tow bar PONTIAC FIERO 1988 Service Repair Manual

[x] Cancel search | Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 135 of 1825

3-10 STEERING, SUSPENSION, TIRES AND WHEELS DIAGNOSIS

Reminder Keeps Operating With Key In Lock

Cylinder, Driver's Door Open Or Closed; Ceases

When Key Is Removed

Inspect

s Door jamb switch on driver's side misadjusted or

inoperative.

e Wire from signal switch to door jamb switch

shorted.

A. This condition indicates the lock cylinder or

the reminder switch is at fault. To verify,

check for continuity at the

"E" and "F"

male column connector contacts, with the

key removed from the lock cylinder. If

continuity exists, the fault is in the column.

B. Insert the key into the lock, then turn the

lock toward the "Start" position. If the

reminder stops when the key is in the

"Run" position or when it is turned past

"Run" toward "Start," the problem is a

sticky lock cylinder actuator.

COLUMN-MOUNTED DIMMER SWITCH

No "Low" or "High" Beam

Inspect

e Loose connector at dimmer switch

e Improper adjustment

e Internally damaged or worn switch. Check the

continuity on the switch at the It. green and at the

tan switch terminals by pushing in the plunger all

the way.

A click should be heard. If there is no

continuity, replace the dimmer switch. If there is

continuity, refer

to'section 8A for electricaldiag-

nosis.

PIVOT AND SWITCH ASSEMBLY

Switch Inoperative: No "Low," "High" and/or

"Wash"

e Loose body-to-switch connector

a Broken or damaged switch

Internally damaged or worn switch. Connect a

new switch without removing the old one. If the

system functions, replace the switch. If the

system doesn't function, refer to Section

8A for

electrical diagnosis.

STEERING GEAR AND PUMP LEAKS

General Procedure

Inspect

s Overfilled reservoir

s Fluid aeration and overflow

e , Hose connections

Verify exact point of leakage Example:

Torsion bar, stub shaft and

adjuster seals are close together; the exact

spot where the system is leaking may not be

clear.

Example: The point from which the fluid is

dripping is not necessarily the point where

the system is leaking; fluid overflowing from

the reservoir, for instance.

e When service is required:

A. Clean leakage area upon disassembly.

B. Replace leaking seal.

C. Check component sealing surfaces for

damage.

D. Reset bolt torque to specifications, where

required.

Some complaints about the power steering system

may be reported as:

A. Fluid leakage on garage floor

B. Fluid leaks visible on steering gear or pump

C. Growling noise, especially when parking or

when engine is cold

D. Loss of power steering when parking

E. Heavy steering effort

When troubleshooting these kinds of complaints,

check for an external leak in the power steering system.

For further diagnosis of leaks, refer to External

Leakage Check in this section.

External Leakage Check

Fig. 12

The purpose of this procedure is to pinpoint the

location of the leak.

In some cases, the leak can easily be located. But,

seepage-type leaks may be more difficult to isolate. To

locate seepage leaks, use the following method.

1. With the engine off, wipe dry the complete power

steering system.

2. Check the fluid level in the pump's reservoir. Add

fluid if necessary.

3. Start the engine, then turn the steering wheel

from stop to stop several times. Do not hold it at

a stop for any length of time, as this can damage

the power steering pump. It is easier if someone

else operates the steering wheel while you search

for the seepage.

4. Find the exact area of the leak and repair leak.

SEAL REPLACEMENT

RECOMMENDATIONS

Lip seals, which seal rotating shafts, require

special treatment. This type of seal is used on the

steering gear and on the drive shaft of the pump. When

there is a leak in one of these areas, always replace the

seal(s), after inspecting and thoroughly cleaning the

sealing surfaces. Replace the shaft only if very severe

pitting is found. If the corrosion in the lip seal contact

zone is slight, clean the surface of the shaft with crocus

cloth. Replace the shaft only if the leakage cannot be

stopped by first smoothing with crocus cloth.

Page 224 of 1825

REAR SUSPENSION 30-3

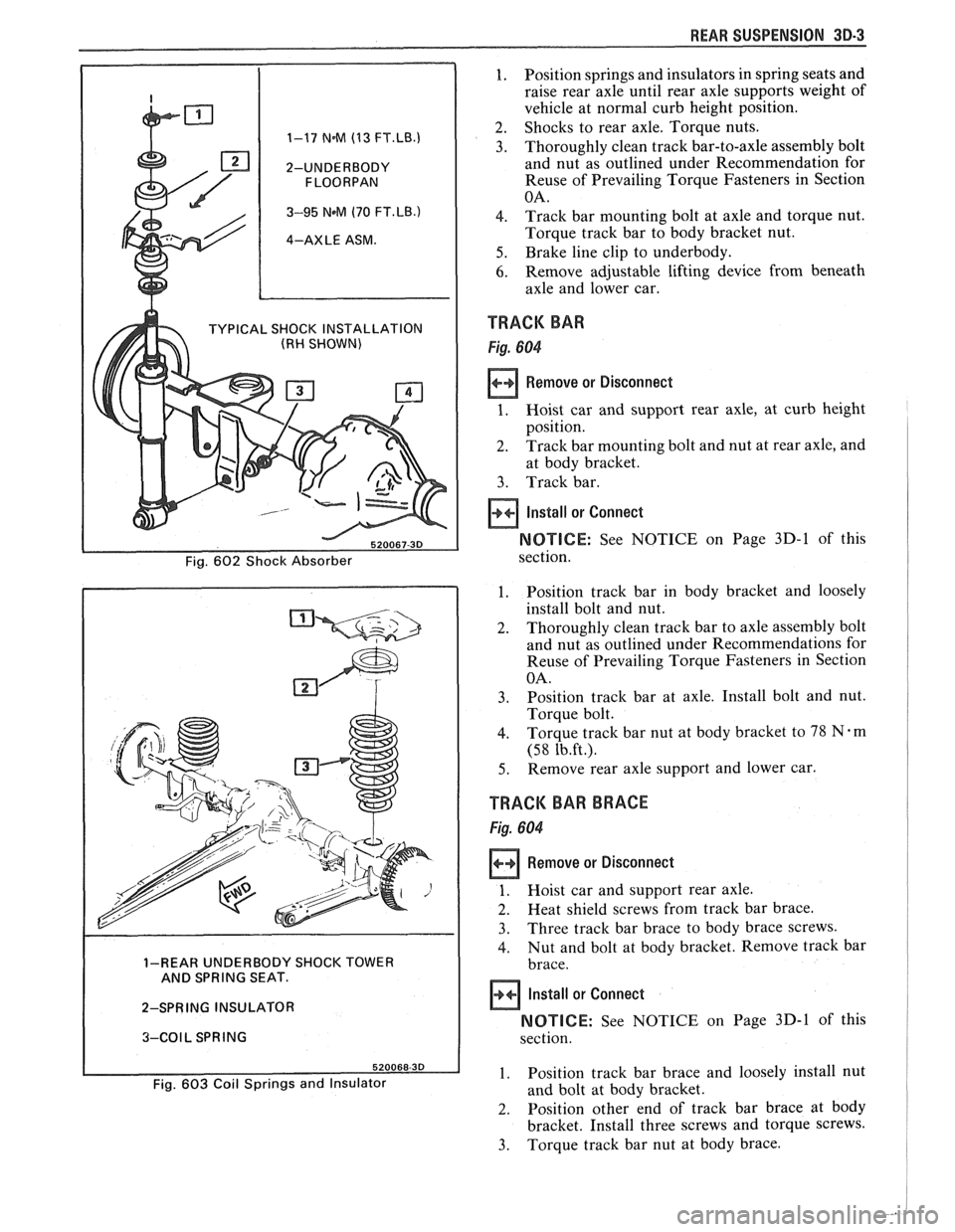

1. Position springs and insulators in spring seats and

raise rear axle until rear axle supports weight of

vehicle at normal curb height position.

2. Shocks to rear axle. Torque nuts. 1-17 N.M (13 FT.LB.1 3. Thoroughly clean track bar-to-axle assembly bolt

2-UNDERBODY and nut as outlined under Recommendation for

Reuse of Prevailing Torque Fasteners in Section

3-95 NeM (70 FT.LB.) 4. Track bar mounting bolt at axle and torque nut.

4-AXLE ASM. Torque track bar to body bracket nut.

5. Brake line clip to underbody.

6. Remove adjustable lifting device from beneath

axle and lower car.

TYPICAL SHOCK INSTALLATION TRACK BAR (RH SHOWN)

Remove or Disconnect

at body bracket.

3. Track bar.

Install or Connect

NOTICE: See NOTICE on Page 3D-1 of this

1. Position track bar in body bracket and loosely

install bolt and nut.

2. Thoroughly clean track bar to axle assembly bolt

and nut as outlined under Recommendations for

Reuse of Prevailing Torque Fasteners in Section

3. Position track bar at axle. Install bolt and nut.

4. Torque track bar nut at body bracket to 78 Nem

5. Remove rear axle support and lower car.

TRACK BAR BRACE

1. Hoist car and support rear axle.

2. Heat shield screws from track bar brace.

3. Three track bar brace to body brace screws.

4. Nut and bolt at body bracket. Remove track bar 1-REAR UNDERBODY SHOCK TOWER

AND SPRING SEAT.

2-SPRING INSULATOR

NOTICE: See NOTICE on Page 3D-1 of this 3-COIL SPRING

1. Position track bar brace and loosely install nut Fig. 603 Coil Springs and Insulator and bolt at body bracket.

2. Position other end of track bar brace at body

bracket. Install three screws and torque screws.

3. Torque track bar nut at body brace.

Page 239 of 1825

3E-8 TIRES AND WHEELS

nearest the valve stem, and a 1/2 ounce balance weight

should be added 180" opposite the locking nut on the

wheel's inboard side.

When rotating tires, always re-install the locking

nut nearest the tire valve stem so that it remains

opposite the 1/2 ounce balance weight. This procedure

will improve the on-car wheel balance by compensating

for the heavy locking wheel nut.

Off-Car Balancing

Most electronic off-car balancers are more

accurate than the on-car spin balancers. They are easy

to use and give a dynamic (two plane) balance.

Although they do not correct for drum or rotor

unbalance as does on-car spin balancing, this is

overcome by their accuracy (usually to within 1/8

ounce). When balancing off-car, the wheel should

locate on the balancer with a cone through the back

side of the center pilot hole (not by the wheel stud

holes).

On-Car Balancing

When needed, on-car balancing will help correct

vibrations due to brake drum, rotor, and wheel cover

imbalance.

When balancing on car, do not remove the

balance weights from the off-car dynamic balance. If

more than one ounce of additional weight is required,

it should be split between the inner and outer rim

flange.

NOTICE: The driven tire and wheel assemblies

should be spun using the engine. Limit speed as

stated in the following Caution.

CAUTION: Do not spin the drive

wheels faster than

35 mph (55 km/h)

as indicated by the speedometer. This

limit is necessary because the

speedometer indicates only one-half

of the actual wheel speed when one

drive wheel is spinning and the other

drive wheel is stopped. Personal injury

and damage may result from high

speed spinning.

CAUTION: On cars equipped with

limited slip rear axles, do not attempt

to balance a tire on a

drive wheel with

the other drive wheel on the ground.

The car may drive through this wheel

and cause the car to move

unexpectedly, resulting in personal

injury and property damage.

To distinguish between standard rear axle and

limited slip, raise rear of car so both tires are clear of

ground. With the transmission in park (in gear with

manual transmission), attempt to turn one wheel by

hand. If the wheel can be turned, it is a standard rear

axle; if the wheel cannot be turned, it is a limited slip

rear axle. Also, check for Limited Slip

(G80) on Service

Parts Identification label.

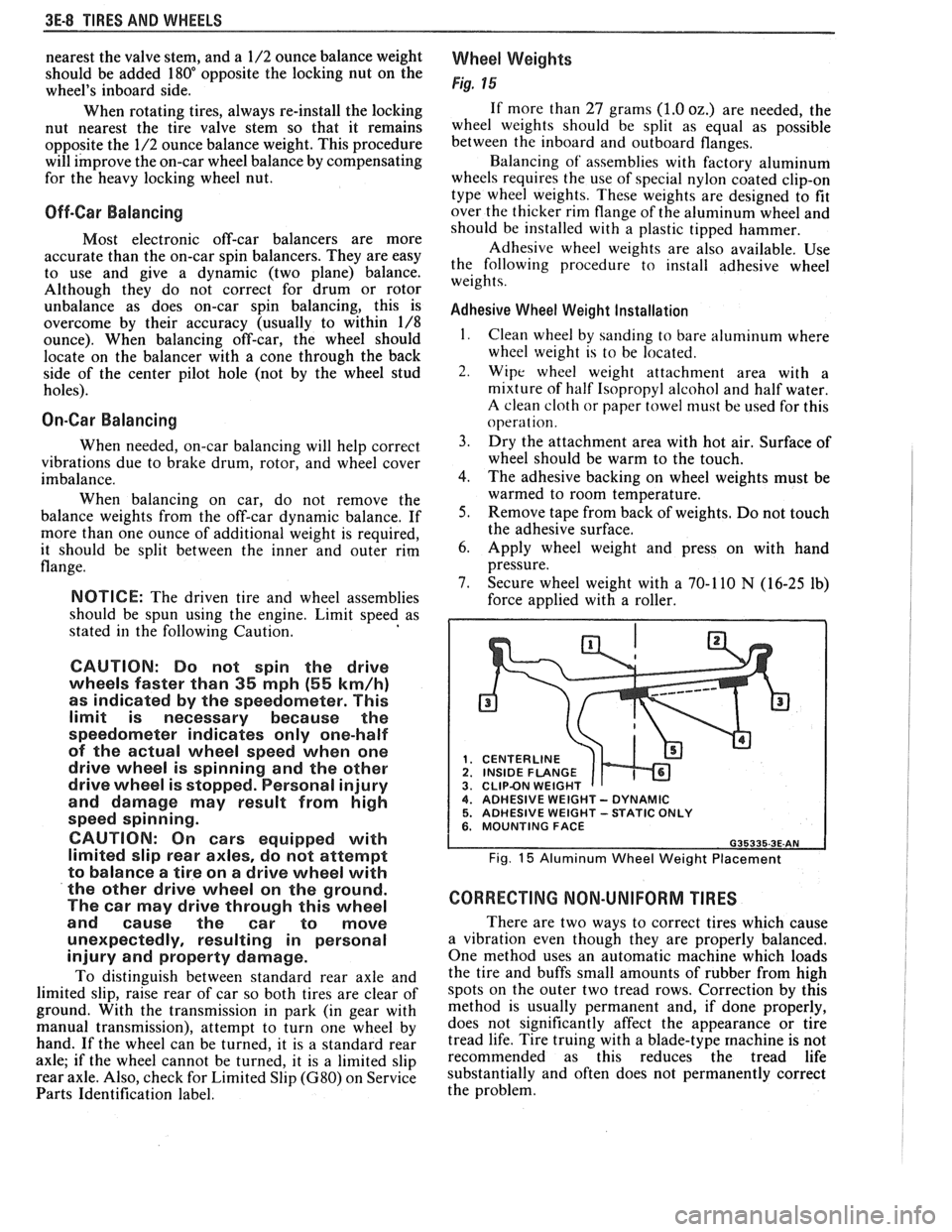

Wheel Weights

Fig. 15

If more than 27 grams (1.0 oz.) are needed, the

wheel weights should be split as equal as possible

between the inboard and outboard flanges.

Balancing of' assemblies with factory aluminum

wheels requires the use of special nylon coated clip-on

type wheel weights. These weights are designed to fit

over the thicker rim flange of the aluminum wheel and

should be installed with a plastic tipped hammer.

Adhesive wheel weights are also available. Use

the following procedure to install adhesive wheel

weights.

Adhesive Wheel Weight Installation

1. Clean wheel by sanding to bare aluminum where

wheel weight is to be located.

2. Wipe wheel weight attachment area with a

mixture of half Isopropyl alcohol and half water.

A clean cloth or paper towel niust be used for this

operat ion.

3. Dry the attachment area with hot air. Surface of

wheel should be warm to the touch.

4. The adhesive backing on wheel weights must be

warmed to room temperature.

5. Remove tape from back of weights. Do not touch

the adhesive surface.

6. Apply wheel weight and press on with hand

pressure.

7. Secure wheel weight with a 70-1 10

N (16-25 lb)

force applied with a roller.

CENTERLINE

1 INSIDE FLANGE CLIPBN WEIGHT 4. ADHESIVE WEIGHT - DYNAMIC 5. ADHESIVE WEIGHT -STATIC ONLY 6. MOUNTING FACE

Fig. 15 Aluminum Wheel Weight Placement

CORRECTING NON-UNIFORM TIRES

There are two ways to correct tires which cause

a vibration even though they are properly balanced.

One method uses an automatic machine which loads

the tire and buffs small amounts of rubber from high

spots on the outer two tread rows. Correction by this

method is usually permanent and, if done properly,

does not significantly affect the appearance or tire

tread life. Tire truing with a blade-type

machine is not

recommended as this reduces the tread life

substantially and often does not permanently correct

the problem.

Page 324 of 1825

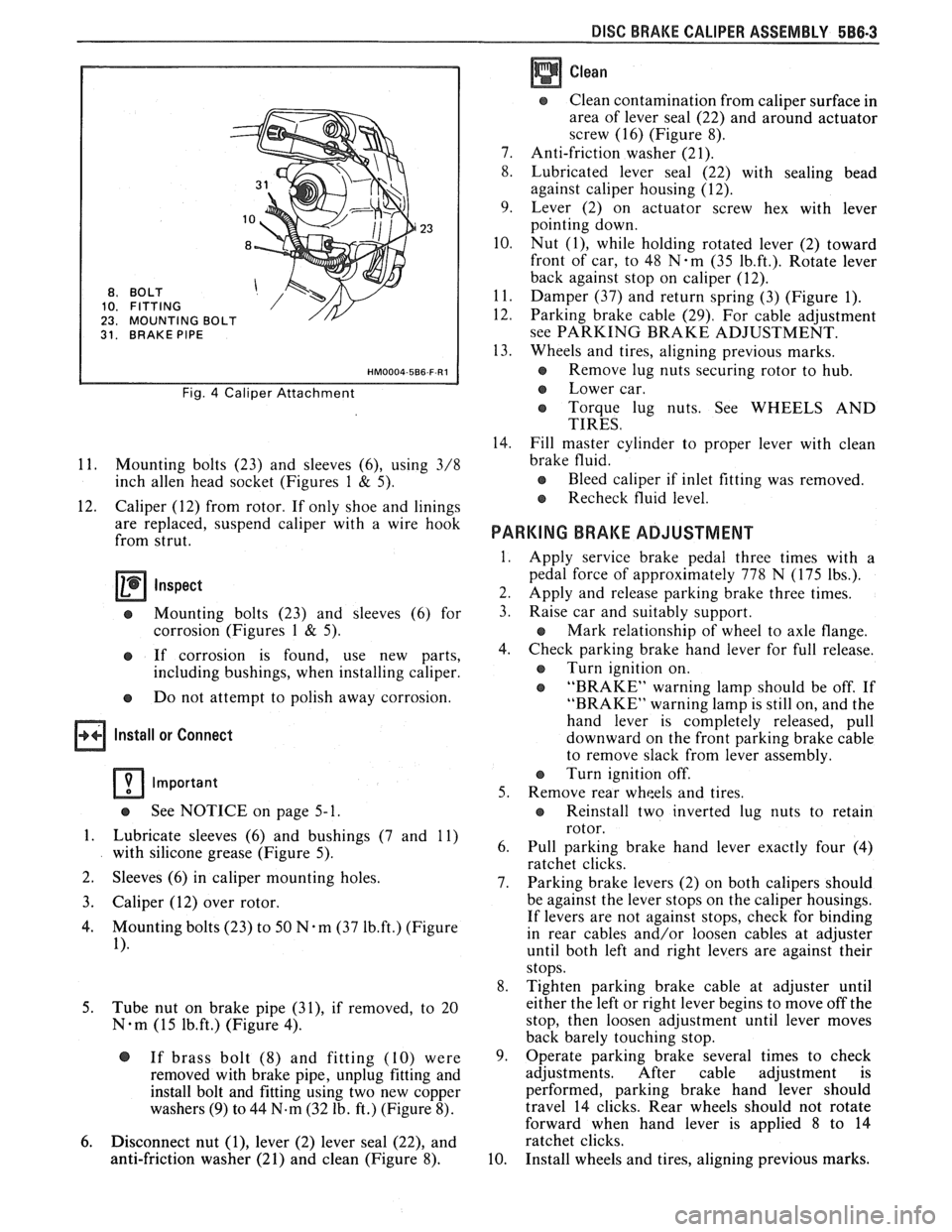

DISC BRAKE CALIPER ASSEMBLY 588-3

BO LT

FITTING

MOUNTING

31. BRAKE PIPE

Fig. 4 Caliper Attachment

11. Mounting bolts (23) and sleeves (6), using 3/8

inch

allen head socket (Figures 1 & 5).

12. Caliper (12) from rotor. If only shoe and linings

are replaced, suspend caliper with a wire hook

from strut.

Inspect

e Mounting bolts (23) and sleeves (6) for

corrosion (Figures

1 & 5).

e If corrosion is found, use new parts,

including bushings, when installing caliper.

e Do not attempt to polish away corrosion.

Install or Connect

Important

See NOTICE on page 5- 1.

1. Lubricate sleeves (6) and bushings (7 and 11)

with silicone grease (Figure 5).

2. Sleeves

(6) in caliper mounting holes.

3. Caliper (12) over rotor.

4. Mounting bolts (23) to 50 N-m (37 1b.ft.) (Figure

1).

5.

Tube nut on brake pipe (31), if removed, to 20

N-m (15 1b.ft.) (Figure 4).

@ If brass bolt (8) and fitting (10) were

removed with brake pipe, unplug fitting and

install bolt and fitting using two new copper

washers

(9) to 44 N.m (32 lb. ft.) (Figure 8).

6. Disconnect nut (I), lever (2) lever seal (22), and

anti-friction washer (21) and clean (Figure 8).

Clean

Clean contamination from caliper surface in

area of lever seal (22) and around actuator

screw (16) (Figure 8).

7. Anti-friction washer (21).

8. Lubricated lever seal (22) with sealing bead

against caliper housing (12).

9. Lever (2) on actuator screw hex with lever

pointing down.

10. Nut

(I), while holding rotated lever (2) toward

front of car, to 48

N-m (35 1b.ft.). Rotate lever

back against stop on caliper (12).

11. Damper (37) and return spring (3) (Figure 1).

12. Parking brake cable (29). For cable adjustment

see PARKING BRAKE ADJUSTMENT.

13. Wheels and tires, aligning previous marks.

s Remove lug nuts securing rotor to hub.

e Lower car.

e Torque lug nuts. See WHEELS AND

TIRES.

14. Fill master cylinder to proper lever with clean

brake fluid.

e Bleed caliper if inlet fitting was removed.

Recheck fluid level.

PARKING BRAKE ADJUSTMENT

Apply service brake pedal three times with a

pedal force of approximately 778 N (175 lbs.).

Apply and release parking brake three times.

Raise car and suitably support.

e Mark relationship of wheel to axle flange.

Check parking brake hand lever for full release.

e Turn ignition on.

e "BRAKE" warning lamp should be off. If

"BRAKE" warning lamp is still on, and the

hand lever is completely released, pull

downward on the front parking brake cable

to remove slack from lever assembly.

Turn ignition off.

Remove rear wheels and tires.

e Reinstall two inverted lug nuts to retain

rotor.

Pull parking brake hand lever exactly four (4)

ratchet clicks.

Parking brake levers (2) on both calipers should

be against the lever stops on the caliper housings.

If levers are not against stops, check for binding

in rear cables and/or loosen cables at adjuster

until both left and right levers are against their

stops.

Tighten parking brake cable at adjuster until

either the left or right lever begins to move off the

stop, then loosen adjustment until lever moves

back barely touching stop.

Operate parking brake several times to check

adjustments. After cable adjustment is

performed, parking brake hand lever should

travel 14 clicks. Rear wheels should not rotate

forward when hand lever is applied

8 to 14

ratchet clicks.

Install wheels and tires, aligning previous marks.

Page 374 of 1825

2.8 LITER V-6 8A2-23

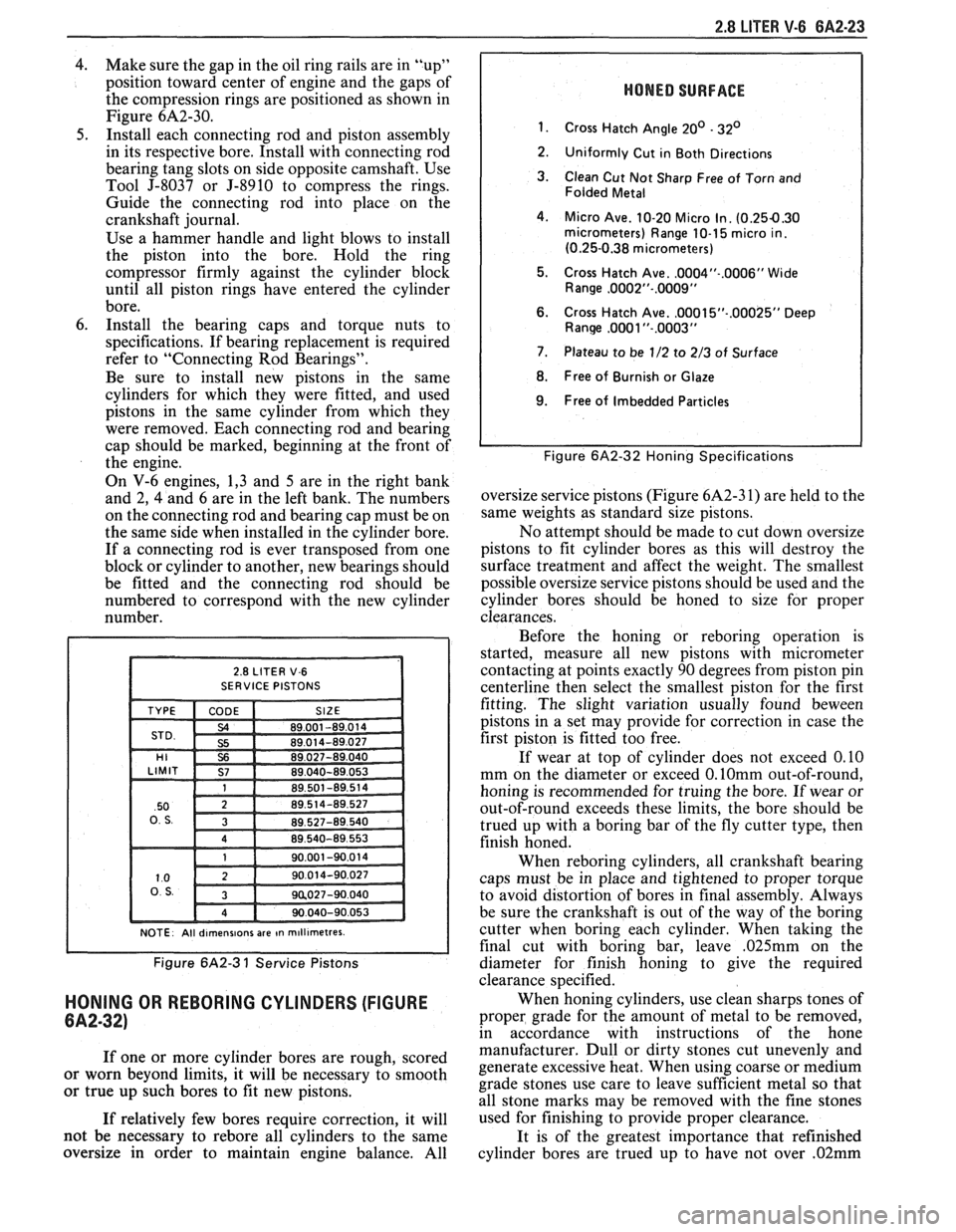

4. Make sure the gap in the oil ring rails are in "up"

position toward center of engine and the gaps of

the compression rings are positioned as shown in

Figure

6A2-30.

5. Install each connecting rod and piston assembly

in its respective bore. Install with connecting rod

bearing tang slots on side opposite camshaft. Use

Tool J-8037 or J-8910 to compress the rings.

Guide the connecting rod into place on the

crankshaft journal.

Use a hammer handle and light blows to install

the piston into the bore. Hold the ring

compressor firmly against the cylinder block

until all piston rings have entered the cylinder

bore.

6. Install the bearing caps and torque nuts to

specifications. If bearing replacement is required

refer to "Connecting Rod Bearings".

Be sure to install new pistons in the same

cylinders for which they were fitted, and used

pistons in the same cylinder from which they

were removed. Each connecting rod and bearing

cap should be marked, beginning at the front of

the engine.

On V-6 engines, 1,3 and 5 are in the right bank

and 2,

4 and 6 are in the left bank. The numbers

on the connecting rod and bearing cap must be on

the same side when installed in the cylinder bore.

If a connecting rod is ever transposed from one

block or cylinder to another, new bearings should

be fitted and the connecting rod should be

numbered to correspond with the new cylinder

number.

NOTE. All dlrnenslons are In rn~ll~rnetres.

Figure 6A2-3 1 Service Pistons

HONING OR REBORING CYLINDERS (FIGURE

6A2-32)

If one or more cylinder bores are rough, scored

or worn beyond limits, it will be necessary to smooth

or true up such bores to fit new pistons.

If relatively few bores require correction, it will

not be necessary to

rebore all cylinders to the same

oversize in order to maintain engine balance. All

HONED SURFACE

1.

Cross Hatch Angle 20' - 32'

2.

Uniformly Cut in Both Directions

3. Clean Cut Not Sharp Free of Torn and

Folded Metal

4. Micro Ave. 10-20 Micro In. (0.254.30 micrometers) Range 10-1 5 micro in.

(0.25-0.38 micrometers)

5. Cross Hatch Ave.

.0004"-.0006" Wide

Range ,0002"-.0009"

6. Cross Hatch Ave. ,0001 5"-.00025" Deep Ranw ,0081 "-.0003"

7. Plateau to be 1/2 to 2/3 of Surface

8. Free of Burnish or Glaze

I 9. Free of Imbedded Particles I

I I Figure 6A2-32 Honing Specifications

oversize service pistons (Figure 6A2-3 1) are held to the

same weights as standard size pistons.

No attempt should be made to cut down oversize

pistons to fit cylinder bores as this will destroy the

surface treatment and affect the weight. The smallest

possible oversize service pistons should be used and the

cylinder bores should be honed to size for proper

clearances.

Before the honing or

reboring operation is

started, measure all new pistons with micrometer

contacting at points exactly 90 degrees from piston pin

centerline then select the smallest piston for the first

fitting. The slight variation usually found

beween

pistons in a set may provide for correction in case the

first piston is fitted too free.

If wear at top of cylinder does not exceed 0.10

mm on the diameter or exceed

0.lOmm out-of-round,

honing is recommended for truing the bore. If wear or

out-of-round exceeds these limits, the bore should be

trued up with a boring bar of the fly cutter type, then

finish honed.

When

reboring cylinders, all crankshaft bearing

caps must be in place and tightened to proper torque

to avoid distortion of bores in final assembly. Always

be sure the crankshaft is out of the way of the boring

cutter when boring each cylinder. When taking the

final cut with boring bar, leave

,025mm on the

diameter for finish honing to give the required

clearance specified.

When honing cylinders, use clean sharps tones of

proper grade for the amount of metal to be removed,

in accordance with instructions of the hone

manufacturer. Dull or dirty stones cut unevenly and

generate excessive heat. When using coarse or medium

grade stones use care to leave sufficient metal so that

all stone marks may be removed with the fine stones

used for finishing to provide proper clearance.

It is of the greatest importance that refinished

cylinder bores are trued up to have not over

.02mm

Page 671 of 1825

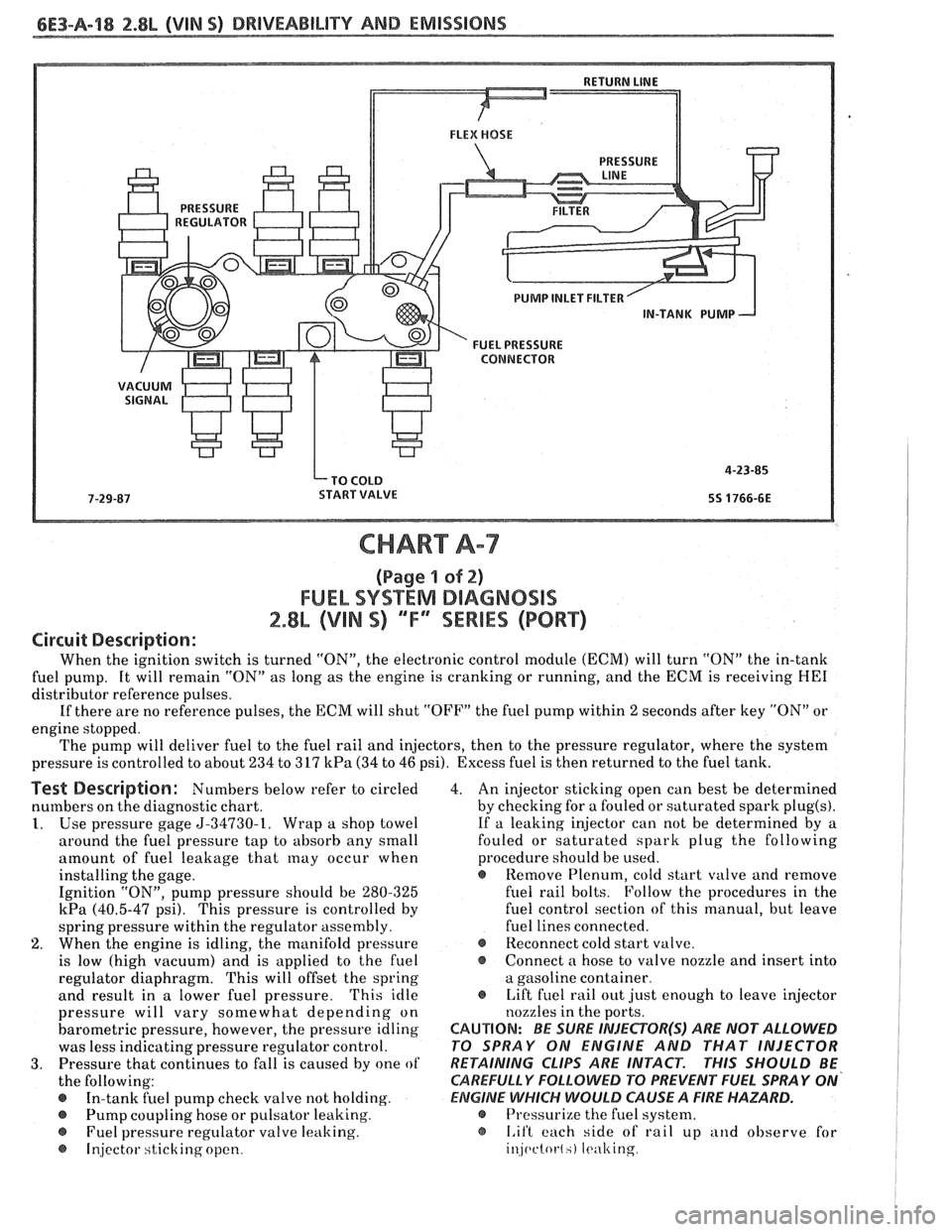

6E3-A-I8 2.8b (VIN 5) DRIVEABILITY AND EMISSIONS

PUMP INLET FILTER

IN-TANK PUMP

FUEL

PRESSURE CONNECTOR

CHART A-7

(Page 4 of 2)

FUEL SYSTEM DsAGNOSBS

2.8L (VIN S) ""FYSERBES (PORT)

Circuit Description:

When the ignition switch is turned "ON", the electronic control module (ECM) will turn "ON" the in-tank

fuel pump. It will remain "ON" as long as the engine is cranking or running, and the ECM is receiving

HE1

distributor reference pulses.

If there are no reference pulses, the ECM will shut "OFF" the fuel pump within

2 seconds after key "ON" or

engine stopped.

The pump will deliver fuel to the fuel rail and injectors, then to the pressure regulator, where the system

pressure is controlled to about 234 to 317

kPa (34 to 46 psi). Excess fuel is then returned to the fuel tank.

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. Use pressure gage 5-34730-1. Wrap a shop towel

around the fuel pressure tap to absorb any small

amount of fuel leakage that

may occur when

installing the gage.

Ignition "ON", pump pressure should be 280-325

kPa (40.5-47 psi). This pressure is controlled by

spring pressure within the regulator assembly.

2. When the engine is idling, the manifold pressure

is low (high vacuum) and is applied to the fuel

regulator diaphragm. This will offset the spring

and result in a lower fuel pressure.

'This idle

pressure will vary somewhat depending on

barometric pressure, however, the pressure idling

was less indicating pressure regulator control.

3. Pressure that continues to fall is caused by one of

the following:

In-tank fuel pump check valve not holding.

@ Pump coupling hose or pulsator leaking.

Fuel pressure regulator valve leaking.

@ Injector sticking open. 4.

An injector sticking open can best be determined

by checking for a fouled or saturated spark

plug(s).

If a leaking injector can not be determined by a

fouled or saturated spark plug the following

procedure should be used.

e Remove Plenum, cold start valve and remove

fuel rail bolts. Follow the procedures in the

fuel control section of this manual, but leave

fuel lines connected.

@ Reconnect cold start valve.

@ Connect a hose to valve nozzle and insert into

a gasoline container.

@ Lift fuel rail out just enough to leave injector

nozzles in the ports.

CAUTION: BE SURE INJEePOR(S) ARE NOT ALLOWED

PO SPRAY ON ENGINE AND THAT INJECTOR

RETAINING

CLIPS ARE INTACT. PHIS SHOULD BE

CAREFULLY

FOLLOWD PO PREVENT FUEL SPRAY ON'

ElZIGlNE WHICH WOULD CAUSE A FIRE HAZARD.

@ Pressurize the fuel system.

@ I.if't each side of rail up and observe for

injc~ctot-l.) It.ulting

Page 821 of 1825

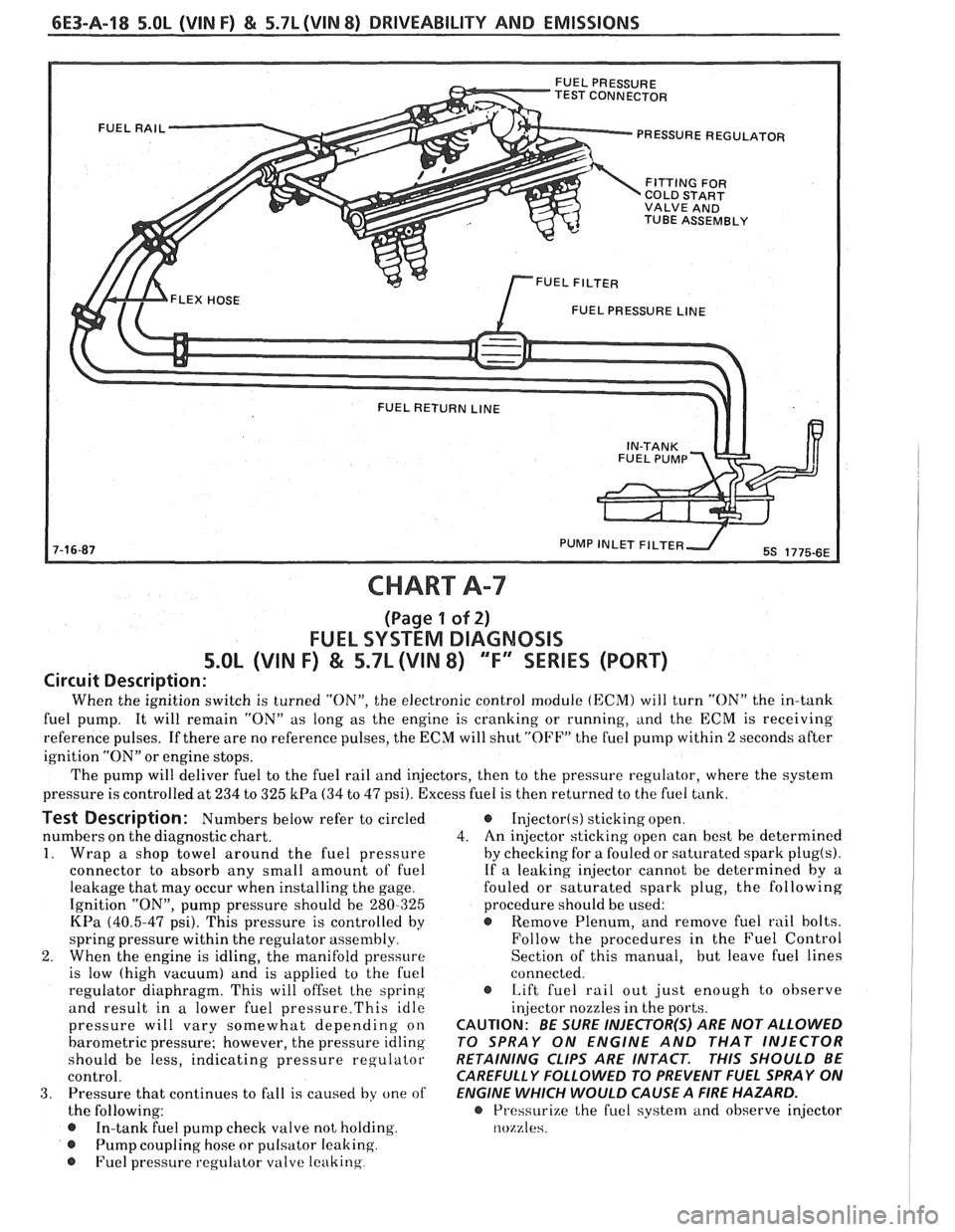

6E3-A-18 5.OL (WIN F) & 5.7L(VIN 8) DRIVEABILITY AND EMISSIONS

PRESSURE REGULATOR

COLD START

TUBE ASSEMBLY

FUEL PRESSURE

LINE

CHART A-7

(Page 1 of 2)

FUEL SYSTEM DIAGNOSIS

5.OL (VIN F) & 5.7L (VIN 8) 'TF'3SERlES (PORT)

Circuit Description:

When the ignition switch is turned "ON", the electronic control module (ECM) will turn "ON" the in-tank

fuel pump. It will remain "ON" as long as the engine is cranking or running, and the

ECM is receiving

reference pulses. If there are no reference pulses, the ECM will shut "OFF" the fuel pump within 2 seconds after

ignition "ON" or engine stops.

The pump will deliver fuel to the fuel rail and injectors, then to the pressure regulator, where the system

pressure is controlled at 234 to 325

kPa (34 to 47 psi). Excess fuel is then returned to the fuel tank.

Test Description: Numbers below refer to circled

numbers on the diagnostic chart.

1. Wrap a shop towel around the fuel pressure

connector to absorb any small amount of fuel

leakage that may occur when installing the gage.

Ignition "ON", pump pressure should be 280-325

KPa (40.5-47 psi). This pressure is controlled by

spring pressure within the regulator

assenlbly

2. When the engine is idling, the manifold pressure

is low (high vacuum) and is applied to the fuel

regulator diaphragm. This will offset

the spring

and result in a lower fuel

pressure.This idle

pressure will vary somewhat depending on

barometric pressure; however, the pressure idling

should be less, indicating pressure regulator

control.

3. Pressure that continues to fall is caused by one of

the following:

In-tank fuel pump check valve not holding.

@ Pump coupling hose or pulsator leaking

@ Fuel pressure regulator valve leaking

Injector(s) sticking open.

4. An

injector sticking open can best be determined

by checking for a fouled or saturated spark

plug(s).

If a leaking injector cannot be determined by a

fouled or saturated spark plug, the following

procedure should be used:

@ Remove Plenum, and remove fuel rail bolts.

Follow the procedures in the Fuel Control

Section of this manual, but leave fuel lines

connected.

s Lift fuel rail out just enough to observe

injector nozzles in the ports.

CAUTION: BE SURE INJECTOR(S) ARE NOT ALLOWED

TO SPRAY ON ENGINE AND THAT INJECTOR

RETAINING CLIPS ARE INTACT.

THIS SHOULD BE

CAREFULLY FOLLOWED TO PREVENT FUEL SPRAY ON

ENGINE WHICH WOULD CAUSE A

FIRE HAZARD.

@ Pressurize the fuel syste~rl and observe injector

nozzles.

Page 1682 of 1825

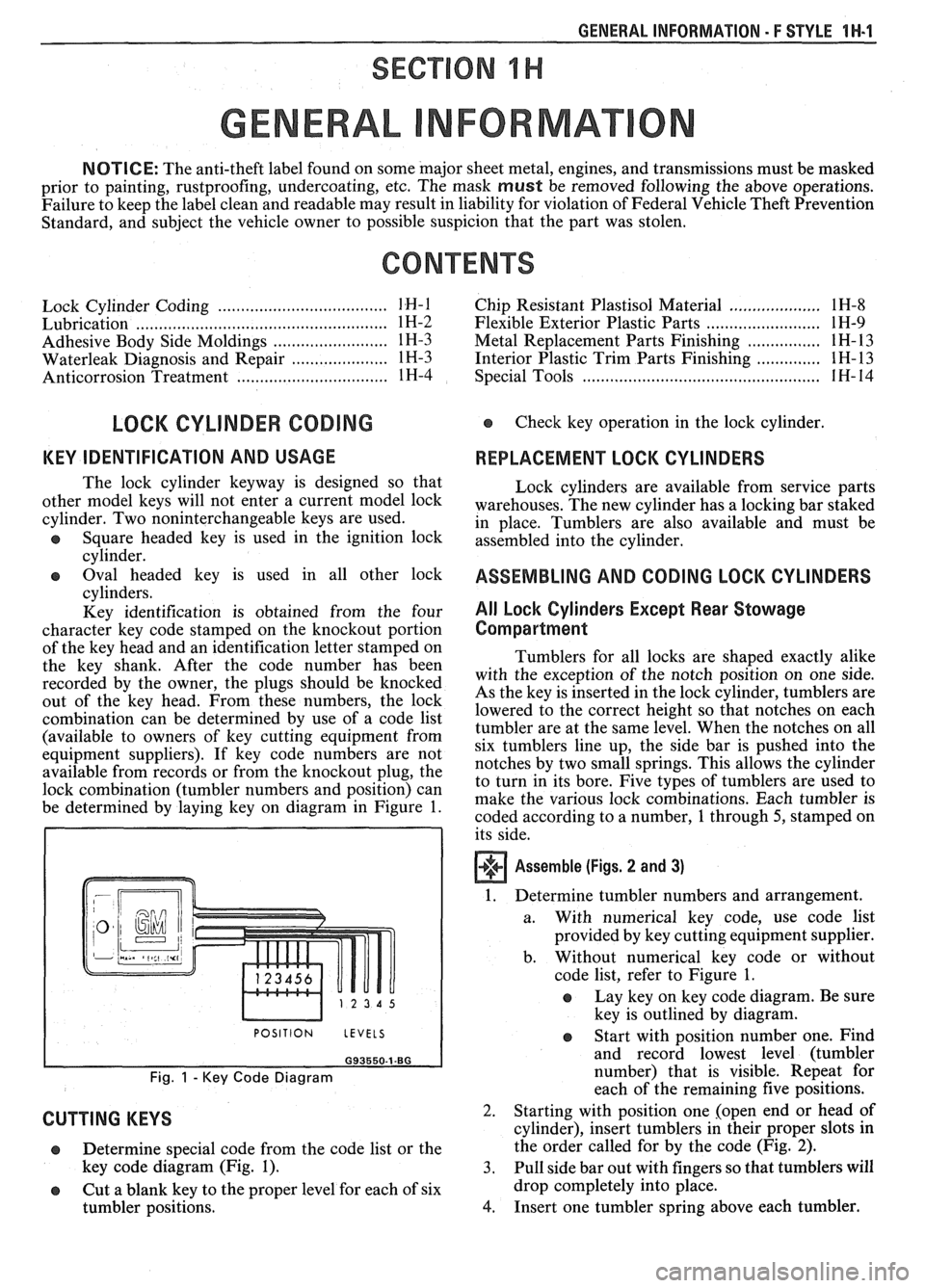

GENERAL INFORMATION - F STYLE 1 H-1

SECTION IH

GENERAL NFORMAT

NOTICE: The anti-theft label found on some major sheet metal, engines, and transmissions must be masked

prior to painting, rustproofing, undercoating, etc. The mask

must be removed following the above operations.

Failure to keep the label clean and readable may result in liability for violation of Federal Vehicle Theft Prevention

Standard, and subject the vehicle owner to possible suspicion that the part was stolen.

Lock Cylinder Coding

..................................... I H-1 Chip Resistant Plastisol Material .................... 1 H-8

...................................................... Lubrication 1 H-2 Flexible Exterior Plastic Parts ......................... 1H-9

Adhesive Body Side Moldings ......................... 1H-3 Metal Replacement Parts Finishing ................ lH-13

Waterleak Diagnosis and Repair ..................... 1H-3 Interior Plastic Trim Parts Finishing .............. 1H-13

.................................................... Anticorrosion Treatment ................................ IH-4 Special Tools I H- 14

LOCK CYL!NDER CODING o Check key operation in the lock cylinder.

KEY IDENTIFICATION AND USAGE

REPLACEMENT LOCK CYLINDERS

The lock cylinder keyway is designed so that

other model keys will not enter a current model lock

cylinder. Two noninterchangeable keys are used.

CB Square headed key is used in the ignition lock

cylinder.

o Oval headed key is used in all other lock

cylinders.

Key identification is obtained from the four

character key code stamped on the knockout portion

of the key head and an identification letter stamped on

the key shank. After the code number has been

recorded by the owner, the plugs should be knocked

out of the key head. From these numbers, the lock

combination can be determined by use of a code list

(available to owners of key cutting equipment from

equipment suppliers). If key code numbers are not

available from records or from the knockout plug, the

lock combination (tumbler numbers and position) can

be determined by laying key on diagram in Figure

1.

I POSITION LEVELS I

Fig. 1 - Key Code Diagram

CUTTING KEYS

Lock cylinders are available from service parts

warehouses. The new cylinder has a locking bar staked

in place. Tumblers are also available and must be

assembled into the cylinder.

ASSEMBLING AND CODING LOCK CYLINDERS

All Lock Cylinders Except Rear Stowage

Compartment

Tumblers for all locks are shaped exactly alike

with the exception of the notch position on one side.

As the key is inserted in the lock cylinder, tumblers are

lowered to the correct height so that notches on each

tumbler are at the same level. When the notches on all

six tumblers line up, the side bar is pushed into the

notches by two small springs. This allows the cylinder

to turn in its bore. Five types of tumblers are used to

make the various lock combinations. Each tumbler is

coded according to a number,

1 through 5, stamped on

its side.

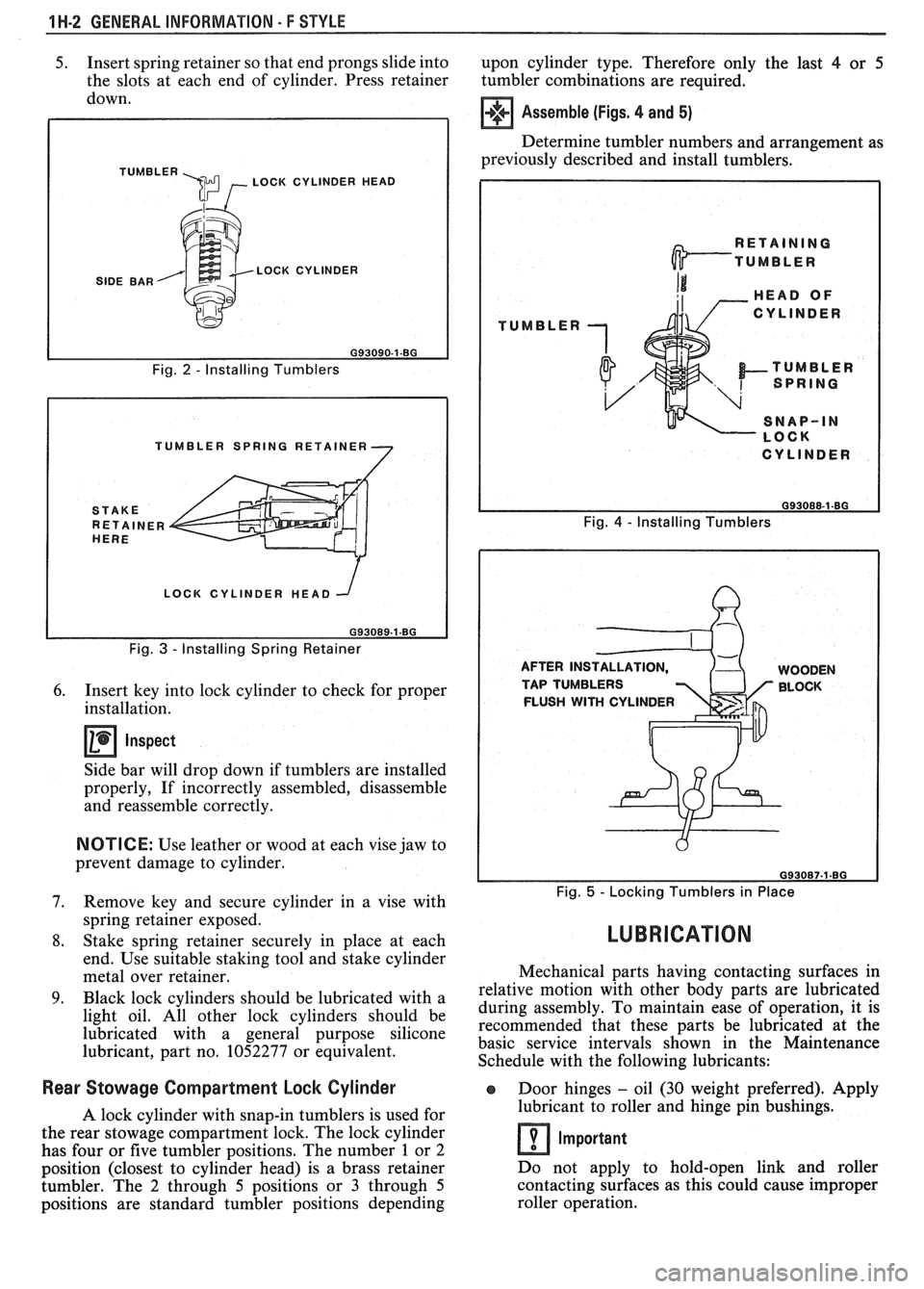

Assemble (Figs. 2 and 3)

1. Determine tumbler numbers and arrangement.

a. With numerical

key code, use code list

provided by key cutting equipment supplier.

b. Without numerical

key code or without

code list, refer to Figure

1.

o Lay key on key code diagram. Be sure

key is outlined by diagram.

Determine special code from the code list or the

key code diagram (Fig.

1). 3.

o Cut a blank key to the proper level for each of six

tumbler positions.

4.

Start with position number one. Find

and record lowest level (tumbler

number) that is visible. Repeat for

each of the remaining five positions.

Starting with position one [open end or head of

cylinder), insert tumblers in their proper slots in

the order called for by the code (Fig.

2).

Pull side bar out with fingers so that tumblers will

drop completely into place.

Insert one tumbler spring above each tumbler.

Page 1683 of 1825

1 H-2 GENERAL INFORMATION - F STYLE

5. Insert spring retainer so that end prongs slide into

upon cylinder type. Therefore only the last 4 or 5

the slots at each end of cylinder. Press retainer

tumbler combinations are required.

down.

TUMBLER \m , LOCK CYLINDER HEAD

SIDE BAR LOCK CYLINDER

Fig.

2 - Installing Tumblers

TUMBLER SPRING RETAINER

LOCK CYLINDER HEAD

Fig.

3 - Installing Spring Retainer

6. Insert key into lock cylinder to check for proper

installation.

Inspect

Side bar will drop down if tumblers are installed

properly, If incorrectly assembled, disassemble

and reassemble correctly.

NOTICE: Use leather or wood at each vise jaw to

prevent damage to cylinder.

7. Remove key and secure cylinder in a vise with

spring retainer exposed.

8. Stake spring retainer securely in place at each

end. Use suitable staking tool and stake cylinder

metal over retainer.

9. Black lock cylinders should be lubricated with a

light oil. All other lock cylinders should be

lubricated with a general purpose silicone

lubricant, part no. 1052277 or equivalent.

Assemble (Figs. 4 and 5)

Determine tumbler numbers and arrangement as

previously described and install tumblers,

TUMBLER

I CYLINDER I

Fig. 4 - Installing Tumblers

AFTER INS WOODEN

TAP TUMBLERS BLOCK

FLUSH

WITH CYLINDER

Fig. 5 - Locking Tumblers in Place

LUBRICATION

Mechanical parts having contacting surfaces in

relative motion with other body parts are lubricated

during assembly. To maintain ease of operation, it is

recommended that these parts be lubricated at the

basic service intervals shown in the Maintenance

Schedule with the following lubricants:

Rear Stowage Compartment Lock Cylinder Door hinges - oil (30 weight preferred). Apply

A lock cylinder with snap-in tumblers is used for lubricant

to roller and hinge pin bushings.

the rear stowage compartment lock. The lock cylinder

Important has four or five tumbler positions. The number 1 or 2

position (closest to cylinder head) is a brass retainer Do

not apply to hold-open link and roller

tumbler. The

2 through 5 positions or 3 through 5 contacting

surfaces as this could cause improper

positions are standard tumbler positions depending roller operation.

Page 1703 of 1825

2H-6 STATIONARY GLASS - F STYLE

all traces of factory installed adhesive must be

removed prior to reinstallation.

5. Wipe sanded mirror support with clean paper

towel saturated with alcohol and allow to dry.

6. Follow directions on manufacturer's kit to

prepare

rearview mirror support prior to

installation on glass.

7. Properly position support to its premarked

location, with rounded end pointed upward; press

support against glass for 30 to 60 seconds,

exerting steady pressure against glass. After five

minutes, any excess adhesive may be removed

with an alcohol moistened paper towel or glass

cleaning solution.

8. Reinstall mirror

4. LOCATING CIRCLE AND BASE OF SUPPORT

LINE ON OUTSIDE GLASS SURFACE

2. CIRCLE ON OUTSIDE GLASS SURFACE

INDICATES AREA TO BE CLEANED

G94301-11 B.BG

Fig. 8-Locating Bonded earv view Mirror Support on

Glass

REAR WlMBOW DEFOGGER

The optional rear window defogger system

consists of a tinted glass that has a number of

horizontal ceramic silver compound element lines and

two vertical bus bars baked into the inside surface

during the glass forming operation. The feed wire or

terminal is soldered to the bus bar on the side. The

ground wire or terminal is soldered to the bus bar on

the right side.

The system operates on 12 volts. Under some

conditions, heat from the glass may not be detected by

finger touch. The length of time required to remove

interior fog from the back glass will vary with such

conditions as vehicle speed, outside glass temperature

and atmospheric pressure and number of passengers. This

system uses an instrument panel mounted

switch with an integral indicator lamp; and will operate

for five to ten minutes and automatically turn off

through the use of an automatic timer. The system can

be turned off during this operating period by turning

either the instrument panel mounted switch or ignition

switch to off.

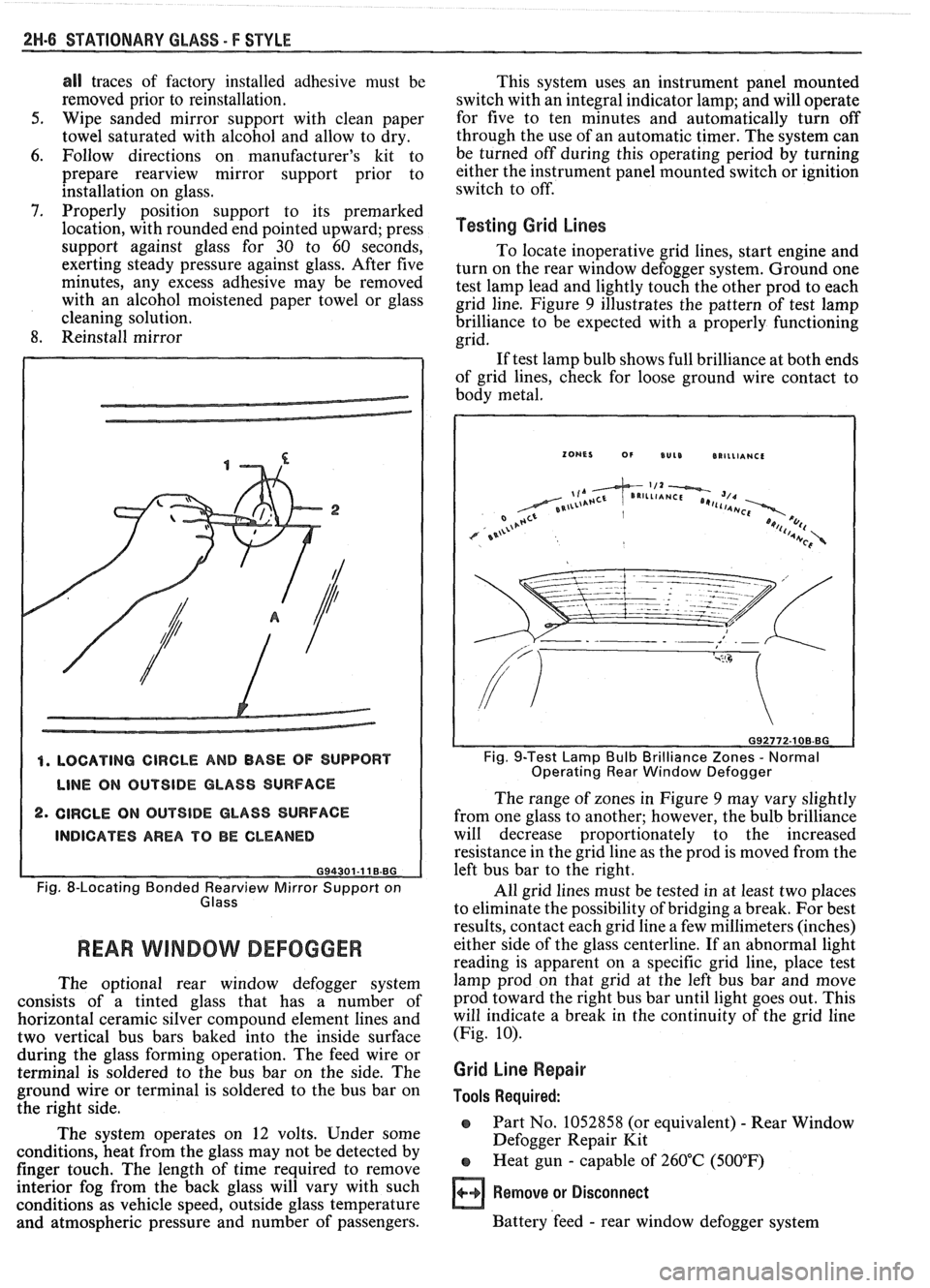

Testing Grid Lines

To locate inoperative grid lines, start engine and

turn on the rear window defogger system. Ground one

test lamp lead and lightly touch the other prod to each

grid line. Figure

9 illustrates the pattern of test lamp

brilliance to be expected with a properly functioning

grid.

If test lamp bulb shows full brilliance at both ends

of grid lines, check for loose ground wire contact to

body metal.

Fig. 9-Test Lamp Bulb Brilliance Zones - Normal

Operating Rear Window Defogger

The range of zones in Figure 9 may vary slightly

from one glass to another; however, the bulb brilliance

will decrease proportionately to the increased

resistance in the grid line as the prod is moved from the

left bus bar to the right.

All grid lines must be tested in at least two places

to eliminate the possibility of bridging a break. For best

results, contact each grid line a few millimeters (inches)

either side of the glass centerline. If an abnormal light

reading is apparent on a specific grid line, place test

lamp prod on that grid at the left bus bar and move

prod toward the right bus bar until light goes out. This

will indicate a break in the continuity of the grid line

(Fig.

10).

Grid Line Repair

Tools Required:

o Part No. 1052858 (or equivalent) - Rear Window

Defogger Repair Kit

e Heat gun - capable of 260°C (500°F)

Remove or Disconnect

Battery 'feed - rear window defogger system