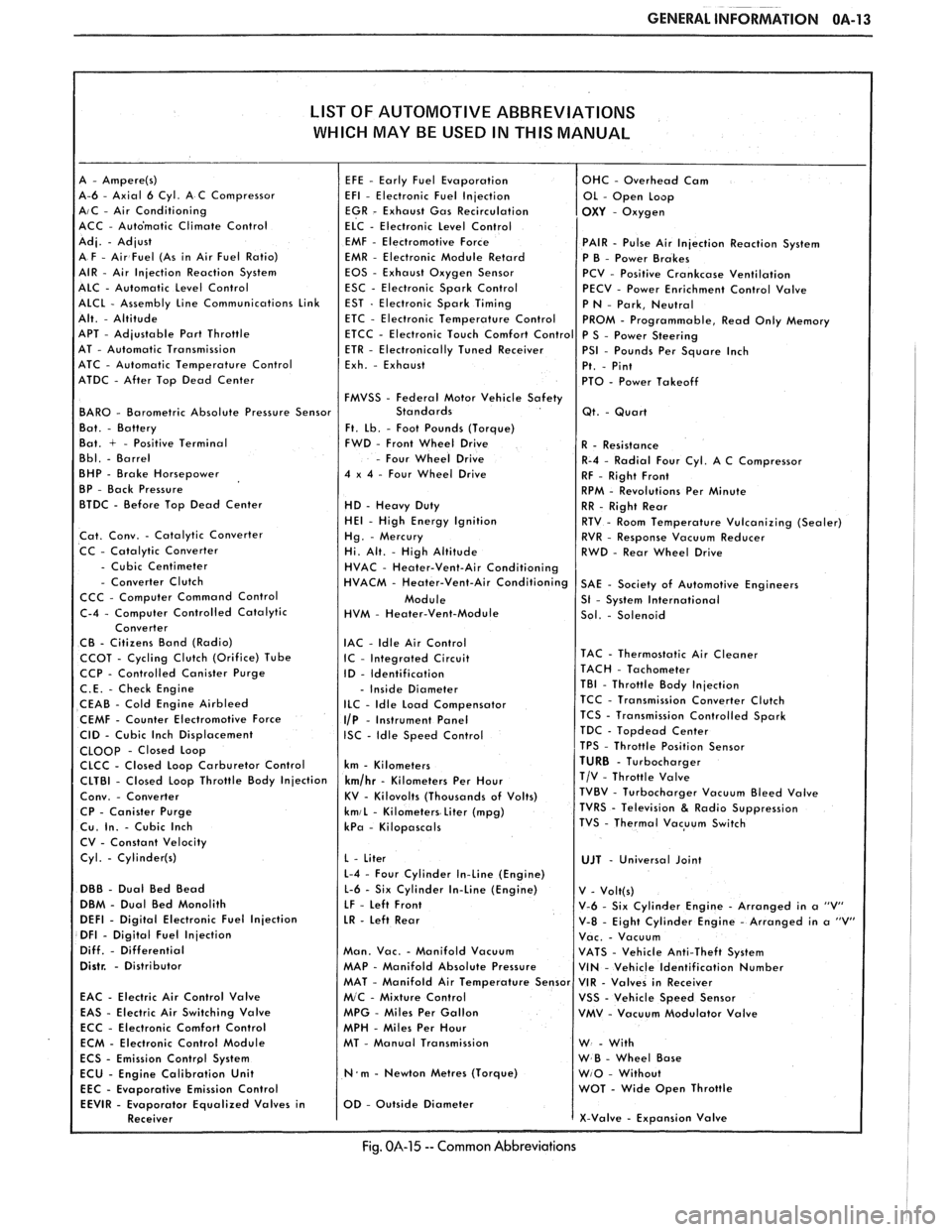

GENERAL INFORMATION OA-13

LIST OF AUTOMOTIVE ABBREVIATIONS

WHICH MAY

BE USED IN THIS MANUAL

A-6 - Axial 6 Cyl. A C Compressor AIC - Air Conditioning

ACC - Auto'matic Climate Control

EMF

- Electromotive Force PAIR - Pulse Air Injection Reaction System

EMR - Electronic Module Retard

P B - Power Brakes

EOS - Exhaust Oxygen Sensor

PCV - Positive Crankcase Ventilation

ESC - Electronic Spark Control

PECV - Power Enrichment Control Valve

APT

- Adjustable Part Throttle

AT - Automatic Transmission

ATC - Automatic Temperature Control

ATDC

- After Top Dead Center

FMVSS

- Federal Motor Vehicle Safety BAR0 - Barometric Absolute Pressure Sensor

Ft. Lb. - Foot Pounds (Torque)

Bat. + - Positive Terminal FWD - Front Wheel Drive

- Four Wheel Drive

BHP - Brake Horsepower 4 x 4 - Four Wheel Drive

BP - Back Pressure

BTDC - Before Top Dead Center

HD - Heavy Duty HE1 - High Energy Ignition

Cat. Conv. - Catalytic Converter

CC - Catalytic Converter

- Cubic Centimeter - Converter Clutch

CCC - Computer Command Control

HVM

- Heater-Vent-Module

IAC

- ldle Air Control CCOT - Cycling Clutch (Orifice) Tube IC - Integrated Circuit CCP - Controlled Canister Purge

ID - Identification

C.E. - Check Engine - Inside Diameter

CEAB - Cold Engine Airbleed ILC - Idle Load Compensator

CEMF - Counter Electromotive Force I/P - Instrument Panel

CID - Cubic Inch Displacement ISC - Idle Speed Control CLOOp - Closed Loop

CLCC - Closed Loop Carburetor Control km - Kilometers

CP

- Canister Purge kmiL - Kilometers Liter (mpg) Cu. In. - Cubic Inch kPa - Kilopascals

CV - Constant Velocity

Cyl.

- Cylinder(s)

L-4 - Four Cylinder In-Line (Engine)

DBB - Dual Bed Bead L-6 - Six Cylinder In-Line (Engine)

DBM - Dual Bed Monolith

LF - Left Front DEFl - Digital Electronic Fuel Injection LR - Left Rear DFI - Digital Fuel Injection

Diff. - Differential Man. Vac. - Manifold Vacuum Distr. - Distributor MAP - Manifold Absolute Pressure

EAC

- Electric Air Control Valve

EAS - Electric Air Switching Valve MPG - Miles Per Gallon

ECC - Electronic Comfort Control

MPH - Miles Per Hour

ECM - Electronic Control Module MT - Manual Transmission

N.m - Newton Metres (Torque)

Emission Control

Fig. 014-15 -- Common Abbreviations

Page 318 of 1825

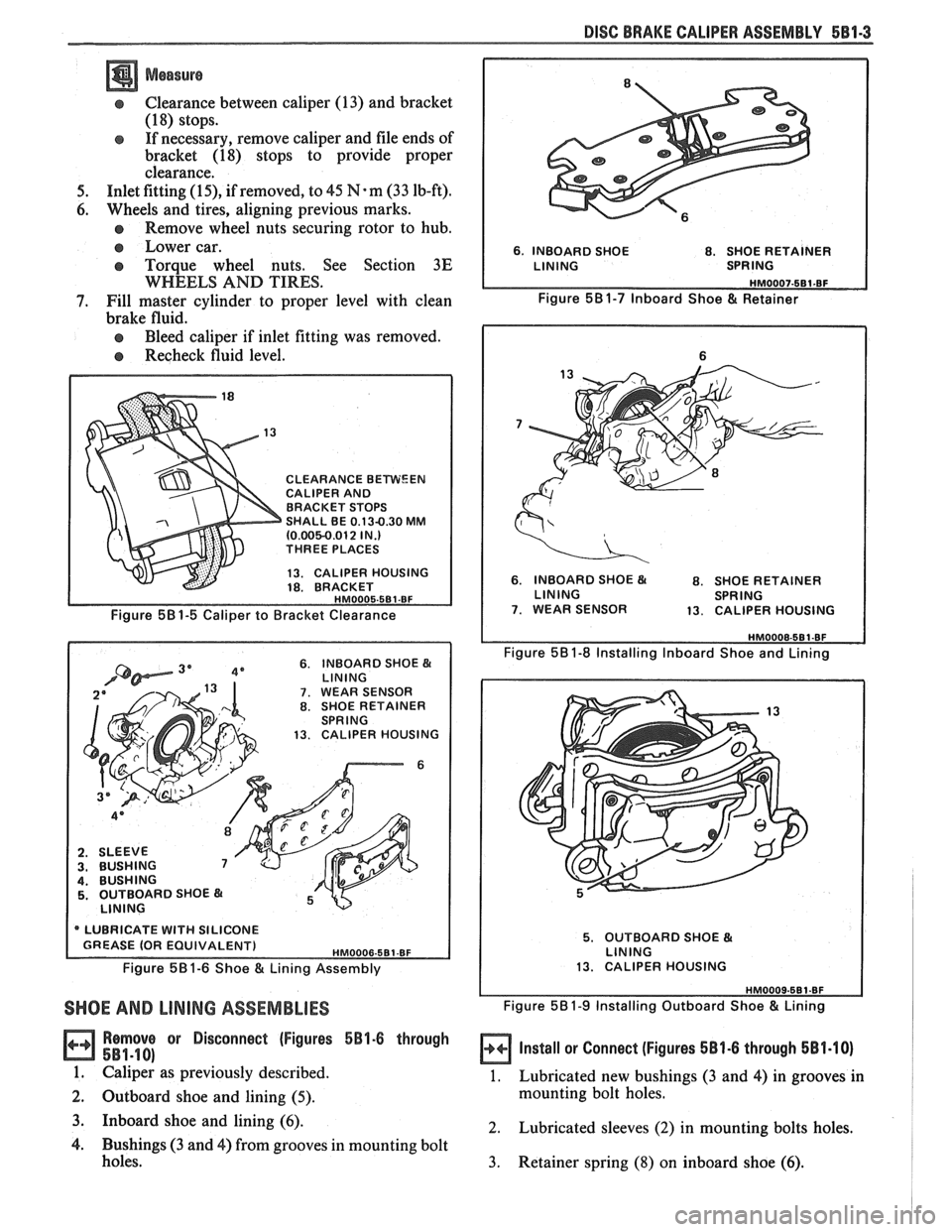

DISC BRAKE CALIPER ASSEMBLY 581-3

a Measure

Clearance between caliper (13) and bracket

(1 8) stops.

If necessary, remove caliper and file ends of

bracket

(18) stops to provide proper

clearance.

5. Inlet fitting (15), if removed, to 45 N-m (33 lb-ft).

6. Wheels and tires, aligning previous marks.

Remove wheel nuts securing rotor to hub.

e Lower car.

e Torque wheel nuts. See Section 3E

WHEELS AND TIRES.

7. Fill master cylinder to proper level with clean

brake fluid.

Bleed caliper if inlet fitting was removed.

Recheck fluid level.

CLEARANCE BEWEEN CALIPER AND

BRACKET STOPS

SHALL BE

0.13-0.30 MM (0.0050.012 IN.) THREE PLACES

13. CALIPER HOUSING

18. BRACKET

Figure 581-5 Caliper to Bracket Clearance

6. INBOARD SHOE B( LlNlNG 7. WEAR SENSOR 8. SHOE RETAINER

SPRING

13. CALIPER HOUSING

6

2. SLEEVE 3. BUSHING 4. BUSHING 5. OUTBOARD SHOE

LlNlNG

* LUBRICATE WITH SILICONE

Figure 58 1-6 Shoe & Lining Assembly

SHOE AND LINING ASSEMBLIES

Remove or Disconnect (Figures 5B1-6 through

581-18)

1. Calipe; as previously described.

2. Outboard shoe and lining

(5).

6, INBOARD SHOE 8. SHOE RETAINER

Figure 581-7 lnboard Shoe & Retainer

6. INBOARD SHOE B( 8. SHOE RETAINER

LINING SPRING

7. WEAR SENSOR 13. CALIPER HOUSING

Figure 581-8 Installing lnboard Shoe and Lining

5. OUTBOARD SHOE & LINING

13. CALIPER HOUSING

Figure 581-9 Installing Outboard Shoe & Lining

Install or Connect (Figures 581.6 through 581.10)

1. Lubricated new bushings (3 and 4) in grooves in

mounting bolt holes.

3. Inboard shoe and lining (6). 2. Lubricated sleeves (2) in mounting bolts holes.

4. Bushings (3 and 4) from grooves in mounting bolt

holes.

3. Retainer spring (8) on inboard shoe (6).

Page 319 of 1825

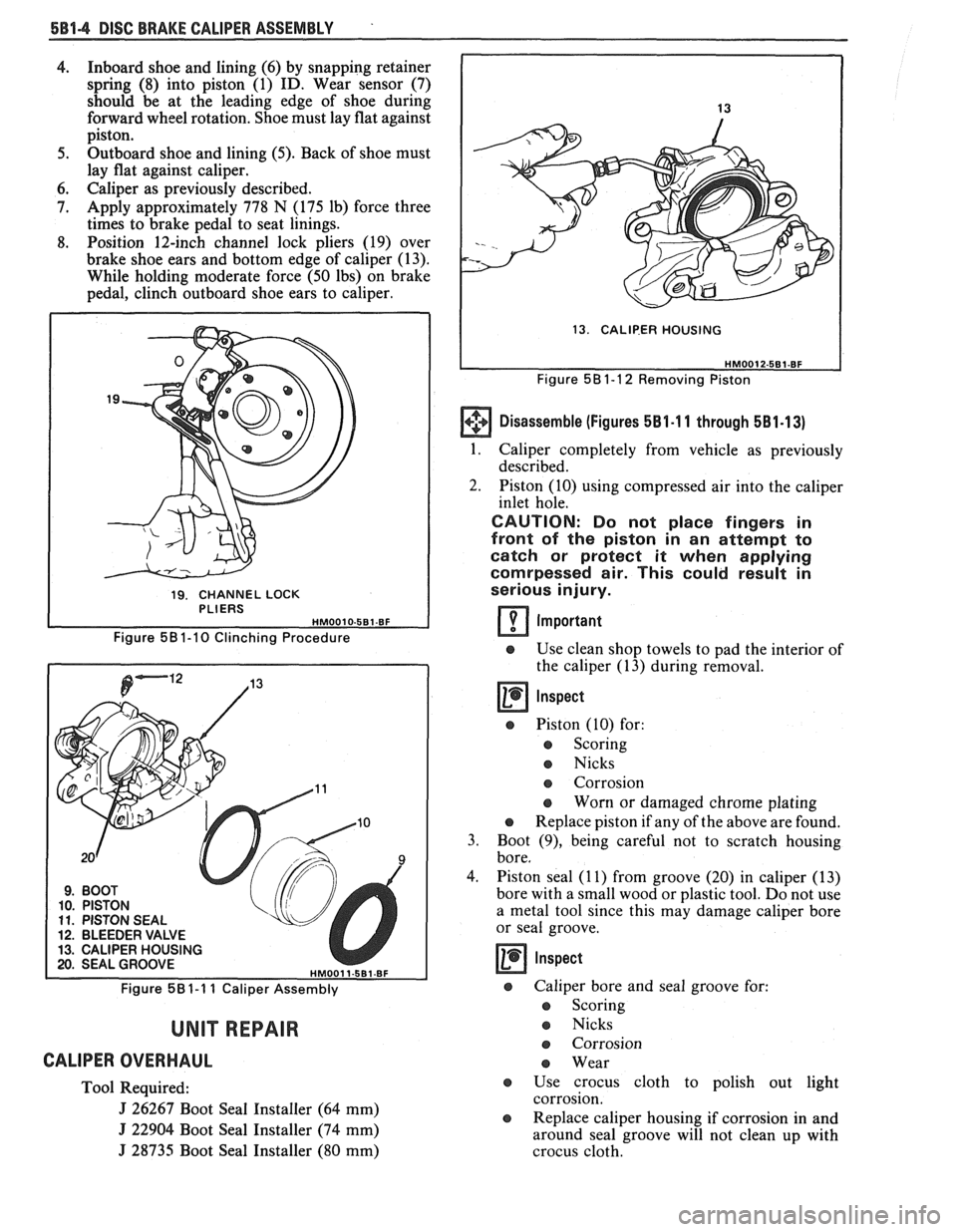

5814 DISC BRAKE CALIPER ASSEMBLY .

4. Inboard shoe and lining (6) by snapping retainer

spring (8) into piston (1) ID. Wear sensor (7)

should be at the leading edge of shoe during

forward wheel rotation. Shoe must lay flat against

piston.

5. Outboard

shoe and lining (5). Back of shoe must

lay flat against caliper.

6. Caliper as previously described.

7. Apply approximately

778

N (175 lb) force three

times to brake pedal to seat linings.

8. Position 12-inch channel lock pliers (19) over

brake shoe ears and bottom edge of caliper (13).

While holding moderate force (50 Ibs) on brake

pedal, clinch outboard shoe ears to caliper.

19. CHANNEL LOCK

PLIERS

Figure 58 1-1 0 Clinching Procedure

9. BOOT 10. PISTON 11. PISTON SEAL 12. BLEEDER VALVE 13. CALIPER HOUSING 20. SEAL GROOVE HMO01 1-5B1-BF

Figure 581-1 1 Caliper Assembly

UNIT REPAIR

CALIPER OVERHAUL

Tool Required:

J 26267 Boot Seal Installer (64 mm)

J 22904 Boot Seal Installer (74 mm)

J 28735 Boot Seal Installer (80 mm)

I

13. CALlP-ER HOUSING

I

Figure 58 1-1 2 Removing Piston

Disassemble (Figures 581-1 1 through 5B1-13)

1. Caliper completely from vehicle as previously

described.

2. Piston (10) using compressed air into the caliper

inlet hole.

CAUTION: Do not place fingers in

front of the piston in an attempt to

catch or protect it when applying

comrpessed air. This could result in

serious injury.

Important

e Use clean shop towels to pad the interior of

the caliper (13) during removal.

@ Piston (10) for:

e Scoring

Nicks

e Corrosion

e Worn or damaged chrome plating

e Replace piston if any of the above are found.

3. Boot (9), being careful not to scratch housing

bore,

4. Piston seal

(1 1) from groove (20) in caliper (13)

bore with a small wood or plastic tool. Do not use

a metal tool since this may damage caliper bore

or seal groove.

Inspect

@ Caliper bore and seal groove for:

e Scoring

e Nicks

e Corrosion

Wear

e Use crocus cloth to polish out light

corrosion.

@ Replace caliper housing if corrosion in and

around seal groove will not clean up with

crocus cloth.

Page 322 of 1825

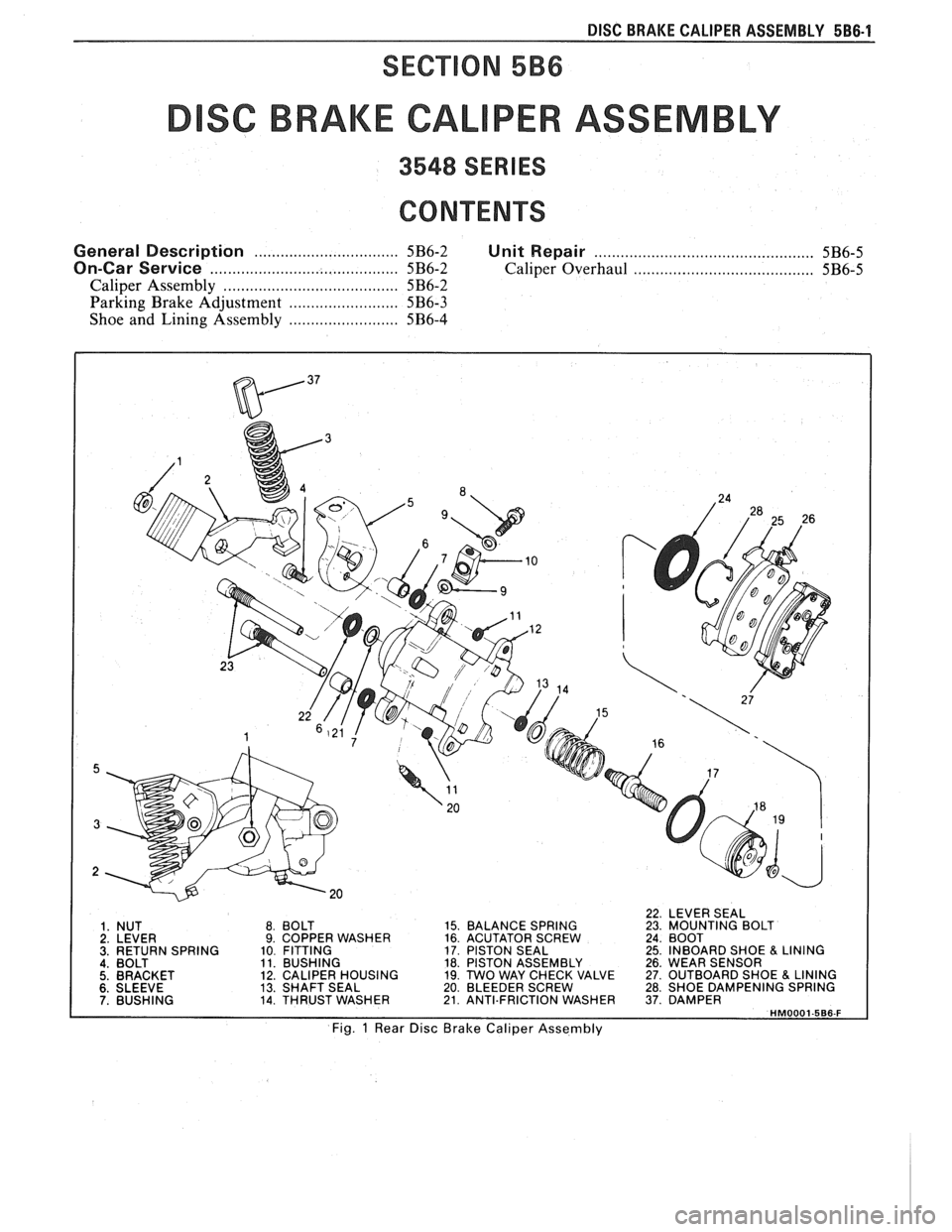

DISC BRAKE CALIPER ASSEMBLY 586-1

SEC"619RI 5B6

SC BRAKE CAL PER ASSEMBLY

3548 SERIES

CONTENTS

General Description ................................. 5B6-2 Unit Repair ........................................... 5B6-5

On-Car Service ........................................ 5B6-2 Caliper Overhaul ....................................... 5B6-5

Caliper Assembly ....................................... 5B6-2

Parking Brake Adjustment ......................... 5B6-3

Shoe and Lining Assembly ......................... 5B6-4

22 LEVER SEAL

1. NUT

2. LEVER

3. RETURN SPRING 4. BOLT 5. BRACKET 8.

BOLT 15.

BALANCE SPRING

23. MOUNT~NG BOLT 9. COPPER WASHER 16. ACUTATOR SCREW 24. BOOT

10 FITTING 17.

PISTON SEAL 25. INBOARD SHOE & LINING 11. BUSHING 18. PISTON ASSEMBLY 26. WEAR SENSOR

12. CALIPER HOUSING 19. TWO

WAY CHECK VALVE 27. OUTBOARD SHOE & LINING 6. SLEEVE 13. SHAFT SEAL 20. BLEEDER SCREW 28. SHOE DAMPENING SPRING 7. BUSHING 14. THRUST WASHER 21. ANTI.FRICTION WASHER 37. DAMPER HM0001-566-F

Fig. 1 Rear Disc Brake Caliper Assembly

Page 325 of 1825

e Remove lug nuts securing rotor to hub.

e Lower car.

o Torque lug nuts. See WHEELS AND

TIRES.

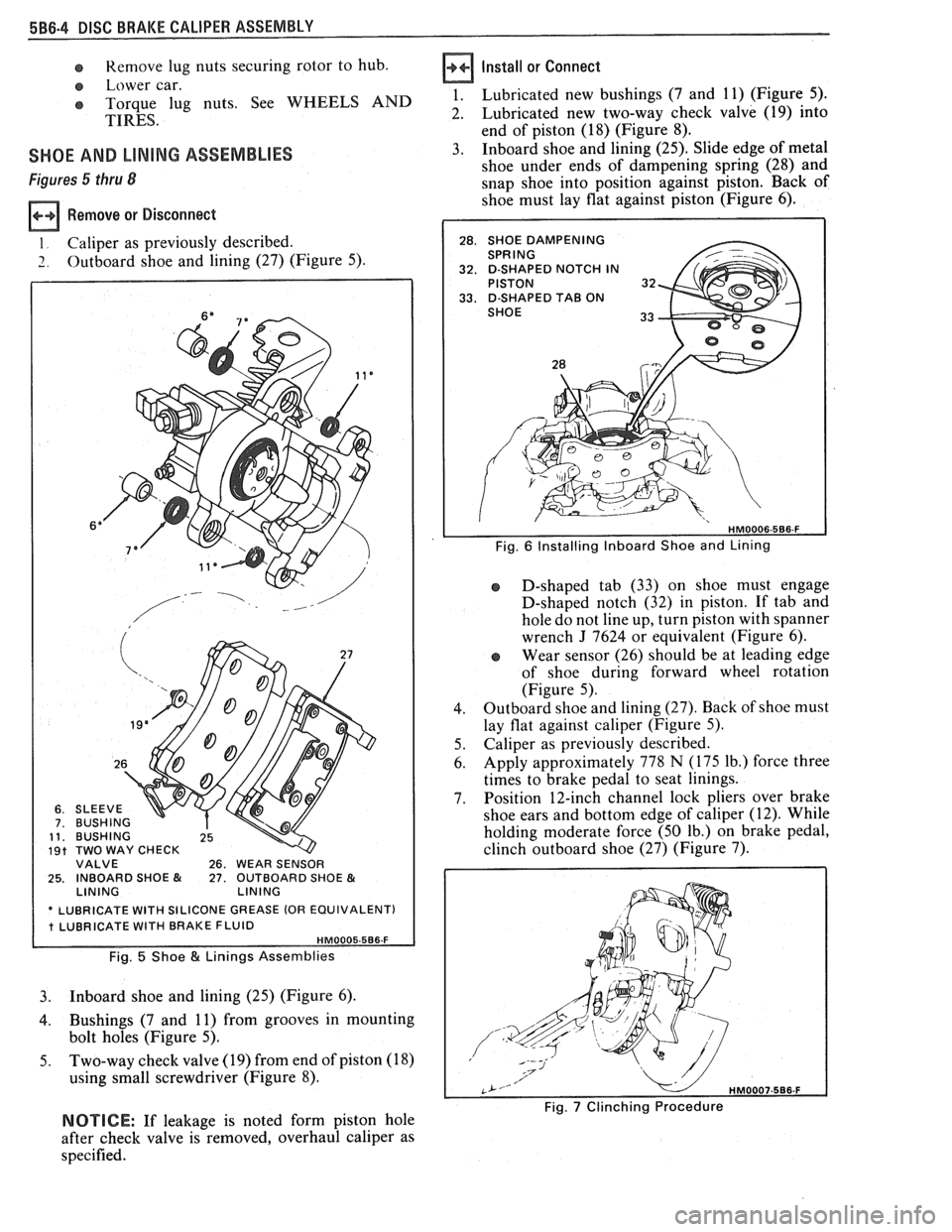

SHOE AND LINING ASSEMBLIES

Figures 5 thru 8

Remove or Disconnect

1. Caliper as previously described.

2 Outboard shoe and lining (27) (Figure 5).

Install or Connect

1. Lubricated new bushings (7 and 11) (Figure 5).

2. Lubricated new two-way check valve (19) into

end of piston (18) (Figure 8).

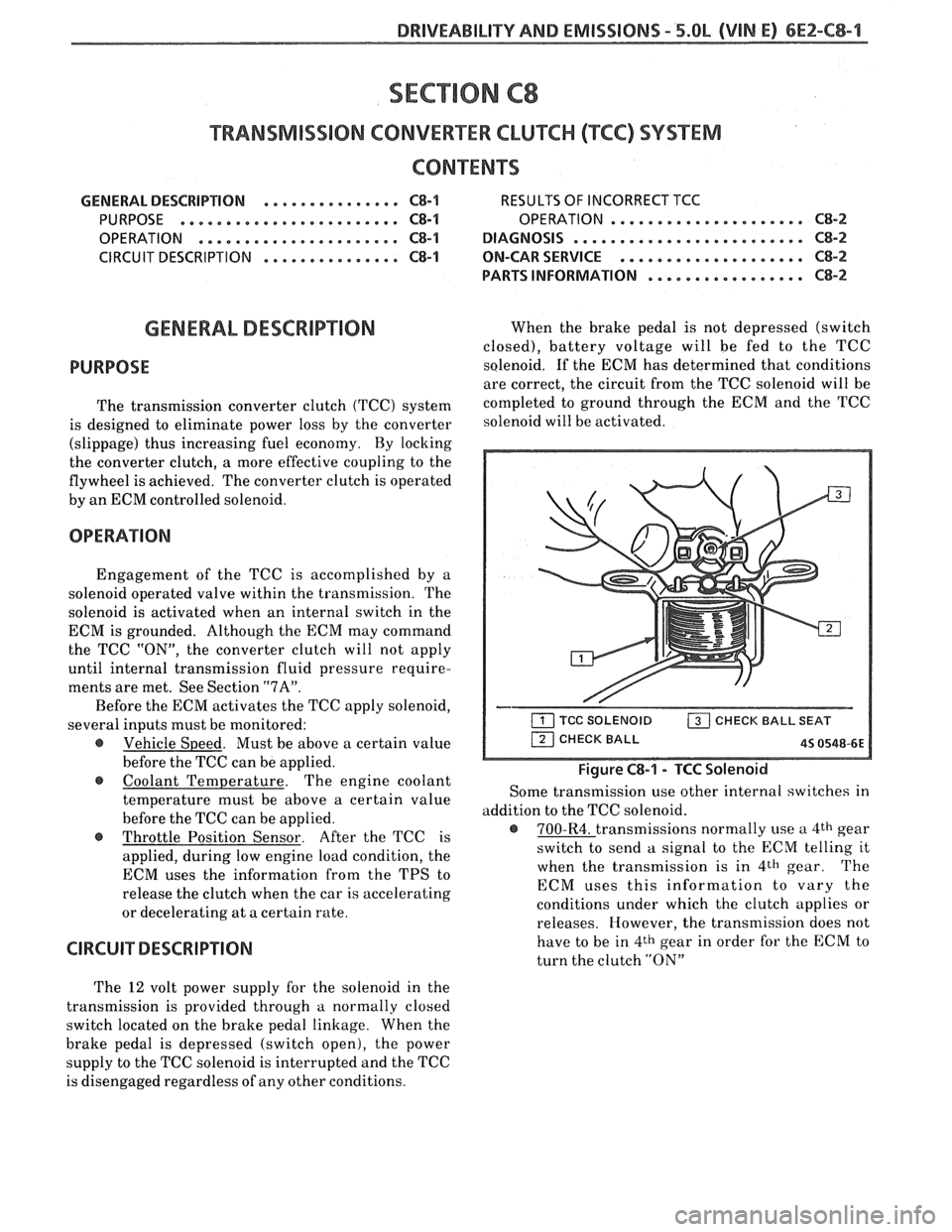

3. Inboard shoe and lining (25). Slide edge of metal

shoe under ends of dampening spring (28) and

snap shoe into position against piston. Back of

shoe must lay flat against piston (Figure 6).

Fig. 6 Installing Inboard Shoe and Lining

26. WEAR SENSOR 25. INBOARD SHOE & 27. OUTBOARD SHOE & LINING

ASE (OR EQUIVALENT)

Fig. 5 Shoe & Linings Assemblies

3. Inboard shoe and lining (25) (Figure 6).

4. Bushings (7 and 11) from grooves in mounting

bolt holes (Figure 5).

5. Two-way check valve (19) from end of piston (18)

using small screwdriver (Figure 8). D-shaped

tab (33) on shoe must engage

D-shaped notch (32) in piston. If tab and

hole do not line up, turn piston with spanner

wrench

J 7624 or equivalent (Figure 6).

r, Wear sensor (26) should be at leading edge

of shoe during forward wheel rotation

(Figure 5).

4. Outboard

shoe and lining (27). Back of shoe must

lay flat against caliper (Figure

5).

5. Caliper as previously described.

6. Apply approximately 778

N (175 lb.) force three

times to brake pedal to seat linings.

7. Position

12-inch channel lock pliers over brake

shoe ears and bottom edge of caliper (12). While

holding moderate force

(50 lb.) on brake pedal,

clinch outboard shoe (27) (Figure 7).

NOTICE: If leakage is noted form piston hole

after check valve is removed, overhaul caliper as

specified.

Page 626 of 1825

DRIVEABILITY AND EMISSIONS - 5.0L (VIM E) 6E2-C8-1

SECTION C8

"FRANSMISSIBN CONVERnEW CLUTCH (TCC) SYSTEM

CONTENTS

GENERAL DESCRIPTION ............... C8-1 RESULTS OF INCORRECT TCC

PURPOSE

........................ C8-1 OPERATION ..................... C8-2

......................... OPERATION ...................... C8-1 DIAGNOSIS CS-2

.................... CIRCUIT DESCRIPTION ....e.e..eea..e C8-1 ON-CAR SERVICE C8-2

................. PARTS INFORMATION C8-2

GENERAL DESCRIPTION

PURPOSE

The transmission converter clutch (TCC) system

is designed to eliminate power loss by the converter

(slippage) thus increasing fuel economy. By locking

the converter clutch,

a more effective coupling to the

flywheel is achieved. The converter clutch is operated

by an ECM controlled solenoid.

OPERATION

Engagement of the TCC is accomplished by a

solenoid operated valve within the transmission. The

solenoid is activated when an internal switch in the

ECM is grounded. Although the ECM may command

the TCC

"ON", the converter clutch will not apply

until internal transmission fluid pressure require-

ments are met. See Section

"7A".

Before the ECM activates the TCC apply solenoid,

several inputs must be monitored:

e Vehicle Speed. Must be above a certain value

before the TCC can be applied.

Coolant Temperature. The engine coolant

temperature must be above a certain value

before the TCC can be applied.

@ Throttle Position Sensor. After the TCC is

applied, during low engine load condition, the

ECM uses the information from the TPS to

release the clutch when the car is accelerating

or decelerating at a certain rate.

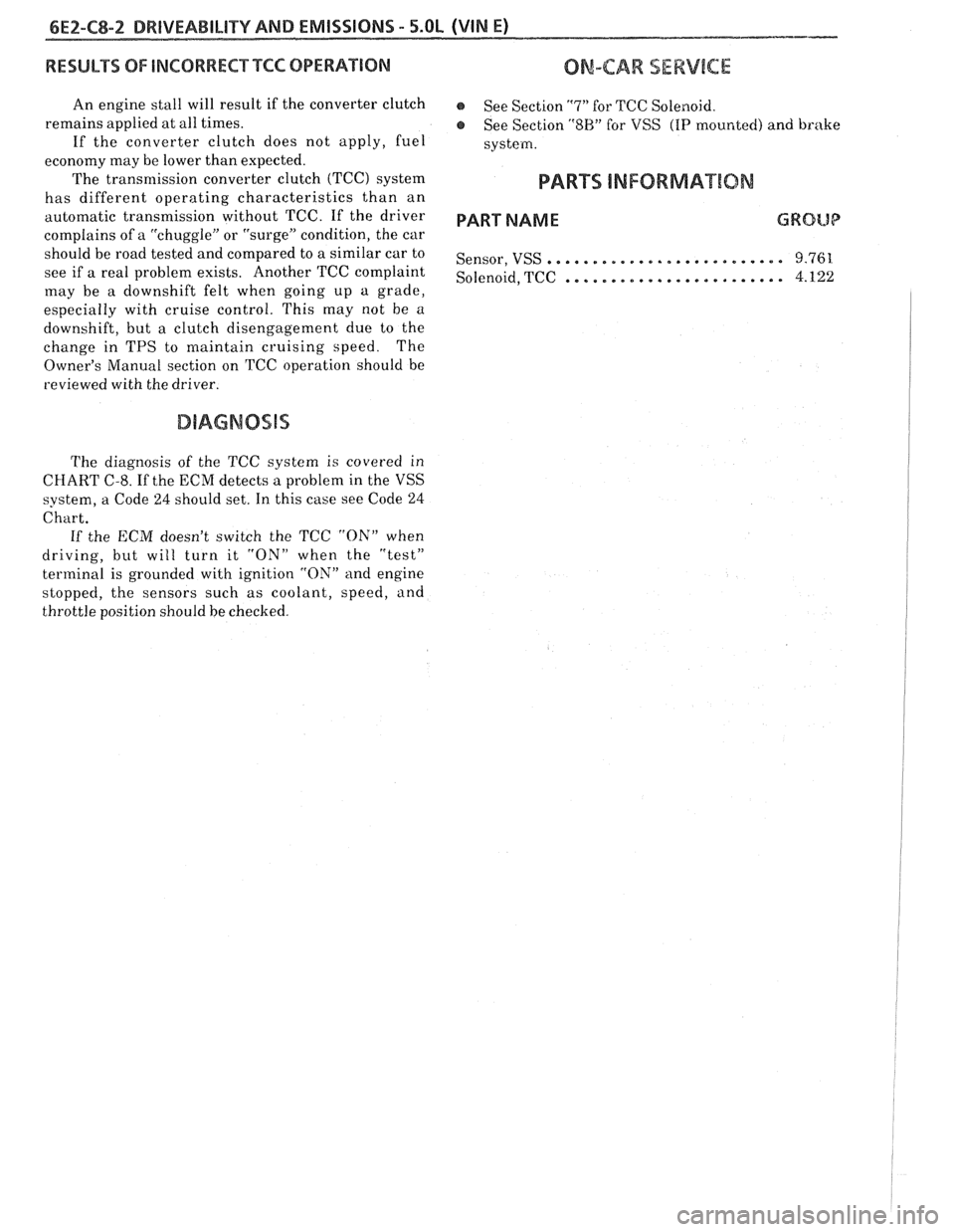

CIRCUIT DESCRIPTION

When the brake pedal is not depressed (switch

closed), battery voltage will be fed to the TCC

solenoid. If the ECM has determined that conditions

are correct, the circuit from the TCC solenoid will be

completed to ground through the ECM and the TCC

solenoid will be activated.

Figure C8-1 - TCC Solenoid

Some transmission use other internal switches in

addition to the TCC solenoid.

@ 700-R4. transmissions normally use a 4th gear

switch to send

a signal to the ECM telling it

when the transmission is in

4th gear. The

ECM uses this information to vary the

conditions under which the clutch applies or

releases. However, the transmission does not

have to be in

4th gear in order for the ECM to

turn the clutch

"ON"

The 12 volt power supply for the solenoid in the

transmission is provided through

a normally closed

switch located on the brake pedal linkage. When the

brake pedal is depressed (switch open), the power

supply to the TCC solenoid is interrupted and the TCC

is disengaged regardless of any other conditions.

Page 627 of 1825

6Ef-C8-2 BRlVEABlLlYV AND EMISSIONS - 5.OL (VIN E) ----

RESULTS OF INCORRECTTCC OPERATION

An engine stall will result if the converter clutch

remains applied at all times.

If the converter clutch does not apply, fuel

economy may be lower than expected.

The transmission converter clutch

(TCC) system

has different operating characteristics than an

automatic transmission without TCC.

If the driver

complains of a "chuggle" or "surge" condition, the car

should be road tested and compared to a similar car to

see if a real problem exists. Another TCC complaint

may be

a downshift felt when going up a grade,

especially with cruise control. This may not be

a

downshift, but a clutch disengagement due to the

change in TPS to maintain cruising speed. The

Owner's Manual section on TCC operation should be

reviewed with the driver.

DIAGNOSIS

The diagnosis of the TCC system is covered in

ClIART C-8. If the ECM detects a problem in the VSS

system, a Code

24 should set. In this case see Code 24

Chart.

If the ECM doesn't switch the TCC "ON" when

driving, but will turn it

"ON" when the "test"

terminal is grounded with ignition "ON" and engine

stopped, the sensors such as coolant, speed, and

throttle position should be checked.

ON-CAW SERVICE

@ See Section "7" for TCC Solenoid.

@ See Section "SH" for VSS (HP mounted) and brake

system.

PAR- SNFORMATBIQN

PART NAME GRQUQ

.......................... Sensor, VSS 9.761

........................ Solenoid, TCC 4.122

Page 629 of 1825

6EZ-C8-4 DRIVEABILITY AND EMISSIONS - 5.OL (VIN E)

I5 WAY (FRONT VIEW)

SPEED INPUT

4rH GEAR SIGNAL

422 TANIBLK

ALDL CONNECTOR

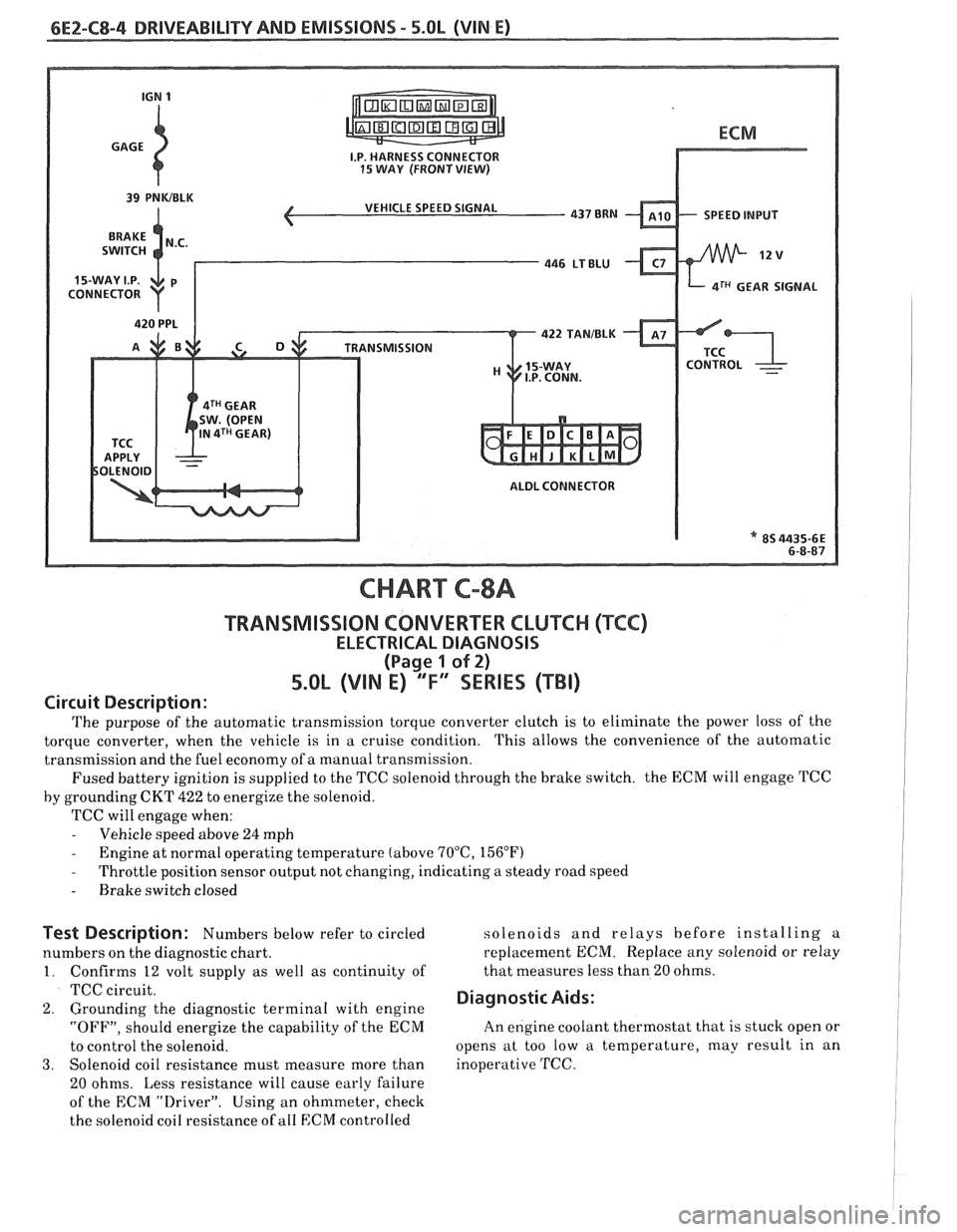

CHART C-8A

TRANSMISSION CONVERTER CLUTCH (TCC)

ELECTRICAL DIAGNOSIS

(Page 1 of 2)

5.OL (VIN E) "F" "SERIES (TBI)

Circuit Description:

The purpose of the automatic transmission torque converter clutch is to eliminate the power loss of the

torque converter, when the vehicle is in a cruise condition. This allows the convenience of the automatic

transmission and the fuel economy of a manual transmission.

Fused battery ignition is supplied to the TCC solenoid through the brake switch. the ECM will engage

TCC

by grounding CKT 422 to energize the solenoid.

TCC will engage when:

- Vehicle speed above 24 mph - Engine at normal operating temperature (above 70°C, 156°F)

- Throttle position sensor output not changing, indicating a steady road speed

- Brake switch closed

Test Description: Numbers below refer to circled solenoids

and relays before installing a

numbers on the diagnostic chart. replacement ECM. Replace

any solenoid or relay

1. Confirms 12 volt supply as well as continuity of that

measures less than 20 ohms.

TCC circuit.

2. Grounding the diagnostic terminal with engine Diagnostic Aids:

"OFF", should energize the capability of the ECM An

engine coolant thermostat that is stuck open or

to control the solenoid. opens

at too low a temperature, may result in an

3. Solenoid coil resistance must measure more than inoperative TCC.

20 ohms. Less resistance will cause early failure

of the ECM

drive^.". Using an ohmmeter, check

the solenoid coil resistance of

all ECM controlled

Page 727 of 1825

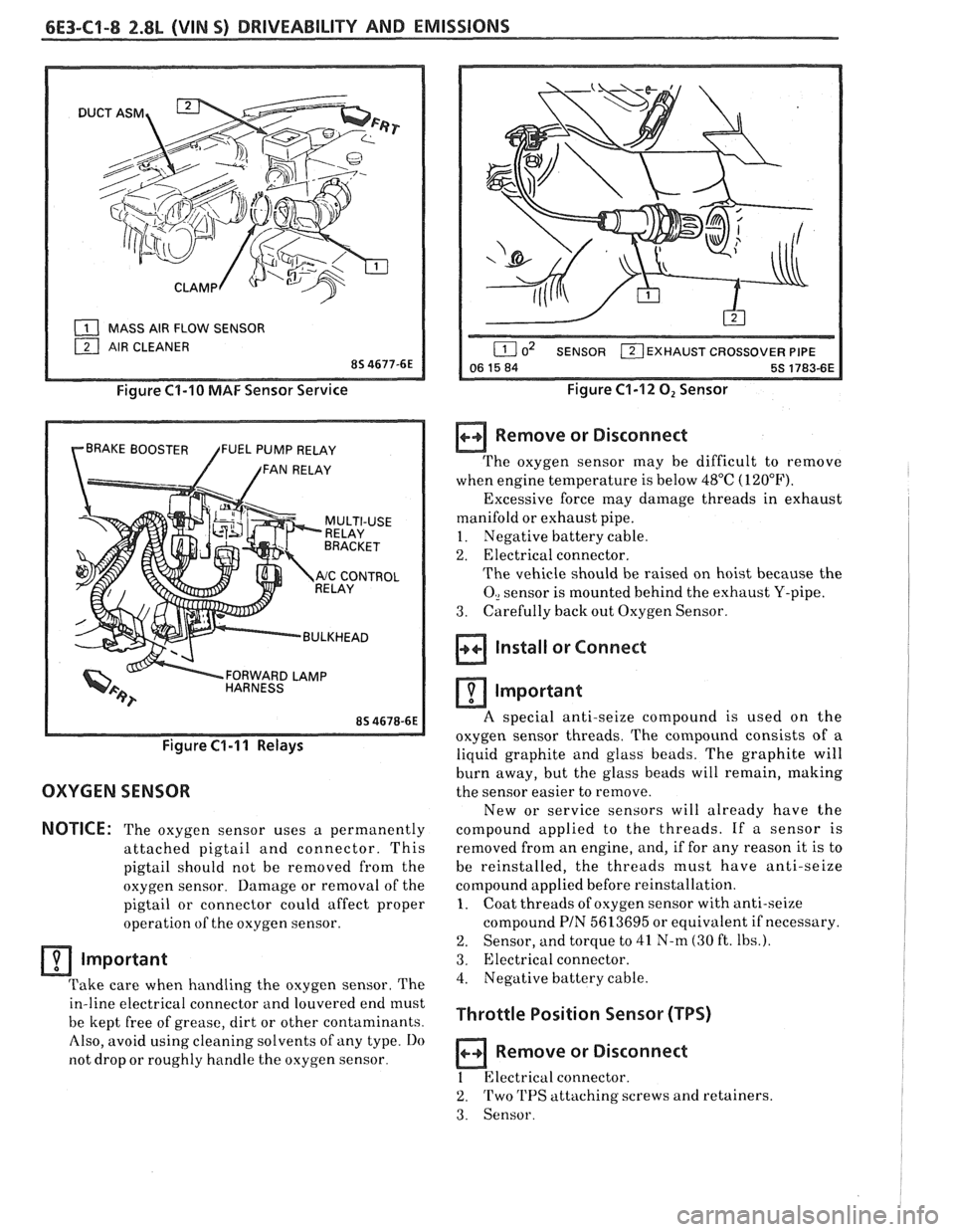

6E3-(31-8 2.8L (VIN S) DRIVEABILITY AND EMISSIONS

( MASS AIR FLOW SENSOR

Figure C1-10 MAF Sensor Service

BRAKE BOOSTER FUEL PUMP RELAY

/ /FAN RELAY

FORWARD LAMP

/ BULKHEAD

Figure C1-I I Relays

OXYGEN SENSOR

NOTICE:

The oxygen sensor uses a permanently

attached pigtail and connector. This

pigtail should not be removed from the

oxygen sensor. Damage or removal of the

pigtail or connector could affect proper

operation of the oxygen sensor.

Important

Take care when handling the oxygen sensor. The

in-line electrical connector and louvered end must

be kept free of grease, dirt or other contaminants.

Also, avoid using cleaning solvents of any type.

Do

not drop or roughly handle the oxygen sensor.

EXHAUST CROSSOVER PIPE

Figure C1-12 0, Sensor

Remove or Disconnect

The oxygen sensor may be difficult to remove

when engine temperature is below 48°C (120°F).

Excessive force may damage threads in exhaust

manifold or exhaust pipe.

~

1. Negative battery cable.

2. Electrical connector.

The vehicle should be raised on hoist because the

0, sensor is mounted behind the exhaust Y-pipe.

3. Carefully

back out Oxygen Sensor.

Install or Connect 1 i

Important I I

A special anti-seize compound is used on the

oxygen sensor threads. The compound consists

of a

liquid graphite and glass beads. The graphite will

burn away, but the glass beads will remain, making

the sensor easier to remove.

New or service sensors will already have the

compound applied to the threads. If a sensor is

removed from an engine, and, if for any reason it is to

be reinstalled, the threads must have anti-seize

compound applied before reinstallation.

1. Coat threads of oxygen sensor with anti-seize

compound

PIN 5613695 or equivalent if necessary.

2. Sensor, and torque to 41 N-m (30 ft. Ibs.).

3. Electrical connector.

4. Negative battery cable.

Throttle Position Sensor (TPS)

a Remove or Disconnect

1 Electrical connector.

2. Two 'I'PS attaching screws and retainers.

3. Sensor.

Page 786 of 1825

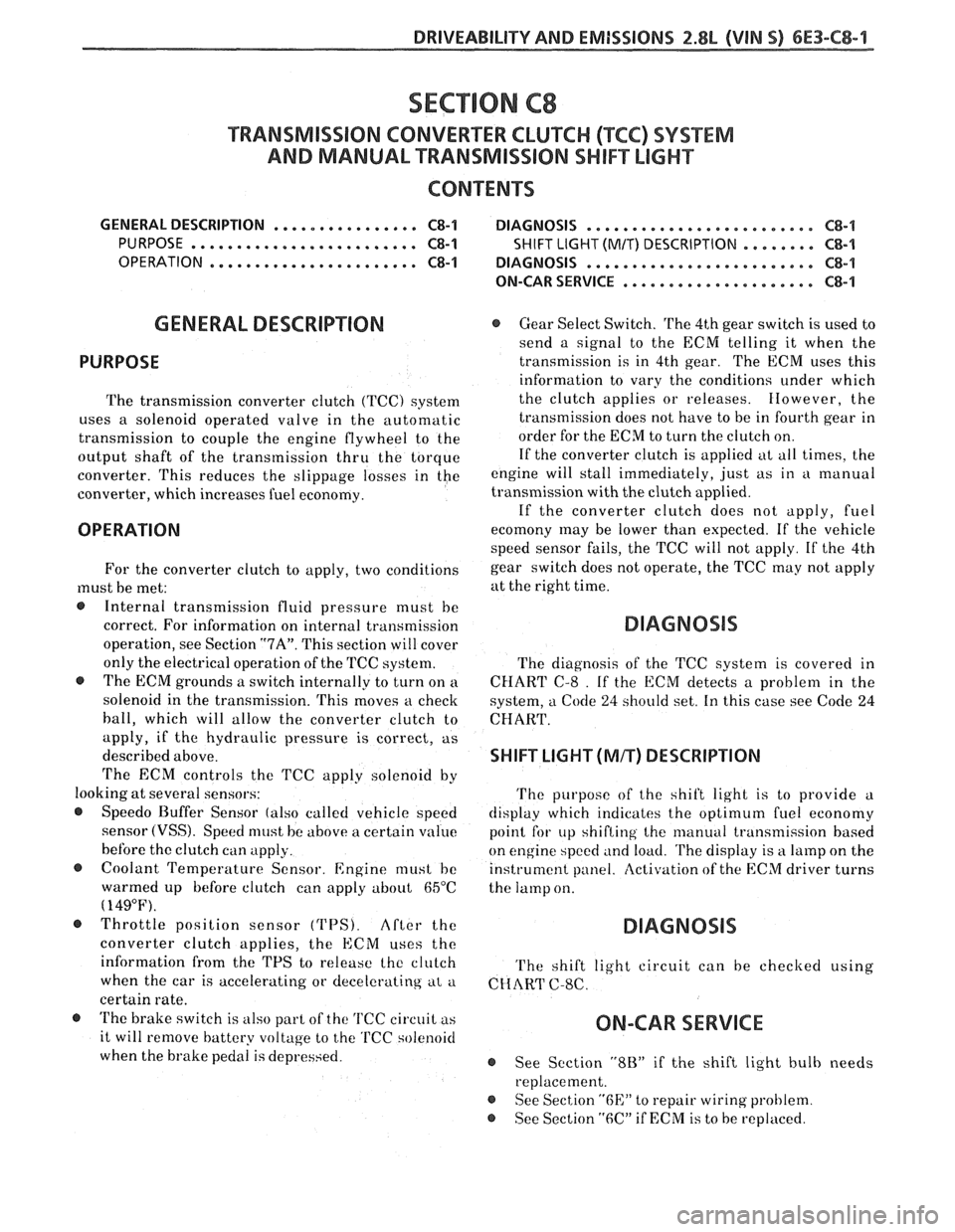

DRIVEABILITY AND EMlSSlONS 2.8L (VIN %I 6E3-C8-1

TRANSMISSION CONVERTER CLUTCH (KC) SYSTEM

AND MANUAL

TRANSMISSION SHIFT LIGHT

CONTENTS

GENERAL DESCRIPTION ................ C8-1 DIAGNOSIS ..........ee...ee....e.e. C8-1

PURPOSE ......................... C8-1 SHIFT LIGHT (MIT) DESCRIPTION ........ C8-1

OPERATION ....................... C8-1 DIAGNOSIS ....................... .. C8-1

ON-CAR SERVICE ...................*. C8-1

GENERAL DESCRIPTION

PURPOSE

The transmission converter clutch (TCC) svstem

uses a solenoid operated valve in the automatic

transmission to couple the engine flywheel to the

output shaft of the transmission thru the torque

converter. This reduces the slippage losses in the

converter, which increases fuel economy.

OPERATION

For the converter clutch to apply, two conditions

must be met:

o Internal transmission fluid pressure must be

correct. For information on internal transmission

operation, see Section

"7A". This section will cover

only the electrical operation of the TCC system.

@ The ECM grounds a switch internally to turn on a

solenoid in the transmission. This moves a check

ball, which will allow the converter clutch to

apply, if the hydraulic pressure is correct, as

described above.

The ECM controls the TCC apply solenoid by

looking at several sensors:

@ Speedo Buffer Sensor (also called vehicle speed

sensor

(VSS). Speed must be above a certain value

before the clutch can apply.

@ Coolant Temperature Sensor. Engine must be

warmed up before clutch can apply about

65OC

(149°F').

Throttle position sensor ('I'PS). After the

converter clutch applies, the

HCM uses the

information from the TPS to release thc clutch

when the car is accelerating or decelerating at a

certain rate.

@ 'I'he brake switch is also part of the 'I'CC circuit as

it will remove battery voltage to the 'KC solenoid

when the brake pedal is depressed.

@ Gear Select Switch. The 4th gear switch is used to

send a signal to the

ECM telling it when the

transmission is in 4th gear. The ECM uses this

information to vary the conditions under which

the clutch applies or releases.

IIowever, the

transmission does not have to be in fourth gear in

order for the ECM to turn the clutch on.

If the converter clutch is applied at all times. the

engine will stall immediately, just as in

u manual

transmission with the clutch applied.

If the converter clutch does not apply, fuel

ecomony

may be lower than expected. If the vehicle

speed sensor fails, the TCC will not apply. If the 4th

gear switch does not operate, the TCC may not apply

at the right time.

DIAGNOSIS

The diagnosis of the TCC system is covered in

CHART C-8

. If the ECM detects a problem in the

system,

a Code 24 should set. In this case see Code 24

CHART.

SHIFT LIGHT (MiT) DESCRIPTION

'The purpose of the shift light is to provide a

display which indicates the optimum fuel economy

point for up

shifling the manual transmission based

on engine speed

and load. 'I'he display is a lamp on the

instrument panel. Activation of the ECM driver turns

the lamp

on.

'I'he shift light circuit can he checlted using

CHAR?' C-8C.

ON-CAR SERVICE

@ See Section "8B" if the shift light bulb needs

replacement.

@ See Section "6E" to repair wiring problem.

@ See Section "6C" if ECM is to be replaced.